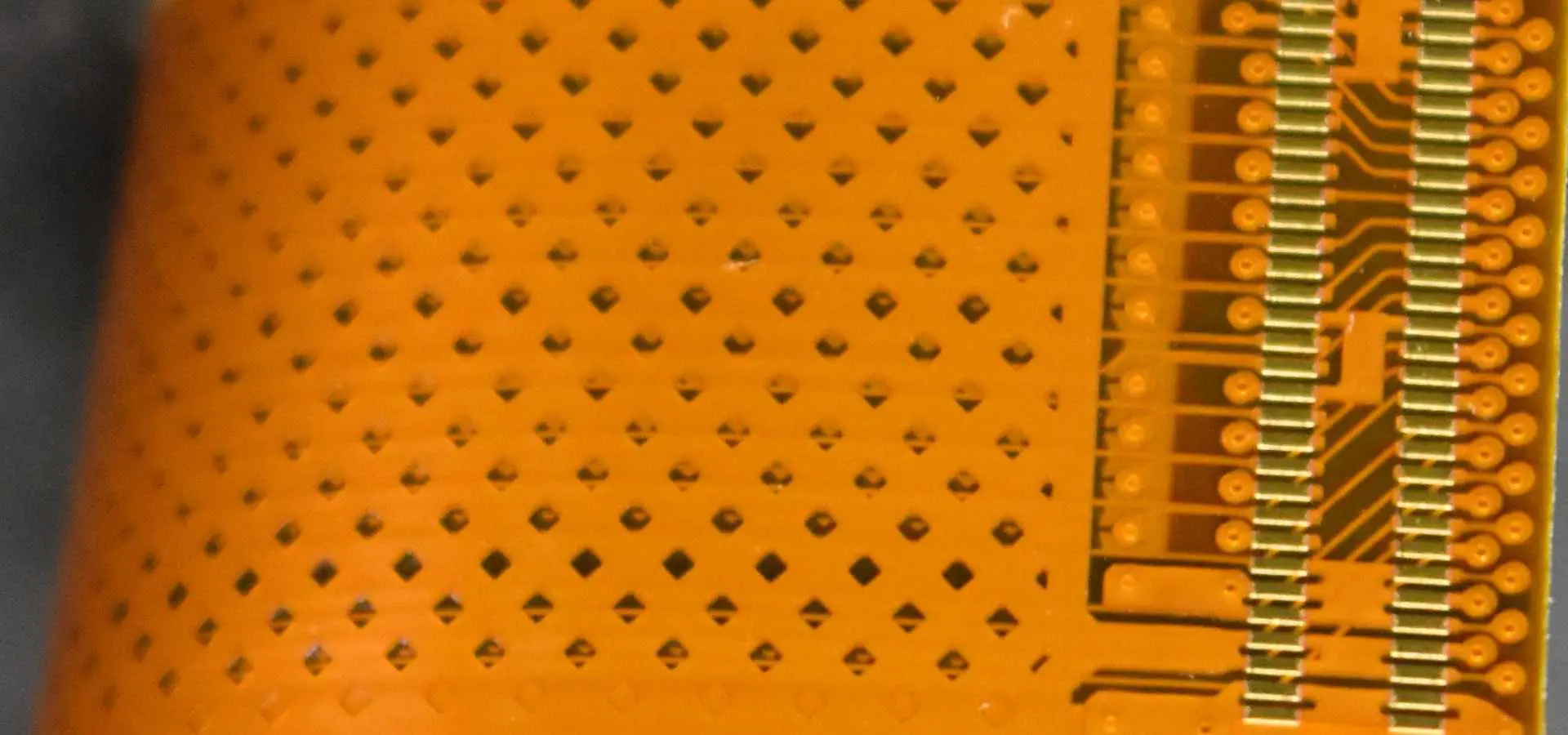

The blistering of the board is one of the more common quality defects in the production process of the PCB circuit board. Because of the complexity of the production process of the PCB circuit board and the complexity of the process maintenance, especially in the chemical wet processing, the prevention of the blistering defects on the board surface is compared. difficult. Based on years of actual production experience and service experience, the author makes a brief analysis of the causes of foaming on the copper plate of the circuit board, and hopes to help the industry peers!

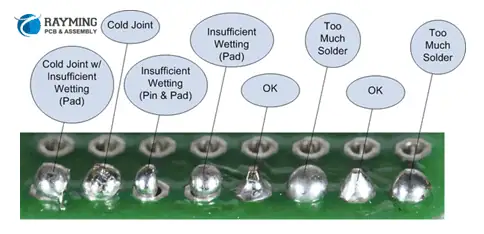

The blistering of the board surface is actually a problem of poor bonding of the board surface.

The extension is also the surface quality problem of the board surface. This includes two aspects:

1. The problem of board cleanliness;

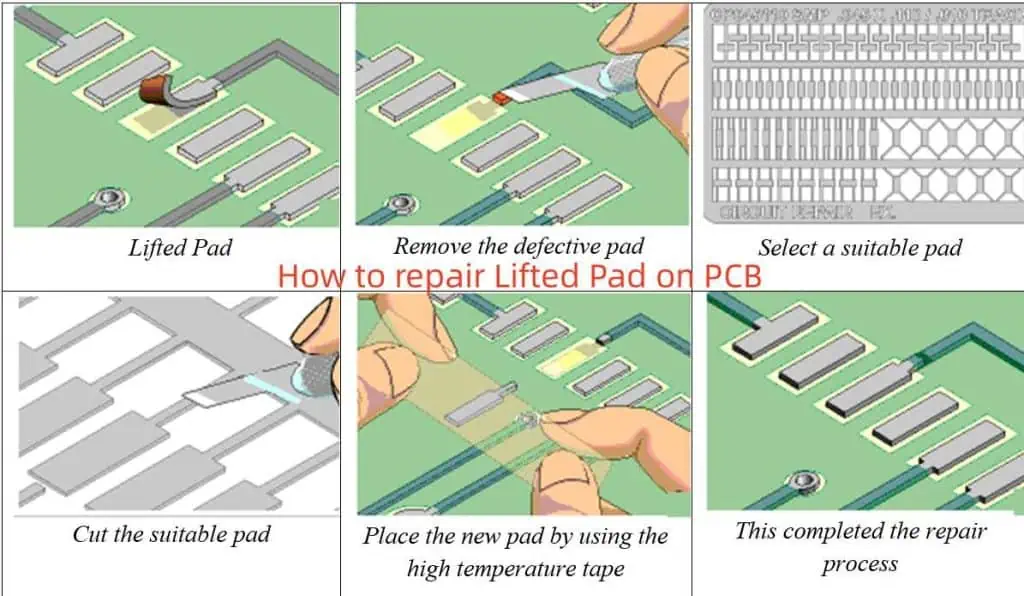

2. The problem of surface micro-roughness (or surface energy); the problem of blistering on all boards can be summarized as the above reasons. The bonding between the coatings is poor or too low, in the subsequent production process and PCB Assembly process It is difficult to resist the plating stress, mechanical stress and thermal stress generated during the production process, and finally cause different degrees of separation between the coatings.

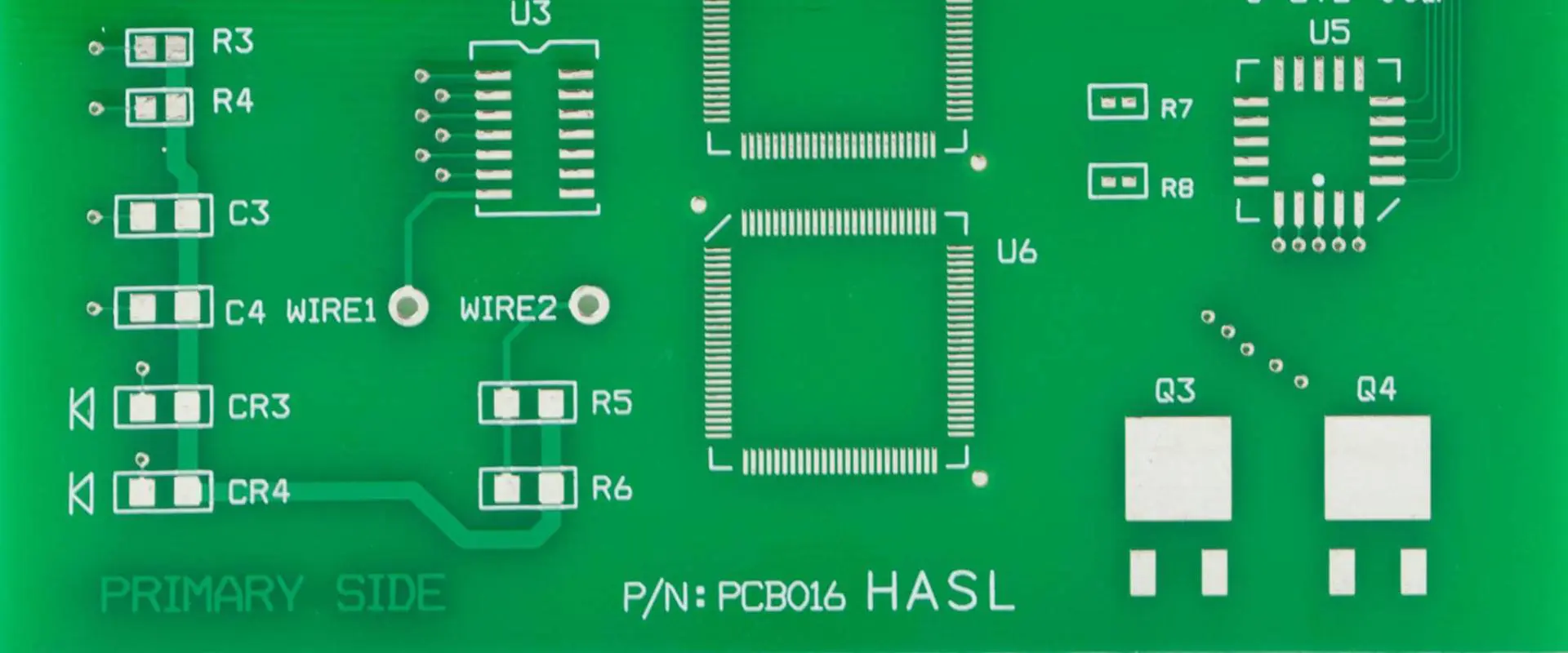

Some factors that may cause poor quality of the board during production and processing are summarized as follows:

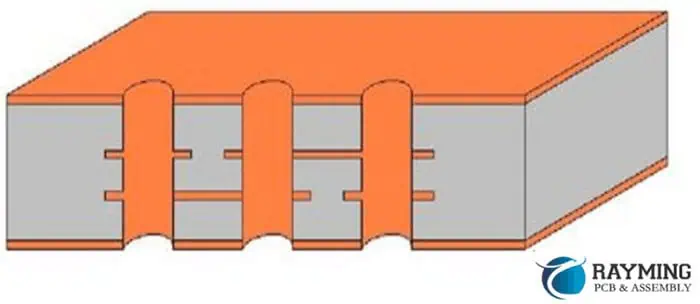

1. The problem of substrate processing; especially for some thin substrates (generally 0.8mm or less), because the substrate is poor in rigidity, it is not suitable to use a brush to brush the board, which may not effectively remove the substrate production and processing. In the process, in order to prevent the oxidation of the copper foil on the board surface, the protective layer is specially treated.

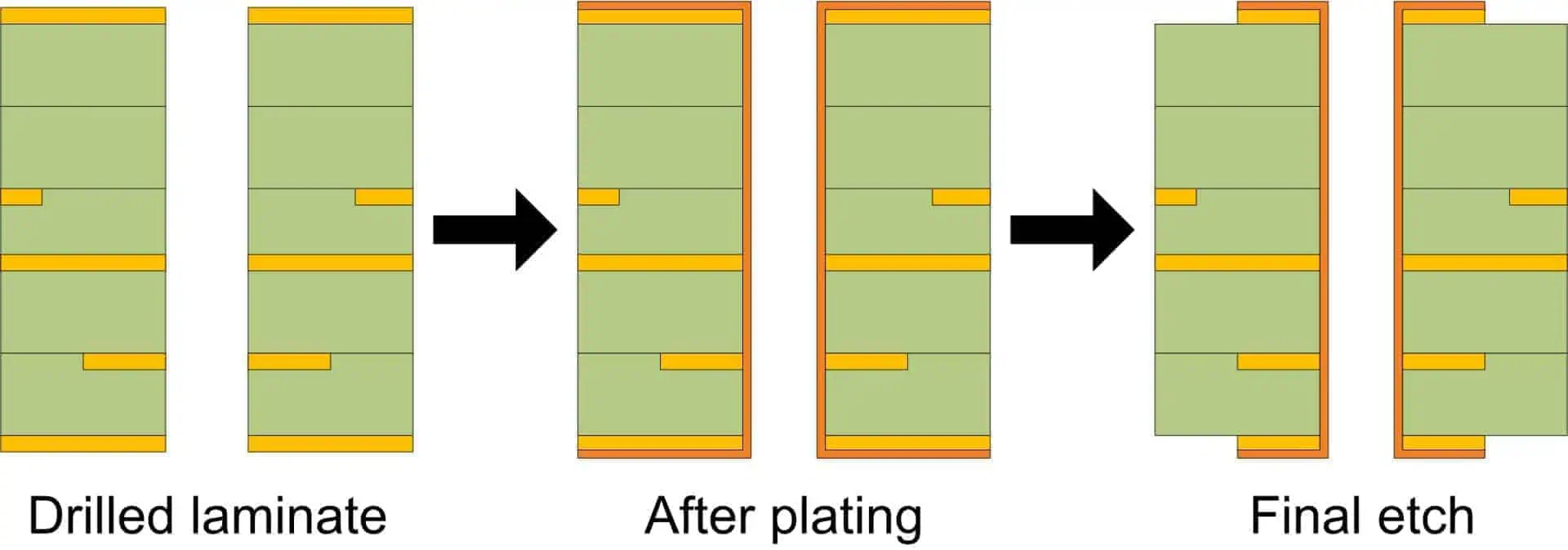

Although the layer is thin, the brush plate is easy to remove, but there is a great difficulty in chemical treatment, so it is important to control the production and processing, so as not to cause the board surface. The problem of blistering of the board caused by the poor bonding force between the substrate copper foil and the chemical copper; this problem also occurs when the thin inner layer is blackened, and there is also blackening and browning, uneven color, and partial black brown. Not getting better

2. The surface of the board is contaminated by oil or other liquids caused by machining (drilling, laminating, milling, etc.).

3. Poor copper plate: The pressure of the plate before the copper sink is too large, causing the hole to deform and brush the copper foil round hole or even the hole to leak the substrate. This will cause the copper plating and pcb soldering process. Foaming of the orifice; even if the brushing plate does not cause leakage of the substrate, the excessively heavy brushing plate will increase the roughness of the copper of the orifice, so that the copper foil is easily liable to excessive coarsening during the microetching roughening process. There will also be certain quality hazards; therefore, it is necessary to pay attention to the control of the brushing process. The process parameters of the brushing plate can be adjusted to the best through the wear scar test and the water film test;

4. Washing problem: Because the copper plating treatment is subject to a large amount of chemical syrup treatment, all kinds of acid-base and non-polar organic solvents are more, and the surface of the board is not cleaned, especially the copper-adjusting degreaser will not only cause cross-contamination. At the same time, it will cause partial treatment of the board surface or poor treatment effect, uneven defects, causing some problems in bonding; therefore, it is necessary to pay attention to strengthen the control of water washing, mainly including cleaning water flow, water quality, washing time And the control of the dripping time of the board; especially in the winter, the temperature is lower, the washing effect will be greatly reduced, and more attention should be paid to the control of the washing;

5. Micro-etching in the pre-treatment of copper sinking and pattern plating; excessive micro-etching will cause the pores to leak to the pcb substrate, causing foaming around the pores; insufficient micro-etching will also cause insufficient binding force and foaming Therefore, it is necessary to strengthen the control of micro-etching; the general micro-etching depth of copper pre-treatment is 1.5–2 micron, and the micro-etching before pattern plating is 0.3–1 micron. It is best to pass chemical analysis and simple conditions.

The test weighing method controls the micro-etching thickness or the etch rate; under normal circumstances, the surface of the board after the micro-etching is bright, uniform pink, and no reflection; if the color is uneven, or there is reflection, there is a quality hazard in the pre-treatment of the process; Strengthen the inspection; in addition, the copper content of the micro-etching tank, the bath temperature, the loading amount, the micro-etching agent content, etc. are all items to be noted;

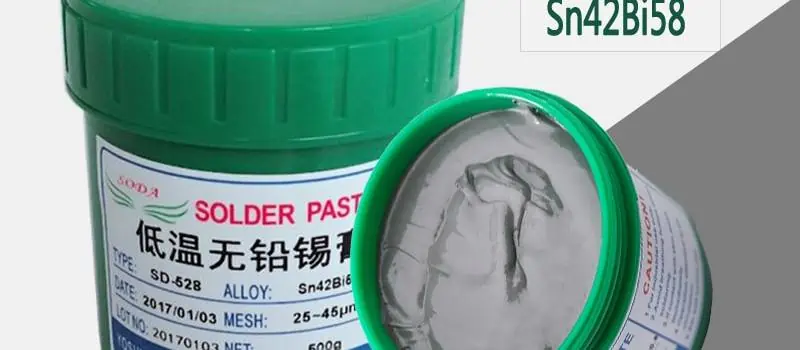

6. The activity of the copper immersion liquid is too strong; the content of the three electronic components in the newly opened cylinder or bath liquid is too high, especially the copper content is too high, which will cause the bath liquid to be too active, the chemical copper deposit is rough, hydrogen, sub Copper oxides and other defects in the chemical copper layer caused by excessive inclusion physical properties and poor adhesion; can be appropriately adopted as follows: reduce copper content, (replenish pure water into the bath) including three groups To appropriately increase the content of the complexing agent and the stabilizer, and appropriately reduce the temperature of the bath;

7. The surface of the board is oxidized during the production process; if the copper plate is oxidized in the air, it may not cause copper in the hole, the surface of the board is rough, and the surface may be foamed; the storage time of the copper plate in the acid solution If it is too long, the surface of the board will also oxidize, and this oxide film is difficult to remove; therefore, the copper plate should be thickened in time during the production process, and it should not be stored for too long. Generally, the copper plating should be thickened within 12 hours at the latest. Finished

8. The copper is reworked poorly; some of the copper or the reworked board after the transfer of the pattern will be foamed due to poor fading during rework, improper rework method or improper control of micro-etching time during rework or other reasons. If the copper plate is reworked, if the copper is found to be bad on the line, it can be directly reworked after degreasing from the line after washing with water.

It is best not to re-de-oil and micro-etch; for the plate that has been thickened by the plate, Now the micro-etching groove is faded. Pay attention to the time control. You can use a plate or two to measure the fading time to ensure the fading effect. After the fading is finished, apply a brush to the soft brush and then press the normal production. The process sinks copper, but the etch time is to be halved or adjusted as necessary;

9. Insufficient water washing after development during the graphic transfer process, too long after development or excessive dust in the workshop, etc., will result in poor surface cleanliness and poor fiber treatment, which may cause potential quality problems;

10. Before picking the copper, the acid pickling tank should be replaced in time. The contamination in the bath is too much, or the copper content is too high, which will not only cause the cleanliness of the board surface, but also cause defects such as rough surface;

11. Organic pollution, especially oil stains, in the plating tank is more likely to occur for automatic lines;

12. In addition, in the case that some of the plants in the winter are not heated, it is necessary to pay special attention to the charging of the plates in the production process, especially the plating tank with air agitation, such as copper and nickel; Before the nickel plating, add a warm water washing tank (water temperature is about 30-40 degrees) to ensure the compactness of the initial deposition of the nickel layer is good;

In the actual production process, there are many reasons for the blistering of the board surface. We can only do a brief analysis. For different manufacturers, the technical level of the equipment may cause blistering caused by different reasons. The specific situation should be analyzed in detail, and it is not possible to generalize. The above reasons are analyzed regardless of the priority and importance. Basic analysis is based on the production process. It is listed here in detail. It only provides a direction for solving the problem and a broader vision. I hope that the process production and problems for everyone. In terms of solution, it can play a role in attracting jade!