PCB Manufacturing

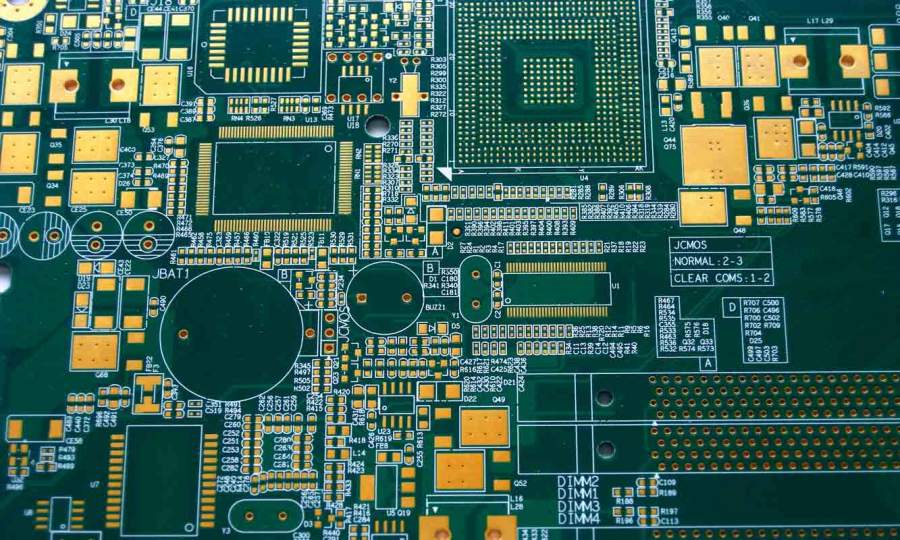

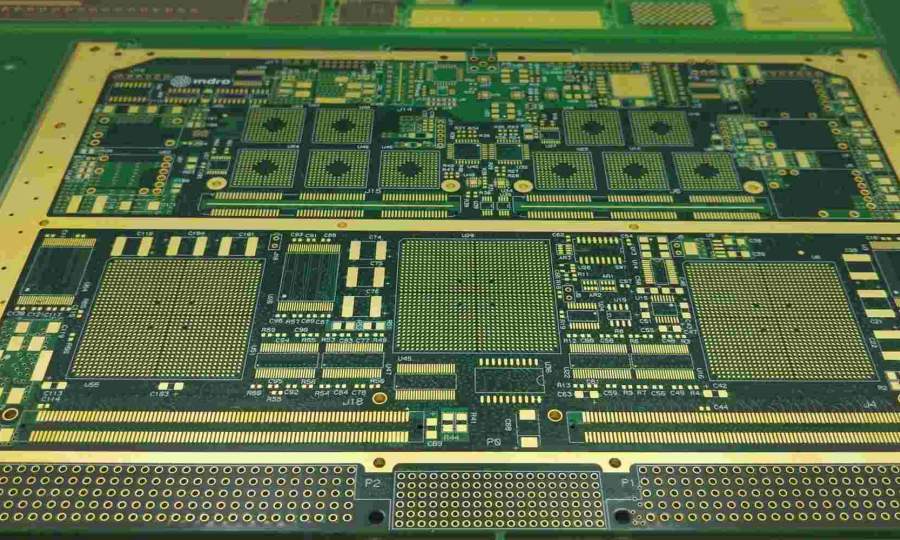

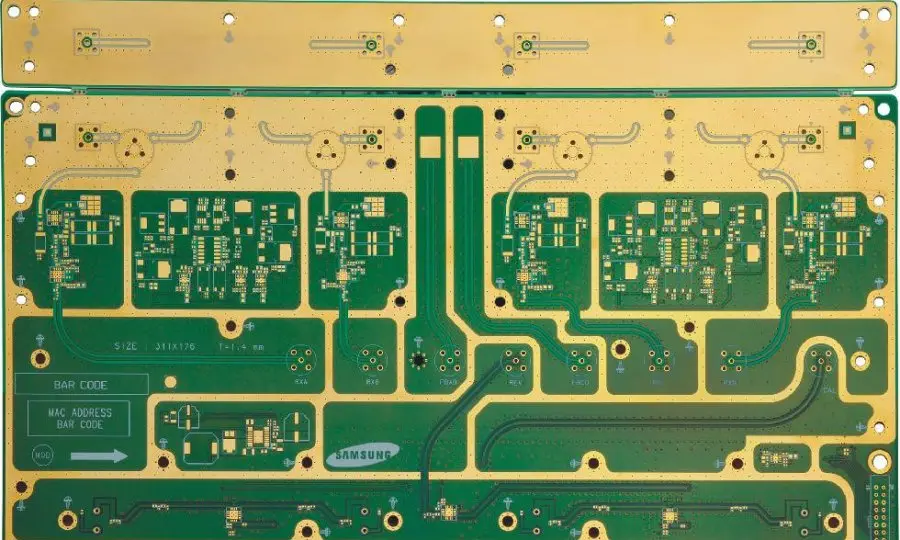

Advanced PCB manufacturing services, specializing in high-precision, high-difficulty, and special materials, serving industries such as scientific research, aviation, military, medical, robotics, and AI.

About Us

20 Years PCB Manufacturer

RAYMING PCB is a leading provider of cutting-edge printed circuit board manufacturing technologies, delivering the highest quality standards for the electronics industry. Our unwavering commitment to technological leadership drives us to continuously innovate and meet new design challenges.

Our state-of-the-art innovation lab and expert engineering team specialize in overcoming complex design hurdles, including:

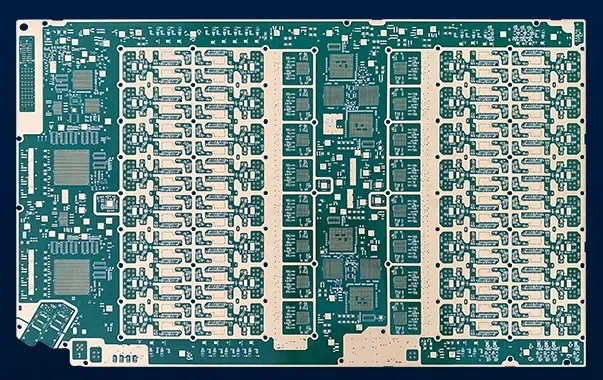

- High Speed and High Capacity circuits

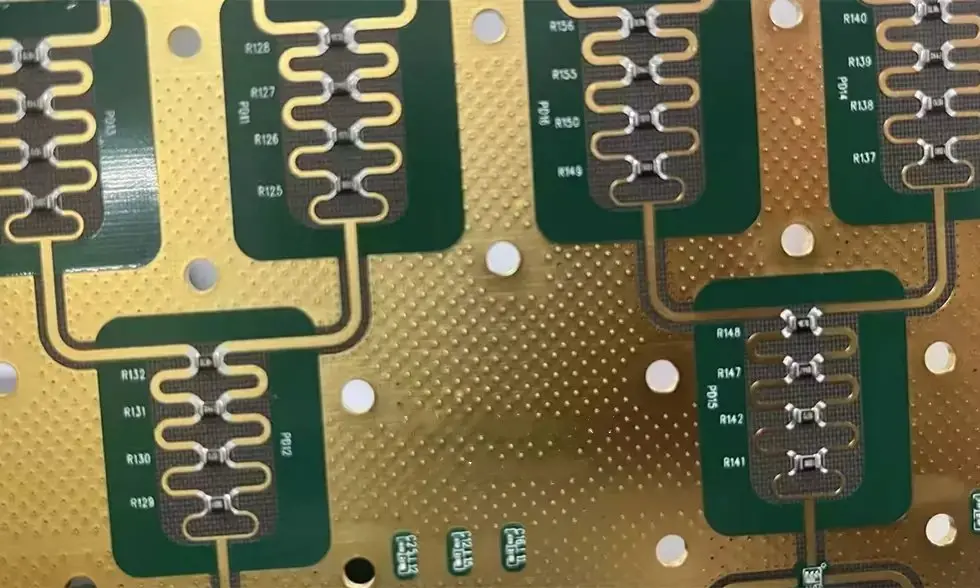

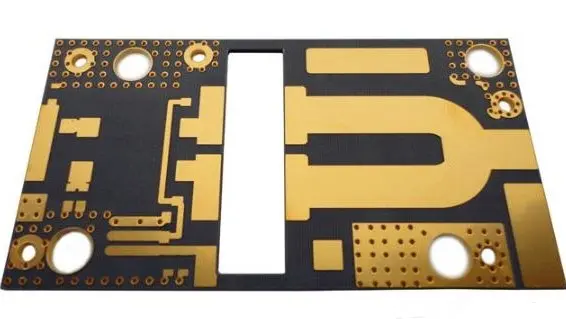

- RF and Microwave technology

- Thermal Management solutions

- Miniaturization techniques

- Chip package substrates

We offer tailored solutions for various industries, including 5G, AI Robotics, and Battery Management Systems (BMS). Our technical capabilities encompass:

- HDI PCB ( Blind with Buried Vias)

- Up to 100 multilayer PCB

- Rigid-flex PCB

- RF PCB (Rogers, Taconic…)

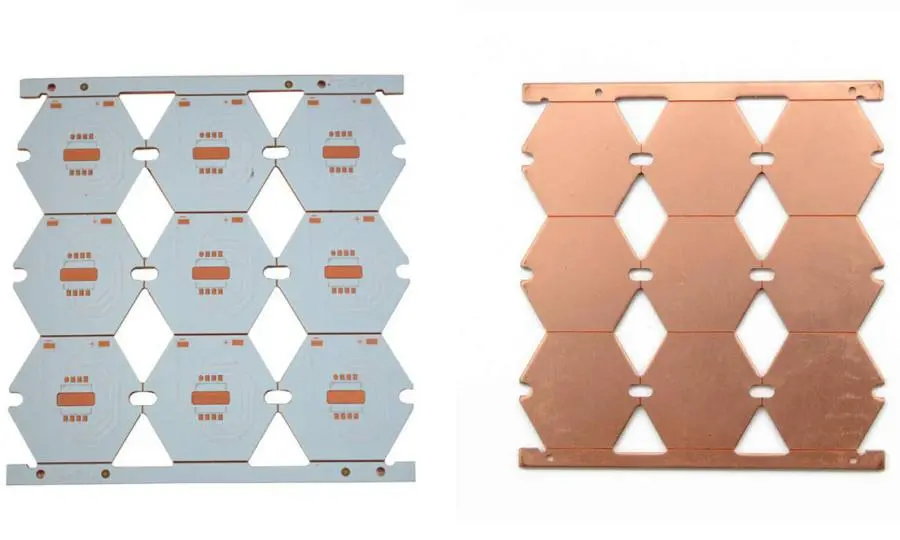

- Heavy Copper PCB

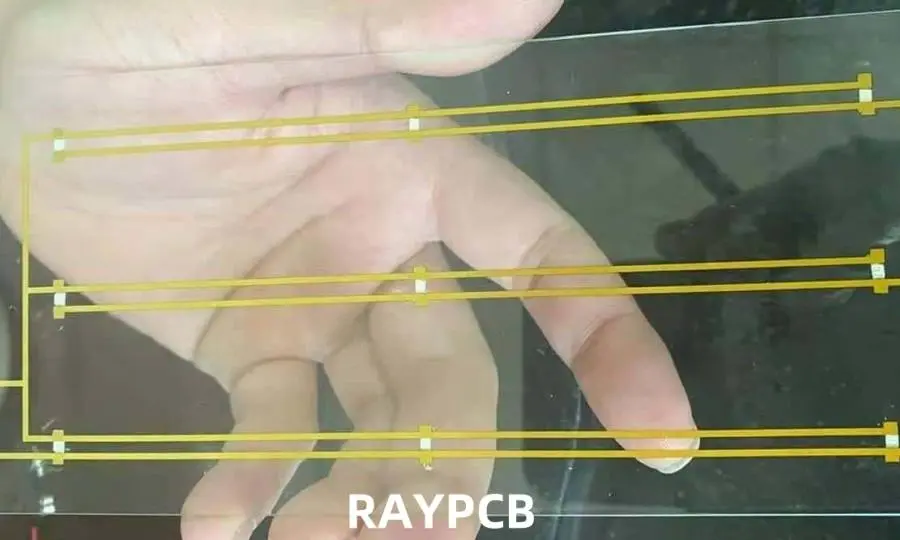

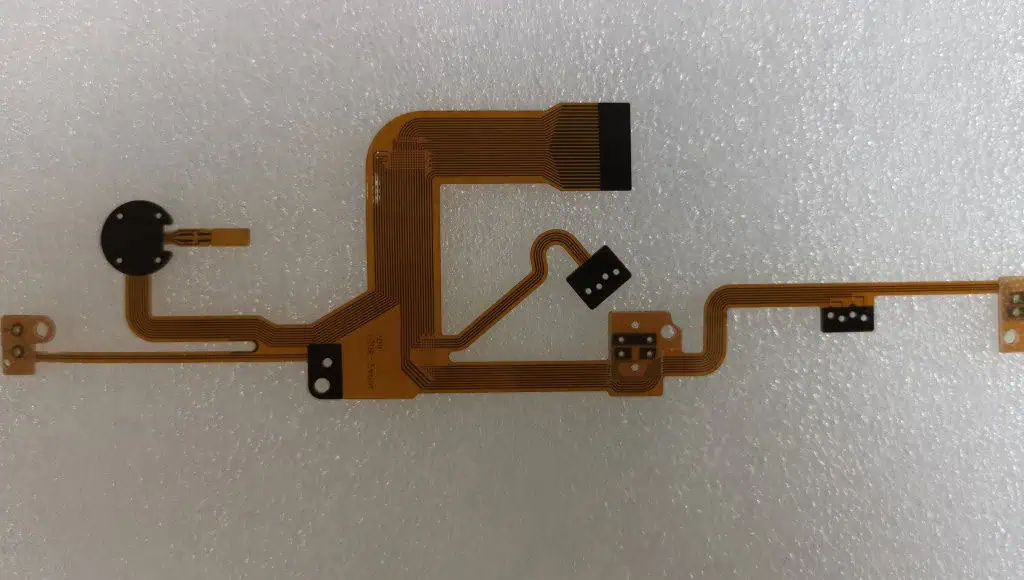

- Flexible PCB

RAYMING welcomes complex RFQs for cost estimation. We are proud to hold UL Certifications for our products:

- Rigid PCB/Aluminum PCB: E472163

- Flex PCB/Rigid-flex PCB: E544606

Latest PCB Projects

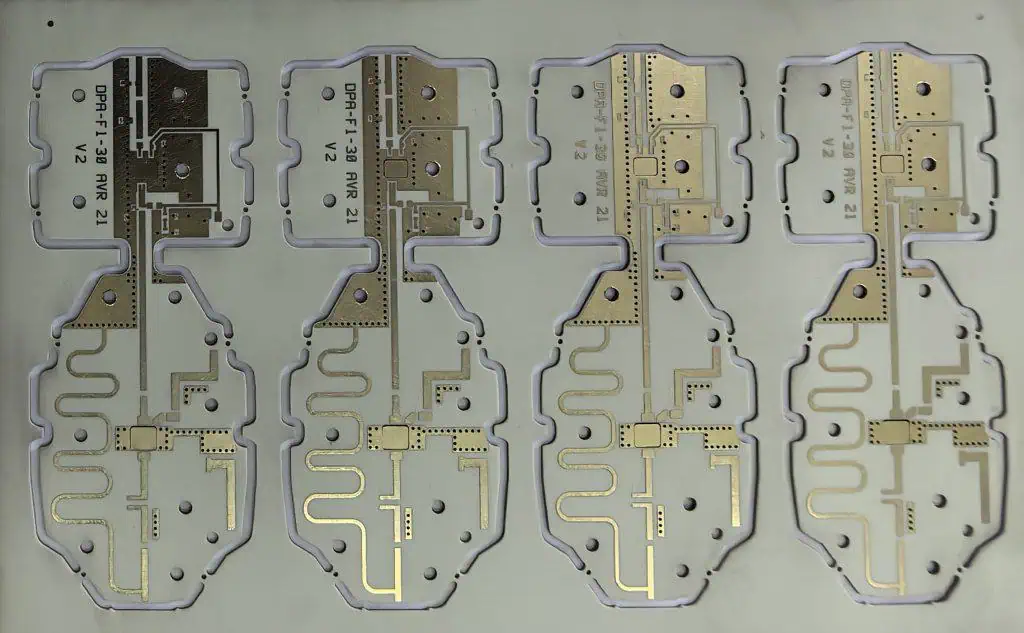

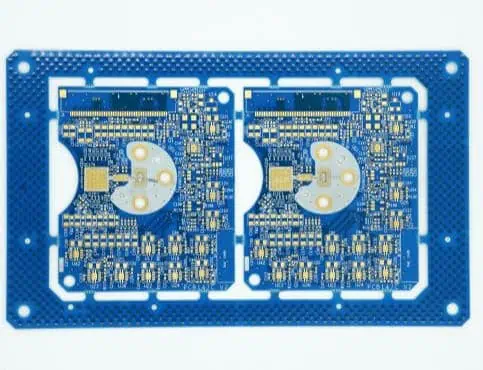

5G TRX PCB

optical module PCB

Medical PCB

Rogers 4350B + Copper Base PCB

Hybrid PCB: Rogers 4350B + Copper Base PCB

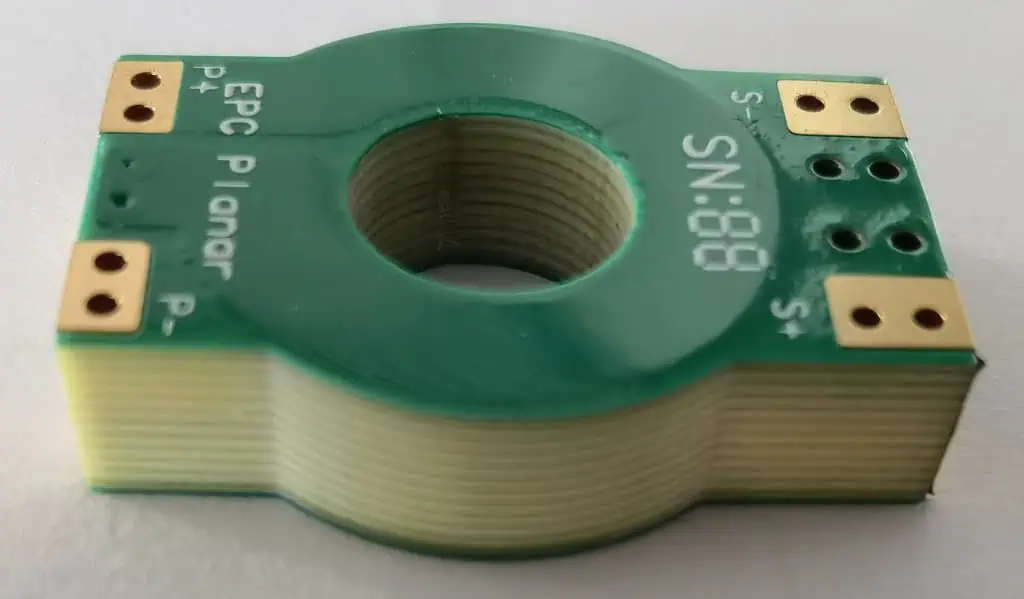

32 layer PCB

32 Layer PCB Manufacturing with 6.5mm thickness, Motor EPC Application

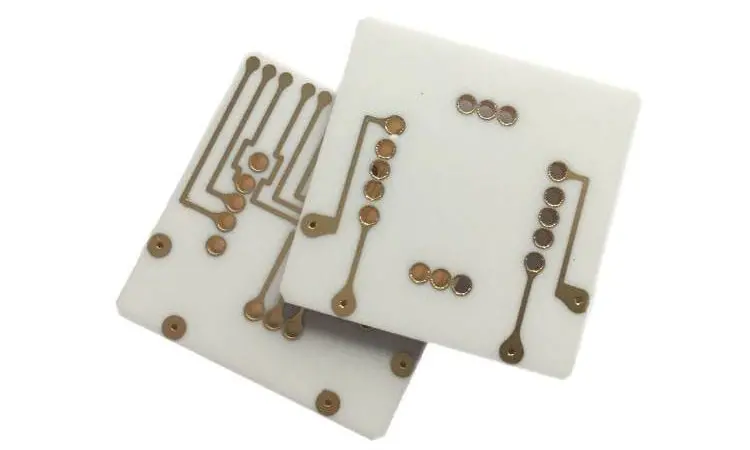

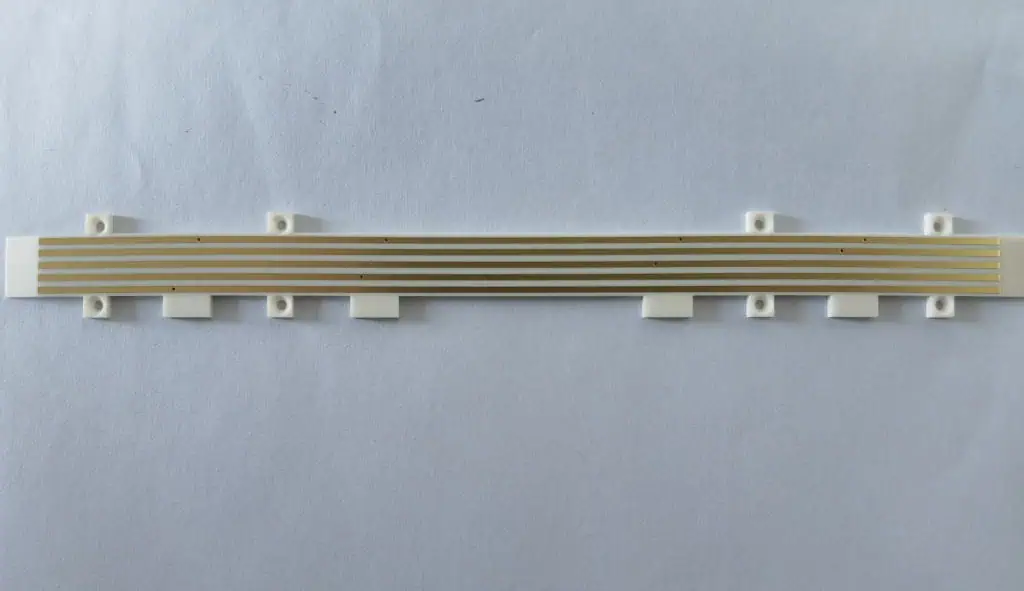

Ceramic PCB

Ceramic PCB manufacturing with Step holes + bevelled edges process

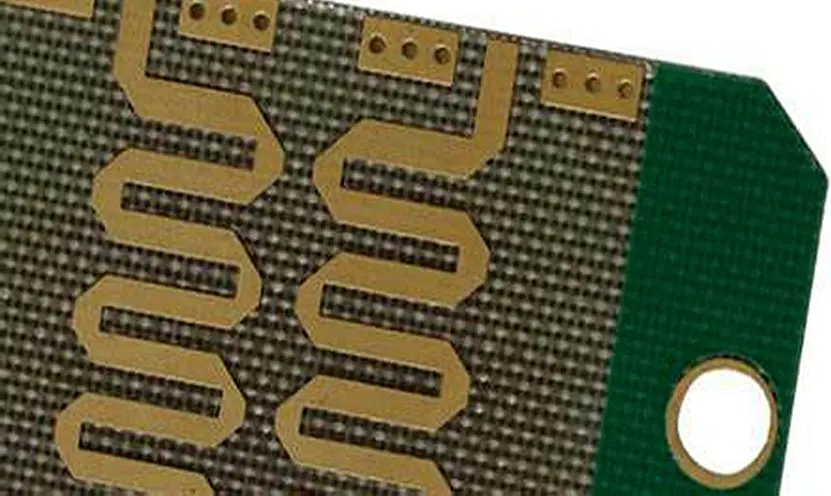

Radar RF PCB

8 Layer 77 GHz millimeter wave radar, Material: Ro3000+IT180A

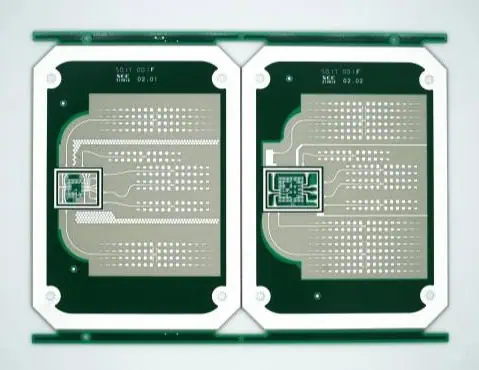

14 layer SSD PCB

14 Layer High TG FR4+ PI, 4 Step HDI PCB

E-band ODU RF Board

4 Layer 1oz E-band ODU RO4350+FR4 Hybrid PCB

Flexible PCB

2 Layer Flex PCB with PI & FR4 stiffener

Rogers 4350b pcb

Rogers 4350B PCB manufacturing, 0.8mm thickness

Rigid Flex PCB

6 Layer Rigid PCB , 2 Layer Flex PCB

PCB Manufacturing Capability

| ems | Mass | Prototypes |

| Layers | 1-18 Layers PCB | 1-56 Layers PCB |

| Max. Panel Size | 600*770mm( 23.62″*30.31″) | 600*770mm(23.62″*30.31″) 500*1200mm(19.69″*47.24″) |

| Max.Board Thickness | 8.5mm | 8.5mm |

| Min. Board Thickness | 2L:0.3mm | 2L:0.1mm |

| 4L:0.4mm | 4L:0.3mm | |

| 6L:0.8mm | 6L:0.6mm | |

| Min Inner Layer Clearance | 3mil | 3mil |

| Min Line width | 3/3 mil | 3/3 mil |

| Min Line space | 3/3 mil | 3/3 mil |

| Min.Hole Size | 0.1mm | 0.1mm |

| Min plated hole thickness | 25um | 25um |

| Min Blind/Buried hole size | 0.1mm | 0.1mm(1-18layers) |

| PTH Dia. Tolerance | ±0.076mm(±3mil) | ±0.076mm(±3mil) |

| Non PTH Dia. Tolerance | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| Hole Position Deviation | ±0.05mm(±2mil) | ±0.05mm(±2mil) |

| Heavy Coppe | 4OZ/140μm | 6OZ/175μm |

| Min S/M Pitch | 0.1mm (4mil) | 0.1mm (4mil) |

| Soldermask colour | Green,black,Blue,White,Yellow,Red | Green,black,Blue,White,Yellow,Red |

| Silkscreen colour | White,Yellow,Red,Black | White,Yellow,Red,Black |

| Outline | Routing,V-Groove, Beveling punch | Routing,V-Groove, Beveling punch |

| Outline Tolerance | ±0.15mm ±6mil | ±0.15mm (±6mil) |

| Peelable mask | Top,bottom,double sided | Top,bottom,double sided |

| Controlled Impedance | +/- 10% | +/- 7% |

| Insulation Resistance | 1×1012Ω(Normal) | 1×1012Ω(Normal) |

| Through Hole Resistance | <300Ω(Normal) | <300Ω(Normal) |

| Thermal Shock | 3×10sec@288℃ | 3×10sec@288℃ |

| Warp and Twist | ≤0.7% | ≤0.7% |

| Electric Strength | >1.3KV/mm | >1.4KV/mm |

| Peel Strength | 1.4N/mm | 1.4N/mm |

| Solder Mask Abrasion | >6H | >6H |

| Flammability | 94V-0 | 94V-0 |

| Test Voltage | 50-330V | 50-330V |

PCB Manufacturing knowledge

- Step by Step to Explain Printed Circuit Board (PCB) Manufacturing Process

- Tolerances on Printed Circuit Boards

- What is PCB Tab?

- How Do You Make a PCB Panel ?

- What is Prepreg in PCBs?

- What is PCB Scoring: Tools, Tolerance and Guideness

- Annular Ring Via: A Comprehensive Overview

- What is Half-Hole PCB

- What is Via Filling in PCB

- What is DRC PCB ?

- Bits,Machines and Process of PCB Drilling

- Process of Etching Solution for PCB

- How to Plan Multilayer PCB Stackup

- Brown oxide vs. black oxide, immersion tin processes for PCB

- What is a silkscreen on a PCB?

- What is Solder Mask

- The Essential Steps to Testing a PCB

- What are the different surface finishes in PCB?

- Final Quality Control (FQC) in PCB Manufacturing

- What You Need for PCB Packaging and Shipping