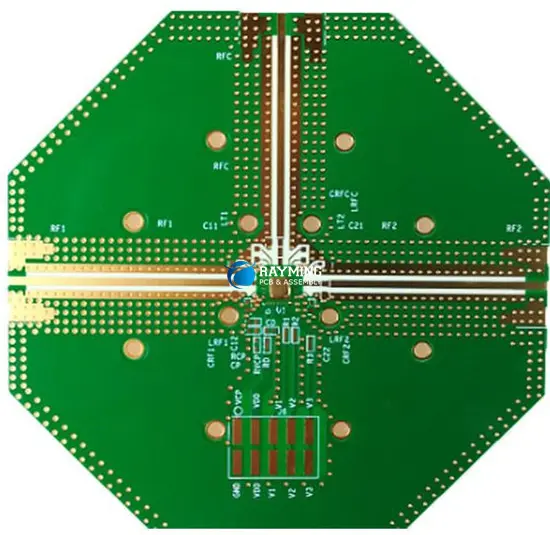

Express PCB Manufacturing Service

RayMing provides hobbyist and engineers from around the world with high-quality Quick Turn PCB at affordable prices. Depending on your PCB requirements, we have a fast turnaround time of just 24 hours. You must submit your files before 9am for same day quick turnaround services. Please call us directly for more information on this service.

Engineers can depend on RayMing because of our reliable on time delivery percentage and high quality manufacturing. Get a faster turnaround time than our standard lead time of 2 weeks, which allows for your company to prototype your critical PCBs faster. With our affordable prices and reliability, decrease the probability for poor quality PCBs and increase your ROI for your PCB prototyping with RayMing .

Submit your PCB specifications by emailing us your Gerber Files , you will attach your gerber files and send them via the mail . Lastly, you can give us a call to talk to a sales representative during normal business hours, or you can click Chat Now to talk with our oversea sales live.

We have many options available for your quick turn PCB manufacturing and with our 10 plus years of fabrication experience, we are confident that we will be able to help you with your project.

When you order from RayMing, you can be sure that your circuit boards will be delivered on time with the highest quality. We appreciate the opportunity to earn your business and we look forward to hearing from you soon.

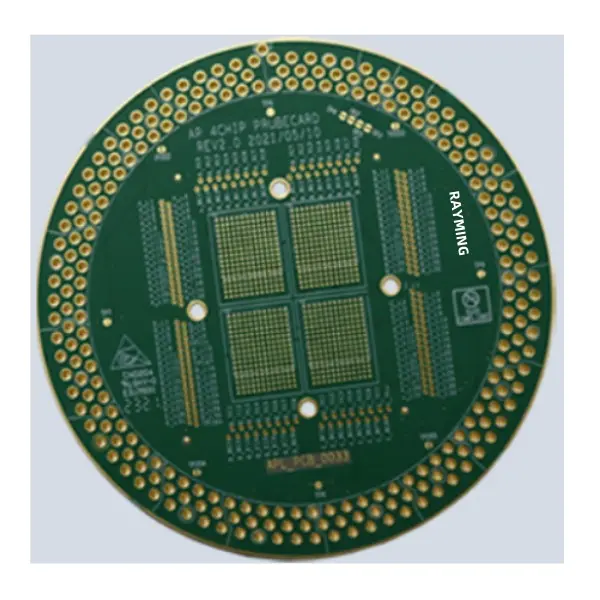

Quickturn Printed Circuit Board Fabrication Highlights:

Accelerated PCB production times

1 (same day to 24 hours), 2, or 3 day turnaround times

Speed up entry into market

Full and Prototype Boards available

Fast and accurate human reviewed PCB quotes

We provide high quality PCB manufacturing with full in house capabilities for projects small and large.

Over 15 years of Quickturn PCB fabrication supplier experience

State-of-the-Art 18,000 square feet Manufacturing facility

Every received order is manually reviewed before production

No minimum lot requirements on orders

All PCBs manufactured in the our facility

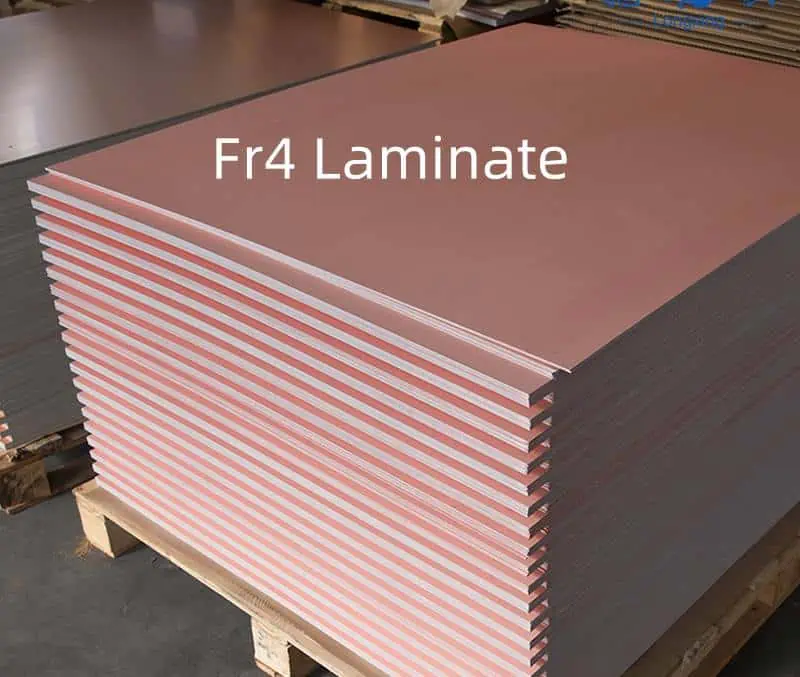

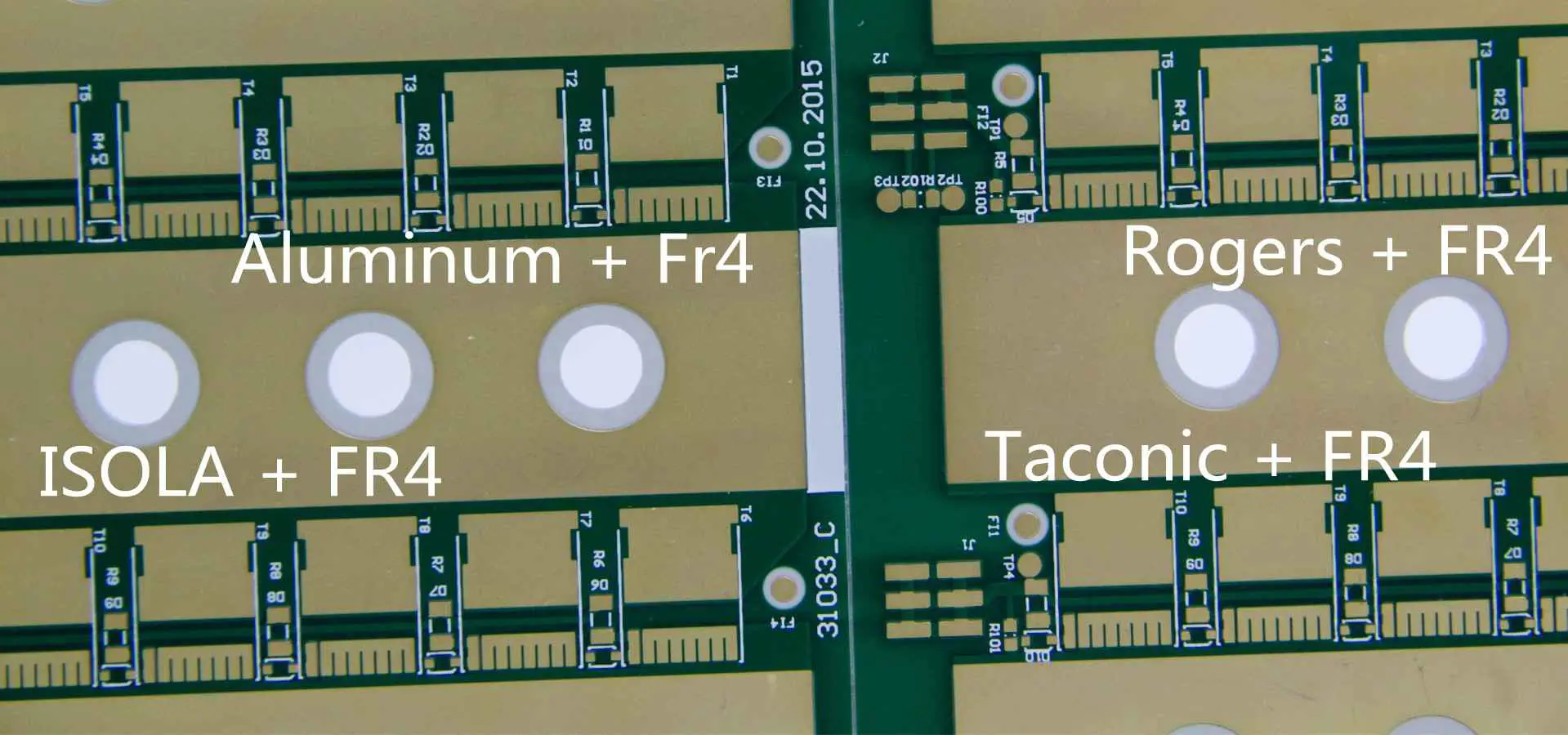

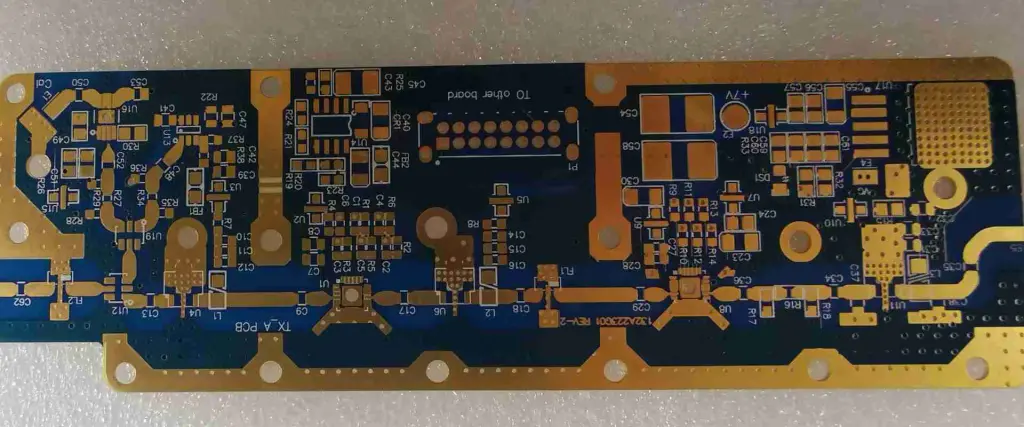

Materials that we keep in stock are:

FR4 (Tg – 135C, 145C, 170C)

Rogers RO4350

Rogers RO4003

Polyimide

Teflon

Clad Thermal Substrates

Hybrid (Rogers and FR4)

If you don’t see the material above, please contact us because we most likely have it in stock, but not listed above, or can special order it for you.

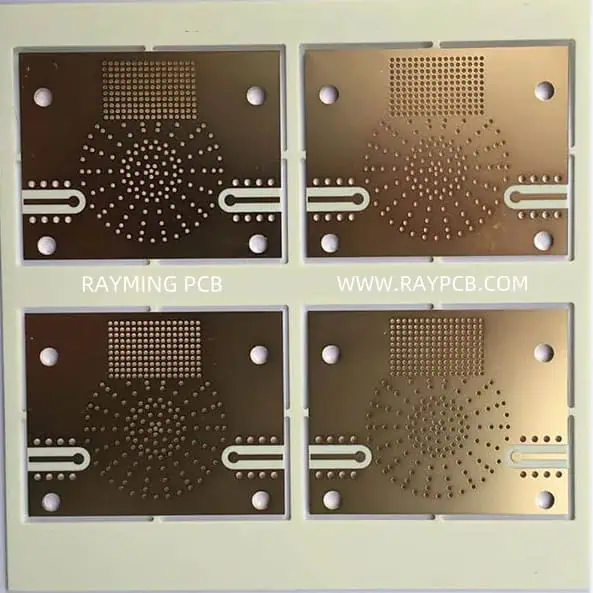

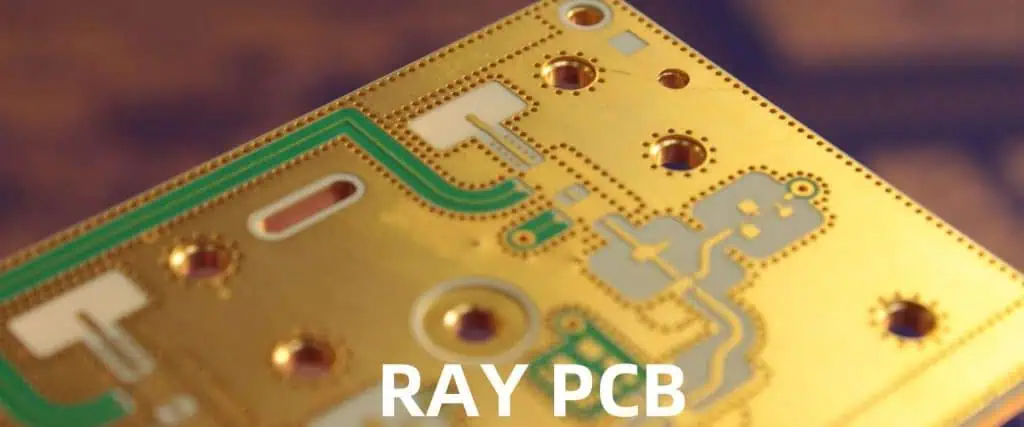

Finishes we are able to provide our customers:

HASL – Leaded Solder Tin/Nickel

HASL – Lead Free Solder

Electroless Soft Gold

Wire Bondable Soft Gold

Nickel Flash Gold

Electroless Nickel

Immersion Gold OSP

Electrolytic Nickel /Hard Gold and Selective Gold

Immersion Silver

Immersion Tin

Carbon Ink

ENIG

Please contact us if you need a finish that is not listed here.

For over 10 years, we have been providing rapid prototyping for our customers, You can send your Quick turn Printed Circuit Board specifications to us. All Gerber files are reviewed in order to provide you with an accurate quote, the first time. We pride ourselves on customer service and our workmanship.

Find a Express PCB Manufacturer and Supplier. Choose Quality Express PCB Manufacturers, Suppliers, Exporters at RayPCB.com.Welcome to send your design to Sales@raypcb.com

How To Get ExpressPCB For Your PCB Design Jobs?

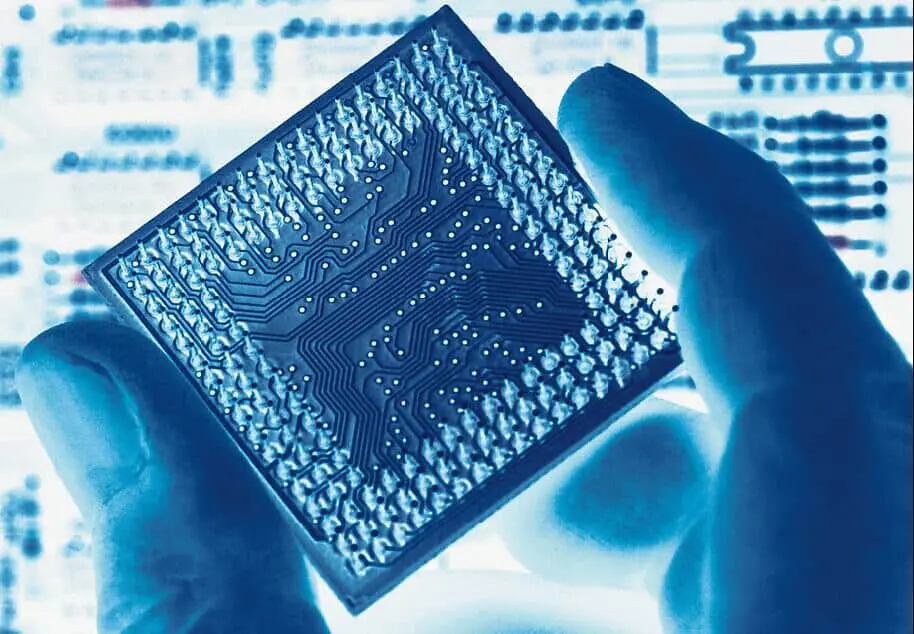

PCB designers are aware of the complexities of designing a printed circuit board and would love to use a feature-rich software. It will reduce the shipment days and complexities by making the design schematics. ExpressPCB is the easiest designing software that you can use to create the boards. This designing software is free to use and supported in Vista, Windows XP, and Windows 7. It is easy to learn, and designers and engineers can use the tool seamlessly. In this article, you can learn how to get ExpressPCB and its unique features.

About ExpressPCB

It is CAD software for creating layouts for printed circuit boards. The CAD is categorized into two sections:

- ExpressSCH: It is used to create the schematics, and the same design software is incorporated with both Classics and downloads. There is no extra thing to download, and the best part is you do not have to learn anything.

- ExpressPCB: It is used to design the printed circuit board and linked to the schematic. To Expresspcb.com, the out file is proprietary. For the Gerber files, you have to pay a fee.

The fast PCB tool is used in assembling the components of the basic design, after which you can change the design quickly. First, the changes are done into the schematics drawing and then into the PCB design layout. The multi-rich software is flexible and can efficiently attain the demands of desired projects.

Check out The Process To Get ExpressPCB

The Downloading Process: When downloading the software, you can get it easily from expresspcb.com. The latest versions are present on the website and use the one according to your desires.

Start Using The Software: You must follow the step-by-step procedure to design the PCB using the tool.

- Open the tool, and a dialog box will appear with two links. It would be best if you went through both the links as they contain instructive information. After that, press the “OK” button to start the file.

- Here you must select a new file, following which a dialog box will open up. The next thing to do is you have to set the dimensions. By default, the dimensions would be 0.056 round with 0.029 holes. It is the maximum default size but can be changed according to your needs.

- Now place all the components in the place and click on the IC icon present in the toolbar. Pull down the menu to pick the necessary components and double click on them to get the properties.

- Click on the same icon if you need a transistor and place it on the Dip-8 pin. After that, for the capacitor, write the cap and assign the part IDs and names.

- If none of the components are present, you have to follow the same procedure for all. You have the flexibility to draw on your own.

- Before proceeding to the component and picking the ungroup PCB, select similar components.

- Draw a circle for photo-resistor and set the radius and width of the line,

- Click on the whole part and proceed to the component. Pick on the group to create the PCB components.

- After that, assign the unique ID and name as you can double-click components and set the parameters.

- Save it as custom components which will help you to use it again if needed.

- You must repeat this step for the entire procedure while making parts.

- For placing power and the grounds into the circuit, pick on the “Filled Planes” bar. It is present on the toolbar, and then you must select on it to press the layer.

- Draw a horizontal line, and you must drag it squarely and pick the place traces.

- While doing so, you will find that an isolated path is formed, separating the ground from power.

- Go to the bottom right corner and then to the left corner and right-click at the box end.

- As the filled plane gets added to the circuit, you must change the plan shape.

- Using solid or thermal shape, you must connect the pads.

- By right-clicking on the right-pad, you should connect the plan. Following this, you can pick the type of plane and pad. With this, you will have a thermal/solid plane and pad.

- In the design, there can be an area where you do not find a filled plan. Here you must select this option and pick the area keeping the plane away from the top toolbox.

- In this way, you can keep the area out of the filled plane.

- Similarly, draw a square in the same area where you do not need a filled plane. Here the area will have the dotted lines.

- Follow this step for all the pads, and while doing, you can see the layout on the screen.

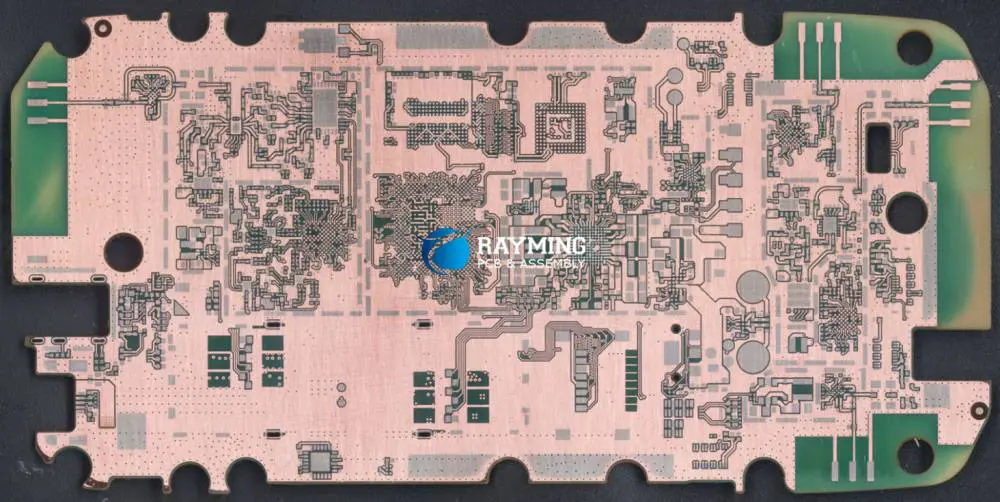

- By using the fast turn PCB software, you can design several layers.

- Firstly, you must set the number of copper layers and then click on them in the layout menu.

- If you choose the four layers, it will add two inner layers, where the first is the ground plane. The next one is the power plane, and both layers are of copper. It helps in improving the noise immunity of the circuit.

- After completing the layout, the software will tell the price you need to play to get the boards.

- Take a print of the manufacturing printed circuit boards. A few precautions are there to keep in mind when taking the print. If you do not, there can be high failure chances in the layout. The precautions to keep in mind are:

- Ensure the tracks should not have less than 100 degrees bends.

- The device might fail if the way touches each other, so make sure that it does not happen.

- After preparing the entire fast PCB prototyping, you can move, delete, copy and even rotate the component.

Place An Order: Now that you have completed the design of the printed circuit board, go ahead and place an order. Here are the steps you must follow now.

- Run the program, which means the ExpressPCB on the laptop or desktop, and get the file.

- Before submitting, you can ask for an exact estimate to get the board through the Compute board cost command. It is present on the layout menu.

- Click on the button that says “Order Boards Via The Internet” and place the order. Before doing this, make sure the PCB file is loaded.

- A form is there where you have to fill in the particulars like name, email address, and address. Click on the manufacturing option that you want, like Standard, 4 Layer-Production, Production, etc.

- Enter the number of boards you need, as it will help specify the exact amount to get them.

- Now you have to make the payment using credit cards as they use only this form of payment.

- Before playing the 24 hour PCB board, you have a chance to review the entire thing and the cost. If you want to make any changes, this is the time to do so.

- Once you are ready to submit, click on the “Send” button. After this step, you will get a mail confirming the details on the email address within an hour.

- You have to wait for some time and then get the printed circuit board.

Features Of ExpressPCB Software

Quite a few features are there about the multi-functional PCB express software. Out of which, some features are here which you can go through once:

- Easy To Use: Most importantly, the software is simple and easy to use. By pressing on the drop-down menu, you will come across all the components and signs. Then double-click on them to use whichever is required. It simplifies the design’s complexities. It has industry-recognized notations, like dimensions, schematics, and designers can use multi-layer or single-layer boards.

- Allowing To Copy And Paste: The software will enable you to copy and paste multiple times to get the desired product. Till the last step, you have the freedom to make changes and eliminate big errors. The software has easy-to-use interfaces that reduce production time as well.

- Streamline The PCB Ordering Process: It is a fast and reliable software you can get the next day PCB. You can use the tool for free and streamline the ordering process. There are advanced component search and component search builders that make the entire process much easier.

- Ability To Modify: By using the tool, you can modify the printed circuit board layout. It has free-form and parametric editing tools and an asymmetrical editing process. You can create custom commands and change the customization file.

Final Thoughts

Well, by using ExpressPCB, engineers and designers can shorten the time to market the new products. In addition, they can pick and test electronic components in a 3D environment. The software helps reduce the production cost to a great extent that you would have spent designing the prototypes. It is said that this process is optimal and most cost-efficient to create the final product. In that way, the errors can also be reduced automatically.