Introduction

Pin in paste (PiP) is an advanced soldering technique used in printed circuit board (PCB) assembly. PiPprinting deposits solder paste inside through-hole vias and pads prior to component placement. This enables soldering the through-hole pins and PCB in a single reflow pass. PiP provides benefits over traditional wave soldering or selective soldering methods for through-hole components. This article will provide an in-depth overview of PiP technology, processes, advantages, and implementation considerations.

Overview of Pin in Paste Basics

Pin in paste soldering involves:

- Depositing solder paste into through-hole PCB locations

- Mounting components on the solder paste deposits

- Reflowing to solder component pins and PCB in one step

This contrasts with:

- First inserting pins through empty holes

- Then wave or selective soldering the pins

PiP enables efficient all-surface-mount assembly without separate soldering passes.

Why Use Pin in Paste Soldering?

Pin in paste offers several advantages over traditional through-hole soldering:

Lower Cost

Eliminates need for wave soldering or selective soldering equipment. Reduces capital investment.

Higher Reliability

Minimizes thermal shock to components by eliminating second reflow pass. Avoiding multiple passes improves reliability.

Design Flexibility

Enables mixed SMT and through-hole components to be assembled together. Simplifies designs.

Process Simplicity

Only a single solder reflow pass required for all components. Reduces production steps and cycle time.

High Density Capability

Fine pitch PiP printing facilitates dense component placement not achievable with wave soldering.

Improved Quality

Lower defect rates and more consistent joint quality than wave or selective soldering.

Lead-Free Processing

Lead-free solder paste used for PiP is compatible with RoHS regulations.

For these reasons, PiP utilization continues growing for high complexity and low/medium volume assemblies.

PiP Printing Process Overview

Implementing pin in paste soldering involves three main steps:

1. PiP Dispensing

Solder paste is precisely jetted into the through-hole pads and vias prior to component placement.

- High accuracy paste dispensing machines are used

- Minimal paste volume is deposited

- 100% of holes can be printed or only selected locations

2. Component Placement

Components are mounted by pick and place systems onto the solder paste deposits.

- Paste holds components in place tentatively

- Some adhesive may still be required in some cases

- Components do not shift or tilt ideally

3. Reflow

The assembly undergoes reflow soldering to “tent” solder component pins and pads.

- SAC305 or other solder paste used

- Same profile as for SMT components

- May require dual speed profile

This reflows solder to electrically and mechanically connect pins and finalize solder joints.

PiP Processing Considerations

Optimizing PiP print quality and reliability involves attention to:

Paste Deposit Accuracy

Paste must cleanly dispense inside holes without smearing or shifting during placement.

Minimum Paste Volume

Only sufficient solder paste to form the joint should be dispensed to avoid overflow.

Component Pitch Range

Printing can accommodate fine pitch but not ultra-fine component spacing.

Hole Wall Preparation

Oxides inside drill walls may require plasma treatment to enhance wetting.

Solder Mask Expansion

Solder mask overlaps onto pad copper improves capillary flow.

Reflow Profile

Dual speed profiles with extended soak above liquidus often works best.

Careful process engineering is needed to implement PiP effectively.

PiP Design Rules

To enable reliable PiP soldering, PCB designs should follow guidelines:

- Via Pad Diameters – 0.3mm to 1.0mm range preferred

- Annular Rings – 0.25mm to 0.5mm annular rings around drilled holes

- Hole Spacing – No closer than 3x hole diameter side-to-side

- Copper Plating – ≥25μm copper thickness in holes

- Solder Mask Expansion – 0.05mm to 0.15mm onto pad copper

- Pad Shapes – Round holes easier than slotted holes

Adhering to these PiP design rules ensures paste can dispense and solder can wick effectively.

PiP Applications

Components suitable for pin in paste soldering include:

- Through-hole connectors

- Press-fit pins

- Transformers, inductors, and coils

- Switches and relays

- Terminal blocks and screw terminals

- Regulators and heat sinks

- LED displays and indicators

PiP enables mixed SMT/through-hole assemblies combining advanced and legacy components.

Pros and Cons of PiP Technology

Pin in paste offers advantages but isn’t ideal for all situations:

Advantages

- Lower capital equipment costs

- Improved joint quality and reliability

- Design flexibility

- Lead-free processing

- High density assembly

Disadvantages

- Tight process controls required

- Potential tombstoning without adhesive

- Additional paste deposit step

- Fine pitch components challenging

- Hole wall preparation may be needed

Assemblers should weigh the tradeoffs versus production volumes, cost targets, and product complexity when considering adopting PiP.

The Future of Pin in Paste Soldering

PiP utilization continues growing as dispensing accuracy improves and designs shift towards mixed SMT/through-hole assemblies. Continued progress in solder paste formulation, hole wall surface finishes, and advanced profiling will further expand PiP soldering adoption. Its flexibility and technical capabilities position PiP well for meeting future electronics assembly requirements.

Conclusion

Pin in paste soldering delivers an efficient process for assembling through-hole components without wave or selective soldering equipment. By dispensing solder paste into PCB pads and vias prior to placement, reflow can solder pins and through-holes in one pass. With tight process controls and design considerations, PiP enables high performance mixed technology assemblies. As demand grows for flexible, high-mix production, PiP stands poised to become an increasingly valued assembly process option.

Frequently Asked Questions

Q: What types of solder paste are used for pin in paste processes?

Standard “no-clean” SAC305 solder pastes are suitable for many PiP applications. For challenging situations, solder pastes engineered specifically for PiP with wider reflow profiles may be preferred.

Q: Does PiP allow double-sided reflow soldering?

Yes, PiP printing can be done on both sides of a PCB followed by double-sided component placement. Dual reflow would then solder all joints in one pass. This further simplifies processing.

Q: How does PiP soldering compare cost-wise to wave soldering?

Eliminating wave soldering equipment provides significant cost savings on lower to medium volume production. For very high volumes, dedicated wave solder may still be more cost effective than PiP bypassing capital expenses.

Q: What are the limitations on component pin pitch with PiP?

The finest pitch achievable with PiP is around 1mm pin spacing depending on hole size. Ultra-fine pitch components may still require traditional soldering approaches.

Q: Can solder paste be dispensed into plated through holes or is plating needed?

PiP printing can work with both plated and non-plated holes. But plating provides stronger metallurgy for soldering. Preparation may be needed on non-plated holes walls.

Pin in Paste (PiP) Technology in SMT Assembly:

We all know the increasing technological advancement in electronics industry, the core reason for which is the growing competition among PCB manufacturers and suppliers. Every PCB CEM (Contract Electronic Manufacturer) is find new ways to cut cost, increase quality and shorten the lead time of PCBs fabrication, assembly, testing and delivery. So talking about the cutting the cost is a highly significant in increasing profit gains and thus ultimately leading the particular CEM in the race of PCB manufacturing competitors.

There are many ways to reduce the manufacturing cost of PCB fabrication and assembly like PCBs with multiple layers are mostly High Density Interconnect (HDI) PCBs, so they are expensive as compared to single or double layer PCBs, so in order to compare the cost analysis of PCB manufacturing, it is important to consider two PCBs with same parameters like they both should be multilayer, HDI and SMT + THT components based. However the difference making aspect in terms of cost analysis are the 1- Surface Finish methods 2- PCB components selection 3- Component Sourcing 4- Process cost 5- Labor Cost and 6- Overhead expenses can determine the ultimate cost per PCB that is produced by CEM.

In this article we will discuss the most powerful method of component mounting in prototype PCB assembly process that will ultimately reduce the cost of manufacturing and speed up the process thus resulting in less lead time.

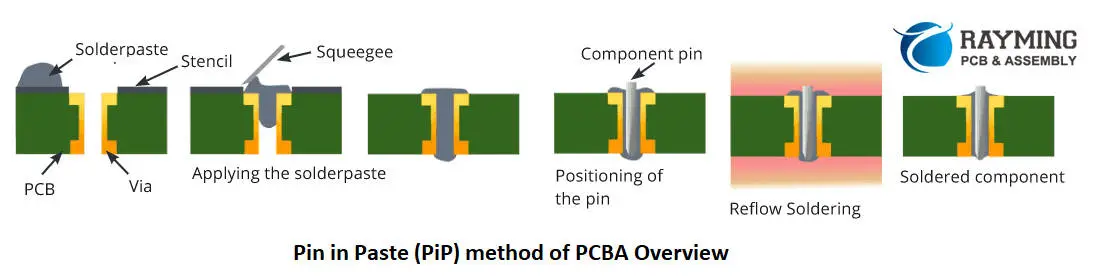

Comparison of Commonly Practiced SMT/THT PCBA and PiP:

While the most of the PCB manufactures and assemblers use the reflow soldering method for SMT (Surface Mount Technology) components assembly and then manual soldering or wave soldering of THT (Through Hole Technology) components, the best method to carry out is the PiP (Pin in Paste) method. The following flow chart shows the common process flow of SMT and THT components assembly.

Now in contrast to the above process flow, the PiP (Pin in Paste) PCBA process flow is lot simpler and easier. Checkout the below mentioned PiP process flow chart.

As you can see that the process is shortened tremendously, this is because the SMT and Through-hole components are baked by the same Reflow Oven that was used to bake only SMT parts. The PiP process is simplified in following manner.

- 1- The additional process of manual assembly of THT electronic components is eliminated

- 2- Wave Soldering is not required

- 3- Additional PCB Assembly process setup machine i.e. Wave soldering machine is not required

- 4- Additional labor not required to work on PCB coming out of vacuum reflow oven

Advantages of PiP:

- 1- Elimination of capital equipment like wave soldering machine, laser soldering machines or any other equipment associated with Through hole soldering

- 2- Saving labor cost by eliminating hand soldering and labor associated with wave soldering process

- 3- Cost can be saved by reclaiming floor space used in the wave and hand soldering processes.

- 4- Material cost saving like solder bars, fluxes, wave solder pallets and other hazardous materials in the wave solder process.

- 5- Other indirect incentives lesser number of through-hole connection by replacing THT components to their equivalent SMT and reduction in heating operations. Because various stages of heating cycle like reflow, wave or hand soldering can increase the risk of damage to the board and component, hence eliminating the wave and hand soldering methods in PiP is a big benefit.

- 6- The greatest advantage of PiP is the ability to design PCB with complex components on bottom side, in traditional process most complex components can only be placed on top side of PCB because they are not able to pass through the wave solder process. By eliminating the wave solder process the PCBs can be designed with complex components on both top and bottom side. This makes it easy to design smaller and denser PCBs for smaller electronic devices

So what is actually PiP technology..?

As we know that the Through-Hole components are those that have pins/leads and they need to be inserted into the PCB holes and then soldered manually or by wave soldering machine. A technology that was first used in 1985 by Motorola to solder the THT components in reflow soldering oven and that made strong joints though.

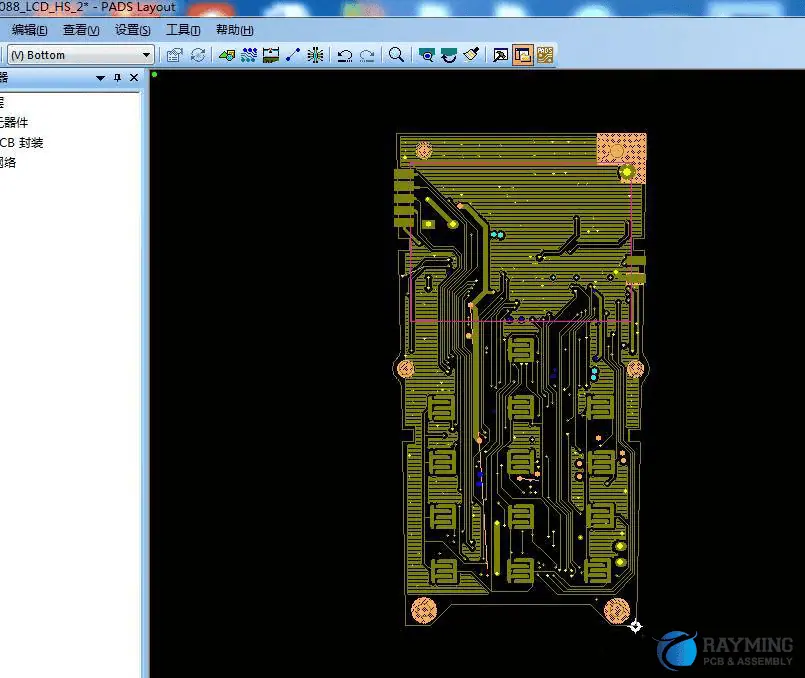

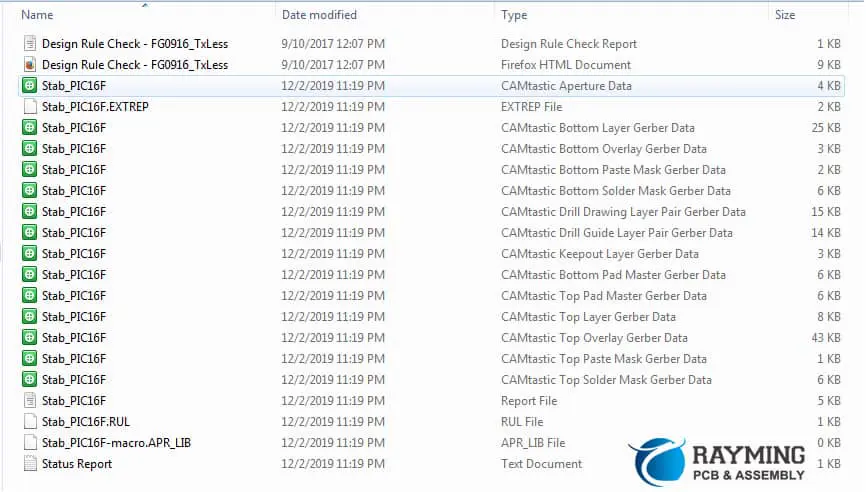

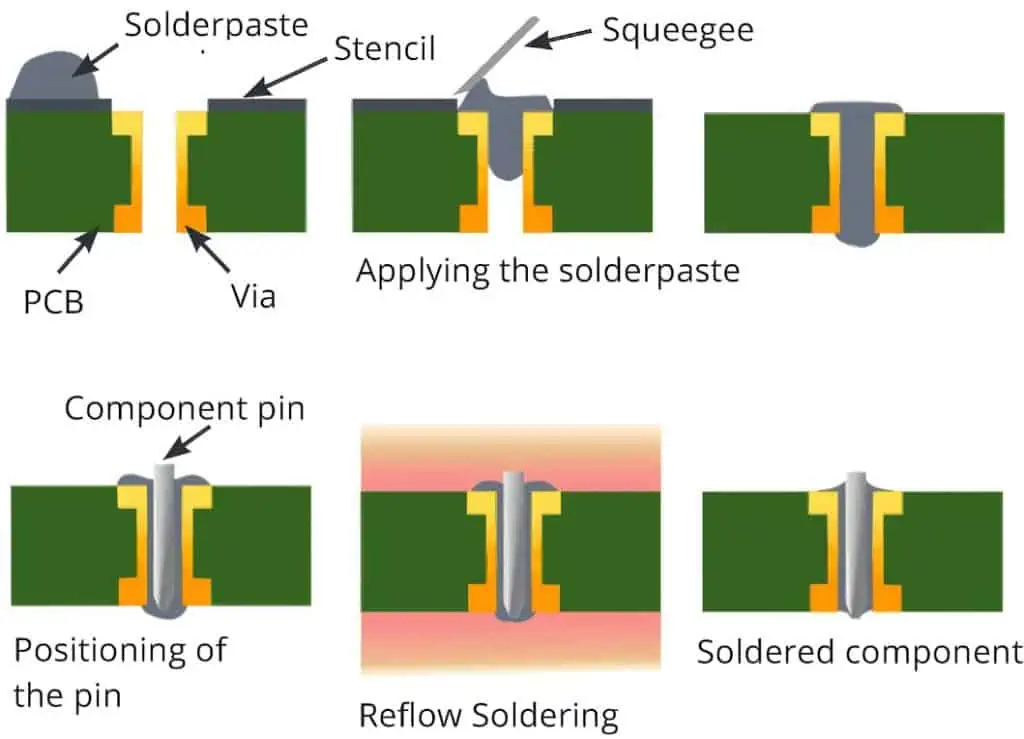

In the pin-and-paste technology, also known as THR (= Through-Hole-Reflow) technology leaded components (THT) are soldered in the reflow process. Paste is printed by means of stencils or dispenser into the through holes for the pins and the through-hole components are assembled on the board. The Pin in Paste PiP is also known as intrusive reflow, Reflow on through hole (ROT), Solder paste on Through Hole technology (SPOTT) and Alternative assembly and reflow technology (AART).

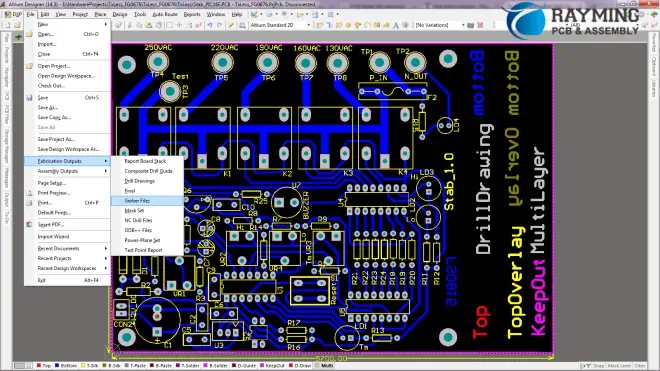

How is PiP Done.?

First of all, the circuit board is printed with solder paste in stencil printer. The stencil printer apply the solder paste on all SMT and THT components locations. Then it may pass through the dispenser for manual dispensing of solder paste, then the SMT and THT components are placed on PCB by means of pick and place robot. After this the whole assembly is placed in vacuum reflow soldering oven, where the solder paste is melted and SMT plus THT components are soldered on PCB. This seems a lot simpler process flow but it can have several challenges which are mentioned below.

Usually the manual hand driven solder paste dispenser is suitable for prototype PCB assembly process where larger production run of PCB is not the case. An example of solder paste dispenser syringe is shown in figure. In the prototyping case, the manual components handling/placement on PCB is recommended.

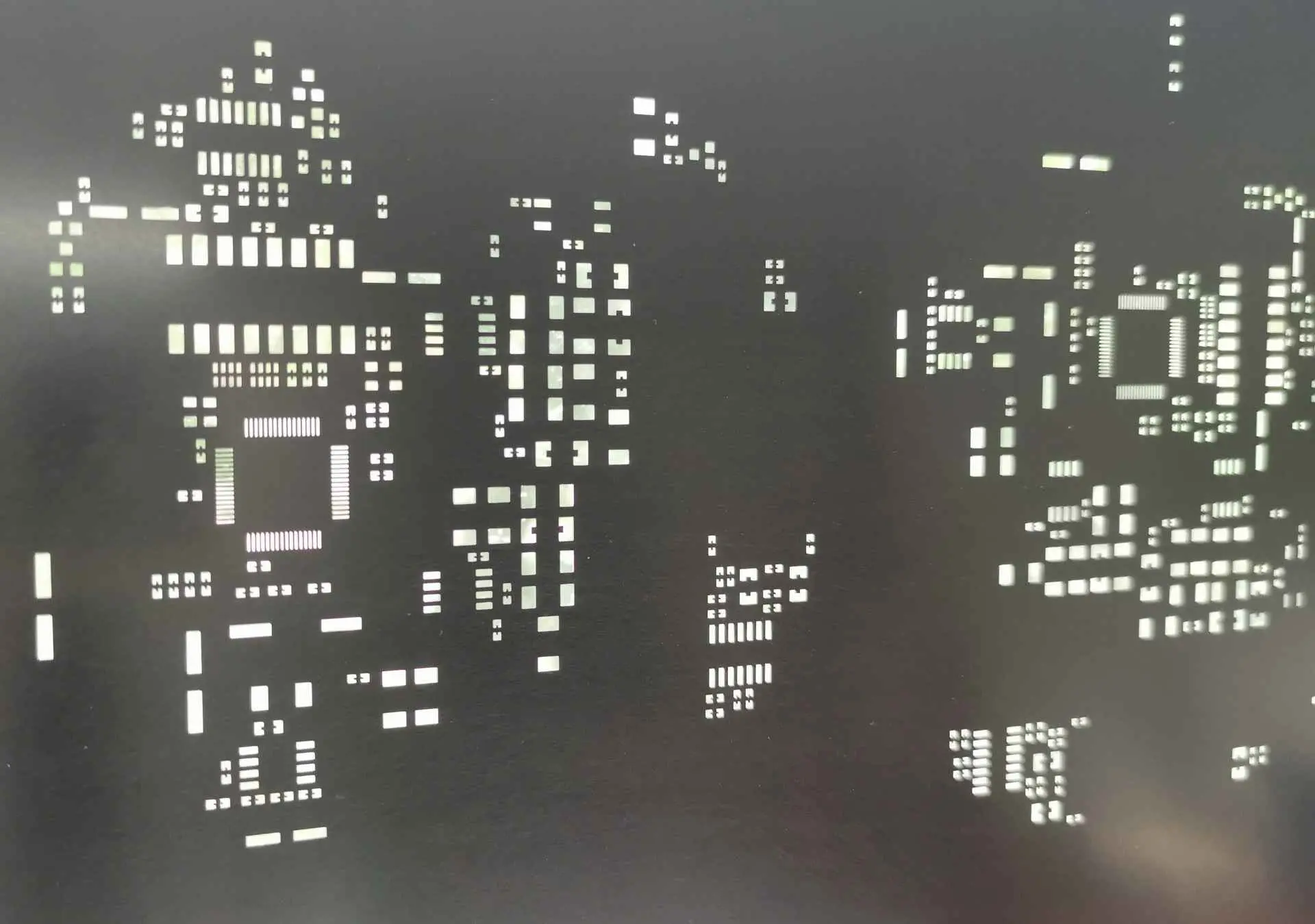

A solder paste stencil example is shown in the figure below

Challenges of PiP PCBA Technology:

- 1- The through hole THT and SMT surface mount components are needed to be baked in Reflow oven hence they (whole component including terminal and plastic body i.e. casing) must have capability to withstand high temperature like 260OC for 10 seconds.

- 2- Because some THT components do not have their equivalent SMT versions so those THT components have to be assembled on PCB and cannot be avoided.

- 3- The THT component should be selected such that its housing/casing construction allow a visual inspection of the solder joint.

- 4- A protective stand-off pad beneath the component’s casing/body must be placed to ensure there is no touching/contact with the solder paste during reflow process.

- 5- The high speed automated pick and place robot can grab the THT and SMT component from its planar surface to place it on PCB.

- 6- It can be difficult to provide an adequate solder paste for through hole joints with stencil printing process.

These challenges can be covered by properly focusing on the requirements of Pin in Paste PCB assembly. Some of them are discussed here.

Component Requirement:

- 1- The component SMT or THT selected for PiP must survive the high temperature of reflow oven

- 2- The THT components must be selected in a way that it fits the requirements of SMT pick and place robot machine, to be picked and placed on PCB automatically and accurately. These requirements are the component height, component shape and spacing between component pins.

- 3- The layer of tin must be coated on top of vias for THR (Through Hole Reflow), hence to achieve this, the minimum distance between component and PCB should be between 0.3mm to 0.7mm and the THT component lead should be 1.5mm thicker than the PCB thickness in order to meet IPC3 standard.

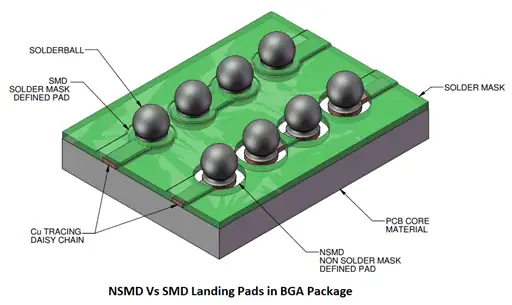

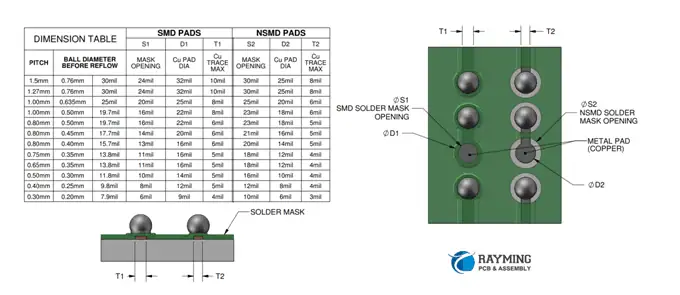

Component Pad Requirements:

- 1- It is recommended that the smaller components placed on bottom side and larger components on top side. A minimum of 2mm spacing must be kept around PIP components; if there are multiple PIP components then at-least 10mm spacing between adjacent PiP components must be ensured to avoid interference during automatic mounting by Pick and place robot.

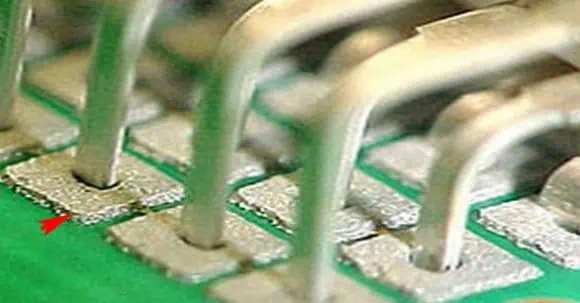

- 2- The distance between adjacent through hole centers should be at least 2mm, distance between edges of adjacent pads should be at least 0.6mm, distance between pad edge and aperture diameter should be at least 0.3mm. Pad aperture diameter should be larger than component pin diameter by 0.2 to 0.4mm. This is done to avoid tin connection between adjacent pins or between pads.

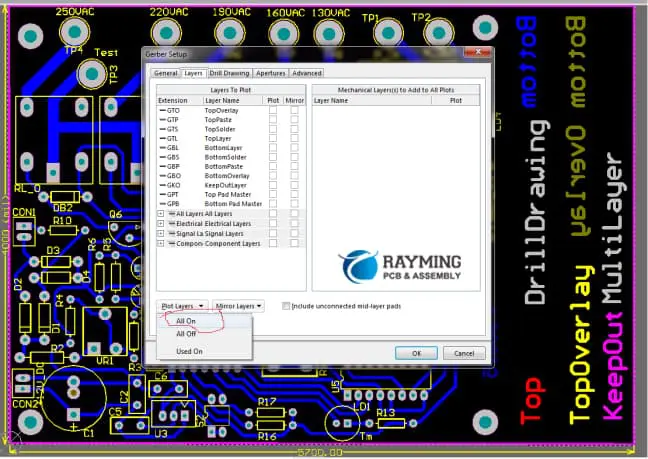

Stencil Requirements:

- 1- The most important parameter for stronger solder joint is the amount/volume of solder paste being printed by stencil, this is governed by diameter of through holes, thickness of substrate and lead shape. The tin paste must fill the electroplated through hole and fillets are on the top and bottom of PCB.

- 2- The amount of tin paste required by THT solder joints is larger than the required by SMT

- 3- Usually the flux fills the 50% of the volume of plated through-hole and remaining 50% is filled by tin paste, hence air bubbles or voids can form when the flux is volatized after soldering process. This can be troublesome, so suitable amount of solder/tin paste must be applied on each through-hole pad.

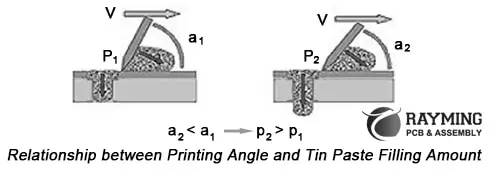

- 4- The ideal tin paste filling must be greater than 90% and tin paste filling amount in through holes must be greater than bottom pad by 0.5 to 1mm. A squeegee angle of 45Ois reasonable however the smaller the squeegee angle the more then tin paste is filled in the through hole and greater the angle the lesser the tin paste fill in through hole as show in diagram below where V velocity is constant in both cases.

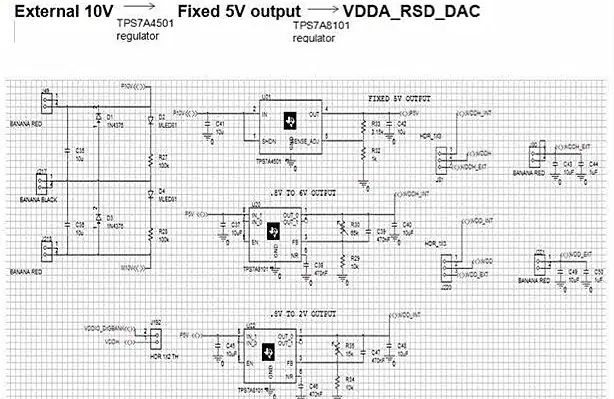

Reflow Oven Requirements:

- The reflow oven temperature settings allow the smooth and steady heat transmission through radiation to the solder pads of SMT and solder joints of THT. As can be seen from the typical reflow temperature profile, the liquidus is at 217OC for 45-75 seconds. This is actually the reflow window, however the slow ramp of 1-3OC is important for stable temperature rise and then degrading the temperature uniformly at the rate of 2-4OC finishes of the reflow process.

Conclusion:

Summing it up all, we can say that PiP (Pin in Paste) method of PCB assembly is extraordinarily useful for mass production of smaller, denser and lighter PCBAs which can cut the cost of production tremendously. With Pin in Paste technology one can have a stronger and better THT solder joint as that of manual or wave soldering and can place complex SMT components on both sides of PCB thus optimizing PCB board space and miniaturizing electronic devices.