Nelco PCB ( Any Nelco PCB Enquiry Pls send mail to Sales@raypcb.com )

Nelco PCB Laminate often choose by our Europes customer, so we have prepared a sufficient conventional Nelco PCB laminate stock,that can on time delivery to your Nelco PCB.

Nelco Circuit board materials that provide superior thermal and mechanical performance. All Nelco materials are RoHS compliant and many provide high thermal reliability and CAF resistance for lead-free assembly compatibility. Nelco is a reliable source with 50+ years of global materials experience. There are many material types available including FR-4, High-Tg and high speed epoxy materials and advanced materials such as BT, polyimide and cyanate ester.

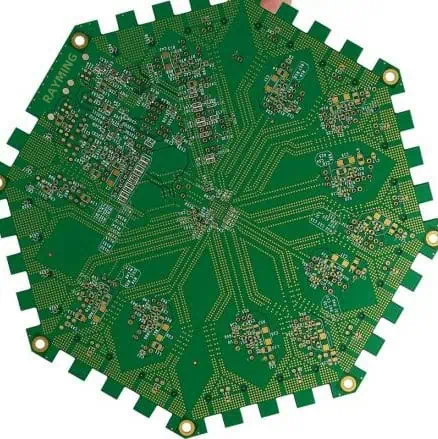

Nelco PCB materials are designed for high layer count PCB and high speed digital applications such as lead–free assemblies, high speed / low loss and fine-line multilayers, backplanes, communications and networking services, wireless handsets and infrastructure, automotive and diverse mounting and packaging.

Nelcote7 Advanced Composites

Nelcote7 Digital Electronic Materials

N4000-13

N4000-13 EP

N4000-29

N4000-7 EF

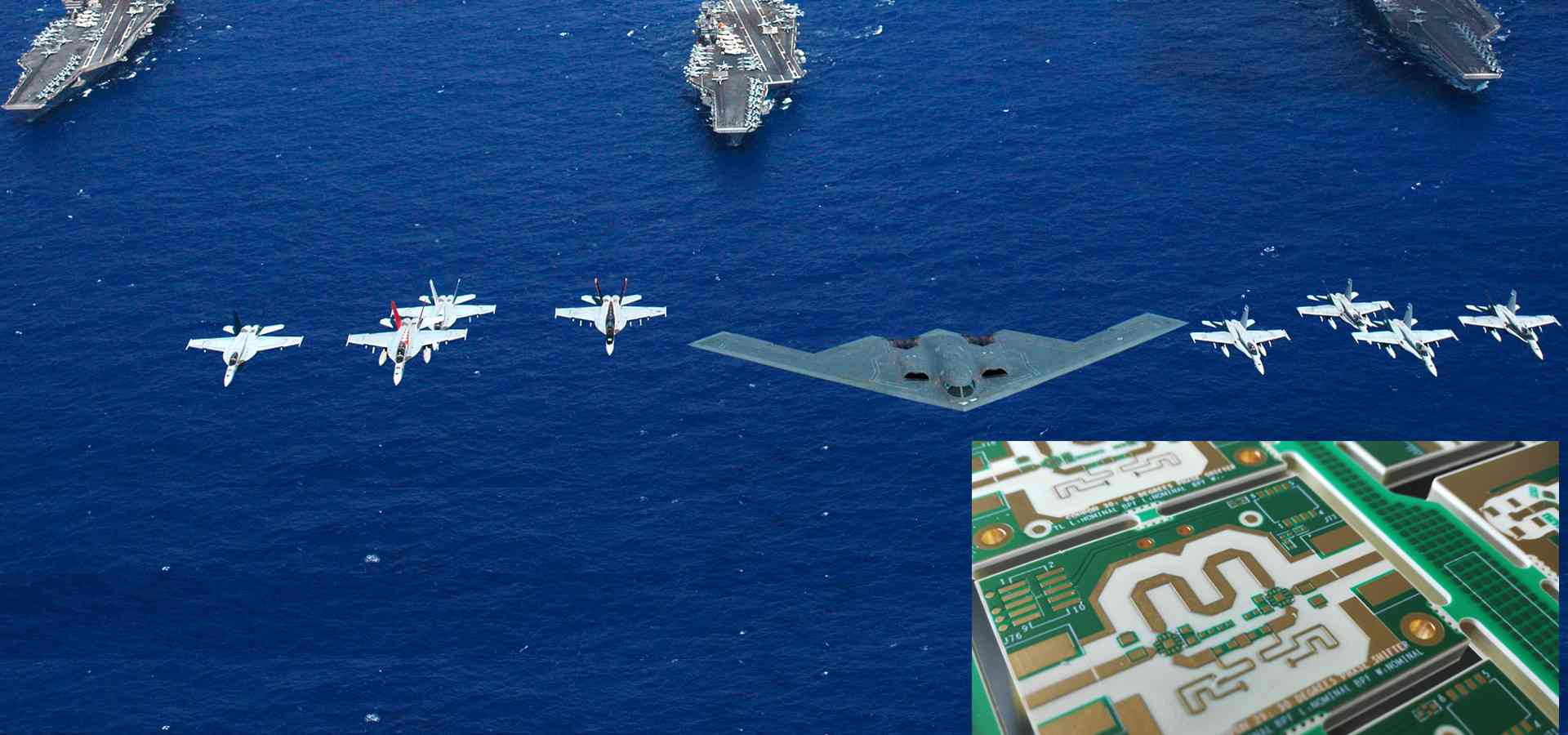

Nelcote7 RF / Microwave Materials

N4350-13 RF

N4380-13 RF

N9000-13 RF

If you want to produce Nelco prototype PCB ,Pls contact use , even high volume is welcome for Nelco material .

Fundamental Facts You Must Know about Nelco PCB

You must have understood the significance of printed circuit boards, especially if you find electronics an intriguing subject. But you, like many other people, can get caught in the intricate and often confusing web of circuit boards. It may seem like fresh concepts keep popping up every other day. So is Nelco PCB among them? Well, do not worry; this article will cover every fundamental aspect of the Nelco printed circuit board.

Nelco Printed Circuit Board

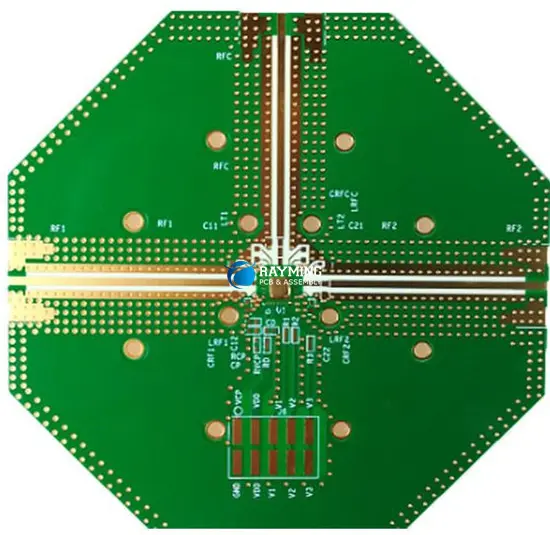

Nelco PCB implies a printed circuit board built using Nelco materials. Such a printed circuit board provides an outstanding thermal and mechanical performance. It is appropriate for multi-layer and high-speed digital printed circuit board applications. However, it is important to note that Nelco produces both printed circuit boards and RF/microwave industry materials. So what constitutes the materials from Nelco?

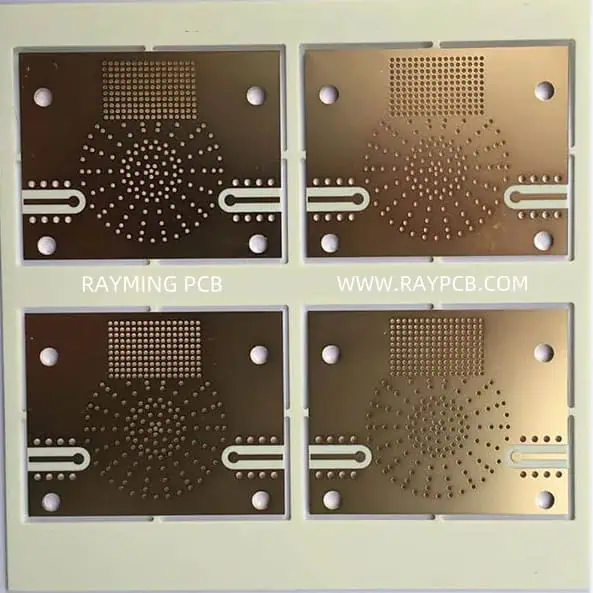

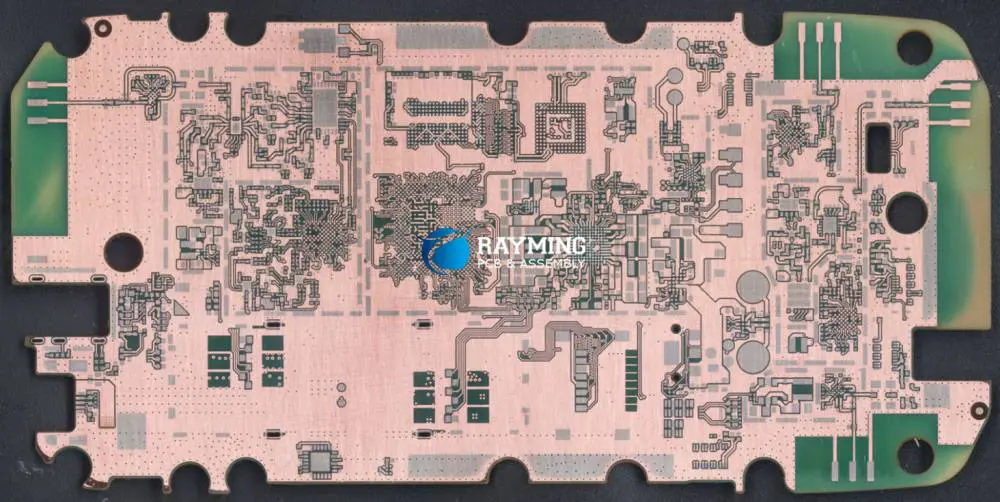

The PCB materials from Nelco include Prepreg materials, Nelco laminates, among other fundamental components of the PCB, and RF/microwave. Such materials offer excellent and high thermal reliability and CAF resistance. Additionally, the materials are compliant with RoHS regulations besides proving compatible with lead-free assembly.

Therefore, if you want to obtain high-quality Nelco PCB products, it is prudent to contract us- RayMing PCB and Assembly for your manufacturing and assembly service needs. You will not only get the Nelco materials, including the Nelco laminates, for producing your Nelco PCB prototype or high-volume production but get them affordably. Consequently, it will reduce the cost of production and make your Nelco PCBs competitive post-production and delivery.

What’s more, the company offers excellent and quality printed circuit board production owing to over fifteen years of industry experience, skilled workforce, and latest technologies and equipment. We can deliver quality Meteorwave 1000, Meteorwave 8300, Meteorwave 8350, Meterorwave 8000, and N4000-29NF.

Nelco PCB also comes with different printed circuit board surface finishes. Therefore, it becomes vital to detail in your submitted Gerber file the specific Nelco PCB surface finish you want.

Designing Your Nelco PCB

The design of the Nelco PCB you come up with will act as the reference upon which the contract manufacturer will prototype, manufacture, and assemble your printed circuit board. Because of this, it helps to consider defining and detailing specific aspects of the PCB design before sending your order to your preferred contract manufacturer.

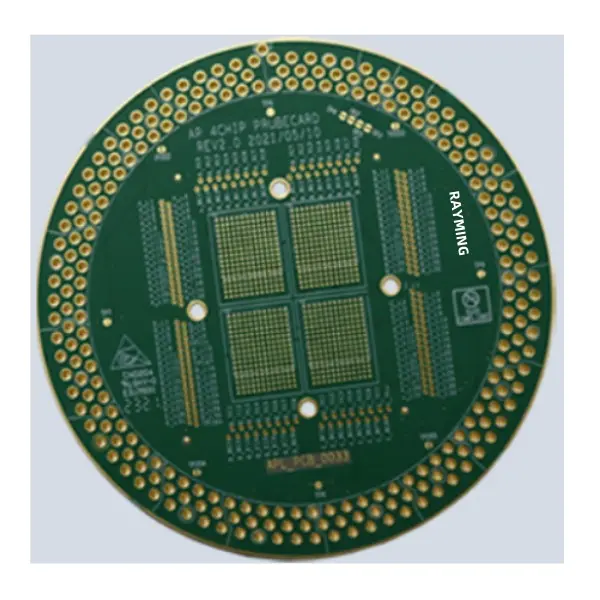

Crucial aspects you must consider for your Nelco PCB design include the PCB stack-up, the board materials (including the Nelco PCB surface finish), copper traces, via types, picking PCB parts, rules of design, besides power and signal integrity.

Nelco PCB Stack-Up: Factors that Determine the Layer Number in the Design

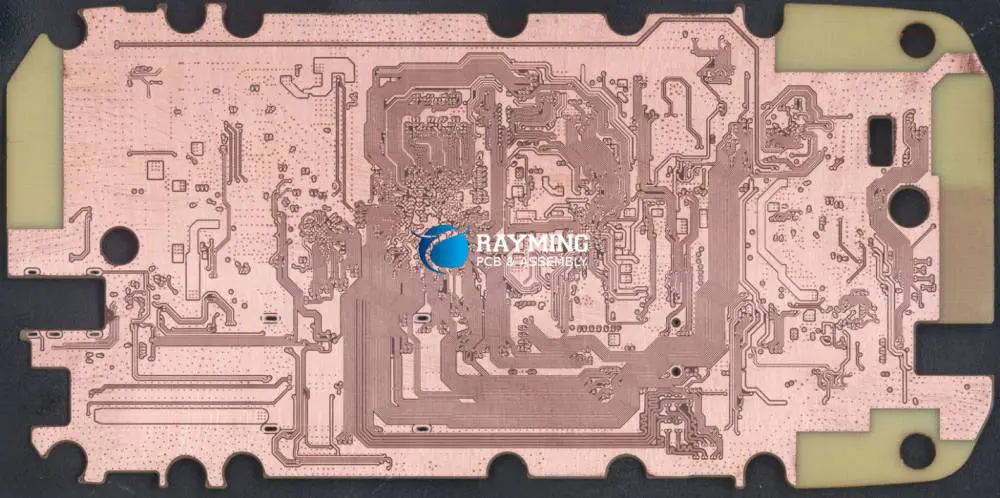

The PCB stack-up design impacts the general performance of the Nelco printed circuit board. It plays a more prominent role, especially in high-performance structures involving transceiver technology. So what is it all about? It implies the substrate and its outlay order upon which you must assemble the PCB components.

The stack-up design quality influences key aspects of the Nelco PCB, such as electrical capability relating to signal transmission, manufacturability, long-term dependability of the PCB product, besides power delivery. Therefore, it becomes prudent to master the printed circuit board fabrication besides factors influencing cost and material choice.

However, this section will focus on the factors that determine the layer number in the Nelco PCB stack-up design. Nelco PCBs possess numerous alternating layers of Prepreg, copper foil, and core materials that all get bound through heat-pressing.

Factors that influence the layer number include the following.

- The total signal nets that you need to shoot off the BGA device

- Packages type for the components and component density

- The total sum of power planes or pours

Please remember that the aggregate layer number in such a design gets defined by the circuit board intricacy.

Important Characteristics of the Different Types of Nelco PCB Materials

As already alluded, diverse Nelco PCB materials exist, with each material having numerous distinctive features. Therefore, whenever you have to pick a specific Nelco material in your Nelco PCB design, you must consider the attributes vis-à-vis your PCB application area. Below, a section of some of the Nelco printed circuit board materials and their respective attributes.

High-performance category:

- Meteorwave 1000 NF. It is a low loss, high reliability, no flow Nelco PCB material. It is a leadless and compatible PCB with a glass transition temperature of 240 degrees centigrade with diverse dielectric constants depending on the capacity of the Nelco PCB material.

- Meteorwave 8000. It possesses an extremely low loss, very high reliability. The material also possesses a high temperature and lead-free assembly besides proving compatible. It is CAF resistant with a glass transition temperature of 185 degrees Celsius. It has a dielectric 3.28 and a dissipation factor of 0.0016.

- Meteorwave 8350. The Nelco PCB material contains an extremely low loss, very high reliability, and a controlled dielectric constant. It is compatible with high-temperature and lead-free assembly. Additionally, it proves CAF resistant with a glass transition temperature of 185 degrees centigrade.

It is important to note that plenty of other materials exist under this classification of Nelco PCB materials.

FR-4 substrate category:

- A representative of the category entails the N4000-29NF. The Nelco material features a lead-free, high glass transition temperature multifunctional epoxy. It is amenable to high temperature, lead-free assembly besides proving CAF resistant. It also has a dielectric constant of 4.5 with a dissipation factor of 0.018.

However, other Nelco materials under this category include N400-6, N400-7, N400-6F, and N4007SI.

Remember, aspects such as the glass transition temperature, dielectric constant, and dissipation factor comprise vital aspects that a circuit board designer must consider regarding their PCB material to ensure a seamless functionality of the PCB under its targeted application.

The Diverse Printed Circuit Board Surface Finishes for Nelco PCBs

The design phase of your Nelco PCB becomes as important as the prototyping, testing, and production phases. Therefore, you have to become as specific and detailed as possible, including specifying the kind of Nelco PCB surface finish that you want. To understand this better, consider the following PCB surface finishes in Nelco printed circuit boards.

- Electroless Nickel Immersion Gold (ENIG). It is a typical alternative deployed in Nelco PCB. It provides a gold (thin) solderable film that safeguards the copper traces through a nickel barrier to separate them from the copper. As a lead-free alternative, it forms a perfect long-lasting finish.

- Hot Air Solder Levelling (HASL). For HASL, the Nelco printed circuit board gets clasped vertically by clamps before getting immersed in a flux bath. It then gets dipped in a hot and melted solder vat before the finish. The finish consists of tin or lead before getting flattened out by hot-air knives. Such a treatment ensures that the thickness of the entire board becomes uniform. Currently, the application of HASL finishes on PCB primarily focuses on the military and aerospace industries.

- Lead-free HSLI. The finishes and application of HASLI have similarities to HASL, though the alloy lacks lead. Instead, it possesses nickel and tin or copper and tin, nickel, germanium, copper, and tin alloy. It is, however, crucial to note that this type of PCB finish is not common.

- Immersion Tin. The finish deploys a thin tin coating over the copper surface via a chemical process. It helps with preventing the oxidation of the copper contained underneath. Such a finish typically gets applied on a high-speed Telco printed circuit board.

- Hard Gold. It represents another Nelco PCB finish, primarily deployed in mechanical contact applications such as buttons and keyboards. The hard gold finish is applied on nickel and attaches perfectly to other PCB finishes that disintegrate fast.

- Entek or Organic Solderability Perseverative. Entek represents a thin organic material coat that gets deposited over copper to shield it before getting soldered. It is water-based though it comes as a non-typical finish currently.

- Immersion Silver. The finish lacks nickel and gets deployed in high-speed signal application areas. It, however, becomes crucial to note that the finish requires special storage to prevent oxidation and subsequent discoloration.

- ENEPIG– Electroless Nickel Electroless Palladium Immersion Gold. It is a three-layer finish composed of metal that gets applied on printed circuit boards and wire connections. The electroless nickel protects the copper and prevents it from contacting other metal parts. On the other hand, the electroless palladium provides an extra anti-oxidation coat that limits nickel corrosion. The gold coat incorporated offers an extra layer to limit oxidation besides covering the printed circuit board wholly.

- Soft Bondable Bond. It possesses a similar bonding technique as ENEPIG. It, however, possesses little space for landing wires because of the crowned surface pad.

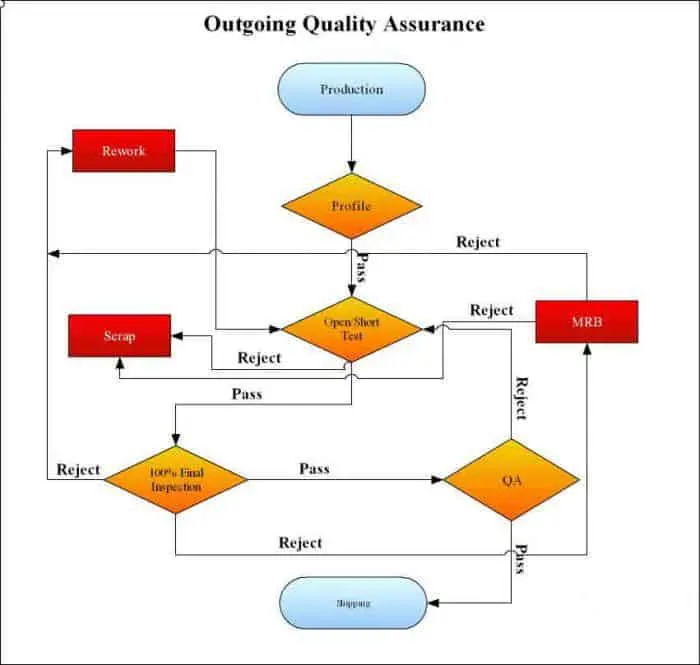

How to Control the Quality of Nelco Printed Circuit Boards

Many manufacturing companies have diverse ways of controlling the quality of Nelco PCB during the fabrication and assembly processes. However, there are a few universal methods of quality control that all PCB companies have to ensure regarding Nelco PCBs. Therefore, typical quality-control tests include the following.

- Differential scanning calorimetry (DSC)

- It represents one of the thermos-analytical methods used to access a number of physical and chemical properties of laminates and prepregs. DSC measures the heat flow variation across a specific resin system as compared to that of aluminum reference.

- Thermos-gravimetric analysis. It determines the loss of weight as a function of temperature when a Nelco material gets heated. Heating happens through a regulated isothermal or heat-up ramp mode.

- Thermos-mechanical analysis. It determines the dimensional variation of a printed circuit board material when it heats up (from the room temperature to the determined temperature.

- Infrared spectrophotometry. Inferred to as IR, infrared spectrophotometry determines a PCB’s chemical fingerprint regarding its characteristic absorption and transmission of infrared frequencies.

Further, the Nelco PCB quality standard gets regulated by UL, CE, ASTM, RoHS, and ISO quality standards. Therefore, whenever you are looking for a Nelco PCB contract manufacturer or PCB product, it helps to use these quality indicators to know the PCB or PCB manufacturing company’s quality regarding quality management systems and standards.

The Importance of Panelization in the Size Determination of Nelco PCBs

The miniaturization of electronic products demands a similar diminishment of circuit board sizes. Consequently, you have to panelize your Nelco board when determining the initial size, especially if you do not want to interfere with its intended functionality and performance. It not only helps with the maximization of the board yield for every PCB panel but also helps in reducing the board cost for each PCB.

Board panelization becomes crucial as you define the usable surface of the board where you can easily route the circuit board (place components and draw copper traces). For instance, a typical PCB board will have a panel size of 12×18 inches and 18×24 inches. However, since the usable surface often proves less across the board with an inch on either side, the usable surface becomes 10×16 inches and 16×22 inches. Additionally, the panelization of a multi-layer board requires a minimum spacing of 100 mils.

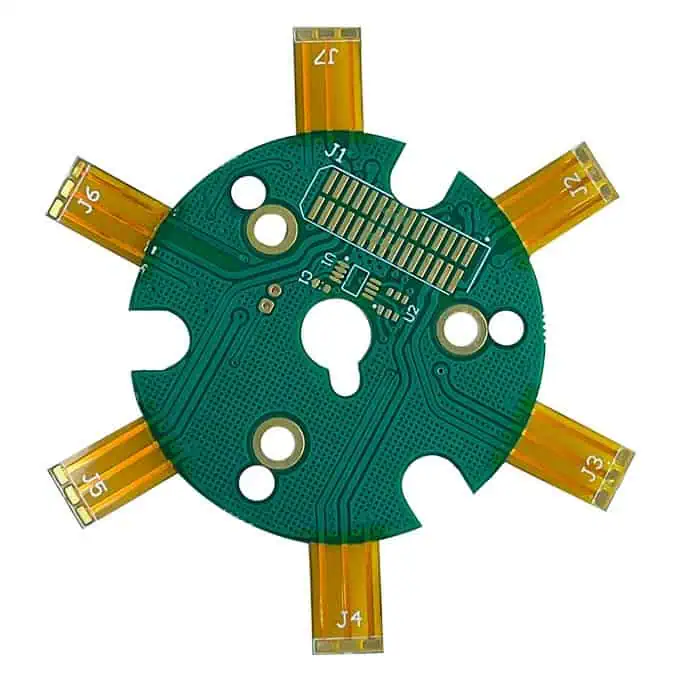

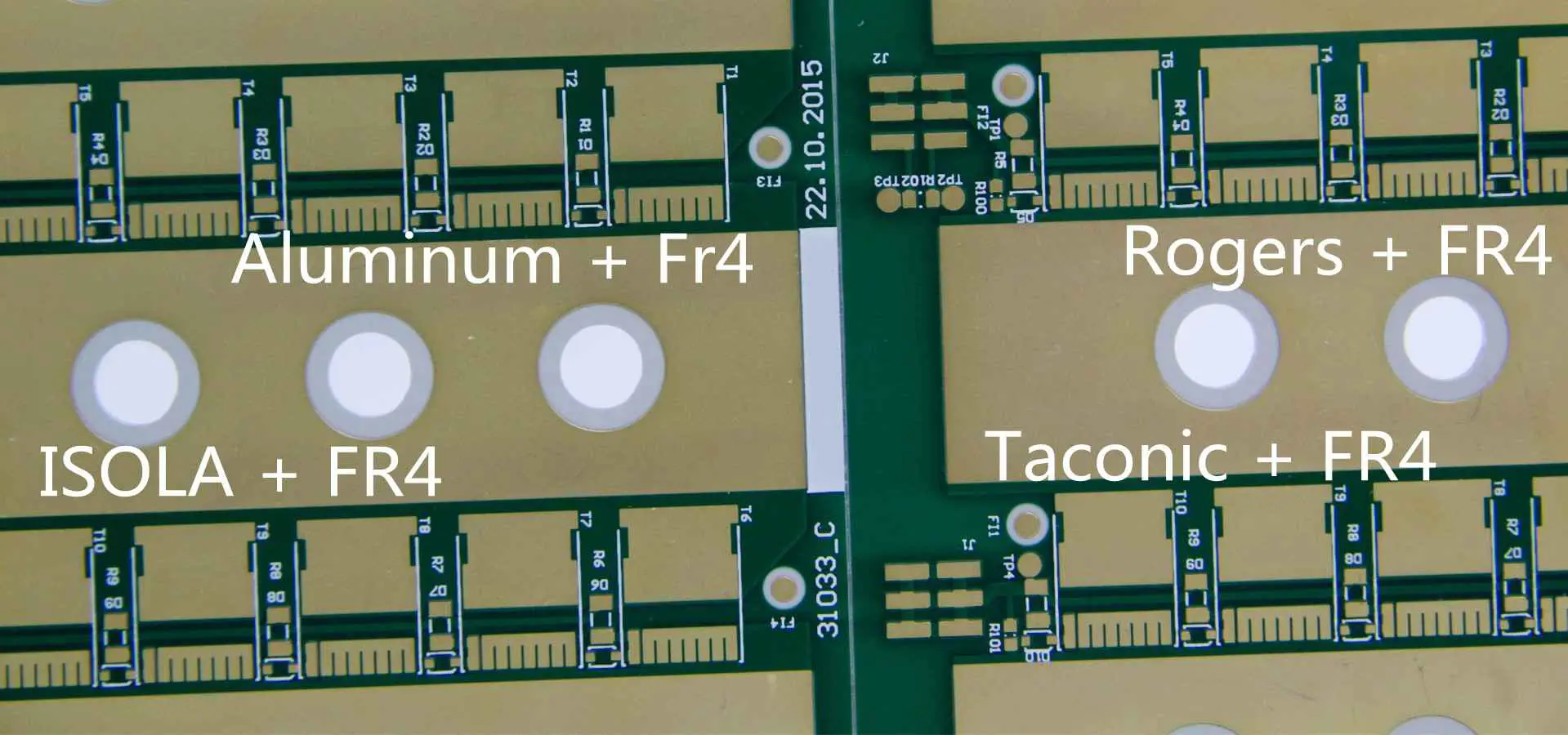

Hybrid Construction of Nelco PCB

The hybrid construction of Nelco printed circuit boards often represents an intriguing area. It is a powerful construction technique in controlling expenses, especially in high-speed printed circuit board designs. Only the layer that requires high-performance signals uses a higher cost, albeit with laminate core material of low loss. Consequently, other remaining PCB layers can use a lower-cost FR-4 core derivative material.

However, it becomes essential to maintain an even Prepreg throughout the printed circuit board to stick the PCB core layers together. Further, you need to avoid blending the Prepreg to avoid issues when laminating, as a proper bonding of the Prepreg may require different temperature regimes.

Material Loss and Vital Strategies of Mitigating the Loss in Nelco PCBs

Diverse fundamental aspects regarding material loss become key when designing a Nelco PCB. Therefore, you have to select Nelco PCB materials by considering these factors. It includes the loss tangent, skin effect, fiberglass weave composition, and relative dielectric constant.

The considerations become crucial because of the impedance mismatches, dielectric losses, and conductor losses, which play a role in causing signal loss, especially at lower data rates in Nelco PCBs. While many people can argue that the impedance mismatch can get addressed through controlling separation, traceroutes, and geometrics during the PCB layout design, it cannot cover the other material loss factors.

Additionally, it is important to address and mitigate all these issues in the design phase of your Nelco printed circuit board.

Final Thoughts

Nelco PCB is a vital type of printed circuit board for application in its niche industries. However, to design and produce a useful Nelco PCB, you have to understand the various aspects of the PCB and how such aspects affect the performance of your Nelco PCB.