Introduction

Fingerprint locks, also known as biometric fingerprint locks, are access control devices that use fingerprint recognition technology for locking and unlocking doors, drawers, lockers and more. They offer a convenient and secure unlocking solution compared to keys or combination locks.

In this comprehensive guide, we’ll cover:

- Applications of fingerprint locks

- How fingerprint lock technology works

- Design considerations for fingerprint locks

- Sensor types

- Processing

- Matching algorithms

- Power options

- Enclosure design

- Manufacturing and assembly of components

- Testing and calibration best practices

- Advancements in fingerprint locks

- FAQs

By the end, you’ll understand the full process of engineering fingerprint locks from initial applications, through design, manufacturing, and testing to bring reliable biometric products to market. Let’s get started!

Applications of Fingerprint Locks

Fingerprint locks are used in a diverse range of applications including:

- Homes and apartments

- Offices and workspaces

- Schools and universities

- Hotels and hospitality

- Residential care facilities

- Gyms and sporting venues

- Laboratories

- Hospitals and healthcare

- Law enforcement facilities

- Financial institutions

- Sensitive industrial sites

They provide convenient access control in virtually any environment where managing keys or remembering codes poses challenges. Users simply enroll their fingerprint once then unlock reliably and instantly.

Next, we’ll take a technical look inside fingerprint lock design and operation.

How Fingerprint Lock Technology Works

Fingerprint locks function using the following key stages:

Fingerprint Capture

The user places their finger on the fingerprint sensor. The sensor images the fingertip and captures the fingerprint pattern.

Processing

The processor digitizes the fingerprint image and extracts unique minutiae points as a mathematical representation.

Fingerprint Matching

The extracted fingerprint data gets compared to stored enrollment templates for a match. Advanced matching algorithms are used.

Access Granted

If a match score exceeds the set threshold, the identity is verified and the lock grants access. The door or safe unlocks.

Storage

Users’ enrollment templates get stored in a protected local memory within the lock. Templates should be encrypted.

This provides a high-level overview of key subsystems in a fingerprint lock. Next we’ll look at design considerations and options for each area.

Fingerprint Lock Design Considerations

Designing an effective, reliable fingerprint lock involves careful selection of:

Fingerprint Sensor Type

Two main sensor technologies:

Optical – Uses a camera with illumination to image the fingertip surface. Offers good image quality if sized adequately.

Capacitive – Senses fingerprint ridges using an array tiny capacitors. Compact but more prone to environment impact.

Key tradeoffs: Image quality vs. size. Capacitive suitable for small locks if calibrated well. Optical preferred for highest accuracy in all conditions.

Processing Hardware

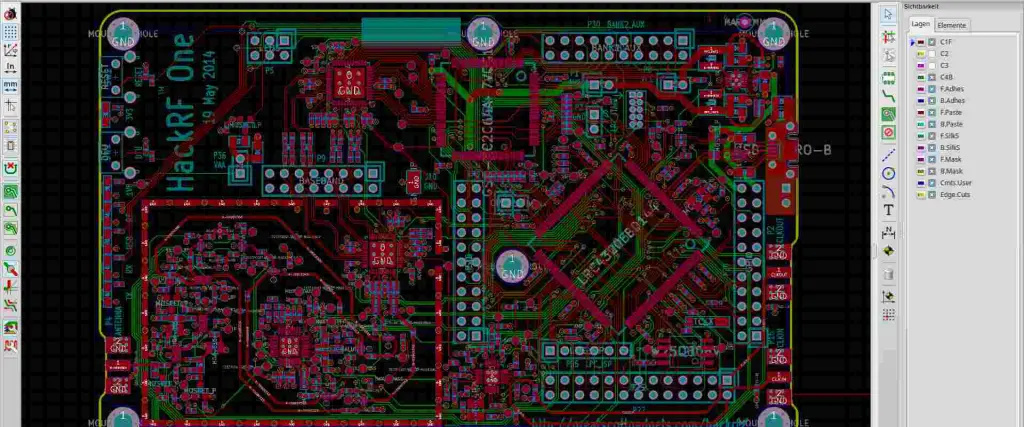

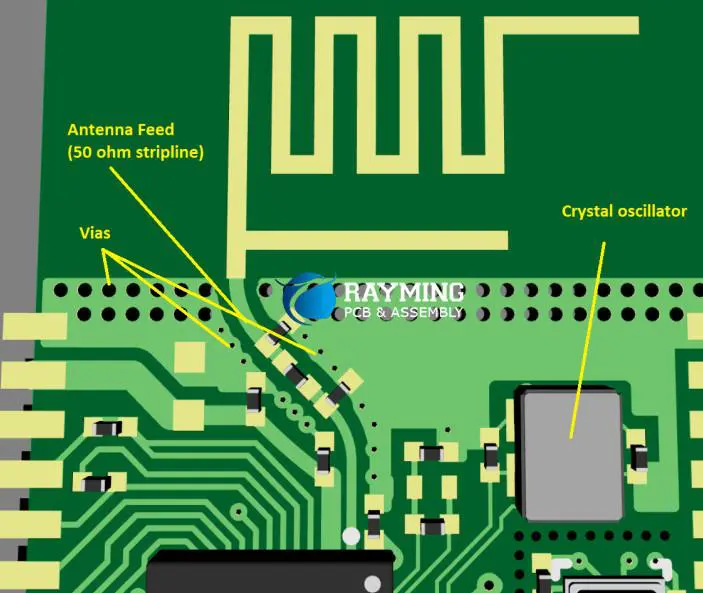

A microcontroller or microprocessor is required to process the raw sensor image, extract features, match against templates, control peripherals, etc.

Key factors: Sufficient performance for image processing and matching algorithms, crypto functions for template security, interfaces for peripherals, low power operation. ARM Cortex M4 or faster 32-bit MCUs are commonly used.

Matching Algorithms

The algorithm used to compare the live fingerprint against enrolled templates is crucial for reliable recognition.

Common matching approaches: Minutiae based, ridge feature based, image correlation, machine learning based. A hybrid approach combining minutiae with other advanced techniques often performs best.

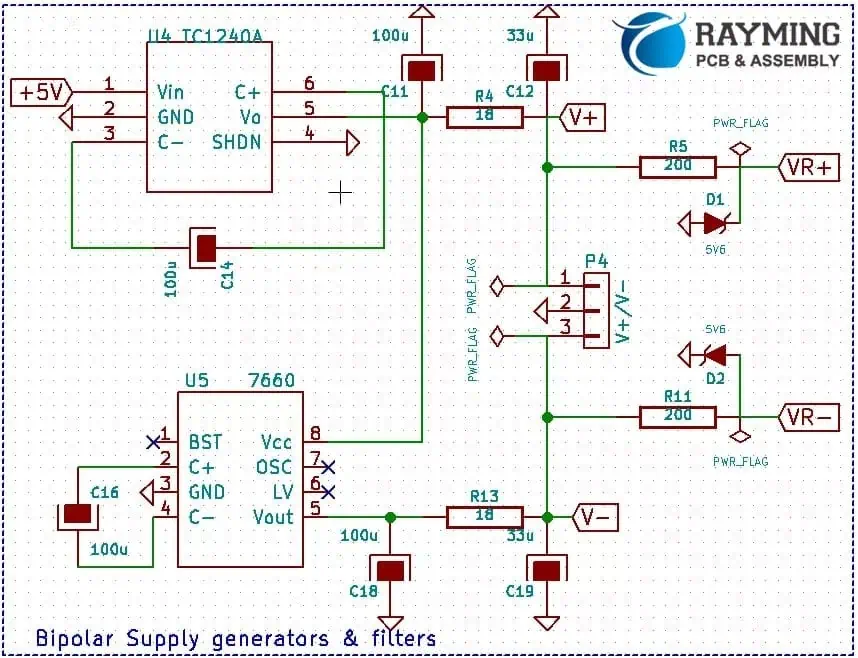

Power Supply

A stable, reliable power source is required. Can use:

- Internal batteries

- External AC adapter

- USB power

Battery is convenient but may require periodic charging/replacement. AC powered locks avoid battery issues but need outlet access.

Enclosure

The lock housing must:

- Protect internal electronics

- Mount sensor ergonomically

- Provide mechanical locks/latches

- Allow accessible wiring

- Withstand use, weather, tampering

Material, seals, construction must balance function, cost and aesthetics.

Careful engineering of all subsystems results in a robust, usable fingerprint lock that provides convenient biometric access control. Next we’ll look at manufacturing critical components.

Fingerprint Lock Manufacturing and Assembly

Producing reliable fingerprint locks requires close attention during:

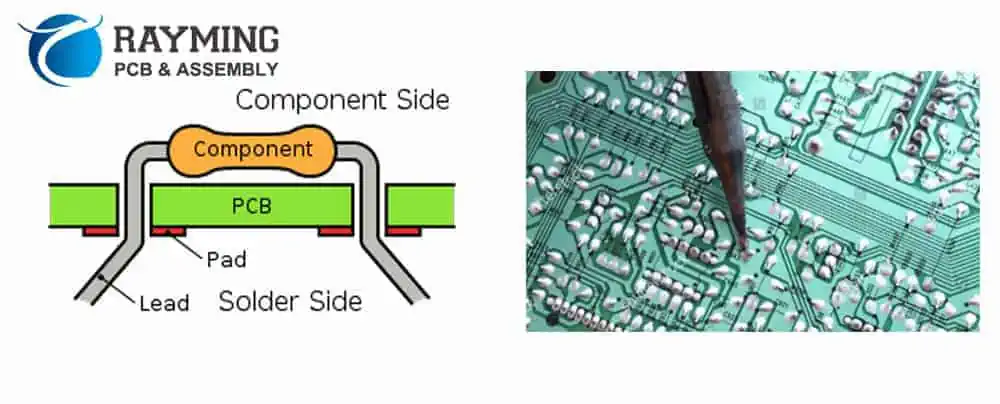

Sensor Manufacturing

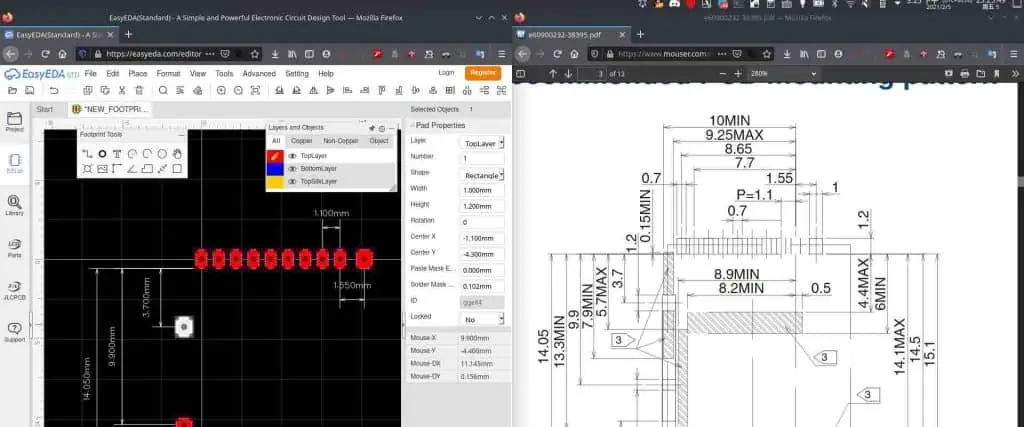

The image sensor integrated circuit fabrication process must achieve:

- High pixel density for detailed imaging

- Low defect rates to avoid bad pixel clusters

- ESD protection for fingerprint static discharges

The silicon fabrication facility must maintain extremely clean conditions.

For capacitive sensors, the capacitor array geometry must be uniformly micro-etched with tight alignment.

Processor Sourcing

The processor is typically sourced as a completed IC component. Key aspects:

- Sourcing from reputable manufacturers like STM, NXP, or ATMEL

- Order sufficient volume to qualify wafer lot and obtain consistent quality

- Rigorously validate received units for defects before assembly

Matching Algorithm Optimization

Extensively tuning matching parameters and testing recognition accuracy using datasets of real fingerprints is key.

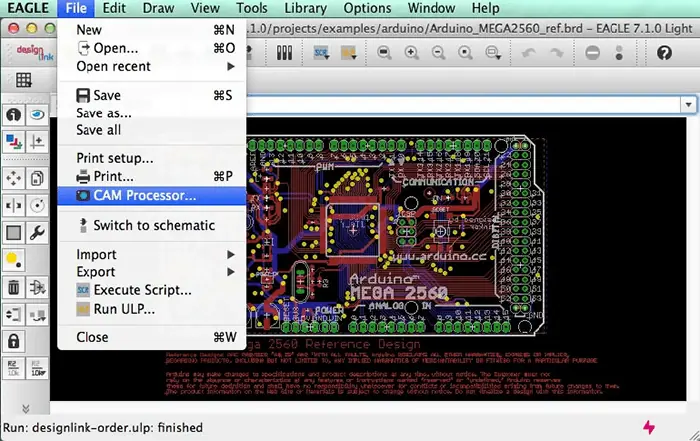

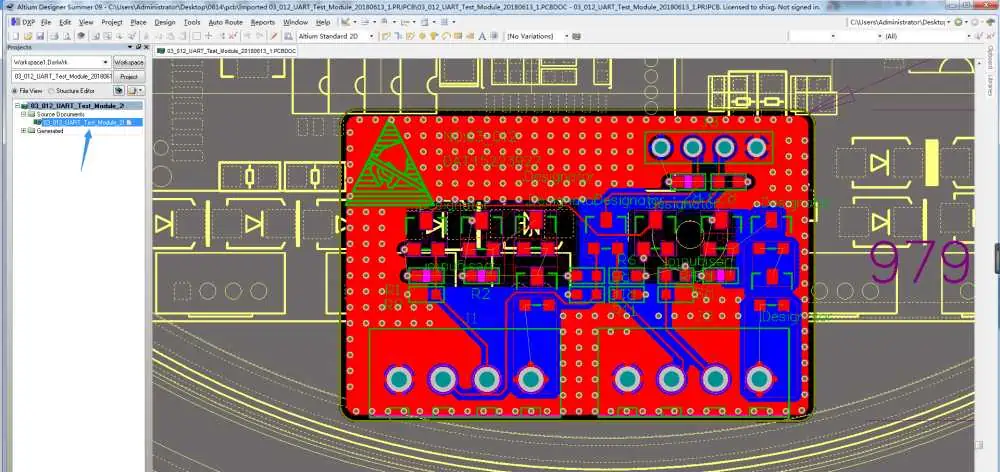

Lock Assembly

Proper assembly protocols must be followed:

- ESD control procedures to avoid static discharge damage

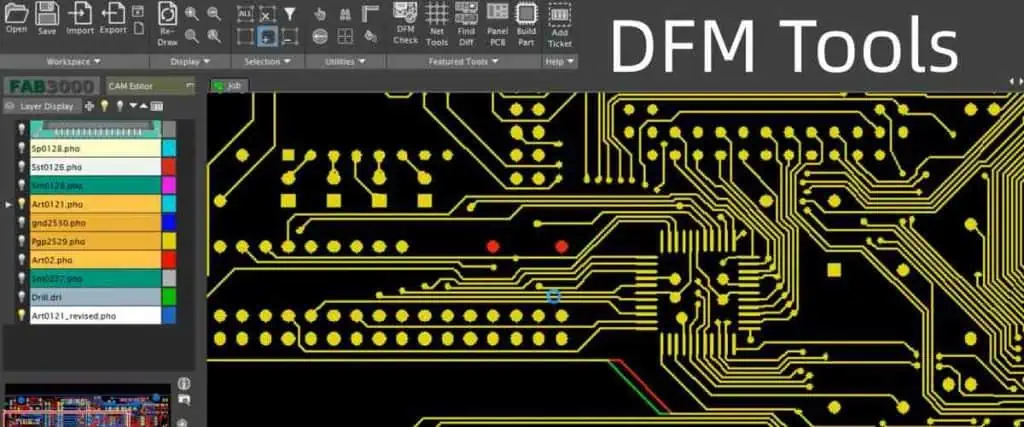

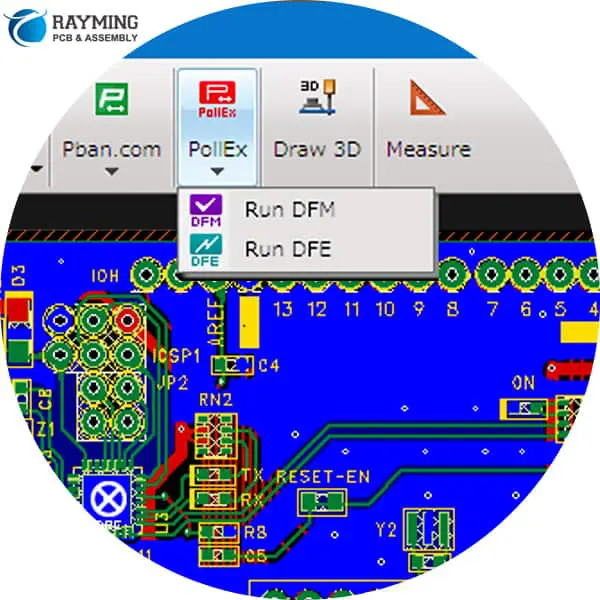

- Component placement following layout design rules

- Process validations e.g. torque requirements for enclosure screws

- Periodic quality audits on units from production line

With rigorous manufacturing practices for critical subsystems, reliably functioning fingerprint locks can be produced at scale.

Testing and Calibration Best Practices

To confirm locks operate properly prior to delivery, key testing and calibration steps include:

Unit Testing

- Verify all electronic components functional

- Validate processor execution timing

- Check current draws and power consumption

- Confirm wired/wireless interfaces working

Sensor Testing

- Inspect image quality – sharpness, artifacts, distortions

- Check live finger imaging reliability across conditions

- Evaluate max image size and resolution

Matching Accuracy Testing

- Test false reject rate with good fingerprints

- Validate low false accept rate on invalid fingerprints

- Tune matching thresholds as needed

Environmental Testing

- Hot and cold exposure

- Drop/shock/vibration resilience

- IP rating validation if relevant

User Testing

- Sample users enroll and unlock with live fingers

- Identify any usability pain points

Extensive testing ensures consistent performance and quality for end customers.

Advancements in Fingerprint Lock Technology

Fingerprint lock technology continues advancing:

- Multimodal – Combining fingerprint sensing with face, iris or other biometrics for multifactor authentication.

- Anti-Spoofing – Detecting fake fingerprints made from silicon molds etc. Liveness detection can use multispectral imaging and deep learning algorithms.

- Cryptography – Implementing highly secure methods to store fingerprint data as digital keys unlocks cloud-based access control frameworks.

- Smart Home Integration – Connecting biometric locks into smart home systems for features like temporary access codes and centralized manageability.

- Mobile Credentials – Using fingerprints matched on a smartphone in place of direct fingerprint enrollment in each individual lock.

Innovations like these will expand the capabilities and applications for fingerprint lock technology.

Frequently Asked Questions

Here are some common questions about fingerprint locks:

Q: Are fingerprint locks suitable for exterior doors?

A: Special waterproof fingerprint locks are available for exterior installation. However, they are less convenient than interior locks since users need to reach outside.

Q: How many fingerprints can be stored in a fingerprint lock?

A: Basic locks store up to 20-50 templates. More advanced locks support 100+ users. This depends on available memory and matching algorithm efficiency.

Q: What authentication options do fingerprint locks have if fingerprint recognition fails?

A: Locks normally support password or RFID card fallback authentication in case of fingerprint sensing issues.

Q: How are fingerprint locks powered?

A: Small batteries, USB or external AC adapter are common. Batteries provide convenient installation but require occasional replacement.

Q: How reliable are fingerprint locks compared to keyed locks?

A: Modern fingerprint locks with advanced sensors and algorithms can actually be more reliable than keyed locks which are susceptible to wear, mechanical issues or lost keys.

Conclusion

In summary, properly engineered fingerprint locks provide convenient, secure access control for a diverse range of applications from corporate offices to private residences.

Critical aspects like the fingerprint sensor, biometric matching algorithms, robust electronics, and calibrated assembly must be carefully designed and manufactured for reliable functionality. Extensive testing across conditions ensures optimal performance.

With innovative advancements in technology like anti-spoofing and smart home integration, fingerprint locks will continue enhancing security and convenience in access control implementations.

The Finger Print Locks design solution

In this modern era, nothing can be declared as completely secure. Locks are picked, safe are breakable, and even passwords are guessable. Therefore, such a device is needed which can provide sense of security. For the purpose of security, numerous things can be utilized such as iris, biometrics, and face detective systems etc. All the three mentioned systems are almost impossible to break. The finger print lock is a device which must be used now a days for securing houses, shops, and offices. A finger print lock is only unlocked with finger of a specific person. The finger print locks come in a variety of designs.

The Reasons why Finger Prints are Unique

It is an obvious fact that each person has fingerprints. The fingerprints are actually the small ridges which are frictional in nature which makes it easier for a person to hold stuff. These fingerprints are being used for the security purpose because their pattern is unique for every individual. The fingerprints remains in its original shape forever, however in cases of severe accidents and burns it vanishes off. As a matter of fact, finger prints are unique for each individual and therefore through sensors its pattern can be acquired and used for making safe locks which are unbreakable. However, these locks are electronic in nature and requires a power bank or battery for its working. There is a small sensor on to which a specific finger is placed. The sensor is then detecting the fingerprint pattern and open up the lock if it matches the pattern saved in its memory, else it generates an alarm for false attempt.

The Process of Enrollment and Verification of Fingerprints

Before the operation of the fingerprint locks you are required to put in the pattern of prints of the person who will be in charge of the security of a specific vicinity. The finger prints of the specific person are first saved in the memory of the lock.

There are two processes for the purpose and each has its own importance. First stage is known as enrollment and the second stage is known as verification. The enrollment step is dealing with the system to learn the patterns of the specific person to be recognize. Some locks are supporting a single pattern while some are supporting more than one pattern recognition. Fingerprints of each person who would deal with the lock are scanned and analyzed and then saved in to the memory of the lock in a coded form which is unbreakable and secure as well. It takes a little time for the process of enrollment.

The next step is verification when the lock is ready to be used. During this stage a person is attempting to open the closed lock. Now if the fingerprint on the sensor of the lock is authenticated, the lock will open up, however if not authenticated the lock will either generate alarm or will remain closed. Some locks are having specific number of attempts for wrong authentication. For instance, if a lock is having 3 attempts, then after 3 wrong authentication the lock will go in idle mode and will not be usable for some specific time encoded in its chip e.g. 1 hour etc.

The Process of Storage and Comparison of Fingerprints

The fingerprints were only used in the criminal investigations in beginning, however gradually it came out to be best for using in security. When computer is checking the fingerprints, it does it by pattern recognition but not manually through a magnifying glass. The comparison among the fingerprints is made among the one which is already stored in the system or memory of the lock and the once which sensor has acquired from the person trying to unlock it. This is done through its comparison with feature known as minutiae which is taken at the time of enrollment and verification steps.

The computer is basically measuring the distances as well as angles among the different prints of the finger through feature of minutiae. This all done through the help of a computer based algorithm known as unique numeric code. The uniqueness of the fingerprints is measured through comparison and the right pattern is detected and the access of the lock is granted.

The Working of Fingerprint Lock

You may have observed the phenomenon of taking fingerprints on a paper i.e. dipping finger in to an ink pad and then pressing it against paper for having its clear image. The prints are also stored in the computer in the same way but through sophisticated techniques. First of all the computer is scanning the entire surface area of the finger and converting in to a code. The sensor or scanner is an optical one which is working with a bright light taken through the finger and taking its photograph in digital format.

The process is somehow different from taking a simple photograph as it has a simple method of flashing through surface and taking its image. The sensor is catching the exact and required amount of the detail of the finger such as contrast and brightness. The ridges of the finger with all necessary details are precisely taken and then matched with one stored in database or memory of the lock. Quality control is one of the major factor of the fingerprint locks.

The following are major points.

- 1- First of all the LEDs beneath the scanner are putting bright light on glass of scanner for taking clean picture of finger.

- 2- Remember, some locks are taking more time for the capturing of picture for a bright and crisp image.

- 3- An algorithm is testing the image taken from the sensor with one stored in database through pattern recognition algorithm.

- 4- The algorithm is calculating the distances among ridges and then comparing with stored image.

- 5- Once both images are matched then the lock is given autonomy to get open and access is granted for the person putting fingers on lock.

- 6- In case of denial of the fingerprint, lock is either generating alarm or submerge to idle mode for a specific time and some locks have message service which sends a message to the owner of the vicinity for false attempt of access to lock.

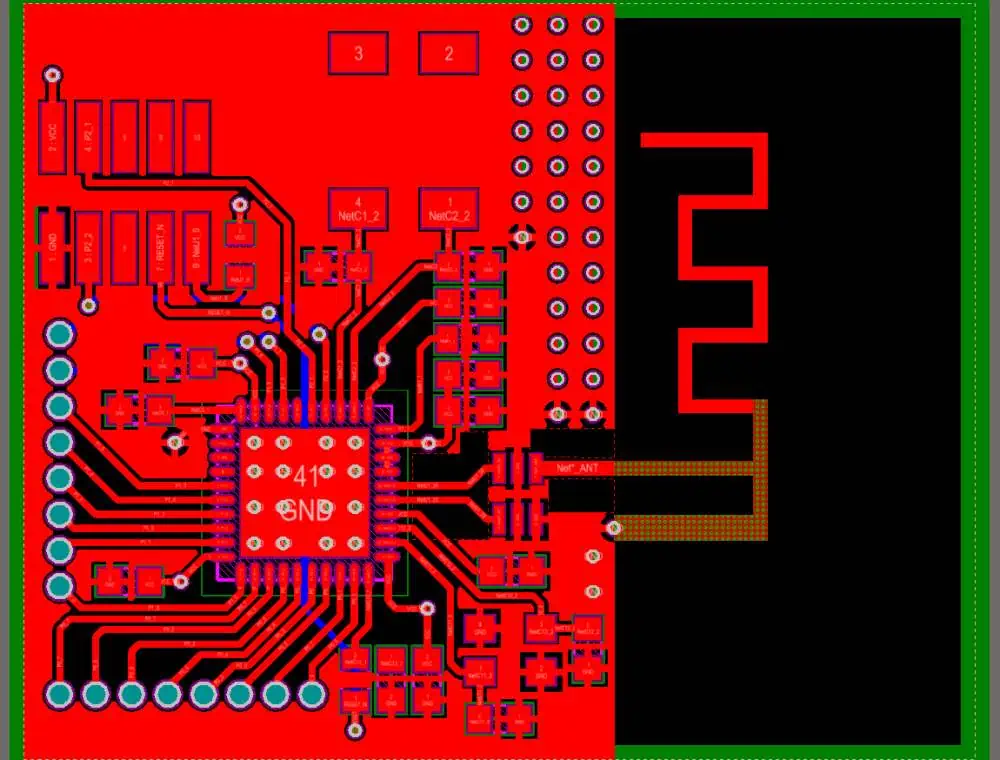

Rayming provide Finger Print Locks design solution services including pcb manufacturing or prototoype pcb assembly services , you can get pcb assembly board Welcome to send mail to sales@raypcb.com , Get good price now !