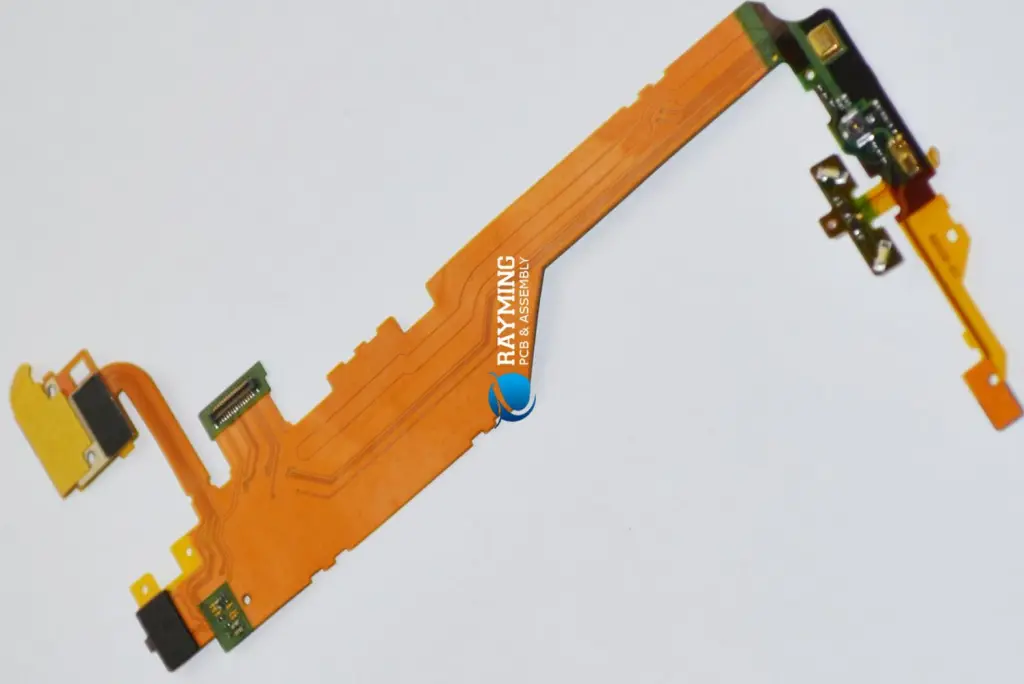

Electromagnetic interference (EMI) presents unique challenges when designing flexible printed circuit boards (flex PCBs) due to their inherent structural characteristics and typical applications in space-constrained, high-frequency environments. Unlike rigid PCBs, flex circuits must maintain signal integrity while bending, folding, and flexing throughout their operational lifetime, making traditional EMI shielding approaches inadequate or impractical. Understanding and implementing effective EMI shielding strategies for flex PCBs requires a multifaceted approach that addresses both design considerations and material selection.

Understanding EMI Challenges in Flex PCB Design

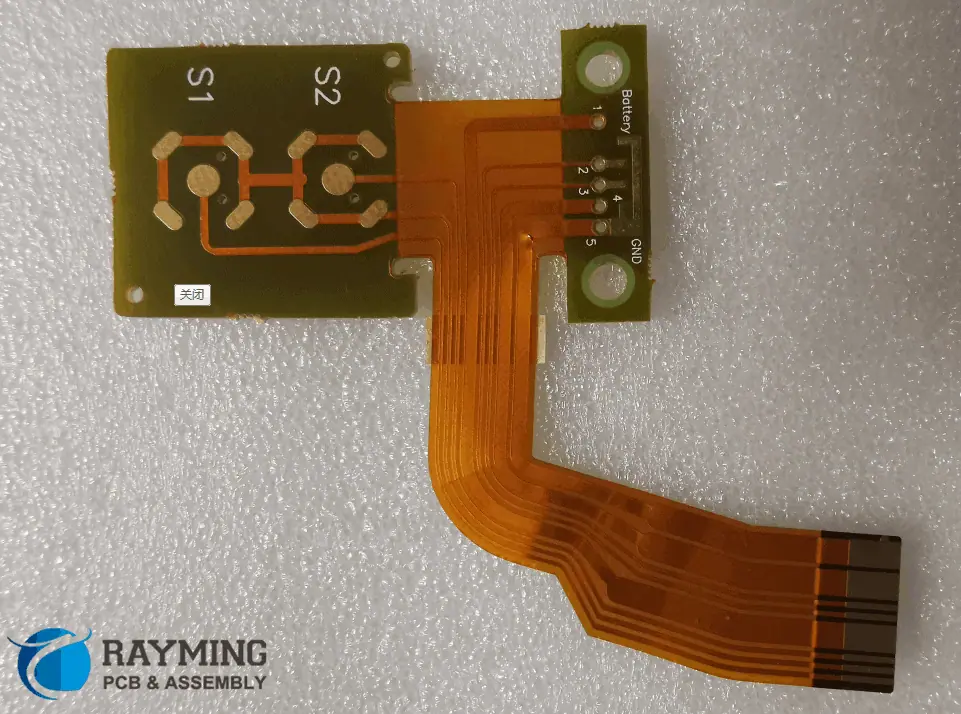

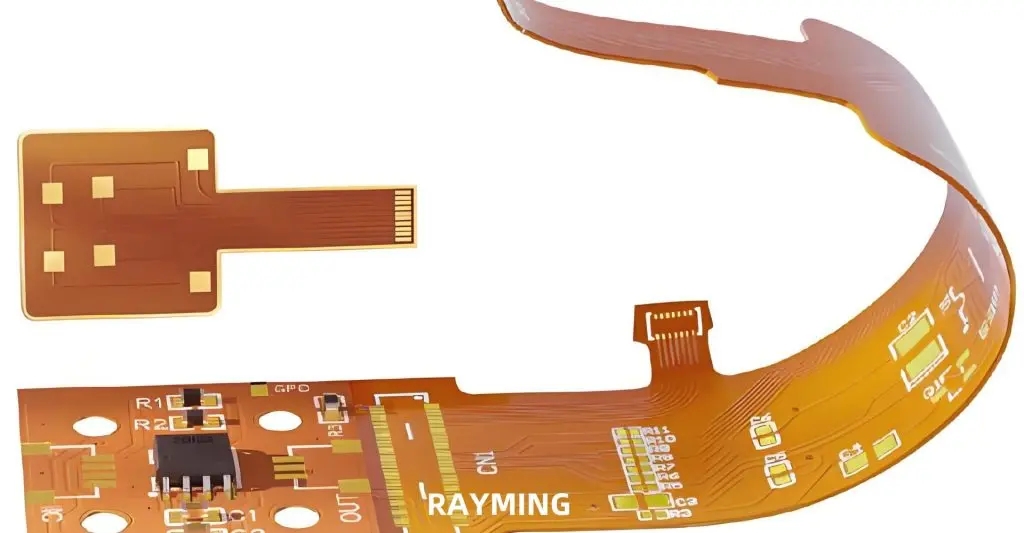

Flex PCBs are particularly susceptible to EMI due to several inherent characteristics. The thin substrate materials, typically polyimide films ranging from 12 to 125 micrometers, provide minimal natural shielding compared to thicker rigid boards. The flexible nature means that trace geometries can change during flexing, potentially altering impedance characteristics and creating impedance discontinuities that can radiate electromagnetic energy. Additionally, flex circuits often operate in close proximity to other electronic components, increasing the likelihood of coupling between circuits.

The dynamic nature of flex PCBs introduces another complexity: shield effectiveness must be maintained throughout the entire range of motion. Traditional rigid shielding solutions can crack, delaminate, or create stress concentrations that lead to failure. This dynamic environment requires shielding solutions that can accommodate repeated flexing while maintaining electrical continuity and mechanical integrity.

Fundamental EMI Shielding Principles for Flex Circuits

Effective EMI shielding in flex PCBs relies on three primary mechanisms: reflection, absorption, and multiple reflections. Reflection occurs at the interface between materials with different impedances, where electromagnetic waves encounter a conductive barrier. The effectiveness of reflection depends on the impedance mismatch between the wave medium and the shield material. Absorption involves the conversion of electromagnetic energy into heat as waves propagate through lossy materials. Multiple reflections occur within the shield material itself, where waves bounce between interfaces, gradually losing energy.

For flex PCBs, achieving adequate shielding effectiveness requires careful consideration of these mechanisms while maintaining flexibility. The shielding effectiveness (SE) is typically expressed in decibels and represents the ratio of incident to transmitted electromagnetic field strength. Practical flex PCB applications often require SE values ranging from 20 to 60 dB, depending on the specific application and regulatory requirements.

Material Selection for Flexible EMI Shielding

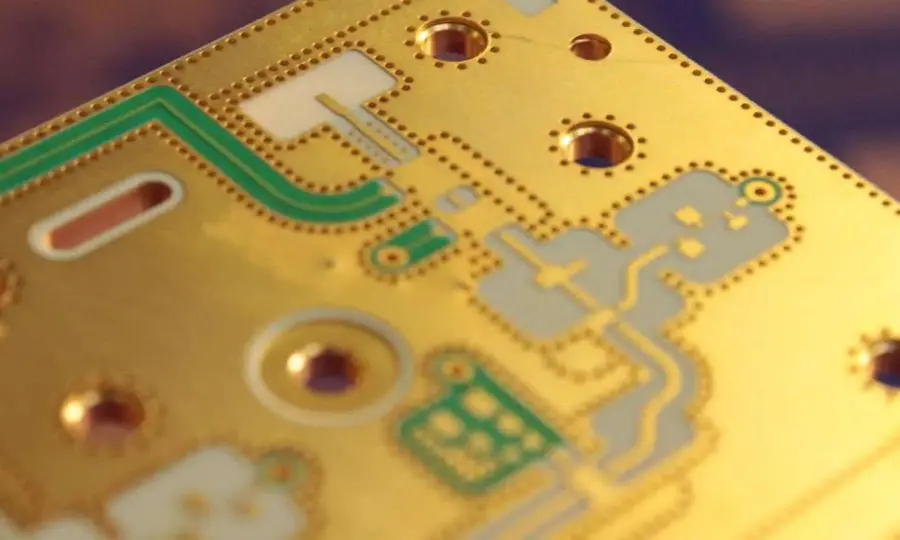

Metallic Foils and Conductors

The choice of shielding materials significantly impacts both effectiveness and mechanical performance. Copper foil remains the most common choice due to its excellent conductivity, relatively low cost, and well-established processing techniques. However, pure copper can work-harden during repeated flexing, leading to fatigue failures. Copper alloys, particularly those containing small amounts of beryllium or phosphorus, offer improved fatigue resistance while maintaining good conductivity.

Conductive Adhesives and Bonding Materials

Conductive adhesives represent another crucial component in flex PCB shielding systems. These materials must maintain electrical continuity while accommodating the mechanical stresses associated with flexing. Silver-filled adhesives provide excellent conductivity but can be expensive and susceptible to migration issues. Copper-filled adhesives offer a good balance of performance and cost, while nickel-filled options provide moderate conductivity with enhanced durability.

Flexible Conductive Fabrics

Flexible conductive fabrics, typically consisting of metallized textile substrates, offer unique advantages for complex geometries and high-flex applications. These materials can accommodate extreme bending without losing conductivity, making them ideal for applications requiring tight bend radii or continuous flexing. The trade-off typically involves reduced shielding effectiveness compared to solid metal foils, particularly at higher frequencies.

Design Techniques for EMI Mitigation

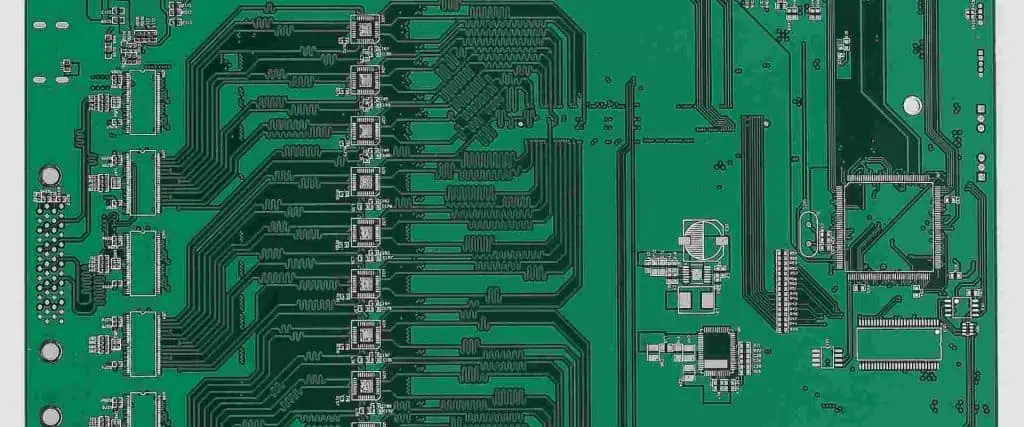

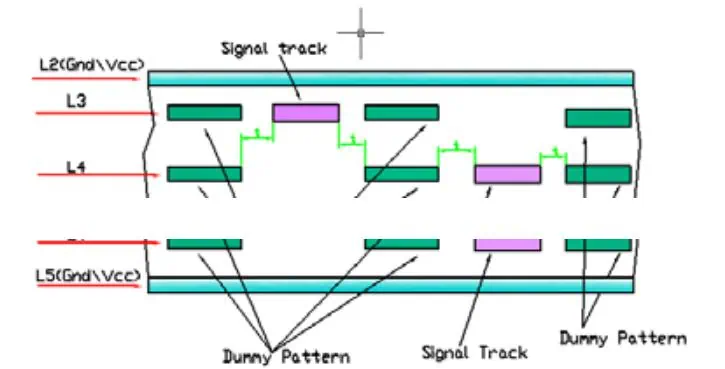

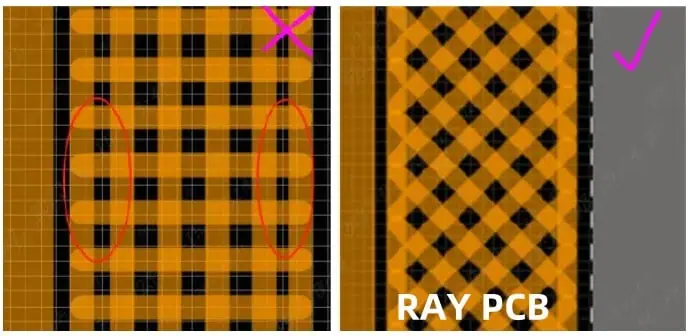

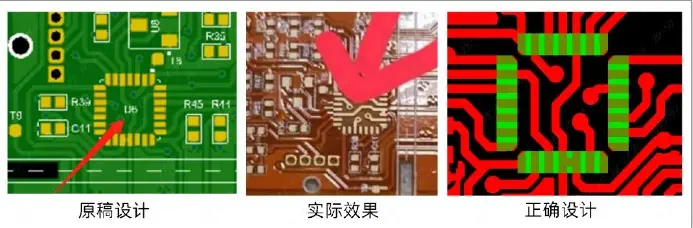

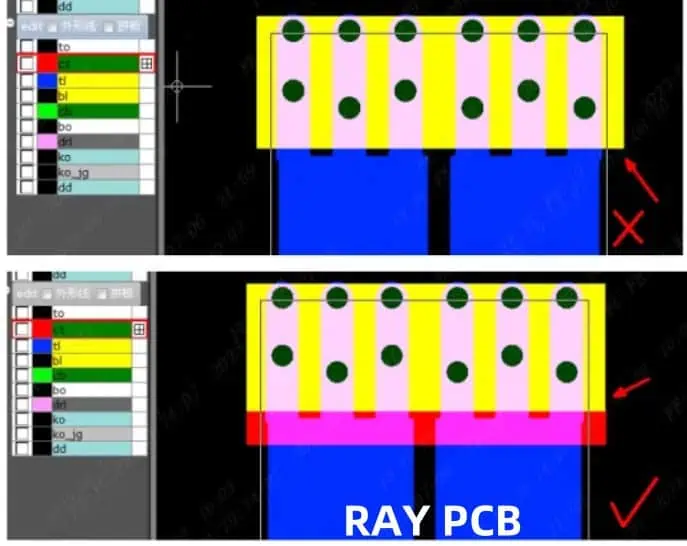

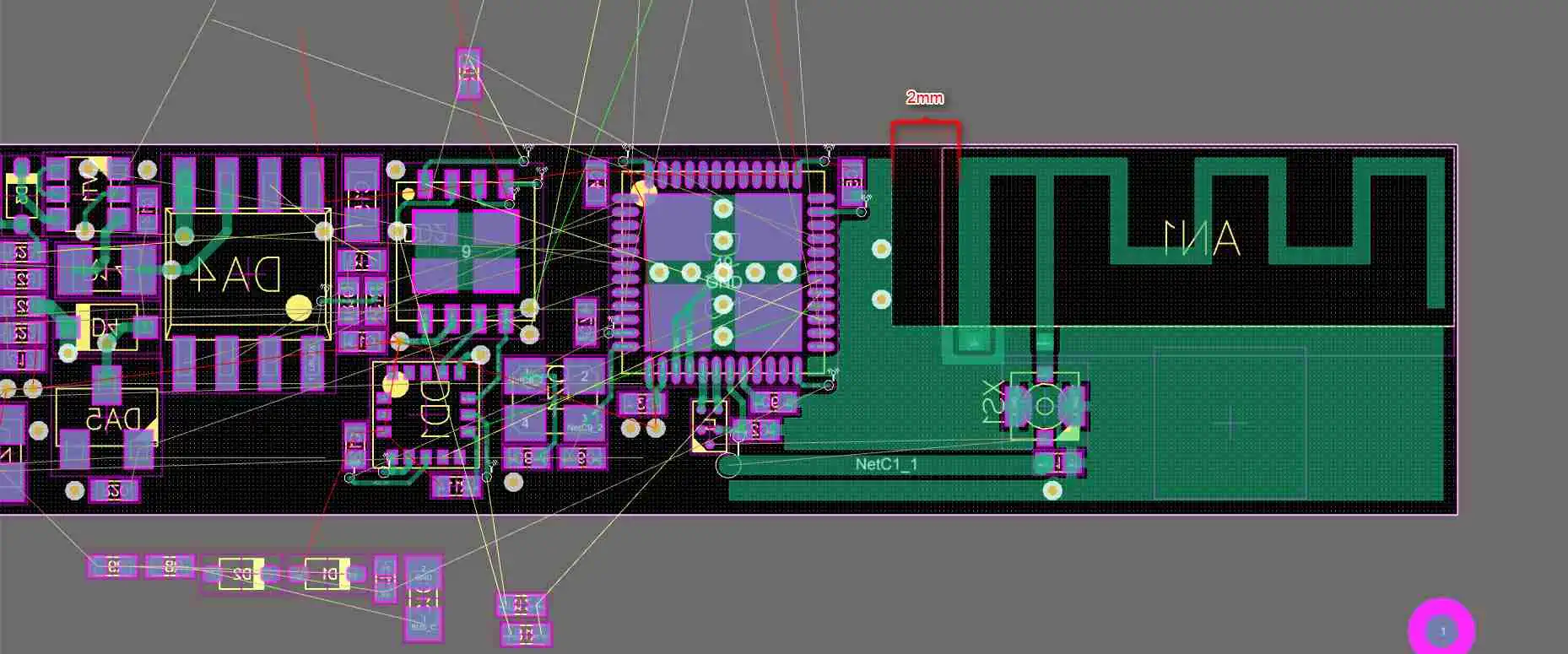

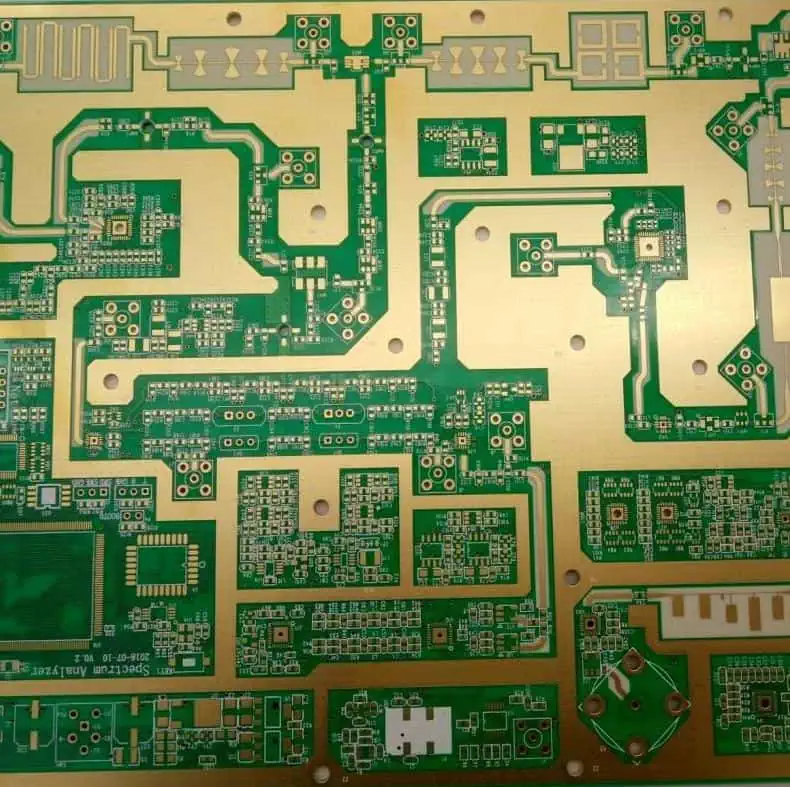

Layer Stack-up Optimization

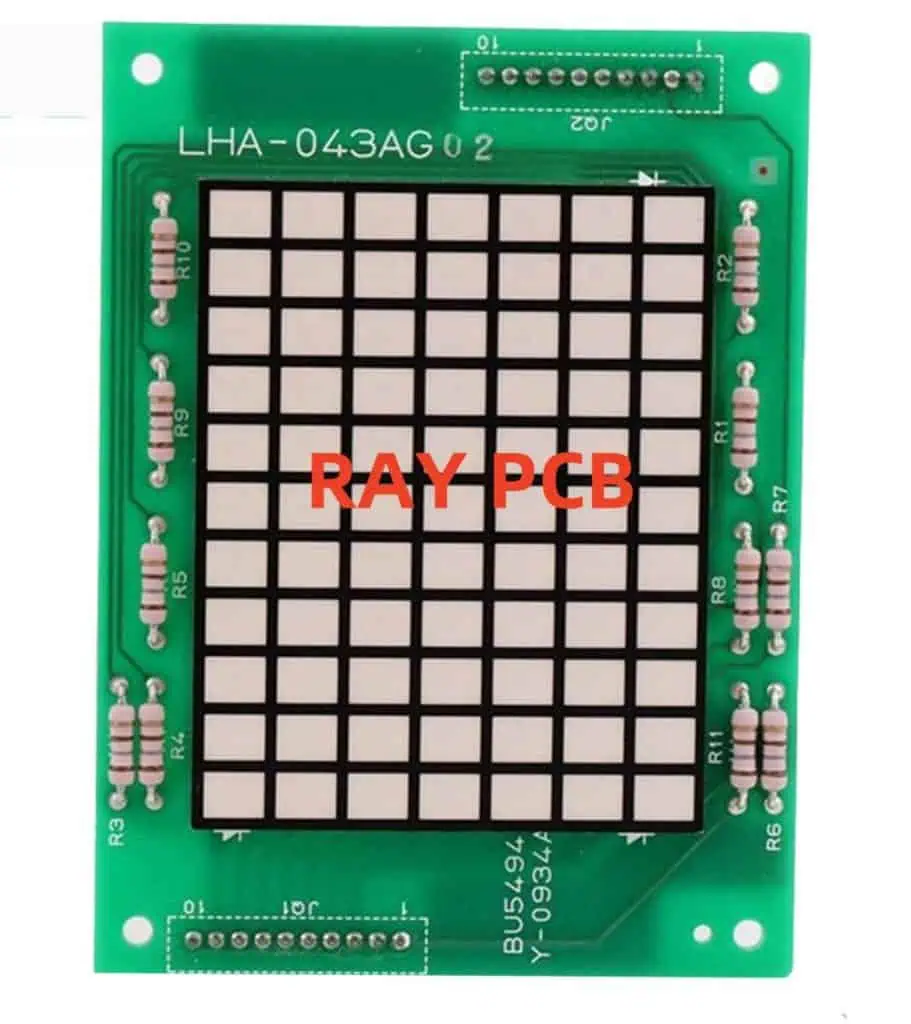

Layer stack-up optimization plays a crucial role in EMI performance. Implementing dedicated ground planes, even in thin flex constructions, significantly improves shielding effectiveness by providing a low-impedance return path for currents and creating a natural barrier to electromagnetic propagation. When thickness constraints prevent full ground planes, hatched or meshed ground patterns can provide substantial benefits while maintaining flexibility.

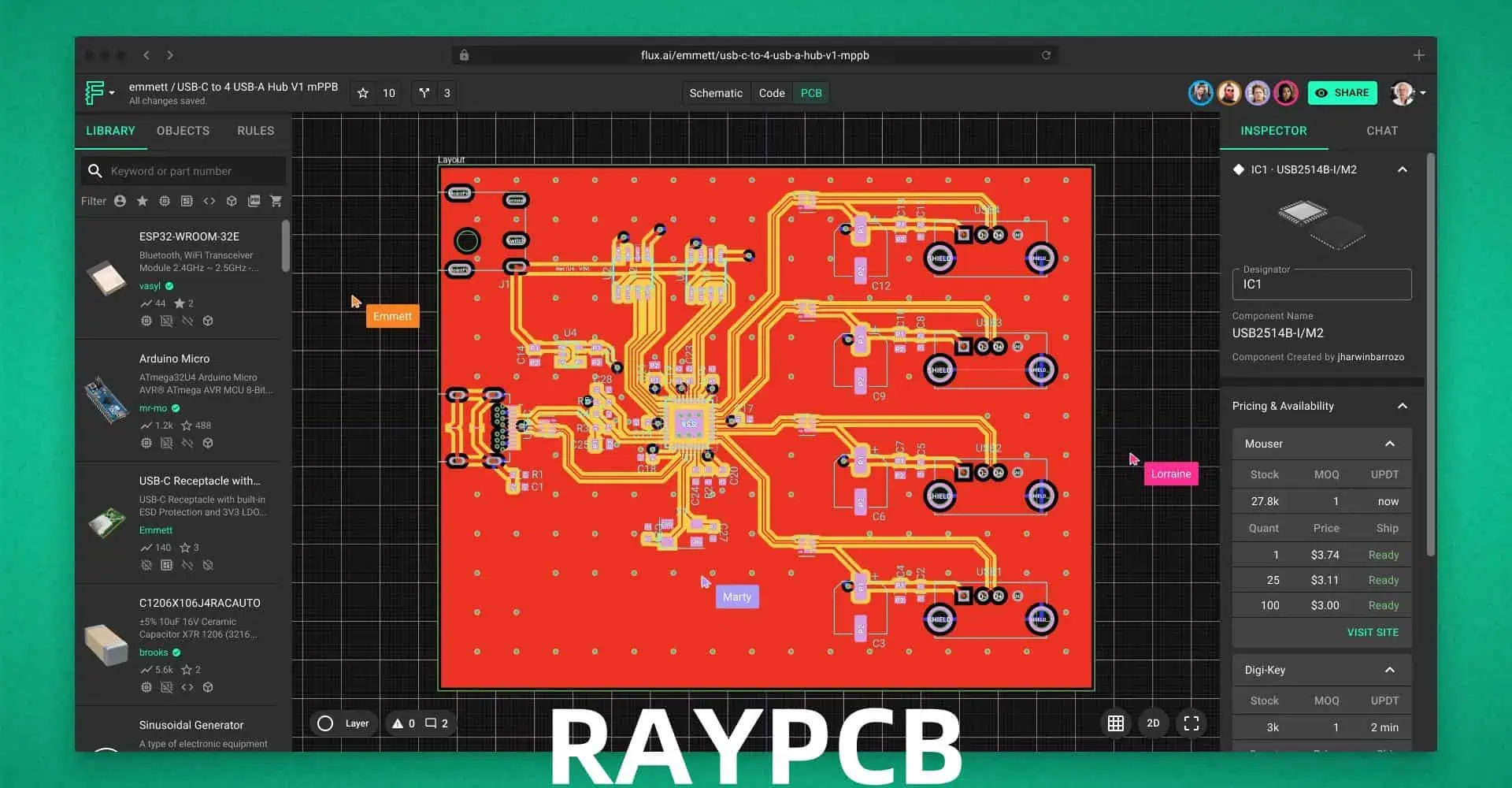

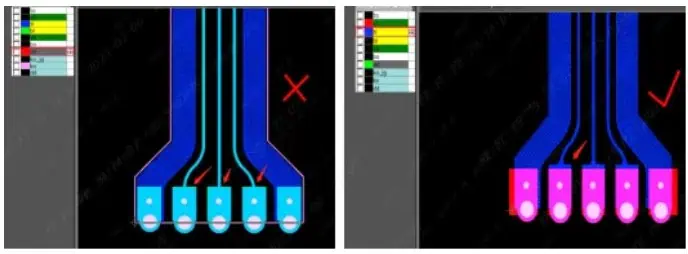

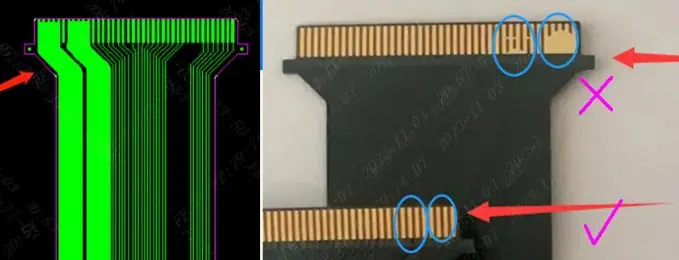

Trace Routing Strategies

Trace routing strategies directly impact EMI performance. Minimizing loop areas by keeping signal traces close to their return paths reduces both radiated emissions and susceptibility to external interference. Differential signaling techniques can provide inherent noise immunity while reducing the need for extensive shielding. When single-ended signals are necessary, maintaining consistent impedance and minimizing trace lengths becomes critical.

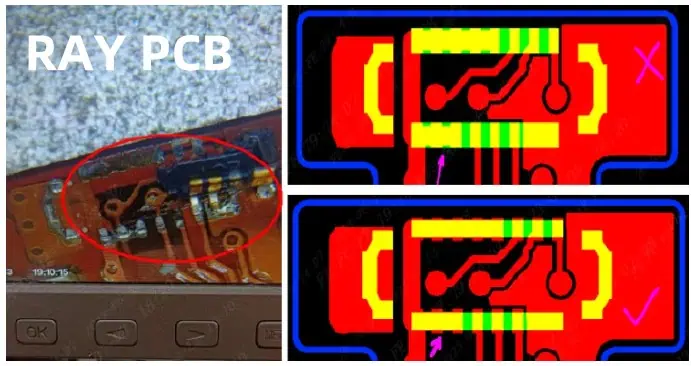

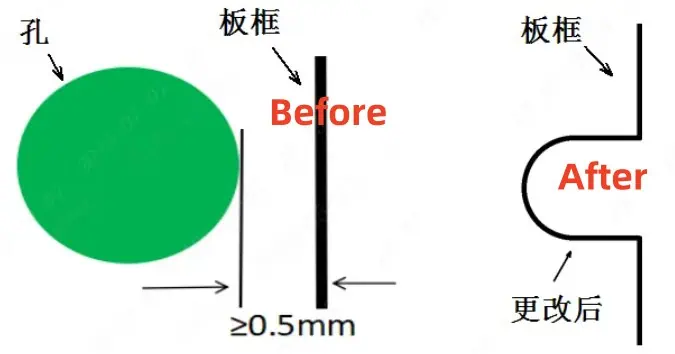

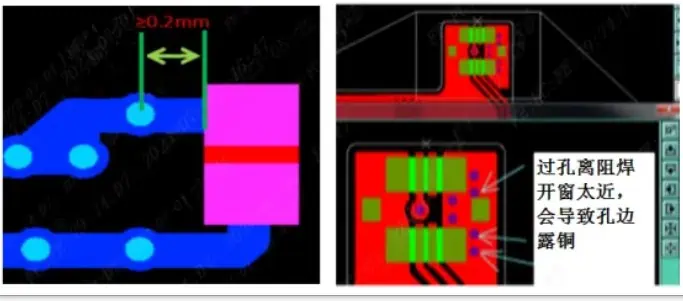

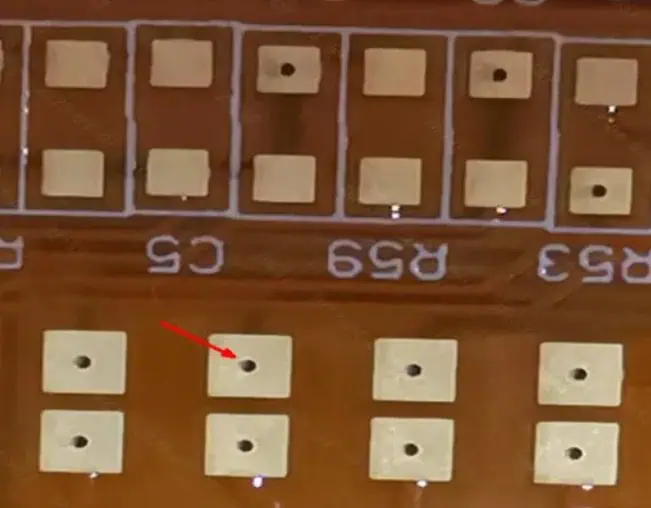

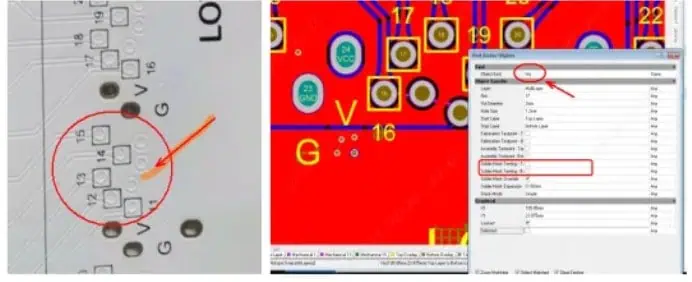

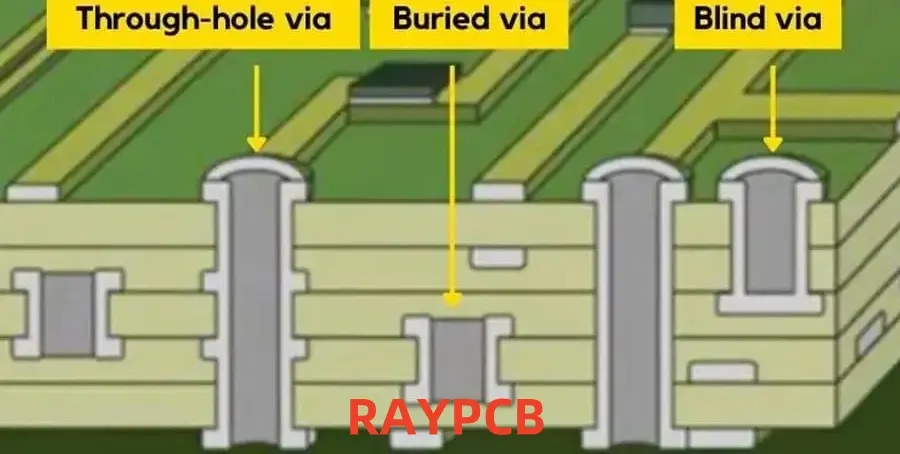

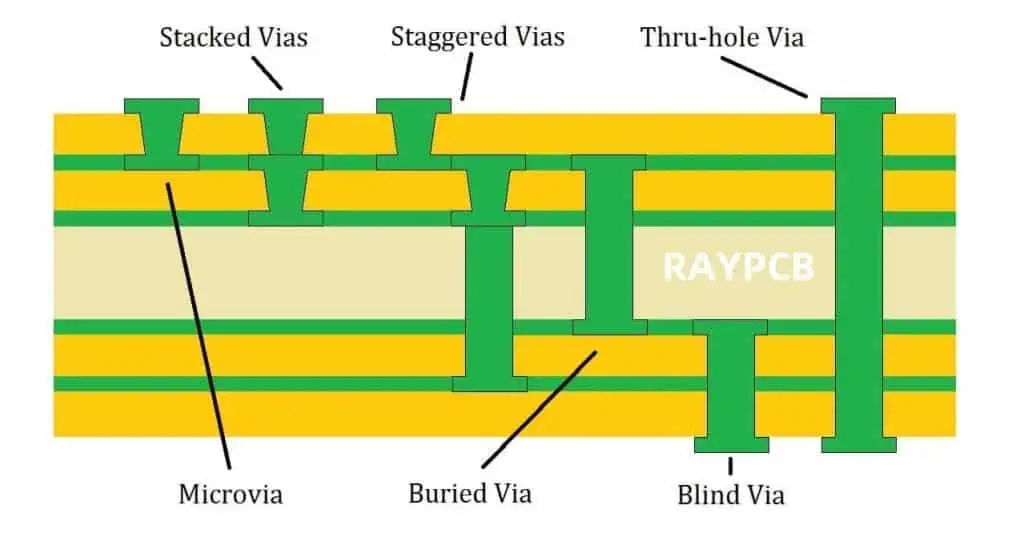

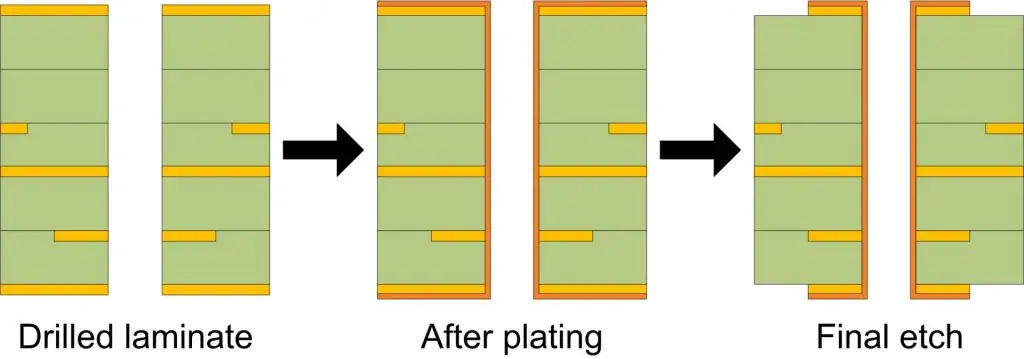

Via Design Considerations

Via design in flex PCBs requires special attention for EMI control. Traditional plated through-holes can create stress concentrations during flexing, potentially compromising both mechanical integrity and electrical continuity. Alternative via technologies, such as laser-drilled microvias or conductive ink-filled vias, can provide better flex performance while maintaining EMI shielding continuity between layers.

Implementation Strategies for Flexible Shielding

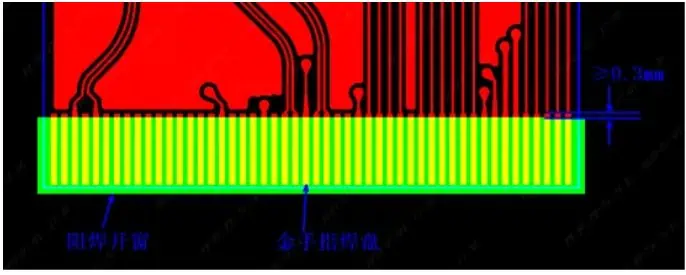

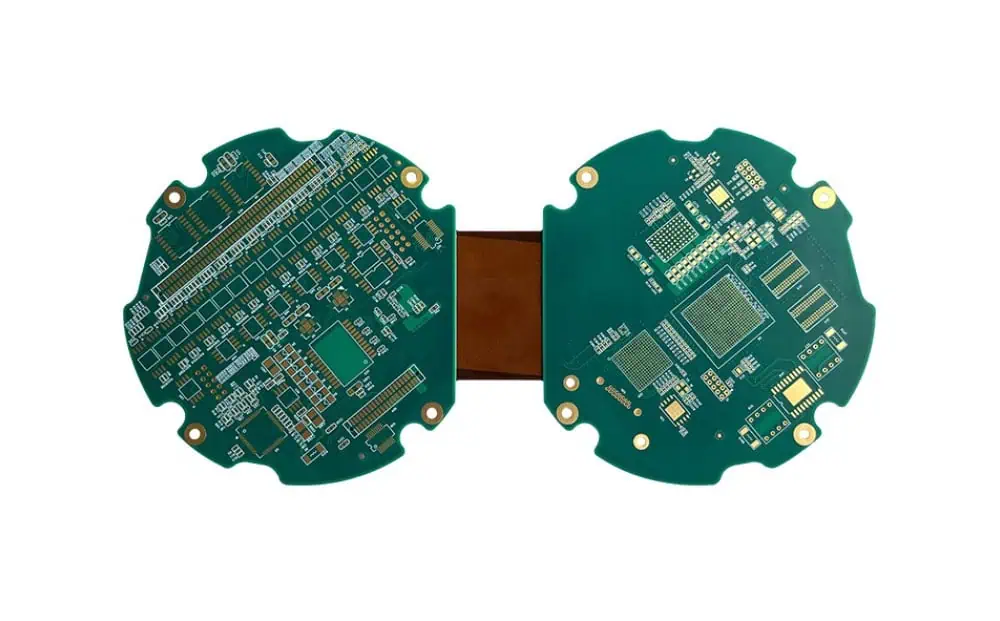

Segmented Shielding Approaches

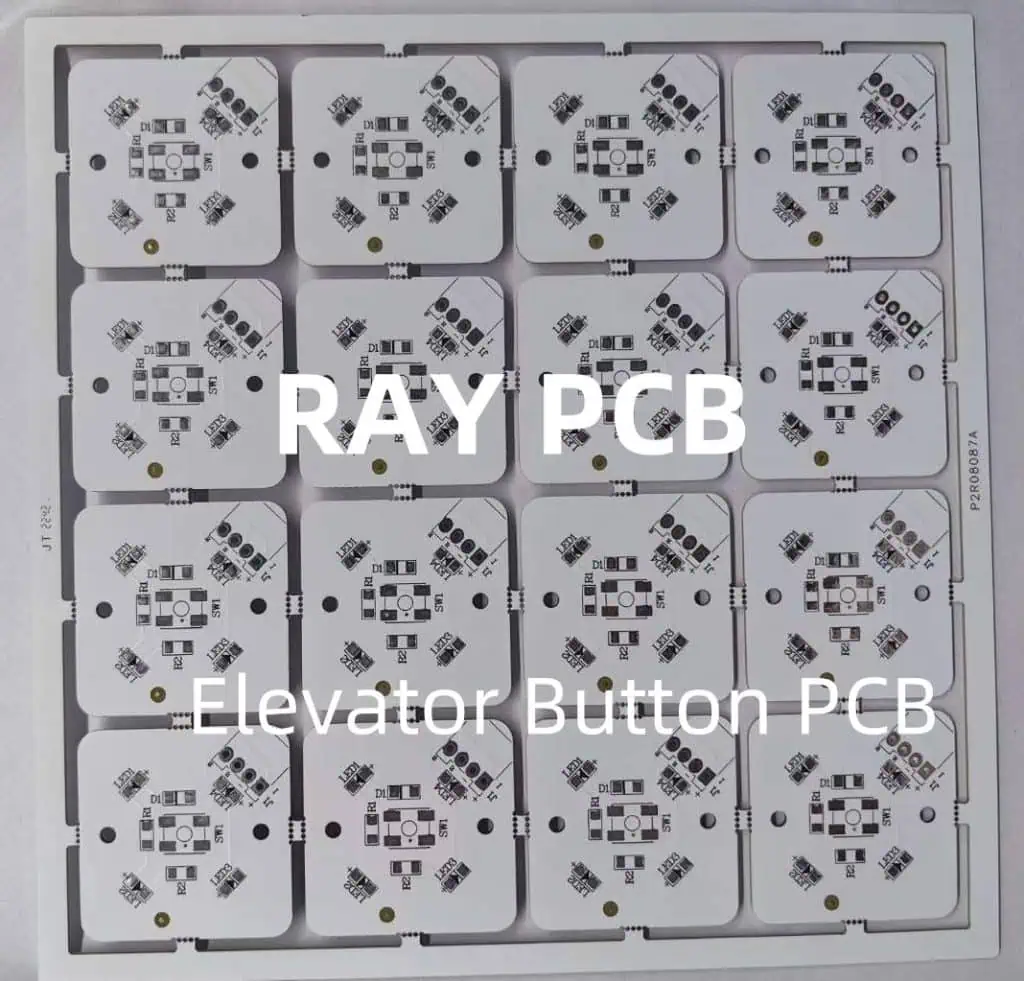

Segmented shielding approaches acknowledge that different portions of a flex circuit may have varying mechanical and EMI requirements. Static sections can utilize more robust shielding solutions, such as solid copper foils or metal-backed adhesive tapes, while dynamic flex regions employ more flexible alternatives like conductive fabrics or elastomeric shields. Careful attention to transitions between shield types ensures continuity while managing mechanical stress.

Gasket and Connector Design

Gasket and connector design significantly influences overall shielding effectiveness. Electromagnetic compatibility (EMC) gaskets must accommodate the mechanical requirements of flex circuits while maintaining reliable electrical contact. Beryllium-copper finger stock, conductive elastomers, and metallized fabric gaskets each offer distinct advantages depending on the specific application requirements.

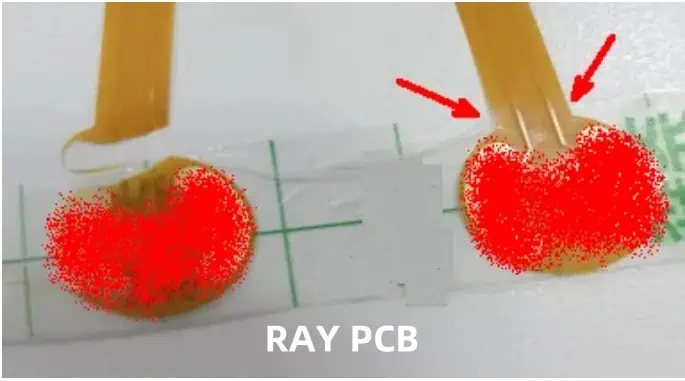

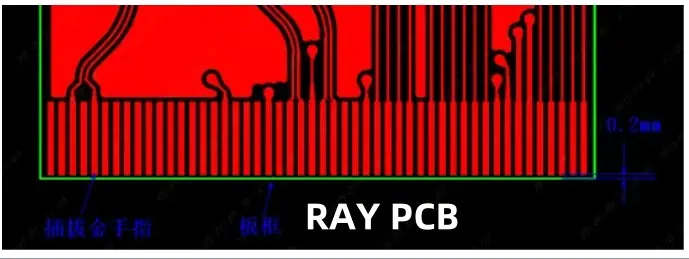

Cable Shielding Integration

Cable shielding integration becomes particularly important when flex PCBs interface with external systems. Ensuring 360-degree shield termination prevents common-mode currents from flowing on cable shields, which can compromise overall system EMI performance. This often requires custom connector solutions or specialized cable assemblies designed specifically for flex circuit applications.

Testing and Validation Methodologies

EMI Testing Procedures

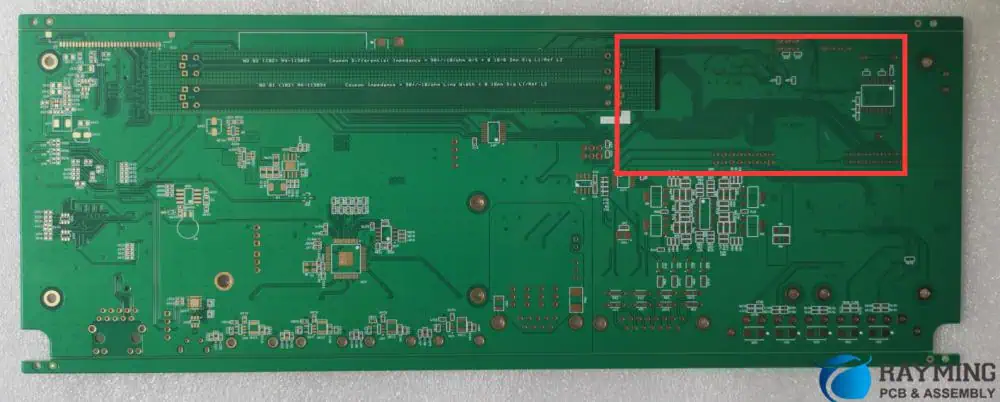

EMI testing for flex PCBs requires modifications to standard test procedures to account for the flexible nature of the circuits. Shielding effectiveness measurements must be performed in multiple mechanical configurations to ensure adequate performance throughout the operational range. Flexural testing combined with EMI measurements can identify potential failure modes and validate design margins.

Advanced Measurement Techniques

Near-field scanning techniques provide valuable insights into EMI performance by identifying specific areas of high electromagnetic field strength. These measurements can guide design optimization efforts and help identify unexpected coupling paths or shield discontinuities. Time-domain reflectometry (TDR) measurements can reveal impedance discontinuities that may contribute to EMI issues.

Advanced Shielding Technologies

Emerging Materials and Processes

Emerging technologies continue to expand the options for flex PCB EMI shielding. Printed conductive inks enable the direct deposition of shielding layers using standard printing processes, potentially reducing cost and complexity. These materials can be formulated to provide specific combinations of conductivity, flexibility, and adhesion properties.

Metamaterial Applications

Metamaterial concepts are being explored for EMI shielding applications, potentially offering enhanced performance at specific frequencies while maintaining mechanical flexibility. These engineered structures can provide unique electromagnetic properties not achievable with conventional materials, though practical implementation remains challenging.

Conclusion

Effective EMI shielding for flex PCBs requires a comprehensive approach that balances electromagnetic performance with mechanical requirements. Success depends on careful material selection, thoughtful design techniques, and thorough validation throughout the development process. As electronic systems continue to increase in complexity and operate at higher frequencies, the importance of robust EMI shielding strategies for flex PCBs will only continue to grow. The ongoing development of new materials and techniques promises to expand the capabilities of flexible electronics while maintaining the EMI performance required for reliable operation in increasingly challenging electromagnetic environments.

The key to successful implementation lies in understanding the fundamental trade-offs between flexibility, shielding effectiveness, and mechanical durability, then selecting the optimal combination of techniques for each specific application. With proper attention to these considerations, flex PCBs can achieve excellent EMI performance while maintaining the mechanical advantages that make them attractive for modern electronic designs.