A heat sink is a passive thermal management component that absorbs and dissipates heat generated by electronic components on a printed circuit board (PCB) through thermal conduction. Heat sinks are used to cool components like power transistors, processors, power amplifiers and high-wattage LEDs that produce significant heat during operation.

Effective heat sinking is critical for maintaining device temperatures within safe operating limits and preventing damage or performance degradation. This article provides a comprehensive overview of PCB heat sink materials, design factors, attachment methods and thermal modeling considerations.

Heat Sink Basics

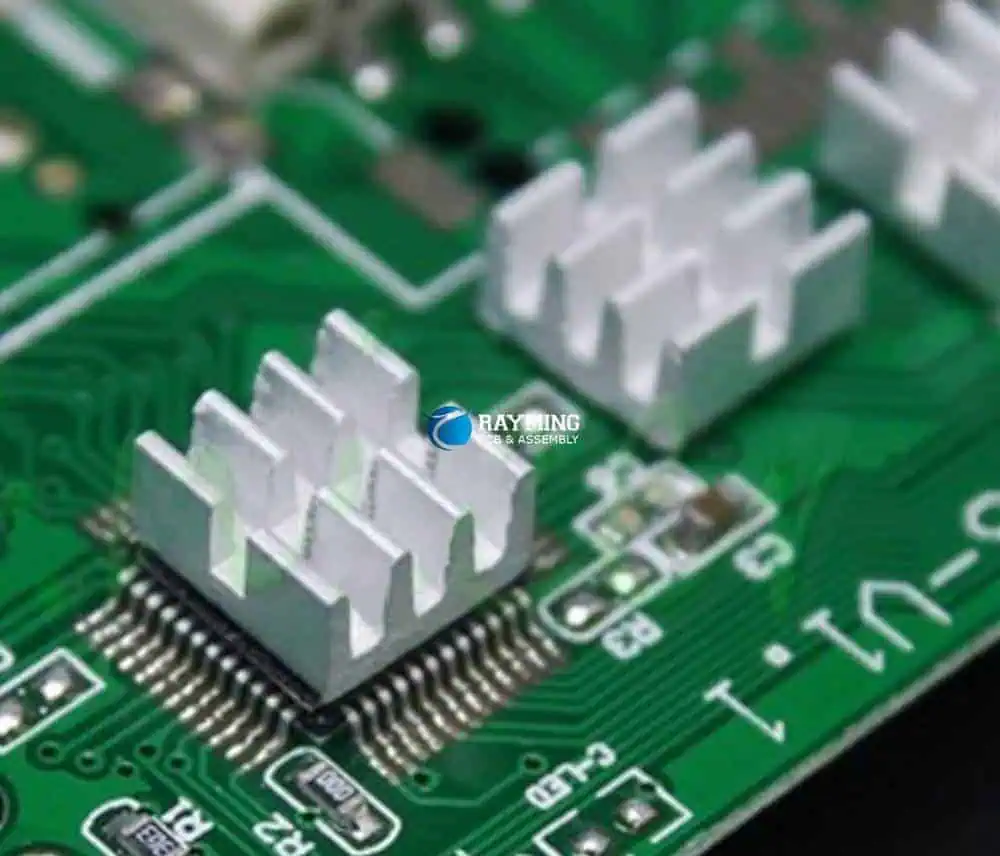

A heat sink comprises of a metal object, typically aluminum or copper, which is placed in contact with a heat generating component to conduct heat away and dissipate it into the ambient via fins exposed to airflow.

Key elements influencing heat sink performance include:

- Base – Flat surface in contact with component to conduct heat from source

- Fins – Ridges to increase surface area for more effective air convection cooling

- Heat pipes – Closed channels containing liquid that evaporates and condenses, transmitting heat

- Fans – Improve airflow across fins to expedite convection heat transfer

- Thermal interface material – Grease/adhesive between sink and component to minimize thermal resistance

By efficiently sucking heat from a hot component and spreading it over a large area for air cooling, heat sinks enable reliable operation at higher powers.

Heat Sink Materials

Heat sink materials are selected for high thermal conductivity to optimize heat transfer from the heat generating component. Common materials include:

- Aluminum – Offers excellent conductivity (200 W/mK) at low cost and weight. Most common sink material.

- Copper – Very high conductivity (400 W/mK) but heavier and costlier than aluminum. Often used in high performance contexts.

- Steel – Low cost but moderate conductivity (50 W/mK). Used when weight is not critical.

- Silicon carbide – Lightweight with high conductivity (120 W/mK). Used in aerospace applications.

- Diamond – Extremely high conductivity (2000 W/mK) but expensive. Used in specialized laser or semiconductor applications.

- Ceramics – Insulating but can sustain high temperatures. Used as coating over metal cores.

Aluminum, copper and their alloys provide the best thermal performance for most electronics cooling applications.

Heat Sink Design Factors

Key aspects considered when designing an effective PCB heat sink include:

- Thermal resistance – Should be low enough for required heat dissipation capacity. Depends on material and sink geometry.

- Component power – Higher power components require greater heat flux capability.

- Allowable temperature rise – Maximum permissible rise over ambient temperature.

- ** Mounting method** – Conduction improved with thermal interface material and securing method.

- Airflow – Natural or forced convection with fans impact heat transfer rate.

- Size constraints – Physical dimensions may limit fin count and surface area.

- Cost – Less expensive materials like aluminum often suffice for thermal needs.

- Corrosion resistance – Sink materials should avoid corrosion over product lifetime.

Optimized heat sink design requires balancing these factors for effective thermal performance at reasonable cost.

Heat Sink Attachment Methods

Integrating heat sinks onto PCBs requires careful mounting provisions to minimize thermal resistance from component to heat sink:

Adhesives

- Thermal adhesive physically attaches sink to component surface or package

- Adhesive fills air gaps, improving thermal conduction

- Silicone, epoxy or acrylic adhesive types available

Clips

- Metal spring clips clamp sink securely onto component

- Avoid applying excessive pressure to avoid damage

- Clips allow sink detachment for component replacement/repair

Screws

- Secure heat sink firmly to board or component using screws

- Use insulation bushings/washers to prevent electrical shorts

Soldering

- Reflowing solder paste permanently solders heat sink to lands around component

- Provides robust thermal conduction path

- Makes rework or repairs difficult

Adhesives, clips and screws allow some rework capability while soldering creates a permanent joint.

Thermal Interface Materials

Thermal interface materials (TIMs) are often inserted between the component and heat sink to minimize thermal resistance by filling microscopic air pockets that would otherwise hinder conduction:

- Thermal greases – Silicone or ceramic pastes squeeze into surface irregularities. Require clamping pressure.

- Thermal pads – Soft conductive sheets conform to surfaces. Some are dry applied, others use adhesive backings.

- Phase change compounds – Wax-like materials melt during operation to fill gaps and voids.

- Epoxy tapes – Adhere to surfaces and set to durable bond. Withstand scrubbing.

Applying the right amount ensures optimal conduction without air voids while avoiding excess amounts that increase resistance.

Heat Sink Fin Design

Fins provide the heat dissipating surfaces enabling convection cooling of heat sinks. Fin design parameters include:

- Fin thickness – Thicker fins conduct heat better but add weight and material cost. Around 3mm is typical.

- Fin height – Taller fins expose more surface area to airflow which increases heat dissipation.

- Fin length – Longer fins increase exposed area but can be prone to bending/damage.

- Fin density – Higher fin density boosts heat transfer but also increases air resistance. Around 5-10 fins per inch is common.

- Fin shape – Rectangular or tapered fins affect airflow resistance and heat transfer characteristics.

- Surface treatment – Textures, microstructures or coatings that increase surface area improve heat transfer.

Computer optimized fin shapes and patterns customized for the thermal profiles and airflow conditions enable maximum heat transfer.

Forced Convection Cooling

In forced convection, fans are mounted over heat sinks to dramatically improve airflow:

- Axial fans – Most common. Direct air flow along length of fins.

- Blowers – High pressure fans pushing air through dense fin arrays.

- Centrifugal fans – Circulate air perpendicular to board expelling heat from enclosures.

Forced convection multiply heat transfer 5-10x compared to natural convection. The right fan needs to be matched to the impedance of the heat sink and airflow restrictions around board.

Heat Sink Modeling and Simulation

Heat sink designs are optimized using thermal modeling and computational fluid dynamics simulations. Important analysis parameters include:

- Flow trajectories – Visualizes airflow patterns through heat sink for uniform distribution.

- Pressure maps – Indicates high or low pressure zones causing flow resistance.

- Air velocity – Quantifies airflow speed through fins ensuring sufficient ventilation.

- Temperature mapping – Predicts localized heating across component, TIM and sink to identify hot spots.

- Thermal gradients – Heat dissipation difference between base and fin tips should not exceed critical levels.

Such modeling ensures effective heat spreading from component to fins and no localized overheating, leading to optimal heat sink performance.

Heat Sink Applications

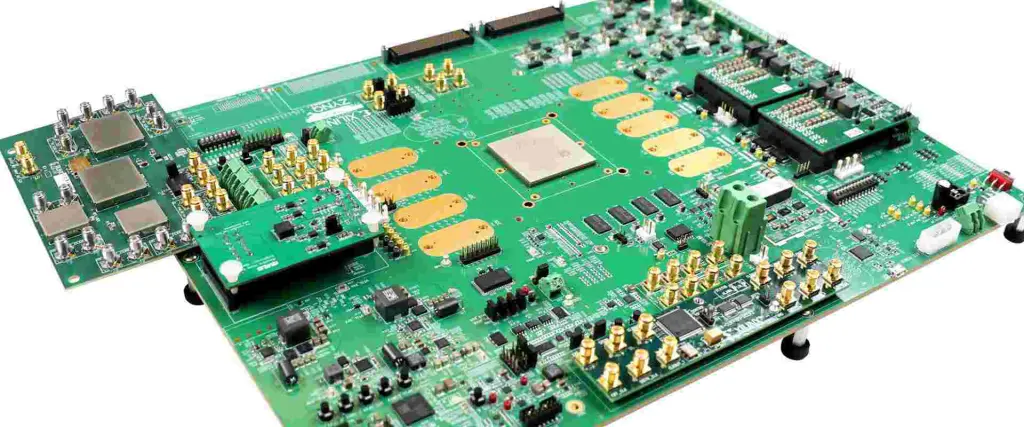

Heat sinks are ubiquitously used on PCB assemblies with high power dissipation components:

Power Supplies

- Switching transistors and regulators

- AC/DC rectifiers and converter ICs

- Bus capacitors

Motor Drives

- IGBTs and power MOSFETs

- DC/AC inverters

- Braking resistors

Servers

LEDs

- High brightness LEDs in lighting or displays

- LED drivers

Audio Amplifiers

- Output transistors

- High wattage audio ICs

Industrial

- PLC system controllers

- Power monitoring equipment

- Motor servo amplifiers

Any application needing to cool components dissipating over 1-2W can benefit from appropriately designed heat sinks.

Heat Sink Design Process

A typical workflow for designing an effective PCB heat sink involves:

- Determine maximum component power dissipation and ambient temperature.

- Estimate required heat sink thermal resistance from junction to ambient.

- Select candidate heat sink considering tradeoffs like performance, size and costs.

- Model heat sink in simulation software and optimize fin parameters.

- Simulate thermal performance under worst-case ambient temperatures and airflows.

- Verify adequate margin between model results and component temperature limits.

- Measure thermal performance on prototypes under real-world conditions.

- Iterate heat sink design as needed if measured results exceed thermal limits.

- Qualify final design across application operating conditions to ensure reliability.

Careful thermal design upfront prevents expensive redesigns and ensures equipment lifetimes and reliability goals are achieved.

Heat Sink Design Guidelines

Here are some best practice guidelines for developing effective heat sinks on PCBs:

- Budget adequate clearance around heat sink for unrestricted airflow.

- Orient heat sink to align with existing or forced airflows across the board.

- Balance thermal dissipation needs with heat sink footprint constraints.

- For ICs, maximize sink contact surface area overlid or exposed pad area.

- Use thermally conductive interface materials to minimize contact resistance.

- Secure heat sink firmly onto component using screws, clamps or soldering.

- Verify heat sink isolation from any charged components to prevent shorts.

- Monitor temperatures during testing to validate thermal design margins.

- Consider adding redundancy with secondary heat sinks, thermal vias and ground planes.

- Oversize slightly to account for degradation over product lifetime.

Conclusion

Heat sinks are an essential component enabling reliable operation of electronics required to dissipate substantial amounts of power. Their ability to efficiently conduct and spread heat using metallic materials with optimized fin geometries prevents device overheating.

With continually increasing power densities in modern PCBs driven by trends like wide bandgap semiconductors, wireless charging and high-speed ICs, effective thermal management using heat sinks, active cooling and thermal-aware design practices becomes mandatory.

The electronics industry will continue relying extensively on heat sink innovations spanning materials, 3D geometries, adaptive algorithms and computer simulations to sustain the relentless pace of advancement in energy efficient, high-performance electronic systems.

Frequently Asked Questions

Q: What is a heat sink in PCBs?

A: A heat sink is a metallic thermal management component like an aluminum plate that absorbs and dissipates heat from hot electronic components on a PCB through conduction and air convection.

Q: Why are heat sinks needed on PCBs?

A: Heat sinks prevent electronic components from overheating by efficiently conducting heat away and spreading it over fins exposed to airflow. This maintains safe device temperatures.

Q: What materials are used to make PCB heat sinks?

A: Aluminum and copper are most common due to high thermal conductivity. Other materials include steel, silicon carbide, diamond and ceramics.

Q: How are heat sinks attached to PCBs?

A: Common attachment methods include thermal adhesive, spring clips, screws and soldering. Thermal interface materials minimize contact resistance.

Q: How are heat sinks designed and simulated?

A: Important factors like airflows, fin parameters and thermal gradients are modeled using CAD and computational fluid dynamics simulation to optimize heat transfer.

Why Heat Sink PCBs are Important in Electronic Circuits

All electrical components in a circuit produce heat while the circuit is functioning. High-power devices such as power transistors, LEDs, and lasers produce heat. Some of these components can’t dissipate heat since they have a low dissipation capability.

Heat build-up in the component can result in total failure or premature failure in the device. Therefore, heat sink boards are a perfect way to conquer these problems. These circuit boards are used in most applications because of their cooling functions. PCB manufacturers include a heat sink in PCB due to the numerous benefits it offers.

Passive Heat Exchange

Heat sink PCBs feature a large surface area that cools off. These boards act as passive heat exchangers. The component of a device that can’t control its temperature needs heat sink PCBs. To improve performance, every heat in a component of an electronic circuit must be dissipated. This will help to prevent the component from experiencing any failure.

Maintains Thermal Stability

Heat sinks in PCB help to maintain thermal stability in any electronic device. Thermal stability is very important for electronic components of any circuit. Heat sink PCBs can survive in any temperature because of their cooling ability. This is a major reason these PCBs are employed in high-performance applications.

Heat sinks don’t only dissipate heat; they also provide heat during low temperatures. They do this by generating thermal energy for the smooth functioning of the circuit.

Spreads heat

Heat sinks serve as heat spreaders in some applications. For instance, a heat sink PCB functions as covers on the memory of a computer. Heat sinks also help to cool off the graphic processors and CPU of computers.

Prevents system failure

Heat sinks prevent system failure in a circuit. The absence of a heat sink can cause the failure of components. It is advisable to implement a heat sink in a PCB to prevent overheating. Component failure is one of the common problems of electronics or electrical devices.

Different types of mechanical and electronic devices generate heat which heat sinks absorb. Heat sink PCBs play significant roles in mechanical, electronic, nuclear, and solar processes.

Types of Heat Sink

Heat sinks are available in various types. Each of these types has its function. However, they share some common characteristics or features. Heat sinks are mostly made from metal like aluminum or copper. The commonest designs for a heat sink are the fin layout. Some versions utilize stamping and pins to increase the surface area and heat transfer rate.

Passive heat sink

A passive heat sink doesn’t feature additional products while cooling a component. It isn’t assisted by additional processes. These heat sinks don’t have any mechanical components. They dissipate heat through the convection process. When you use this heat sink on PCB, it gives reliable results. Experts recommend that engineers should maintain the flow of air across the fins of this heat sink.

Passive heat sinks serve as a standalone solution since they don’t use other cooling methods. These heat sinks are bigger than active heat sinks. Passive heat sinks disperse absorbed heat via the direct contact between them.

Active heat sink

This type of heat sink uses additional products to enhance its cooling capacity. Active heat sinks use powered processes like water pumps and fans. These processes or products help to increase the heat transfer rate. In some electronic systems, these coolers run off the internal power supply. This type of heat sink isn’t ideal for long-term applications. This is because it has moving parts.

Active heat sinks make use of one or more fans. These fans are either above or on the side of the fin stack. Some advanced active heat sinks use water to transfer heat from a source.

Types of Heat Sink Based on Material

Aluminum heat sink

An aluminum heat sink is a less expensive choice for heat sinks. This type of heat sink is designed in a way that the generated heat escapes via some thin metal fins. Aluminum is the commonest material used in heat sinks. The thermal conductivity of aluminum is different from copper. The thermal conductivity of the metal affects the heat sink’s heat transferring capacity.

Copper heat sink

Most heat sinks are made of copper. Copper is a good thermal conductor and has got great heat transfer capabilities. This type of heat sink draws away heat from the device you want to cool. Heat sink PCB made of copper is more expensive. Most PCB heatsink designs use copper.

Pinned heat sink

A pinned heat sink is an alternative design fin heat sink. The core block of the pinned heat sinks features a cluster of rods or pins that extends outward or upward. This type of heat sink has a better overall surface. But, they don’t offer good performance improvement in most applications.

Finned heat sink

This type of heat sink is designed from a block of metal. This metal is available in a large number of thin plates that extend away from the central block. Finned heat sink features a better surface area. This makes it more effective in transferring heat away from the component. The manufacturing and designing of this heat sink involve either die-cast or forged models.

Heat Sink Types Based on Manufacturing Techniques

Various manufacturing methods are used in manufacturing heat sinks.

Stamped heat sink

This type of heat sink features stamped metals. These metals can form a certain shape. The stamp designs the heat sinks anytime metal moves via the stamping machine. Stamped heat sinks are ideal for low-power applications.

Bonded heat sink

This type of heat sink is ideal for large applications that demand sensible performance. Bonded heat sinks are designed by combining separate fins of metal to the heat sink’s base. There are two different methods for doing this. They are the brazing and the thermal epoxy methods.

Skived heat sink

Skived heat sinks employ skiving for their manufacturing. Skiving is the use of fine blocks of metals for manufacturing heat sinks. Skived heat sinks can be high or medium-performing heat sinks.

Swaged heat sink

Swaged heat sinks are medium-performing heat sinks. Swaging is a manufacturing technique that involves a cold working forging process. However, it can undergo a hot working process.

Forged heat sink

Forging involves utilizing compressive forces. This technique is used for manufacturing aluminum and copper heat sinks.

Machining heat sink

This type of heat sink uses a machining process for its manufacturing. Gangsaw helps to eliminate a block of material. This type of manufacturing process is expensive since a lot of metal may waste.

Applications of Heat Sink PCB

Heat sink PCBs are used in several applications due to the functions they perform. These circuit boards are ideal for high-performance applications. They are also suitable for use in devices that produce a high amount of heat.

LEDs

Heat sink PCBs are commonly used in Light-emitting diodes (LED). These PCBs provide effective cooling for LED pcb. Heat sink circuit boards prevent excess heat from damaging LEDs. Most high-power LEDs feature heat sink PCBs.

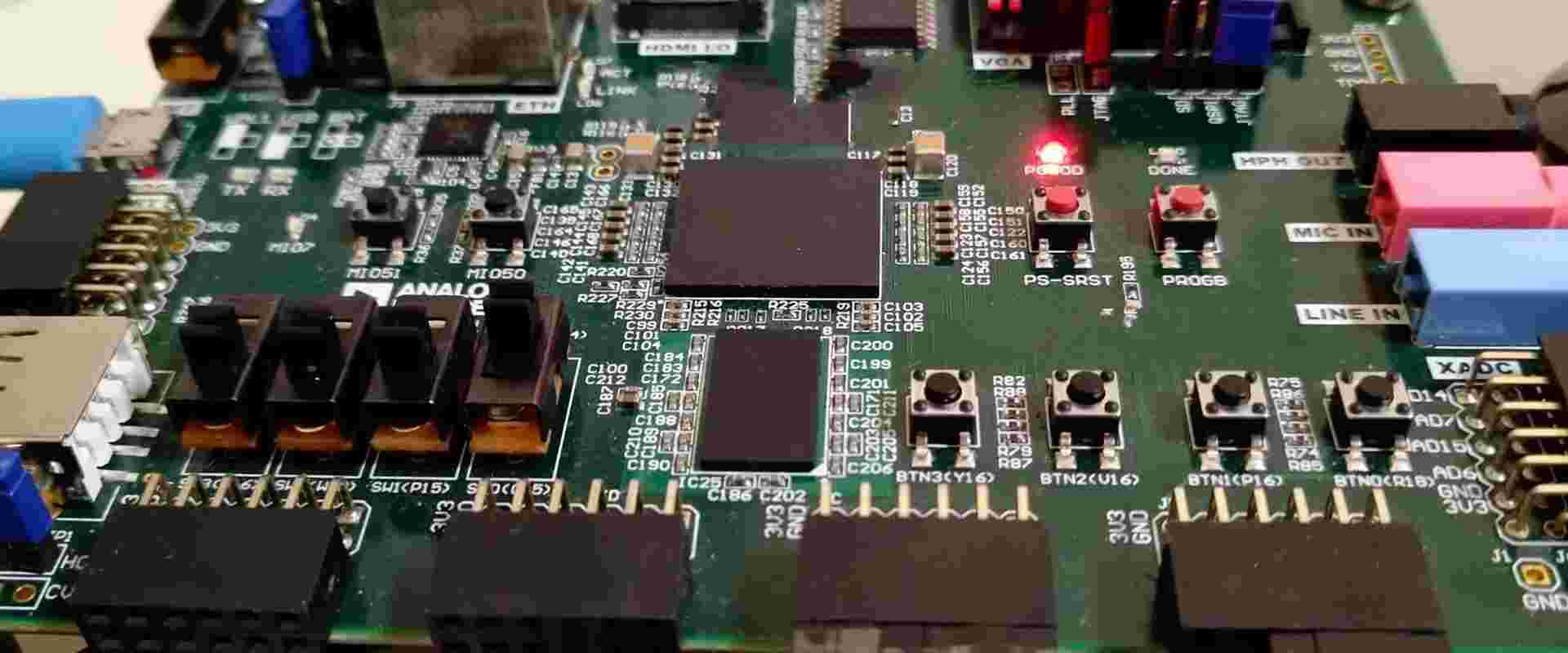

Computers

Heat sink PCBs are a common component of computers. The CPU of computers needs a heat sink. Electrical activity in the CPU produces a good amount of heat. This may cause damage to the chipset. A heat sink helps to offer a good path for heat to pass through. The CPU comes with a heat sink. Some manufacturers use a particular type of heat sink for their CPUs.

Industrial facilities

Most industrial devices generate heat while in use. Therefore, a heat sink PCB is ideal for use in industrial equipment. Heat sinks are connected on a circuit board because of their cooling properties. They reduce the amount of absorbed heat in a mechanical device while running.

Soldering

During the soldering process, heat sinks help to protect electronic components. Some components need the protection of a heat sink during soldering.

Consumer products

Heat sink PCBs are used in most consumer products. Some electronic devices in the home come with heat sinks. This is because some components of these devices generate a lot of heat. Therefore, heat sink PCBs help to dissipate heat in these devices.

The Limitations of Heat Sink PCB

The cooling of electronic devices is important for their long-lasting function. The need for circuit bard cooling has continued to increase. Heat Sink PCBs help to dissipate heat in electronic devices. The importance of the use of heat sinks in PCBs can’t be overemphasized.

There are different types of heat sink PCB with different thermal resistance values. These PCBs ensure cooling. Heat sink PCBs have their challenges. One of the major challenges is the joining of the circuit board with the heat sink.

Another challenge is the aerial use of thermal adhesive without air pockets between the components. The properties of the thermal adhesive caused this problem. However, thermal engineers achieved good distribution by using pressure pins. The vacuum joining process presents a reliable result.

The dissipation of heat loss from chips is a major issue for developers. There are several ways to link a heat sink to the source of the heat. The fabrication of a heat sink PCB involves creating a separate metal heat sink. Then, manufacturers use liquid adhesive to attach this heat sink to a finished board.

Heat Sink Dissipation Method

Heat sink PCBs use some methods to dissipate heat which are:

- Heat transfer compounds

- Metal heat-conducting plate

- Higher copper thickness

- Metal core

Heat transfer compounds

For heat sink PCBs, fabricators use a screen-printing procedure to apply the heat transfer compound to the silkscreen. The layer’s thickness ranges between 100 – 150 μm.

Metal core

Rather than using the standard base material, a copper or aluminum sheet is used here. A prepreg is used to laminate a copper foil onto a metal core.

Higher copper thicknesses

When it comes to thick-copper boards, the copper absorbs the heat and directly dissipates it. The copper thicknesses are 400 μm, 210 μm, and 105 μm. This method involves high-cost production since the conductor structure requires much effort.

Metal heat-conducting plate

In this method, a heat sink PCB goes through the standard production process. Manufacturers use a prepreg to press mold the PCB to the metal heat-conducting plate.

Factors to Consider in Heat Sink Design

The design of a PCB is a very complex process. The importance of heat sinks in PCB can’t be overstressed. Engineers need to consider some factors when implementing a heat sink on PCB. Heat sinks transmit thermal energy from electronic components into a cooling medium.

Several factors determine the performance of heat sinks. The material’s thermal conductivity and attachment method are some of these factors. Engineers can determine the parameters of a heat sink via analysis and modeling.

Heat sink materials

Alloys, aluminum, and copper are materials used for designing heat sinks. Copper is a good thermal conductor that resists corrosion and absorbs heat. This material is ideal for heat sinks due to its properties. However, it is a more expensive option.

Diamond is another ideal material for thermal applications. This is because it features lattice vibrations. Another alternative is the bonding of aluminum and copper. In this case, aluminum is the dominant material due to its lightweight. This is a perfect combination for heat sinks in computers.

Heat sink fins

Heat sinks feature fins in their design. These fins offer the necessary surface area for heat dissipation. They cool the heat source. The fin’s efficiency determines the performance of the heat sink. Once there is a flow of heat through the fin the temperature reduces from the base.

The arrangement and location of the fins also affect the performance of the heat sink. The design and shape of the fins will greatly determine the heat sink’s performance.

Thermal resistance

Thermal resistance determines how heat sinks perform. This factor determines heat flow. In order to achieve an efficient heat sink, the thermal management system needs to be combined with a cost-effective design.

Attachment methods

There are different methods of attaching heat sinks to the component of a device. Using the appropriate method helps to enhance the heat sink’s thermal performance. Thermal tape, standoff spacers, epoxy, and flat spring clips are examples of attachment methods.

Characteristics of a Good Heat Sink

A good heat sink features some characteristics that make them ideal in most applications. The characteristics of this heat sink are;

- Heat dissipation correlates with the temperature difference between the ambient temperature and the device.

- The mounting method is very critical. It uses screws rather than utilizing glue, clips, or sticky tape.

- Heat dissipation correlates with the fins’ surface area. Therefore, it should have a very large surface.

- Flat surface must have contact with the source of heat. This is very important as it allows a layer of thermal compound to minimize thermal resistance between the devices.

- Heat sink design must enable free flow of air through the fins.

PCB Heat Dissipation Techniques

As PCBs are a core aspect of electronic devices, heat dissipation techniques are very important. Most electronic devices produce heat while they are running. Heat sink PCB helps to spread heat across components in a circuit. Below are some heat dissipation techniques;

Use cooling fans and heat sinks

If a printed circuit board generates a high amount of heat. You will have to incorporate fans and heat sinks in the design. Manufacturers attach heat sinks to components that produce the most heat. Power transistors, CPUs, and voltage regulators are such components. Here, the heat sinks are on the PCB. You can also install a cooling fan to help discharge the hot air in the environment.

Thermal via arrays

You can make use of thermal via arrays to transform a PCB into an onboard heat sink. The idea behind this is for flow of heat from the components to the copper area. Then the heat dissipates via the air from the vias.

Thermal via array must feature a large diameter to allow effective dissipation of heat. The vias must feature padded holes that connect to the copper area. More thermal vias also help dissipation of heat.

Use wider traces

Ensure you increase the trace’s width to improve heat dissipation to the air. This will help to reduce the trace’s thermal resistance and also minimize heat spots. Good copper trace thickness can offer a low impedance path.

These heat dissipation techniques are very important in electronics. Heat sinks play a significant role in the dissipation of heat in electronic devices. Components like power transistors and microcontrollers often generate heat. This happens especially when the load current rises.

Frequently Asked Questions

How do you calculate heat sink performance?

The performance of heat sinks is also known as thermal resistance. It is measured in °C/W. If a heat sink has a thermal load of 50W and the heat source rises by 20 °C. One can say the heat sink rating is 20/50 °C/W. This is equal to 0.40 °C/W.

How can the impact of heat on PCBs be minimized?

To do this, separate heat-sensitive components and heat-generating ones on the PCB. This can help you concentrate heat dissipation to a certain area. Doing this will also prevent the heat from going towards the heat-sensitive components. Place heat-producing components on the top when mounting the PCB vertically. You can reduce the heat dissipation path by placing the components towards the PCB’s edge.

What is a thermal simulation in PCB?

Thermal simulation locates the temperature of a thermal hotspot in a printed circuit board. Locating the thermal hotspots help to prevent the risk of failure in devices.

Conclusion

Electronic components can operate within a definite temperature range. When the temperature around these components rises beyond the upper limit, there can be a breakdown. Excessive heat can have a negative effect on the performance of the component.

For instance, MCU uses more energy at high temperatures. The lifespan of an electronic device will reduce if it is exposed to too much heat. Too much heat can lead to premature failure of components. Therefore a heat sink PCB is an ideal choice for most electronics.