PCB reverse engineering (also known as reverse technology) is a process of printed circuit board design technology reproduction, reverse analysis and research of a target PCB board. It is also to deduce and obtain the design of the product’s processing flow, structure, functional characteristics, and technical specification elements to produce products with similar, but not exactly the same, functions. Reverse engineering originates from hardware analysis in the commercial and military fields. Its primary purpose is to directly analyze the finished product and push out its design principle when the necessary production information cannot be easily obtained.

Another service we offer at RayMing is Printed Circuit Board Reverse Engineering. We can take your sample, including components, and completely reverse engineer it. We create all the data you need to make duplicates. We can even reverse engineer boards that include programmed IC‘s, custom parts, and obsolete parts.

1. What Is PCB Reverse Engineering?

Definition and Purpose

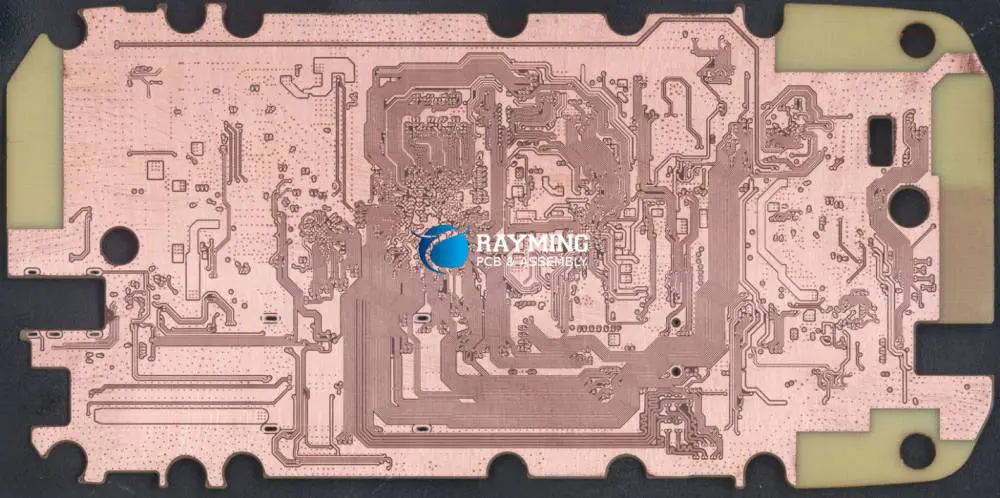

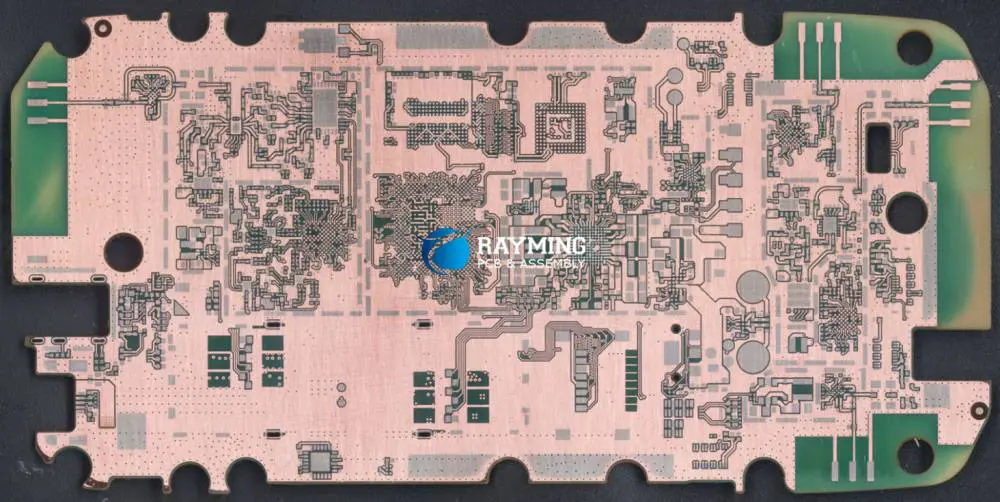

PCB reverse engineering is the process of analyzing and documenting an existing printed circuit board to recreate its schematic diagram and understand its functionality. This technique involves a combination of visual inspection, electrical testing, and advanced imaging technologies to deconstruct the PCB layer by layer, tracing connections and identifying components.

Common Use Cases

PCB reverse engineering finds applications in various scenarios:

- Legacy System Repair: When dealing with obsolete or out-of-production systems, reverse engineering can help create documentation for repairs or replacements.

- Competitive Analysis: Companies may analyze competitors’ products to understand their design choices and technologies.

- Lost Documentation: In cases where original schematics are lost or unavailable, reverse engineering can recreate essential documentation.

- Modernization: Updating older designs to incorporate newer technologies or improve efficiency.

- Failure Analysis: Investigating the cause of PCB failures in critical systems.

Ethical and Legal Considerations

While PCB reverse engineering is a powerful tool, it’s essential to consider the ethical and legal implications:

- Intellectual Property: Ensure you have the right to reverse engineer a PCB, especially if it’s not your own design.

- Patents and Copyrights: Be aware of potential patent infringements or copyright issues.

- Non-Disclosure Agreements: Respect any NDAs that may prohibit reverse engineering of certain products.

- Ethical Use: Use the knowledge gained responsibly and avoid replicating proprietary designs for commercial purposes without permission.

2. The PCB Reverse Engineering Process: Step-by-Step

To successfully reverse engineer a PCB, follow these key steps:

2.1 Initial Inspection and Documentation

Begin by thoroughly examining the PCB and documenting its physical characteristics:

- Measure board dimensions

- Note the number of layers

- Identify key components and their locations

- Photograph the board from multiple angles

2.2 Layer-by-Layer Board Analysis

Carefully analyze each layer of the PCB:

- Top Layer: Document visible traces, components, and connections.

- Inner Layers: Use X-ray imaging or careful removal of layers to reveal hidden traces.

- Bottom Layer: Examine solder joints, vias, and additional components.

2.3 Tracing and Mapping Connections

Systematically trace and map all connections on the PCB:

- Use a multimeter to verify continuity between points

- Create a netlist of all connections

- Document component values and specifications

2.4 Schematic Diagram Reconstruction

Based on the gathered information, recreate the schematic diagram:

- Use schematic capture software to draw the circuit

- Ensure all components and connections are accurately represented

- Include component values and specifications

2.5 Verification and Testing

Finally, verify the accuracy of your reverse-engineered schematic:

- Compare the schematic to the original PCB

- Conduct electrical tests to ensure functionality matches

- Simulate the circuit if possible to validate behavior

Read more about:

3. Essential Tools for PCB Reverse Engineering

Successful PCB reverse engineering requires a combination of basic and advanced tools. Let’s explore the essential equipment needed for this process.

3.1 Basic Tools

Every PCB reverse engineering toolkit should include these fundamental items:

- Multimeter: For measuring voltage, current, and resistance.

- Magnifying Glass or Loupe: To inspect small components and trace fine details.

- Digital Camera: For documenting the PCB at various stages.

- Calipers: To measure precise dimensions of the board and components.

- Desoldering Equipment: For removing components when necessary.

3.2 Advanced Tools

For more complex PCBs or professional-grade reverse engineering, consider these advanced tools:

- X-ray Imaging System: To reveal hidden layers and connections within multi-layer PCBs.

- 3D Scanner: For creating detailed 3D models of the PCB.

- Laser Depaneling Tool: For precise separation of PCB panels without damaging components.

- Microscope with Digital Imaging: For detailed inspection and documentation of tiny components and traces.

- Oscilloscope: To analyze signal behavior and timing in active circuits.

3.3 Hand Tools vs. Automated Tools: When to Use Which

The choice between hand tools and automated equipment depends on several factors:

- Project Complexity: Simple single-layer PCBs may only require basic hand tools, while complex multi-layer boards benefit from automated systems.

- Time Constraints: Automated tools can significantly speed up the process for large or intricate PCBs.

- Budget: Hand tools are more budget-friendly for occasional use, while automated systems are cost-effective for frequent reverse engineering tasks.

- Accuracy Requirements: Automated tools generally offer higher precision and repeatability for critical applications.

4. Best Software for PCB Reverse Engineering

Choosing the right software is crucial for efficient PCB reverse engineering. Here’s an overview of some popular options:

4.1 Schematic Capture and PCB Design Software

- KiCad

- Open-source and free

- Comprehensive suite for schematic capture and PCB layout

- Large community support

- Altium Designer

- Professional-grade software with advanced features

- Excellent for complex multi-layer designs

- Steep learning curve but powerful capabilities

- OrCAD

- Industry-standard for many professional engineers

- Robust simulation capabilities

- Integrates well with other Cadence tools

4.2 Imaging and Analysis Software

- GIMP/Photoshop

- Useful for image stitching and enhancement of PCB photographs

- Can help in tracing and isolating layers visually

- Gerber Viewers (e.g., GerbView, CAM350)

- Essential for viewing and analyzing Gerber files

- Helps in understanding layer structure and trace routing

4.3 Specialized Reverse Engineering Suites

- ScanCAD

- Dedicated PCB reverse engineering software

- Automates much of the tracing and component identification process

- Expensive but time-saving for frequent use

- PCB Investigator

- Combines Gerber viewing with reverse engineering tools

- Offers layer comparison and net extraction features

4.4 Comparison Table

| Software | Best For | Pricing | Key Features |

|---|---|---|---|

| KiCad | Hobbyists, Small Projects | Free | Open-source, Community support |

| Altium Designer | Professional Engineers | Subscription-based | Advanced routing, 3D modeling |

| OrCAD | Industry Professionals | License-based | Powerful simulation, Integration with other tools |

| ScanCAD | Dedicated RE Teams | High (Contact for quote) | Automated tracing, Component identification |

| PCB Investigator | Mixed-use Engineers | Modular pricing | Layer comparison, Net extraction |

5. Cost Analysis: How Much Does PCB Reverse Engineering Cost?

The cost of PCB reverse engineering can vary widely depending on several factors. Let’s break down the potential expenses:

5.1 DIY vs. Professional Service Costs

- DIY: Initial investment in tools and software, plus time cost.

- Professional Service: Typically charged per project or hour, with costs varying based on complexity.

5.2 Cost Breakdown

- Equipment Costs:

- Basic tools (multimeter, magnifier, etc.): 100−100−500

- Advanced tools (X-ray system, 3D scanner): 10,000−10,000−100,000+

- Software Licensing Fees:

- Open-source options: Free

- Professional suites: 1,000−1,000−10,000+ per year

- Labor/Time Costs:

- DIY: Your personal time investment

- Professional services: 50−50−200+ per hour

5.3 Factors Influencing Costs

- Board Complexity: Multi-layer PCBs require more time and advanced tools.

- Board Size and Density: Larger or densely packed boards increase complexity.

- Urgency: Rush jobs often incur premium fees.

- Level of Detail Required: Full component-level analysis costs more than basic tracing.

5.4 Sample Real-World Cost Estimates

- Simple Single-Layer PCB (DIY): 500−500−1,000 (tools and software)

- Complex Multi-Layer PCB (Professional Service): 5,000−5,000−20,000+

- High-End Industrial PCB (Specialized Service): 20,000−20,000−50,000+

6. Challenges and Pitfalls in PCB Reverse Engineering

PCB reverse engineering, while powerful, comes with its share of challenges:

6.1 Hidden Internal Layers

Multi-layer PCBs often contain hidden traces and connections, making complete analysis difficult without specialized equipment.

6.2 Obfuscated Traces and Protective Coatings

Some manufacturers intentionally obscure traces or use protective coatings to deter reverse engineering efforts.

6.3 Risk of Damaging the Board

Invasive techniques like layer removal can potentially damage the PCB, especially if it’s a rare or valuable board.

6.4 Incomplete or Inaccurate Schematics

Errors in tracing or component identification can lead to inaccurate schematics, potentially causing issues in reproduction or repair.

6.5 Intellectual Property and Legal Issues

Unauthorized reverse engineering may infringe on patents or copyrights, leading to legal complications.

7. Tips to Speed Up and Improve Accuracy

To enhance your PCB reverse engineering process:

7.1 Best Practices for Image Capture

- Use consistent, high-quality lighting

- Capture images at high resolution

- Take multiple angles of each layer

7.2 Layer Separation Techniques

- Use chemical etching carefully for non-destructive layer removal

- Consider X-ray imaging for preserving the original board

7.3 Creating High-Fidelity Netlists

- Use automated netlist generation tools when possible

- Double-check connections manually to ensure accuracy

7.4 Cross-referencing BOMs (Bill of Materials)

- If available, use the original BOM to verify component specifications

- Create a comprehensive BOM during the reverse engineering process

7.5 Leveraging AI and Machine Learning

- Explore emerging AI-powered PCB analysis tools

- Use machine learning algorithms for pattern recognition in complex layouts

8. When to Hire a Professional PCB Reverse Engineering Service

Sometimes, it’s best to leave PCB reverse engineering to the professionals. Consider professional services when:

8.1 Criteria for Outsourcing

- The PCB is highly complex or multi-layered

- You lack specialized equipment or software

- Time is a critical factor

- Legal expertise is required to navigate IP issues

8.2 What to Look for in a PCB Reverse Engineering Service Provider

- Experience with similar projects

- Advanced equipment and software capabilities

- Clear communication and project management processes

- Confidentiality agreements and security measures

8.3 Typical Service Agreements and NDAs

- Ensure clear scope definition in the service agreement

- Sign robust NDAs to protect your intellectual property

- Clarify ownership of the resulting documentation and designs

Conclusion

PCB reverse engineering is a complex yet rewarding process that bridges the gap between existing hardware and documented designs. From the initial inspection to the final schematic reconstruction, each step requires attention to detail and a combination of the right tools and expertise.

Whether you choose the DIY route or opt for professional services, understanding the full process from board to schematic is crucial. By balancing the use of hand tools and advanced equipment, leveraging appropriate software, and being aware of the potential challenges, you can approach PCB reverse engineering projects with confidence.

Remember to always consider the ethical and legal implications of reverse engineering, especially when dealing with proprietary designs. With the right approach, PCB reverse engineering can be an invaluable skill in your engineering toolkit, enabling you to breathe new life into legacy systems, understand complex designs, and innovate for the future.

We encourage you to share your experiences with PCB reverse engineering or seek expert consultation for your specific projects. The world of PCBs is vast and ever-evolving, and there’s always more to learn and explore in this fascinating field.

FAQ Section

Is PCB reverse engineering legal?

PCB reverse engineering can be legal, depending on the circumstances. It’s generally acceptable for personal use, repair, or interoperability purposes. However, it may be illegal if it violates patents, copyrights, or terms of service agreements. Always check the legal implications before starting a reverse engineering project.

How long does PCB reverse engineering take?

The time required for PCB reverse engineering varies greatly depending on the complexity of the board and the methods used. A simple single-layer PCB might take a few hours, while a complex multi-layer board could require weeks or even months of work.

Can any PCB be reverse engineered?

In theory, most PCBs can be reverse engineered. However, some boards may have anti-tampering measures or be so complex that reverse engineering becomes impractical or prohibitively expensive. Additionally, some cutting-edge or proprietary designs may be challenging to fully understand without insider knowledge.

What skills are needed for PCB reverse engineering?

Successful PCB reverse engineering requires a combination of skills:

- Strong understanding of electronic circuits and components

- Familiarity with PCB design and manufacturing processes

- Proficiency with relevant software tools

- Attention to detail and patience

- Problem-solving and analytical thinking

- Basic understanding of intellectual property laws (for professional work)

By continually developing these skills and staying updated with the latest tools and techniques, you can become proficient in the art and science of PCB reverse engineering.