In today’s rapidly evolving automotive industry, radar technology has become a cornerstone of vehicle safety and autonomous driving capabilities. Among the most significant technological shifts in recent years is the transition from 24GHz to 77GHz radar systems. This change represents more than just a numerical upgrade – it marks a fundamental improvement in how vehicles perceive and interact with their surroundings. As automotive manufacturers and suppliers race to develop safer, more intelligent vehicles, understanding the advantages and implications of 77GHz radar technology has become essential knowledge for industry professionals and tech enthusiasts alike.

Understanding Automotive Radar Frequencies

Before diving into the specific benefits of 77GHz radar, it’s important to understand the fundamental differences between the two major frequency bands used in automotive applications.

What is 24GHz Radar?

24GHz radar systems have been the workhorses of automotive sensing for over two decades. Operating in the K-band of the electromagnetic spectrum (24.05-24.25 GHz), these systems were revolutionary when first introduced, enabling features like basic blind-spot detection and simple adaptive cruise control. Their relatively low cost and established manufacturing processes made them the default choice for early Advanced Driver Assistance Systems (ADAS).

The 24GHz radar technology operates in two primary bands:

- Narrow-band (24.05-24.25 GHz)

- Ultra-wideband (21.65-26.65 GHz)

While these systems provided adequate performance for basic safety features, their limitations in range, resolution, and interference management became increasingly apparent as automotive safety demands evolved.

What is 77GHz Radar?

77GHz radar represents the next generation of automotive sensing, operating in the W-band (76-81 GHz) of the electromagnetic spectrum. This significantly higher frequency enables dramatic improvements in performance across multiple dimensions. The 77GHz radar leverages millimeter-wave technology to achieve sensing capabilities that simply weren’t possible with previous generations.

The 77GHz band typically spans from 76 to 81 GHz, providing a much wider bandwidth than 24GHz systems. This expanded bandwidth is crucial for next-generation automotive applications, particularly those requiring high-resolution imaging and precise object detection.

Why Frequency Matters for Radar Systems

The fundamental physics behind radar operation explains why the shift to higher frequencies delivers such substantial benefits. Radar works by transmitting radio waves that bounce off objects and return to the sensor. The properties of these waves—including wavelength, beam width, and propagation characteristics—are directly influenced by their frequency.

Higher frequency waves (like 77GHz) have shorter wavelengths, which enable:

- More precise measurement of object position and velocity

- Better discrimination between closely spaced objects

- Smaller antenna size for a given level of performance

- Improved resistance to certain types of interference

These physical advantages translate directly into real-world performance improvements that are driving the industry-wide shift toward 77GHz technology.

Key Advantages of 77GHz Radar over 24GHz

The transition from 24GHz to 77GHz radar brings several critical advantages that directly impact vehicle safety and autonomous driving capabilities.

Higher Resolution and Accuracy

The most immediately noticeable benefit of 77GHz radar is its dramatically improved resolution. Resolution in radar terms refers to the ability to distinguish between objects that are close together.

Improved Object Detection

77GHz radar can detect smaller objects at greater distances than 24GHz systems. This improvement is particularly important for identifying vulnerable road users like pedestrians and cyclists, as well as potentially hazardous debris on the roadway.

The angular resolution of 77GHz radar is typically 1-2 degrees, compared to 5-10 degrees for 24GHz systems. This finer angular resolution means that vehicles can more precisely locate objects in their environment, leading to more accurate decision-making by ADAS systems.

Narrower Beam Width

The higher frequency of 77GHz radar naturally produces a narrower beam width. This focused energy allows the radar to:

- Provide more precise angular measurements

- Reduce false detections from adjacent lanes

- Better identify the edges and boundaries of objects

- Maintain performance even in complex driving environments

These capabilities are essential for advanced features like automatic emergency braking and lane-keeping assistance, where precise object location is critical for safe operation.

Greater Detection Range

One of the most significant advantages of 77GHz radar is its extended detection range.

Longer Sensing Distance

77GHz radar systems typically achieve effective ranges of 200-300 meters, compared to the 70-100 meter range of traditional 24GHz systems. This extended range provides crucial additional seconds of reaction time at highway speeds, allowing vehicles to:

- Begin braking earlier for obstacles

- Make more gradual speed adjustments

- Plan lane changes and maneuvers with greater foresight

- Maintain safer following distances in adaptive cruise control

Real-World Applications

This extended range is particularly valuable for highway driving scenarios, where vehicle speeds are high and early detection of traffic patterns is essential. Practical applications include:

- Long-range adaptive cruise control that can track vehicles at distances of 200+ meters

- Early collision warning systems that provide more time for driver response

- Highway autopilot features that can anticipate traffic flow changes well in advance

- Improved all-weather performance, maintaining reliable detection even in fog, rain, and snow

Smaller Antenna Size

The physics of radar mean that higher frequency systems can achieve comparable performance with significantly smaller antenna sizes.

Compact Design Advantages

77GHz radar modules are typically 50-70% smaller than equivalent 24GHz units. This size reduction offers multiple benefits:

- More flexible mounting options around the vehicle

- Less intrusive integration into vehicle styling

- Ability to place multiple radar units for 360-degree coverage

- Reduced impact on vehicle aerodynamics and design aesthetics

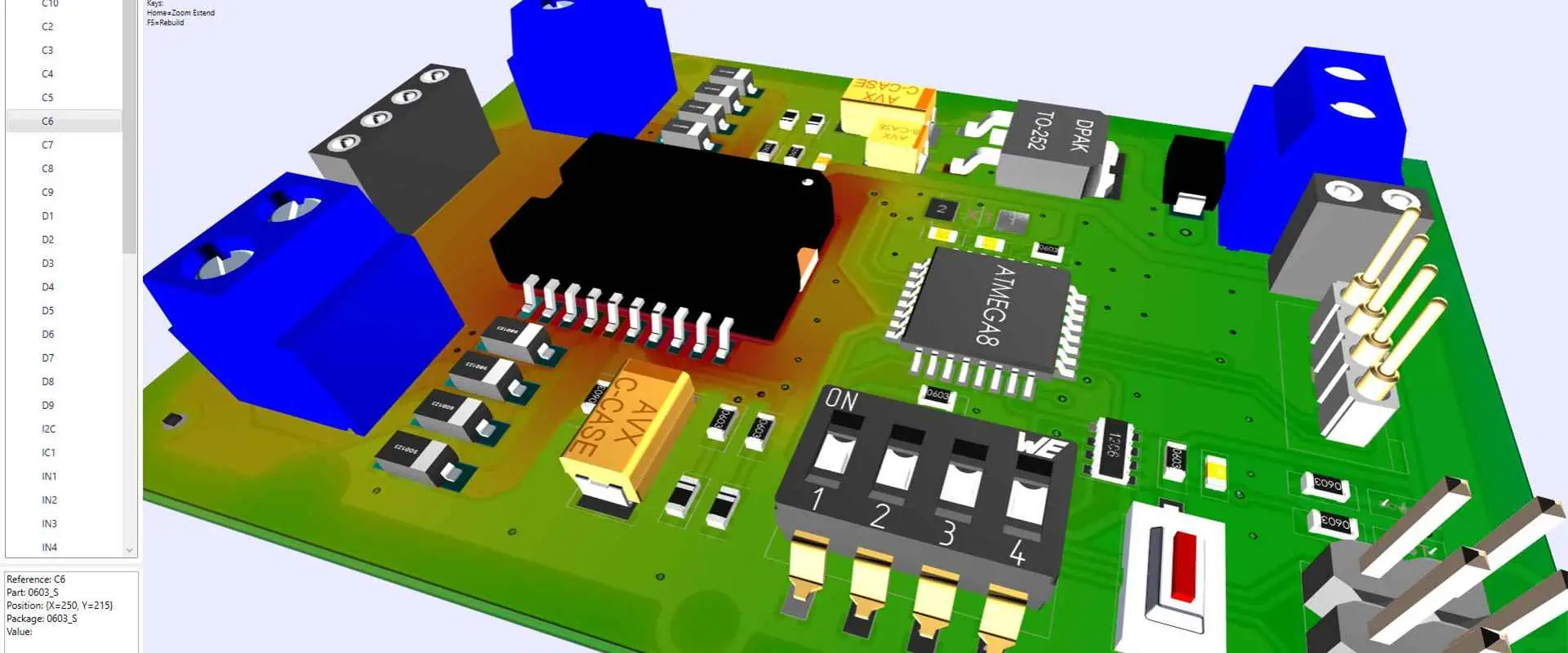

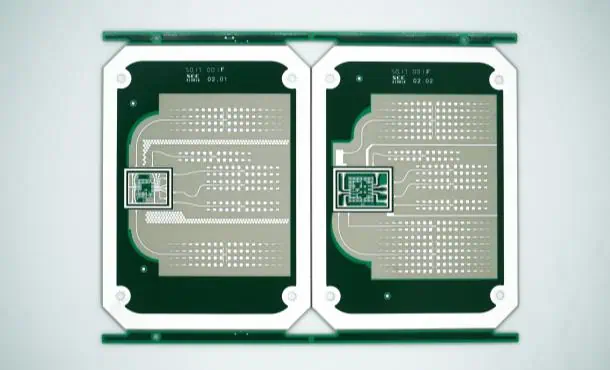

Multi-Radar Integration

The compact size of 77GHz radar units makes it practical to integrate multiple sensors around the vehicle, creating a comprehensive sensing network. Modern vehicles often incorporate 4-6 radar sensors, providing overlap between detection zones and redundancy for safety-critical functions.

Regulatory Changes Driving the Shift

Beyond the technical advantages, regulatory factors are accelerating the transition to 77GHz radar technology.

Global Regulatory Landscape

Telecommunications regulatory bodies worldwide have been coordinating a managed transition from 24GHz to 77GHz radar for automotive applications:

- The Federal Communications Commission (FCC) in the United States has allocated the 76-81 GHz band specifically for vehicular radar systems.

- The European Telecommunications Standards Institute (ETSI) has similarly designated the 77GHz band for automotive use while phasing out certain 24GHz applications.

- Similar regulatory frameworks have been adopted in Japan, China, South Korea, and other major automotive markets.

Phase-Out of 24GHz Ultra-Wideband

Perhaps the most significant regulatory driver is the planned phase-out of ultra-wideband 24GHz radar systems. These systems were always approved on a temporary basis, as they operated in frequency bands shared with other critical applications, including:

- Earth exploration satellite services

- Radio astronomy

- Fixed wireless communications

To address potential interference concerns, regulatory bodies have established timelines for the transition away from these temporary allocations, pushing manufacturers toward 77GHz technology.

Environmental and Spectrum Management Considerations

The shift to 77GHz also reflects broader goals in efficient spectrum management. The 77GHz band provides dedicated spectrum for automotive applications, reducing potential conflicts with other services and allowing for more effective management of this limited resource.

Read more about:

Performance Metrics: 77GHz vs 24GHz Radar

When directly comparing the two technologies, the advantages of 77GHz radar become clear across multiple performance dimensions.

These performance improvements translate directly into enhanced capabilities for safety-critical vehicle systems.

Applications Powered by 77GHz Radar

The superior capabilities of 77GHz radar are enabling a wide range of advanced automotive applications.

Advanced Driver-Assistance Systems (ADAS)

77GHz radar serves as the primary sensor for numerous ADAS features:

- Adaptive Cruise Control (ACC) with full-speed range capability

- Automatic Emergency Braking (AEB) with pedestrian and cyclist detection

- Cut-in detection for highway driving

- Traffic jam assist and low-speed following

Autonomous Driving Support

For vehicles with Level 2-4 autonomous capabilities, 77GHz radar provides critical environmental perception:

- 360-degree environmental monitoring

- Long-range forward sensing for highway autopilot

- Reliable operation in adverse weather and lighting conditions

- Redundant sensing for safety-critical decisions

Specialized Safety Applications

Beyond general perception tasks, 77GHz radar enables specific safety features:

- Cross-traffic alert systems for intersections

- Enhanced blind spot detection with longer-range tracking

- Pre-crash sensing and predictive safety systems

- Exit warning systems to prevent door opening into traffic

Parking and Low-Speed Maneuvering

At the other end of the speed spectrum, high-resolution 77GHz radar improves parking capabilities:

- Precise detection of curbs and parking boundaries

- 3D sensing for complex parking environments

- Integration with automated parking systems

- Low-speed collision avoidance

Challenges and Considerations with 77GHz Radar

Despite its clear advantages, the transition to 77GHz radar does present certain challenges.

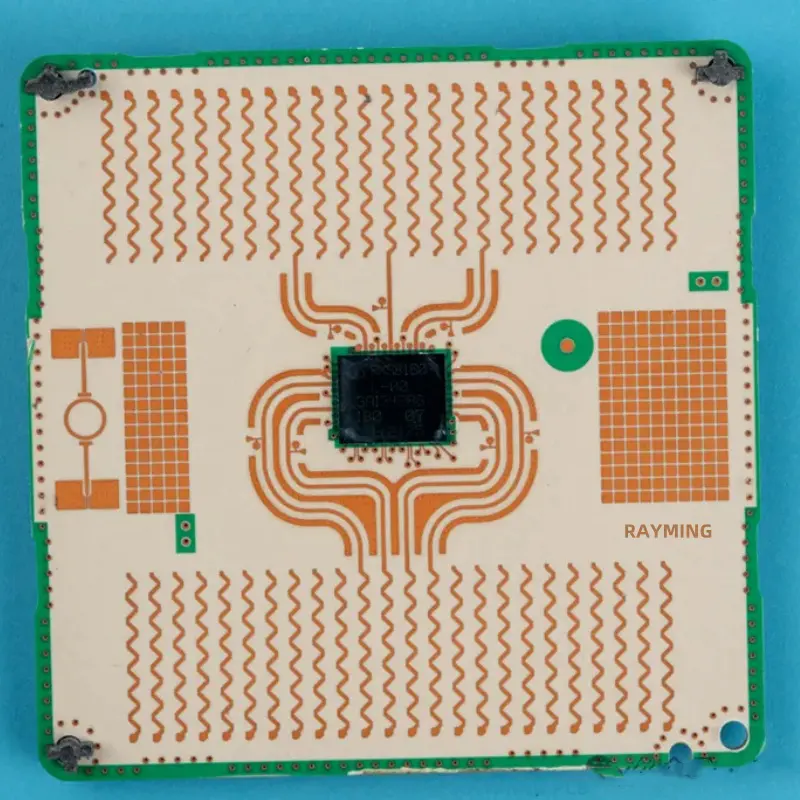

Cost and Manufacturing Complexity

77GHz radar systems typically cost 20-40% more than their 24GHz counterparts, primarily due to:

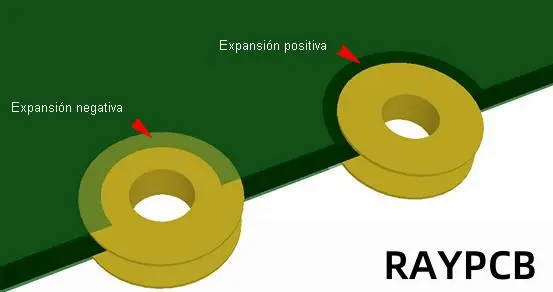

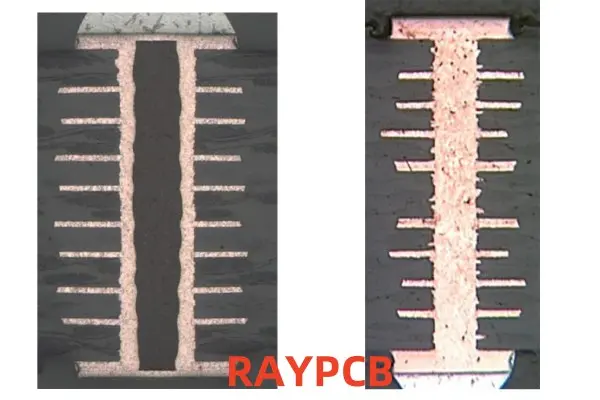

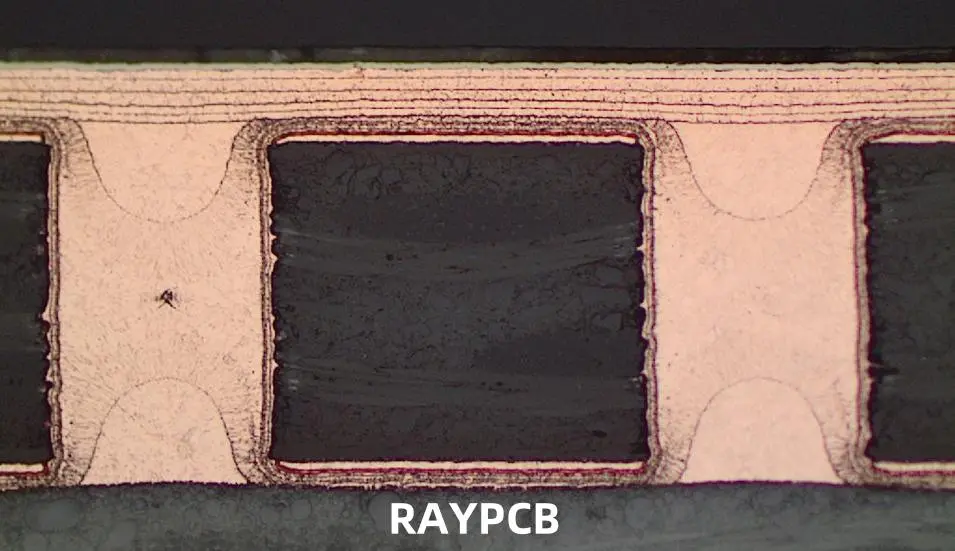

- More stringent manufacturing tolerances

- Higher-performance RF components

- More complex signal processing requirements

- Advanced packaging technologies

However, these costs are decreasing as production volumes increase and manufacturing processes mature.

Calibration and Testing Requirements

Higher frequency radar systems require more precise calibration to maintain their performance advantages:

- More sophisticated alignment procedures during manufacturing

- Field calibration requirements after vehicle repairs

- Specialized testing equipment for validation

Integration with Sensor Fusion Systems

Modern vehicles rely on multiple sensing technologies working together, including cameras, lidar, and ultrasonic sensors. Integrating 77GHz radar into these comprehensive sensing systems requires careful engineering to:

- Harmonize detection ranges and fields of view

- Reconcile different data formats and update rates

- Manage sensor redundancy and fault tolerance

- Optimize overall system performance

The Future of Automotive Sensing: Beyond 77GHz?

While 77GHz radar represents the current state-of-the-art, the technology continues to evolve.

Emerging 79GHz Ultra-Wideband Radar

Even higher frequency systems operating in the 79GHz band (77-81 GHz) are beginning to emerge. These systems offer:

- Even finer resolution for detailed environmental mapping

- Potential for radar-based imaging applications

- Better discrimination of complex objects

Sensor Fusion and AI Integration

The future of automotive sensing lies not just in better individual sensors, but in smarter integration:

- Deep learning algorithms that enhance radar signal processing

- Fusion of radar, lidar, and camera data for comprehensive perception

- Real-time environmental mapping and prediction

Beyond Traditional Automotive Applications

The capabilities of advanced radar systems are enabling applications beyond basic safety:

- Vehicle-to-everything (V2X) communication augmentation

- Infrastructure monitoring and smart city integration

- Advanced weather sensing and road condition detection

Conclusion

The transition from 24GHz to 77GHz radar represents one of the most significant technological shifts in automotive safety systems. The superior performance characteristics of 77GHz radar—including extended range, higher resolution, and compact form factor—provide the sensing capabilities required for advanced driver assistance and autonomous driving features.

As regulatory changes continue to phase out older 24GHz technologies, vehicle manufacturers and suppliers are investing heavily in 77GHz radar systems. This shift is not merely a response to regulations but a recognition of the fundamental advantages that 77GHz technology brings to vehicle safety and capability.

For automotive engineers, system integrators, and technology strategists, embracing 77GHz radar technology is not just about compliance—it’s about enabling the next generation of intelligent vehicles that can perceive their environment with unprecedented clarity and precision. As the industry continues its march toward autonomous driving, 77GHz radar will remain a cornerstone technology, providing the reliable, high-performance sensing that makes these advanced systems possible.