Introduction

In the ever-evolving world of electronics, thermal management and signal integrity have become critical factors in design and performance. Enter the Aluminum PCB Stackup, a innovative solution that addresses these challenges head-on. This article delves into the intricacies of Aluminum PCB Stackups, exploring how they balance thermal conductivity and signal integrity to meet the demands of modern electronic devices.

Aluminum PCBs have gained significant traction in recent years, particularly in applications requiring efficient heat dissipation. The importance of Aluminum PCB Stackup in modern electronics cannot be overstated, as it offers a unique combination of thermal management and electrical performance. As we push the boundaries of what’s possible in electronic design, striking the right balance between these two critical aspects becomes increasingly crucial.

What is an Aluminum PCB Stackup?

Definition and Structure

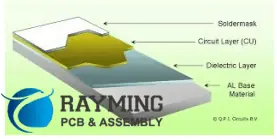

An Aluminum PCB Stackup refers to the layered construction of a printed circuit board that incorporates an aluminum base layer. This structure typically consists of three main components:

- Metal Base Layer (Aluminum Core): This forms the foundation of the PCB, providing mechanical support and excellent thermal conductivity.

- Dielectric Insulating Layer: A thin layer of thermally conductive yet electrically insulating material that separates the aluminum core from the copper circuitry.

- Copper Circuitry Layer: The topmost layer where electronic components are mounted and interconnected.

Comparison to Traditional FR4 Stackups

Unlike traditional FR4 (Flame Retardant 4) stackups that use a fiberglass-reinforced epoxy laminate as the base material, Aluminum PCB Stackups leverage the superior thermal properties of aluminum. This fundamental difference results in significantly improved heat dissipation capabilities, making Aluminum PCB Stackups ideal for high-power applications.

Key Benefits of Aluminum PCB Stackups

Superior Thermal Conductivity

The standout feature of Aluminum PCB Stackups is their exceptional thermal conductivity. The aluminum core acts as a built-in heat sink, efficiently spreading and dissipating heat generated by electronic components. This property is particularly valuable in applications where thermal management is critical, such as high-power LED lighting or automotive electronics.

Enhanced Mechanical Durability

Aluminum’s inherent strength and rigidity contribute to the overall durability of the PCB. This increased mechanical stability helps protect sensitive components from vibration and physical stress, making Aluminum PCB Stackups well-suited for rugged environments.

Lightweight and Compact Design

Despite its strength, aluminum is relatively lightweight compared to other metals. This characteristic allows for the creation of robust yet lightweight PCBs, which is particularly advantageous in applications where weight is a concern, such as aerospace or portable electronics.

Cost-effectiveness for High-Power Applications

While the initial cost of Aluminum PCB Stackups may be higher than traditional FR4 boards, they often prove more cost-effective in high-power applications. The improved thermal management can reduce or eliminate the need for additional cooling solutions, potentially lowering overall system costs.

Challenges in Designing an Aluminum PCB Stackup

Managing Differential Thermal Expansion

One of the primary challenges in designing Aluminum PCB Stackups is managing the differential thermal expansion between the aluminum core and other materials in the stackup. As temperature fluctuates, materials expand and contract at different rates, which can lead to stress and potential delamination if not properly addressed.

Maintaining Signal Integrity at High Frequencies

While Aluminum PCB Stackups excel in thermal management, they present unique challenges for signal integrity, especially at high frequencies. The proximity of the conductive aluminum layer to the signal traces can affect impedance and introduce unwanted capacitance, requiring careful design considerations.

Layer Adhesion and Material Compatibility

Ensuring strong adhesion between the aluminum core, dielectric layer, and copper circuitry is crucial for the longevity and reliability of the PCB. Selecting compatible materials and employing appropriate manufacturing processes are essential to prevent delamination and ensure the PCB’s long-term performance.

Thermal Conductivity Considerations

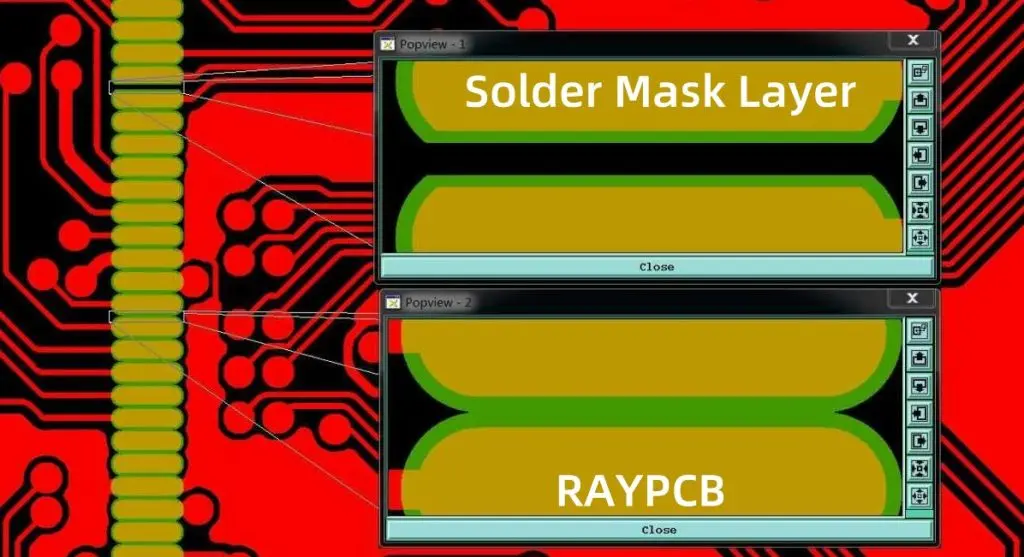

Role of the Dielectric Layer’s Thermal Conductivity

The dielectric layer plays a crucial role in the thermal performance of an Aluminum PCB Stackup. While it must provide electrical isolation, it should also facilitate heat transfer from the copper layer to the aluminum core. Selecting a dielectric material with high thermal conductivity is key to maximizing the stackup’s heat dissipation capabilities.

Thickness of the Aluminum Core and Heat Dissipation

The thickness of the aluminum core directly impacts the PCB’s ability to spread and dissipate heat. A thicker core generally provides better thermal performance but comes at the cost of increased weight and potentially higher manufacturing complexity. Designers must carefully balance these factors based on the specific requirements of their application.

Examples: Applications in LED Lighting, Automotive, and Power Electronics

Aluminum PCB Stackups find extensive use in applications requiring efficient thermal management:

- LED Lighting: High-power LED modules benefit from the enhanced heat dissipation, allowing for brighter and more reliable lighting solutions.

- Automotive Electronics: Under-hood electronics and LED headlights leverage Aluminum PCB Stackups to withstand high temperatures and vibrations.

- Power Electronics: Inverters, motor drives, and power supplies use Aluminum PCB Stackups to manage the heat generated by high-current components.

Read more about:

Signal Integrity Factors in Aluminum PCB Stackups

Importance of Consistent Impedance Control

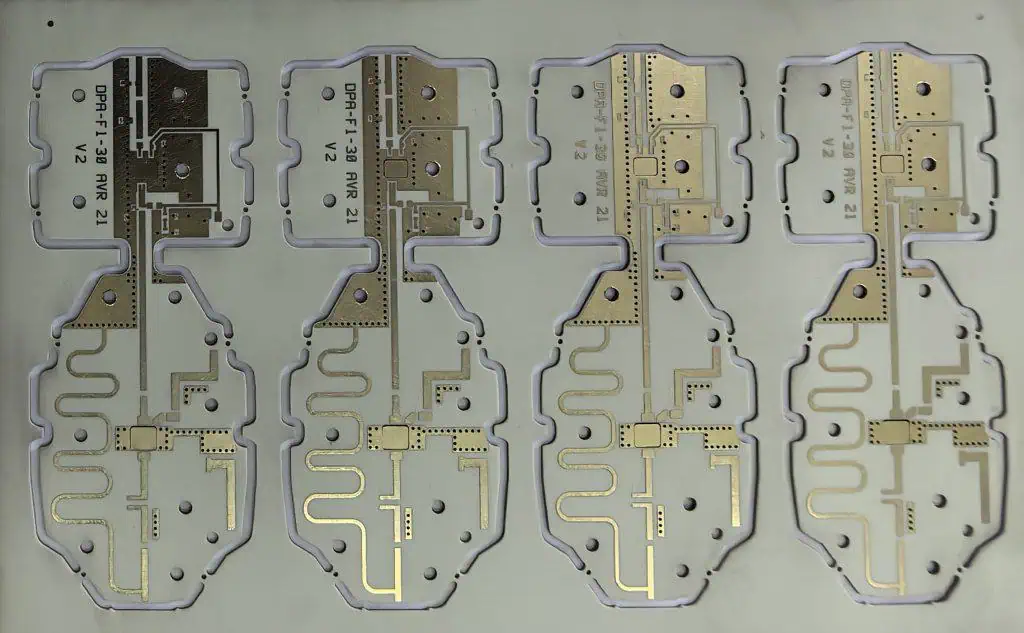

Maintaining consistent impedance throughout the PCB is crucial for signal integrity, especially in high-speed digital and RF applications. The presence of the aluminum layer can affect impedance characteristics, requiring careful design and potentially the use of impedance-controlled dielectric materials.

Effects of the Dielectric Constant on Signal Propagation

The dielectric constant of the insulating layer influences signal propagation speed and can impact timing in high-speed circuits. Designers must consider this factor when selecting materials and determining trace geometries to ensure proper signal timing and minimize reflections.

Mitigating Signal Loss and Cross-talk in Multilayer Aluminum PCBs

As with traditional PCBs, multilayer Aluminum PCB Stackups must address signal loss and cross-talk issues. The proximity of the aluminum layer can exacerbate these problems, necessitating careful layer stackup planning, appropriate use of ground planes, and strategic trace routing to maintain signal integrity.

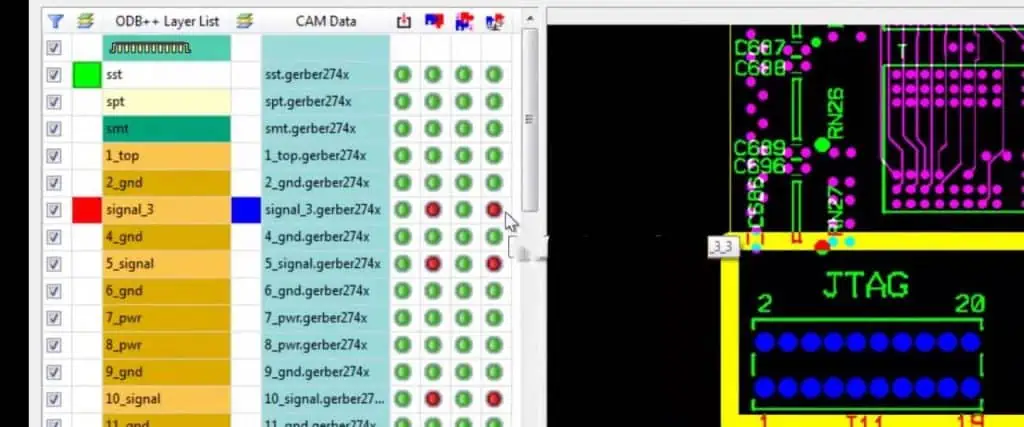

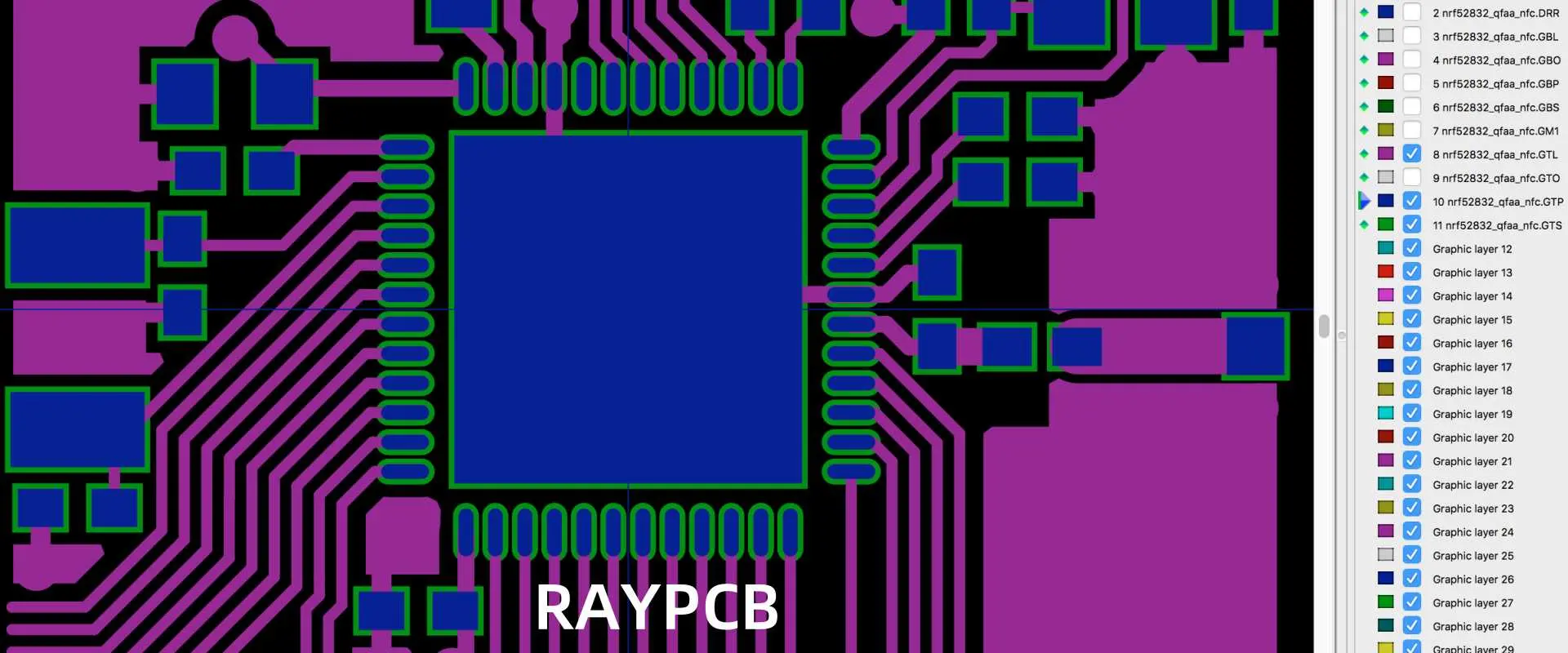

Common Aluminum PCB Stackup Configurations

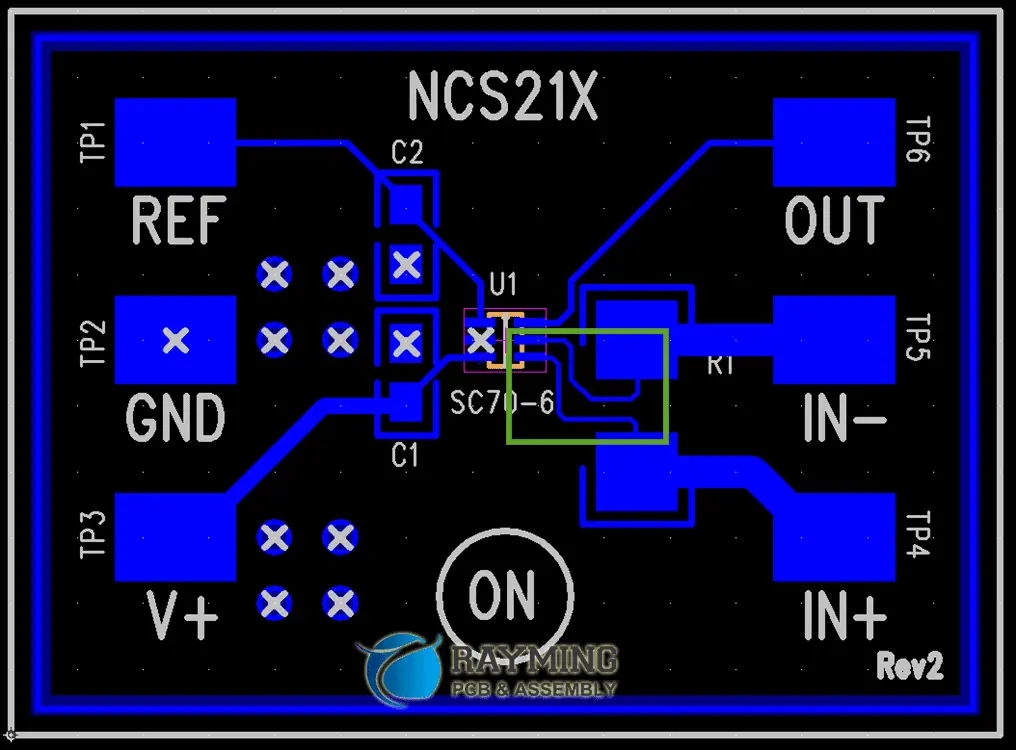

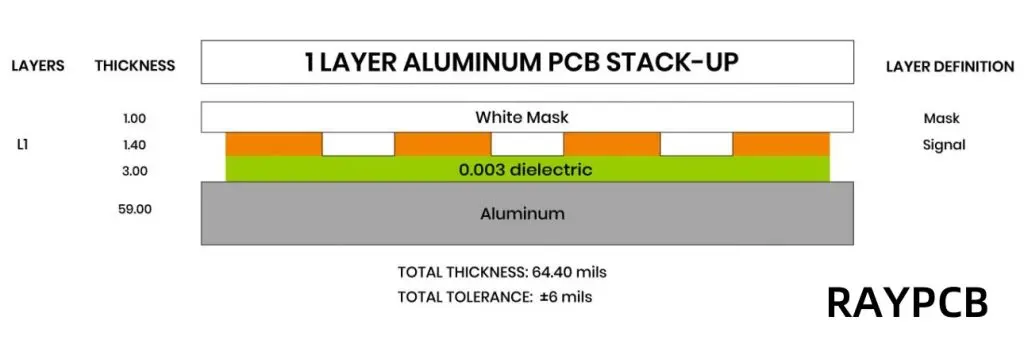

Single-sided Aluminum PCB Stackup

The simplest configuration consists of an aluminum base, a dielectric layer, and a single copper layer for circuitry. This design is cost-effective and suitable for applications with straightforward thermal requirements and low complexity.

Double-sided Aluminum PCB Stackup

This configuration adds a second copper layer on the opposite side of the aluminum core, separated by another dielectric layer. It offers increased routing flexibility and can accommodate more complex circuits while maintaining excellent thermal properties.

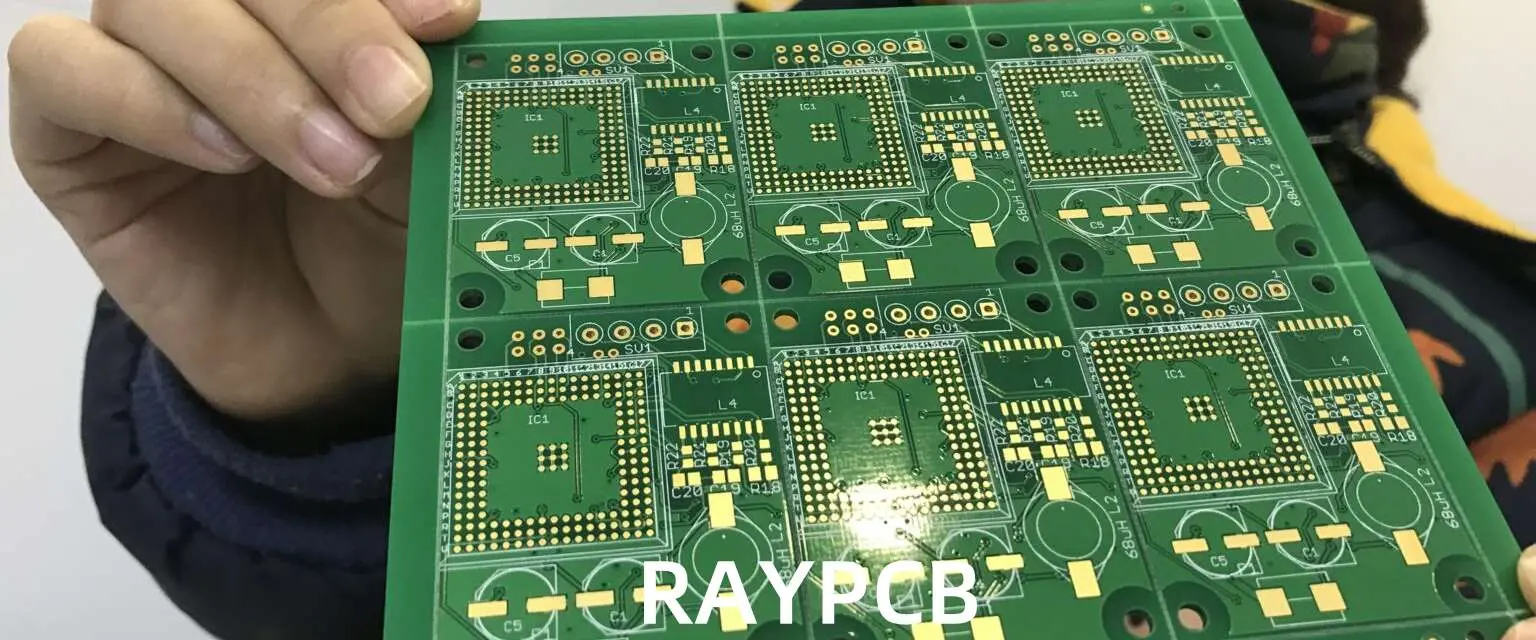

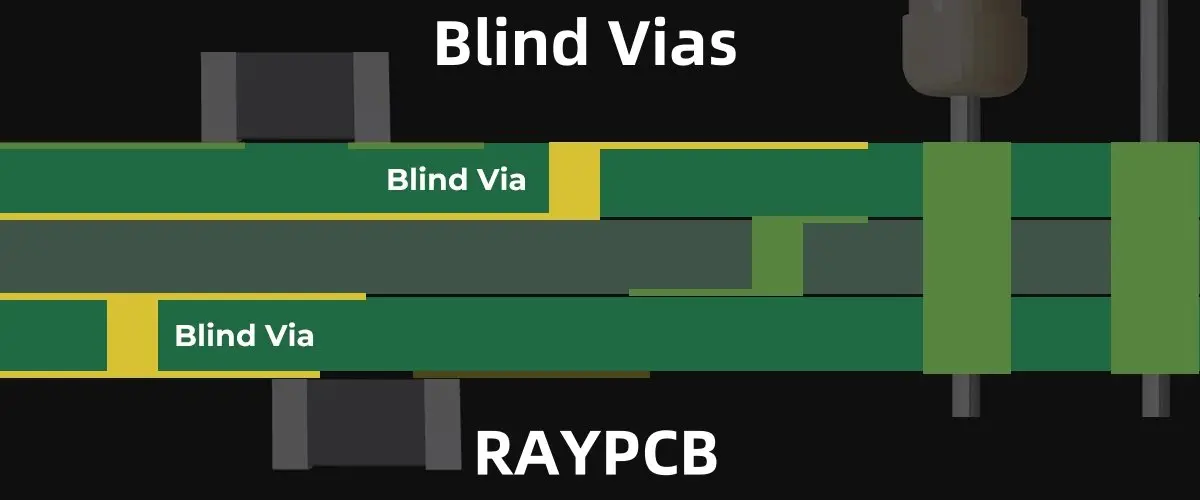

Multilayer Aluminum PCB Designs

For applications requiring higher complexity, multilayer Aluminum PCB Stackups can be created. These designs typically involve additional dielectric and copper layers built up on one or both sides of the aluminum core. Careful consideration must be given to thermal vias and layer arrangement to maintain optimal heat dissipation.

Hybrid Structures: Combining FR4 and Aluminum Layers

Some designs benefit from a hybrid approach, combining the thermal advantages of aluminum with the cost-effectiveness and familiarity of FR4. These stackups might feature an aluminum core with FR4 layers built up on one or both sides, offering a balance between thermal performance and traditional PCB design techniques.

Material Selection for Optimal Performance

Choosing the Right Dielectric Material

Selecting the appropriate dielectric material is crucial for balancing thermal conductivity and signal integrity. Materials like ceramic-filled epoxy offer high thermal conductivity but may have higher dielectric constants, affecting signal propagation. Conversely, materials with lower dielectric constants might not provide optimal thermal performance.

Copper Thickness Considerations

The thickness of the copper layers affects both electrical and thermal performance. Thicker copper can carry higher currents and aid in heat spreading but may complicate fine-pitch routing and impedance control. Designers must balance these factors based on their specific application requirements.

Aluminum Alloy Types and Their Impact

Different aluminum alloys offer varying thermal, mechanical, and cost characteristics. Common choices include Alloy 1050A for general applications and Alloy 6061 for improved strength. The selection of aluminum alloy can impact the overall performance and cost of the Aluminum PCB Stackup.

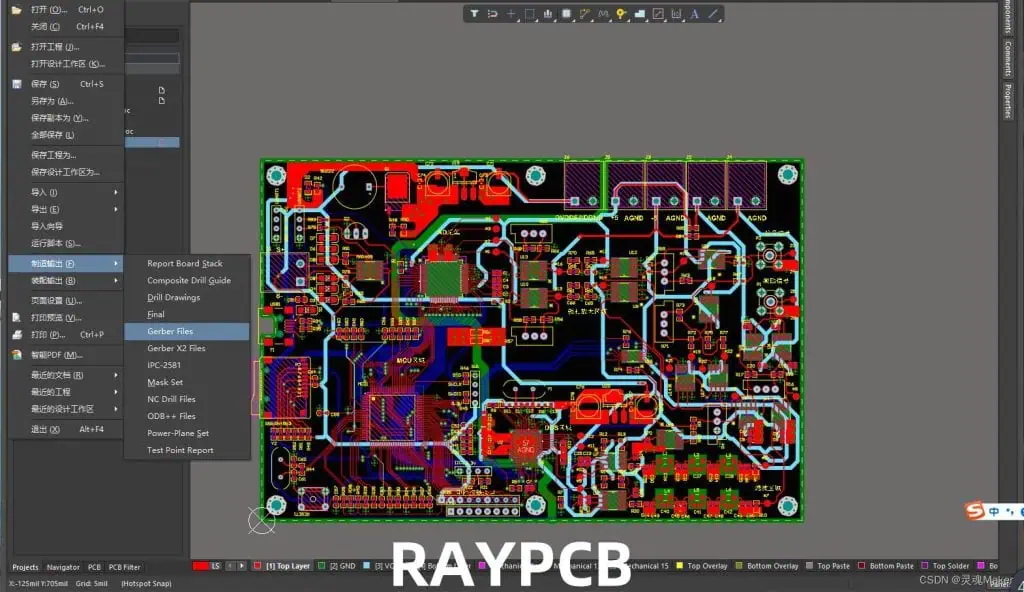

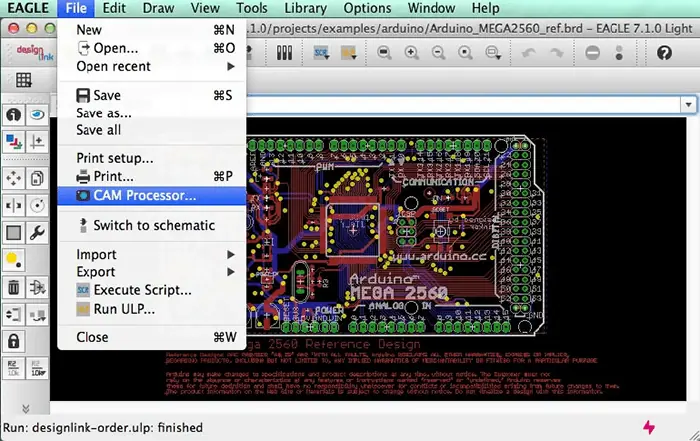

Best Practices for Designing an Effective Aluminum PCB Stackup

Thermal Simulation During Design

Utilizing thermal simulation tools during the design phase is crucial for optimizing heat dissipation. These simulations can help identify hotspots, validate cooling strategies, and ensure that the Aluminum PCB Stackup meets the thermal requirements of the application.

Via Design and Thermal Vias

Strategic placement of vias, especially thermal vias, is essential for efficient heat transfer in multilayer designs. Thermal vias provide direct paths for heat to travel from outer layers to the aluminum core, improving overall thermal performance.

Balancing Cost, Performance, and Manufacturability

While Aluminum PCB Stackups offer superior thermal performance, they can be more expensive and challenging to manufacture than traditional PCBs. Designers must carefully balance these factors, considering the entire system cost and performance requirements when deciding on the optimal stackup configuration.

Applications of Aluminum PCB Stackups

High-power LED Modules

Aluminum PCB Stackups are widely used in high-power LED applications, from street lighting to automotive headlights. The efficient heat dissipation allows for higher LED density and brightness while ensuring long-term reliability.

Automotive Electronics

The automotive industry leverages Aluminum PCB Stackups for various applications, including engine control units, LED lighting, and power converters. The combination of thermal management and mechanical durability makes them ideal for the harsh automotive environment.

Industrial Power Equipment

Industrial motor drives, inverters, and power supplies benefit from the high current-carrying capacity and thermal performance of Aluminum PCB Stackups. These attributes enable more compact and efficient power electronics designs.

RF and Microwave Devices

Despite the challenges in maintaining signal integrity, carefully designed Aluminum PCB Stackups find use in RF and microwave applications. The thermal benefits can outweigh the design complexities in high-power RF amplifiers and transmitters.

Future Trends in Aluminum PCB Stackups

Advances in Dielectric Materials

Ongoing research into advanced dielectric materials promises to further improve the thermal and electrical performance of Aluminum PCB Stackups. Materials with higher thermal conductivity and lower dielectric constants will enable even more efficient designs.

Innovations in Multilayer Aluminum Stackups

As demand for higher complexity circuits with excellent thermal management grows, we can expect innovations in multilayer Aluminum PCB Stackup designs. This may include novel layer arrangements and improved manufacturing techniques to optimize both thermal and electrical performance.

Integration with Flexible and Hybrid PCB Technologies

The future may see increased integration of Aluminum PCB Stackups with flexible and rigid-flex technologies, combining the thermal benefits of aluminum with the versatility of flexible circuits. This could open up new possibilities in wearable electronics and other applications requiring both flexibility and thermal management.

Conclusion

Aluminum PCB Stackups represent a significant advancement in PCB technology, offering a powerful solution to the dual challenges of thermal management and signal integrity. By leveraging the superior thermal properties of aluminum while carefully addressing the unique design considerations, engineers can create high-performance PCBs capable of meeting the demands of modern electronics.

As we’ve explored throughout this article, the key to success with Aluminum PCB Stackups lies in understanding their unique characteristics and applying best practices in design and material selection. Whether it’s for high-power LEDs, automotive electronics, or cutting-edge RF devices, a well-designed Aluminum PCB Stackup can provide the perfect balance of thermal conductivity and reliable signal performance.

As technology continues to advance, we can expect further innovations in Aluminum PCB Stackup designs, materials, and manufacturing processes. These developments will undoubtedly expand the applications and capabilities of this versatile technology, solidifying its place as a cornerstone of modern electronic design.

FAQs about Aluminum PCB Stackup

- What makes Aluminum PCB Stackups different from standard PCBs? Aluminum PCB Stackups feature an aluminum core that provides superior thermal conductivity compared to traditional FR4 PCBs. This makes them ideal for applications requiring efficient heat dissipation.

- Can multilayer Aluminum PCBs maintain high signal integrity? Yes, with careful design considerations. While the aluminum layer can affect signal propagation, proper stackup planning, material selection, and layout techniques can ensure high signal integrity in multilayer designs.

- How does the aluminum core thickness affect PCB performance? A thicker aluminum core generally improves thermal performance by providing better heat spreading. However, it also increases weight and can affect manufacturing complexity, so the thickness must be balanced with other design requirements.

- Are Aluminum PCB Stackups suitable for all types of electronic designs? While Aluminum PCB Stackups excel in high-power and thermally demanding applications, they may not be necessary or cost-effective for all designs. They are most beneficial in scenarios where thermal management is a critical concern.

- How do you address the differential thermal expansion in Aluminum PCB Stackups? Careful material selection, appropriate layer thicknesses, and strategic use of vias can help manage differential thermal expansion. Some designs may also incorporate stress-relief features to minimize the impact of thermal cycling.