Introduction

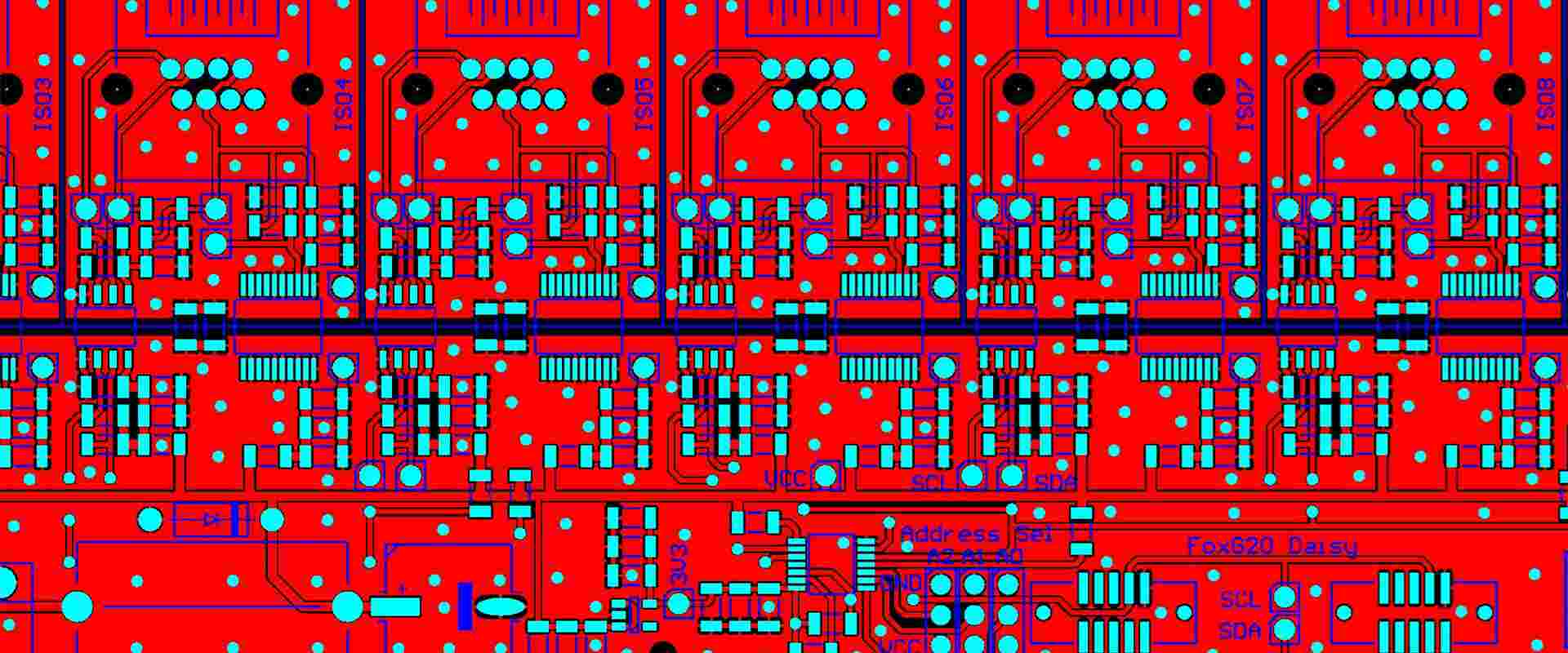

A Gerber file viewer refers to software tools that allow viewing and analyzing Gerber files containing 2D CAD data describing printed circuit board (PCB) designs. Online Gerber viewers provide the capability to upload Gerber files and visualize PCB designs within web browsers without needing to install any software.

This article covers:

- Gerber file format overview

- Need for online viewers

- Features and capabilities

- Benefits of online tools

- Top online Gerber viewers list

- Using online viewers effectively

- Limitations to consider

- The future of online tools

Understanding online Gerber file viewers enables PCB designers to efficiently inspect designs, communicate with manufacturers and speed up prototyping iterations.

Gerber File Format

Gerber files are the standard file format used to transfer PCB design data between CAD software and PCB manufacturing equipment like photoplotters. Some key points:

- 2D vector image format representing PCB layers

- Contains PCB outlines, copper traces, pads, holes

- Developed by Gerber Systems decades ago

- Extensively used in PCB industry workflows

Types of Gerber files

- Copper layers – Top, bottom, internal layers

- Soldermask layers – Top, bottom

- Silkscreen layer – Legends, symbols

- Solder paste layer

- Drill files – For holes

Gerber files are exported layer-wise from PCB design software like Altium Designer or KiCad before manufacturing. Each layer describes a unique aspect of the PCB design data.

Need for Online Gerber Viewers

Sharing PCB designs with manufacturing partners worldwide requires sharing large Gerber files containing the intricate board details. However, transferring and then viewing these files on local CAD software is cumbersome. Online Gerber viewers provide a quick and easy way to visualize the design and collaborate by:

- Allowing uploads of zipped Gerber folders or individual files

- Rendering 2D previews of the PCB instantly

- Enabling sharing accessible links with the hosted view

- Visualizing from any device without software downloads

- Inspecting specifics with pan/zoom capabilities

This makes online viewers indispensable tools for PCB designers aiming to speed up design reviews, manufacturing discussions and prototyping iterations.

Features of Online Gerber Viewers

Online Gerber viewers offer a suite of features for comprehensive PCB visualization and inspection:

Multi-layer Preview

- View individual inner and outer layers

- Switch between layers

- Adjust layer transparency

Measurements

- Check dimensions and distances

- Analyze spacing between tracks and pads

High Resolution Rendering

- Sub-micron accuracy

- Captures fine features and geometries

Annotation Tools

- Draw, add text, shapes on layers

- Collaborate with annotations

Cross-section View

- Visualize multi-layer stackup

- Inspect construction and vertical interconnects

3D View

- Realistic 3D rendering of PCB

- View component placement

BOM Extraction

- Recognizes components for bill of materials

- Exportable BOM spreadsheet

Design Rule Checking

- Automated DRC runs

- Highlights potential violations

File Conversion

- Output edited files in PDF, image formats

Sharing and Collaboration

- Share links with views for feedback

The range of analysis, inspection and collaboration features offered make online tools invaluable for optimizing PCB designs before manufacturing.

Benefits of Online Gerber Viewers

Online Gerber viewers provide powerful advantages:

Easy Sharing

- Hosted views allow sharing PCB design details with anyone instantly

Accessibility

- View designs and collaborate from anywhere through browsers

Ease of Use

- No need to install complex PCB software locally

Time Savings

- Significantly faster design reviews and vendor discussions

Enhanced Visualization

- Zoom into finest routing details for clarity

Team Collaboration

- Annotate and share feedback on hosted views

Manufacturing Insights

- Get assembly feedback from manufacturer teams

Cost Reduction

- Avoid multiple PCB design iterations and corrections

Design Validation

- Thoroughly inspect designs prior to fabrication

By facilitating instant PCB visualization and feedback online without software hassles, significant time and cost savings can be achieved during product development.

Top Online Gerber Viewers

Many free and paid online Gerber viewers provide capabilities for PCB inspection. The most popular choices are:

Gerber-Viewer.com

- Free online viewer with basic PCB viewing features

- Good rendering but lacks advanced capabilities

ViewMate

- Basic layer viewing along with annotations

- Limited collaboration features

JustGerb.com

- Free online tool with good visualization

- Email sharing and simple measurement

Tracespace Viewer

- Advanced 3D rendering engine built on WebGL

- Capabilities like DRC, BOM, step-and-repeat

CircuitHub

- Feature-rich online viewer integrated with PCB services marketplace

- Design reviews, quotes, orders managed through platform

Altium 365 Viewer

- Tightly integrated with Altium Design tools

- Enables real-time design collaboration

PCBWeb Viewer

- High performance online viewer tailored for fabrication needs

- Extensive layer control and visualization options

The ideal choice depends on specific workflow needs ranging from basic sharing to tight design tool integration.

Using Online Gerber Viewers Effectively

To leverage online Gerber viewers optimally for PCB needs:

Prepare Files

- Export separate Gerber files for copper layers, soldermask, silkscreen, drill and routing

Check Plot

- Always cross-verify exported layers against design software plot

Upload Relevant Layers

- Avoid uploading irrelevant auxiliary layers

Inspect High Resolution

- Zoom into routing layers to check track widths and spaces

Leverage Layer Control

- Isolate or switch off layers for clarity as needed

Use Annotation

- Add shapes, text to highlight areas of interest

Capture Images

- Use screenshot tools to save images of key areas under review

Enable Design Reviews

- Share hosted view links with fabrication partners

Iterate Rapidly

- Use online inspection to quickly finalize designs

Employing online viewers strategically helps identify issues early, enables collaborative reviews and reduces overall design cycles.

Limitations of Online Gerber Viewers

Despite immense capabilities, online Gerber viewers also have certain limitations:

- Lack advanced PCB editor features only available in full desktop CAD tools

- May not render some component 3D models or pad shapes accurately

- DRC checks may not be as exhaustive as desktop tools

- Annotation capabilities are limited compared to design software

- Can handle moderate sized designs but very large boards can get slow

- Proprietary data not fully secured compared to local viewers

- Require active internet connection unlike standalone tools

Online tools complement but cannot fully replace advanced desktop PCB design software yet. Secure data transfers and downloads are recommended for proprietary designs.

The Future of Online Gerber Viewers

Online Gerber viewers are expected to evolve with:

- Enhanced Real-time Collaboration – Allow multiple stakeholders to visualize and annotate PCB designs seamlessly in real-time.

- Augmented Previews – Offer augmented layer previews combining 2D, 3D and x-ray views for enhanced visualization.

- Design Editing – Move beyond just visualization to limited PCB editing capabilities.

- Deeper CAD Integration – Tighter integration with popular PCB design tools for seamless workflows.

- Advanced DRC – Faster and more sophisticated design rule and electrical checking algorithms.

- BOM Integration – Intelligent data extraction to build component lists and Bom directly online.

- Manufacturing Integration – Close integration with manufacturing through ordering and production tracking.

- Scalability – Ability to handle larger designs, higher data volumes as internet speeds increase.

As online tools gain more sophisticated capabilities, they are poised to become integral hubs connecting PCB design, analysis, collaboration, manufacturing and production workflows in the future.

Conclusion

Online Gerber viewers provide a quick and easy way to visualize, inspect and collaborate on PCB designs through an accessible online platform. They fill a vital need in electronics product development by facilitating rapid design reviews, discussions with manufacturers and speeding up iterations required before finalizing board fabrication. While lacking advanced editing features of full desktop tools, online viewers in their current form complement design software through key capabilities like multi-layer previews, annotations, measurements, screenshots and online sharing. With continual improvements in real-time collaboration, augmented views, design rule checking and deeper integration with PCB CAD, online Gerber viewers hold immense potential to enhance and integrate the electronics development workflow.

What is Online Gerber File Viewer? – FQA

Q1. What file format do Gerber viewers allow inspecting online?

Gerber viewers enable viewing Gerber files – the standard file format for transferring PCB design data to manufacturing containing 2D CAD information of the board.

Q2. What are the key advantages of online Gerber viewers?

Benefits include easy online sharing, accessibility through browsers, quicker design reviews and collaboration, rapid iterations and avoiding multiple board fabrication cycles.

Q3. What are some examples of popular online Gerber viewers?

Top online Gerber viewers are Gerber-Viewer.com, ViewMate, JustGerb.com, Tracespace Viewer, CircuitHub Viewer, Altium 365 Viewer and PCBWeb Viewer.

Q4. What are some limitations of online Gerber file viewers?

Limitations are lack of full editing features in desktop tools, inability to handle very large designs, lower data security than local viewers and need for active internet connection.

Q5. What future improvements are expected in online Gerber viewers?

Future advances include enhanced real-time collaboration, augmented layer views, limited editing, tighter CAD integration, advanced DRC/DFM analysis and closer manufacturing workflow integration.

How to find and use an Online Gerber viewer

Viewing modes

You can open the PCB online Gerber file viewer with PCB editor software in two modes: online or offline.

In online mode, you can open the software directly from the PCB editor software. The two are running at in same time. You can use them independently or each other for cross-checking purposes. For example, you can view the Gerber file in PCB editor software, change some information and then switch to online Gerber viewer to review how it affects the Gerber file. You can also check how your layout looks like after printing it out. Or you can do all three at the same time. You can save the layout to an external file (it is handy if you need to modify/edit it in another software) and then reload it to PCB editor software.

You must open the Gerber file with PCB editor software offline, then open the online Gerber viewer application separately. We use them independently, but no communication between them. Once you complete your layout in the PCB editor software, you can save it in Gerber file format. Then launch the online Gerber viewer application to view and check your layout in the Gerber file. It is also handy if you need to modify/edit it in some other software.

The following sections will show you how to use both modes, step by step.

Step 1: open PCB online Gerber viewer with PCB editor software

(1) Online mode:

- Launch the PCB editor software you are using and load a Gerber file to open the layout

- Go to view>More>Online Gerber Viewer, click it to launch it

- The system will display the layout in the online Gerber viewer

(2) Offline mode:

- Launch the PCB editor software you are using and load a Gerber file to open the layout

- Optional: use the Plus icon to create a new folder and name it as you like

- The system will display the in the online Gerber viewer

(3) Close online Gerber viewer:

- Right-click the item highlighted in the following screenshot and selected Close from the popup menu

- You will see the Gerber file in offline mode in PCB editor software. You can edit it there

Step 2: edit specs online

- Select Online Gerber Viewer>Edit>Edit Spec to edit the single layer, multi-layer, Excellon drill file, or screen dump data.

- You can use the following options to change any information you want:

The option arrow keys will allow you to zoom in for more details, so you can see exactly where it needs modification.

Step 3: print out the modified Gerber file

- Select Online Gerber Viewer>File>Print, set printing options.

- The system will print out the modified Gerber file automatically. Before printing, check if there is enough space on the paper to print it out, or you need to adjust page size in your printer driver settings.

- We will refer the virtual printer to as “Gerber Viewer” by default, but you can change it to whatever you like in the Printer name:

- The system will print out the Gerber file on paper:

- The Gerber viewer automatically connects to the directory of the Gerber file on your computer and shows you the image of the printout:

- Close online Gerber viewer:

- Right-click the item highlighted in the following screenshot and select Close from the popup menu:

- Note down your modified Gerber file in a location you can find it easily later.

- Transfer your modified Gerber file to the PCB editor software, open it to review it.

Layout mode

2D Layout Viewer

You can open with online gbl file Viewer in the 2D layout view. It is useful to view your layout on a two-dimensional plane, without the PCB design software, by just using an online Gerber viewer. To do so, go to file>View>Online Gerber Viewer>2D Layout Viewer.

This view works similarly to Windows Paint, where you can draw lines and shapes with your mouse. If you have been making PCB layouts for a while, then this will be familiar to you. You can change the background color with the checkbox in view>Color>Back; enter a color code there.

The user interface is simple and easy to use. You can drag the screen around to look at the layout from different angles. You can also right-click on the screen or any object and select various options from the popup menu.

3D view

You can use a 3D Gerber viewer to see your design from all angles in this model. To enter 3D view, go to view>3D View or press the F3 key. You can use Alt+Arrow keys to pan around the screen, scroll up/down using the up/down arrow keys on the keyboard and rotate by pressing the left/right mouse button on it.

Zoom

Zooming in and out was a common function in the past. In 2D, you can use Ctrl-Z and Ctrl-Z to zoom in/out, respectively. In the 3D view, you can use the mouse wheel to zoom in, the Ctrl+Plus key to zoom out, or the Alt+Plus key to reset. You can also enter the value through the keyboard by pressing NumLock once and the letter you want to change next time.

Projection

This function works in the 3D mode that you can use to create a perspective view of your PCB layout. To enter projection view, go to view>Projection. If you want to restore the default setting, go to Projection>Preset and select default (keep existing settings).

The zoom must be off when entering projection view. You need to switch it on after entering the new settings.

Snap to Grid

You can superimpose the grid over your layout to make drawing the tracks easier. The grid is not visible when working directly on the design, but you will see it in editing mode or viewing the design. It is useful for making sure your track widths and spacing’s meet their manufacturing tolerances. To set up a grid:

- Go to view>Grid and select Grid (in v0.16, the grid is not available by default, you need to select it from view>Grid menu or View>More>Grid). It will add a blue grid line to the layout.

- To remove the grid, repeat step one but choose Grid (Off) instead.

- If you have made changes to your layout and want to view them again with a grid on, go to view>More>Grid and select Grid (Recalculate).

- To change the size of your grid, go to view>Tools. There are many sizes available. If you want to calibrate your grid, go to view>Tools>Calibrate grid.

- The grid display will only update if you zoom the view in or out or change your layout.

You cannot edit the directly in the design view. 2 ways are available to do it:

- Use view>Snap to Grid command to overlay a grid over the design.

- Use the Traces command to draw a rectangular grid that you can edit. The grid cells will appear as you draw and will also appear when you turn off the grid.

You must draw the rectangle within your design view. It must completely fit within the boundaries of your layout (not outside and not overlapping any object). It cannot extend past the last line or first line of the design.

Alignment

This function is useful for aligning objects on the same layer in the same direction. To align something vertically, choose View>Alignment and select Vertical or Horizontal. For horizontal alignment, choose View>Alignment and select Horizontal. To align objects in an angle to cross each other, select view>Alignment, select Angle or Normal, and click on your track or object. You can use our button to do it.

The define button is at the bottom of this dialog. You can click on the button to open the following dialog:

Line up two grids with each other. The first grid is the one that goes through your reference point. Suppose you want to align objects vertically or horizontally with each other, drag-and-drop one of them into the first column. Then drag the second object into any column, and click the Match with First/Second Grid button if needed.

The Angle alignment is useful when you want to align objects at an angle to cross each other. For example, making a wire track on the bottom layer with 45-degree alignment will cross another wire track on the top layer.

Import Layout

If you are working on another layout in the PCB editor, I recommend you import your layout with this function to check your design easily. To import your layout, go to file>Import Layout. The ‘Import Layout’ dialog will appear. Then go to the directory where you saved your design and select the file.

Export Layout

You can export your layout in Gerber or Import it into another PCB editor with this function. To export, go to file>Export Layout… The ‘Export Layout’ dialog will appear. Select the target directory where you want to save it, then enter a name for your file in Output File. You can also select the output format through File Format.

Snap Resolution

The resolution determines the minimum increment that tracks. You can change it by going to view>Tools or enter a value for this parameter directly into the toolbar. Set this value in one mil (1/1000 inches). The default setting is one mil, and there is no other significant increment. The highest possible setting will be 0.0187” (8 mils).

Draw Mode

To switch between the various drawing modes, go to view>Draw Mode. There are also options for scaling the view. The choices are Independent or Relative scaling. With independent scaling, you scale each object separately to see whether they are in proportion to one another easily. Relative scaling scales everything according to its distance from the viewport (the boundary around your layout) and does not take objects into account that are outside of it (i.e., off-screen).

To switch to a different drawing mode, check the appropriate checkbox above the list, and select a drawing mode from the drop-down menu. There are also options for scaling the view. The choices are Independent or Relative scaling. With independent scaling, you scale each object separately to see whether they are in proportion to one another easily. Relative scaling scales everything according to its distance from the viewport (the boundary around your layout) and does not take objects into account that are outside of it (i.e., off-screen).

Line Style

To change the line style, go to view>Line Style. There are many types of lines available. Please visit view>Line Style for details.

Text Style

To change the text style, go to view>Text Style. There are three text styles available, each with different options. For more information on how to use them, refer to the Text section of this tutorial.

Hatch Pattern

To change the hatch pattern, go to view>Hatch Pattern. There are many types of hatch available. Please visit view>Hatch Pattern for details.

Layer

To change the layer, go to view>Layers or click on the Layer button in the toolbar. The layers dialog appears, then you can use it to switch between layers, set the layer color and properties.

Layer Color

You can use the view>Layer Color command to change the color of your active layer. The Layer Color dialog appears, then you can choose either Solid Color or Gradient. If you choose Gradient, you need to set Start and End colors.

Layer Properties

In the layers dialog, you have a list of all your layers. In there, you can check the color for your layer. If you click on the triangle beside the layer name, a dialog will appear where you can set properties for your layer. You can set Layer Name, Description, Orginal Size, and Position.

PCB online Gerber viewer supports PCB editing functions. It includes cube selection, layer stacking determination, wiring management, data transmission line generation, hole drill generation, and auto-printing.

PCB online Gerber viewer supports drag-and-drop, which makes the different editing functions very convenient.

PCB online Gerber viewer supports hotkeys for easy access and quick operation.

Online PCB Graphic Tool

A PCB fabrication service company has developed an online PCB graphic tool with a very simple user interface. This tool allows you to view your Gerber files anytime and anywhere you go, with the facility of storing them on the company’s live web page. It is just a normal jpeg image file that you have uploaded to the web pages. You can also download the Gerber viewer free of charge. Working with global manufacturers such a RayMing PCB and Assembly will help ensure that your product will be up to standard since they are using some of the best tools as Gerber viewer.

To open your Gerber file, first, you should download it from your PCB manufacturer or reseller. Then open the Gerber file with GERBER_FILE_WIZARD. To open the dialog, you need to go to file>Open. The ‘Open’ dialog will appear. If you have already downloaded your Gerber file, select the directory where you stored it and enter its name into File Name. Then click on Open

To view your Gerber file, first, you should create a file, then open the Gerber file with GERBER_VIEWER. To open the dialog, you need to go to file>Open. The ‘Open’ dialog will appear. If you have already created a file and opened the Gerber file in it, click on Open.

Gerber Viewer

Gerber Viewer is an editor for viewing Gerber files which one writes in C++. It is a cross-platform tool, so it will support all platforms, including Linux and Mac OS X. You can view your Gerber files online instantly after downloading the Gerber file from your PCB manufacturer or reseller. Just click the button, and the Gerber file will appear in your browser. You can then download it or save it into your local system.

There are free online Gerber viewers who support viewing both single and multiple Gerber files. You can view these files very easily after you have downloaded them from your PCB manufacturer or reseller. You can drag the file onto the window. If you want to zoom in, double-click the window, or use [Ctrl] [Mouse wheel].

Online Gerber Viewer

You can view your Gerber files in this tool anytime and anywhere you go, once you have captured them with your camera or scanner, and then uploaded the image to their website, where they have a special section for PCB design projects.

The first two are free online Gerber viewers that allow you to view your Gerber files anytime and anywhere you go. After you have captured them with your camera or scanner, upload the image to the website and then view them at any time.

Eagle CAD

Eagle is a combined schematic and layout editor and is part of the Electronics Workbench (EWB) suite (www.electronics-workbench.com). Working with schematics and boards in Eagle breaks down into three steps: creating a new design, modifying it, or backing it up for later editing.

Eagle CAD Block Editor

It is a free online component editor by Universal Devices Inc. that makes a wide range of embedded system products, including the MAX232 serial I/O IC, MAX4630 temperature sensor IC, and MAX6675 absolute temperature sensor IC. So you can use this block editor to view your Gerber files at anytime and anywhere you want as it supports both viewing and editing of these files and viewing of schematics and boards made by them too.

Eagle CAD Block Editor can view the schematics and boards created by Eagle CAD.

This component editor can easily view the Gerber files edited by Eagle CAD as it automatically supports viewing of edited Gerber files.

SparkFun

The schematic capture and board layout software used in the SparkFun Electronics open-hardware library is OpenOffice OrgChart (www.openofficeorgchart.org). It is a schematic capture and board layout software developed by OrgChart Team for editing and drawing organization charts. This tool does not support Gerber file viewing, but it supports the open-source Gerber file format, which is not viewable in most tools or online viewers.

Eagle Library

There is an online library for eagle parts called eagle lib (www.eaglelib.net). It is a library of Eagle parts and contains 3D models for many components. You can view your eagle parts anytime and anywhere you go. Once you have captured them with your camera or scanner, you can upload them to this site.

This library also hosts the eagle file format (EAGLE), used to store board designs made in Eagle. This library supports many different PCB manufacturers and PCB designers too.

Thus, this library will also store your Gerber files if you mark them in EAGLE file format.

DesignSpark PCB

There is an open-source PCB design software called DesignSpark PCB (www.designsparkpcb.com). You can easily create your designs with drag and drop components and then export them into DXF files compatible with many PCB manufacturers.

You can easily view the Gerber files created by DesignSpark PCB by Sparkfun, Eagle CAD, and eagle lib.

But it is challenging to view them in most online tools or website viewers because Sparkfun, Eagle CAD, and eagle lib support the open-source Gerber file format, which is not viewable in most tools and website viewers.

Max + MBE + BEE

Max is a programming language created by MIT which helps create interactive applications. The development environment uses the Processing language library, which depends on Java.

We can find Max on many different sites, but the best one is the original site designed to teach programming to artists and non-technical people.

The online version of Max is an interactive board editor released under the GNU GPL. It uses the Processing language library, which depends on Java.

Processing

Processing is a programming language created by MIT which helps create interactive applications. The development environment also uses the Processing language library, which depends on Java.

We can find Processing in many different sites, but the best one is the original site designed to teach programming to artists and non-technical people.

Conclusion

The future of PCB design and manufacturing requires the use of open-source Gerber files. They will allow anyone to share their designs with anyone else and provide a way to view those designs for those who don’t have the right equipment or software. The ability to share Gerber files means anyone can create and view open-source PCBs.

To create a new design, you must view the Gerber file, part of your design. Without Gerber file viewing in CAD tools, it won’t be easy to develop new designs.

The old way of storing the Gerber files on a website is no longer a good solution as most people only have access to a few websites. If a person wants to view your Gerber files, they must know where they are and how to look for them.