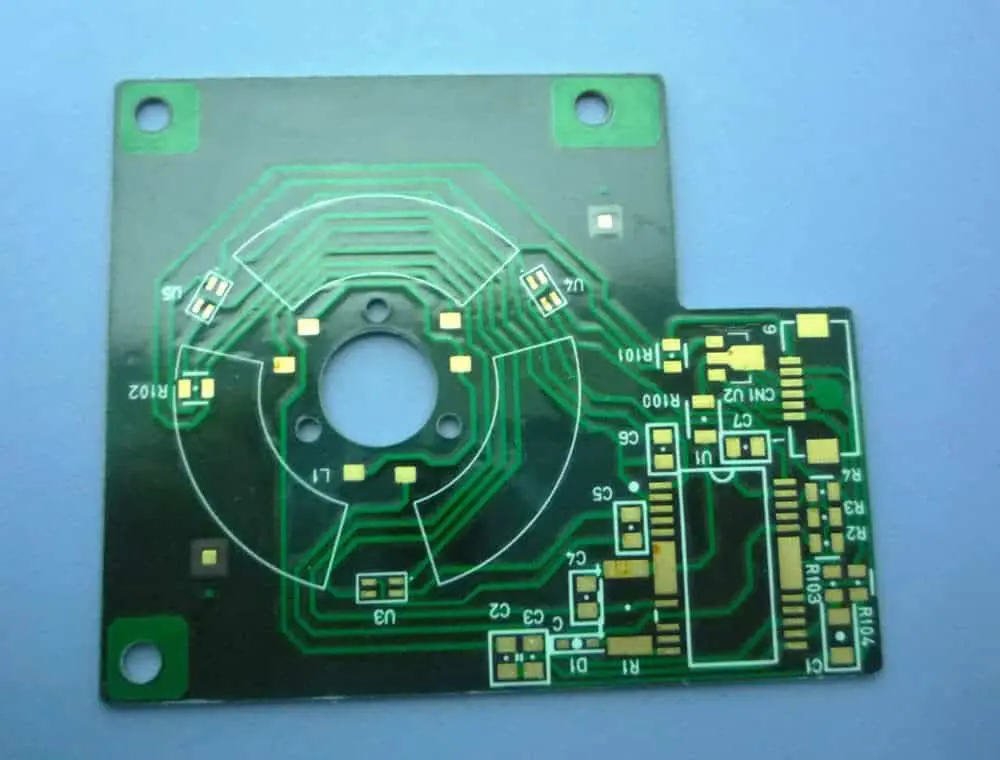

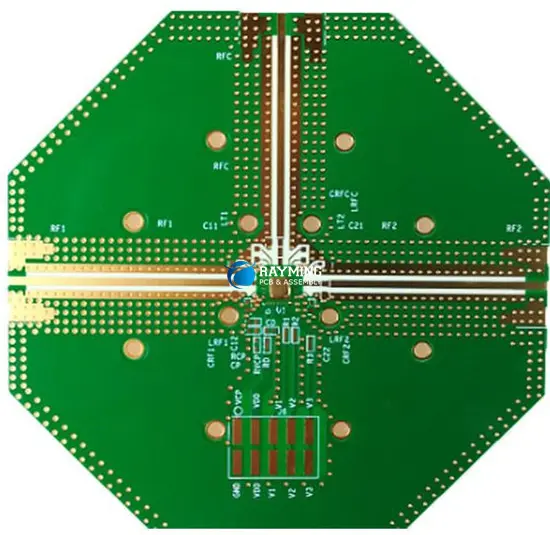

12 Layer Rogers + Fr4 PCB Multifunctional integrated copper plate

Layer : 12 layer pcb

Board thickness: 2.6mm

Copper thickness :1oz

Material: Rogers 4350B+FR4

Type: Metal Base Power Amplifier Board

Technical features: Integrated design

Local mixed pressure

PCB buried I/U copper

Control deep power amplifier

Uses: wireless communication base station

Need 12 layer pcb board stackup suggestion, pls contact us

Introduction

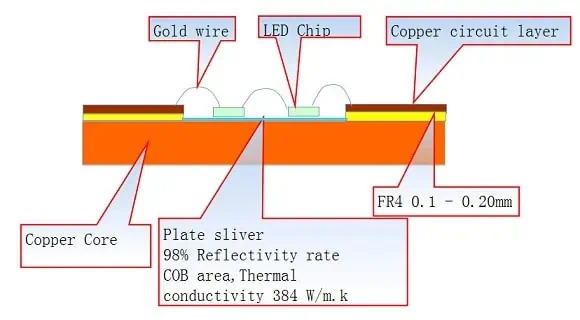

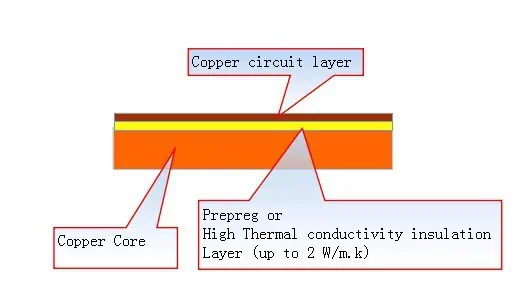

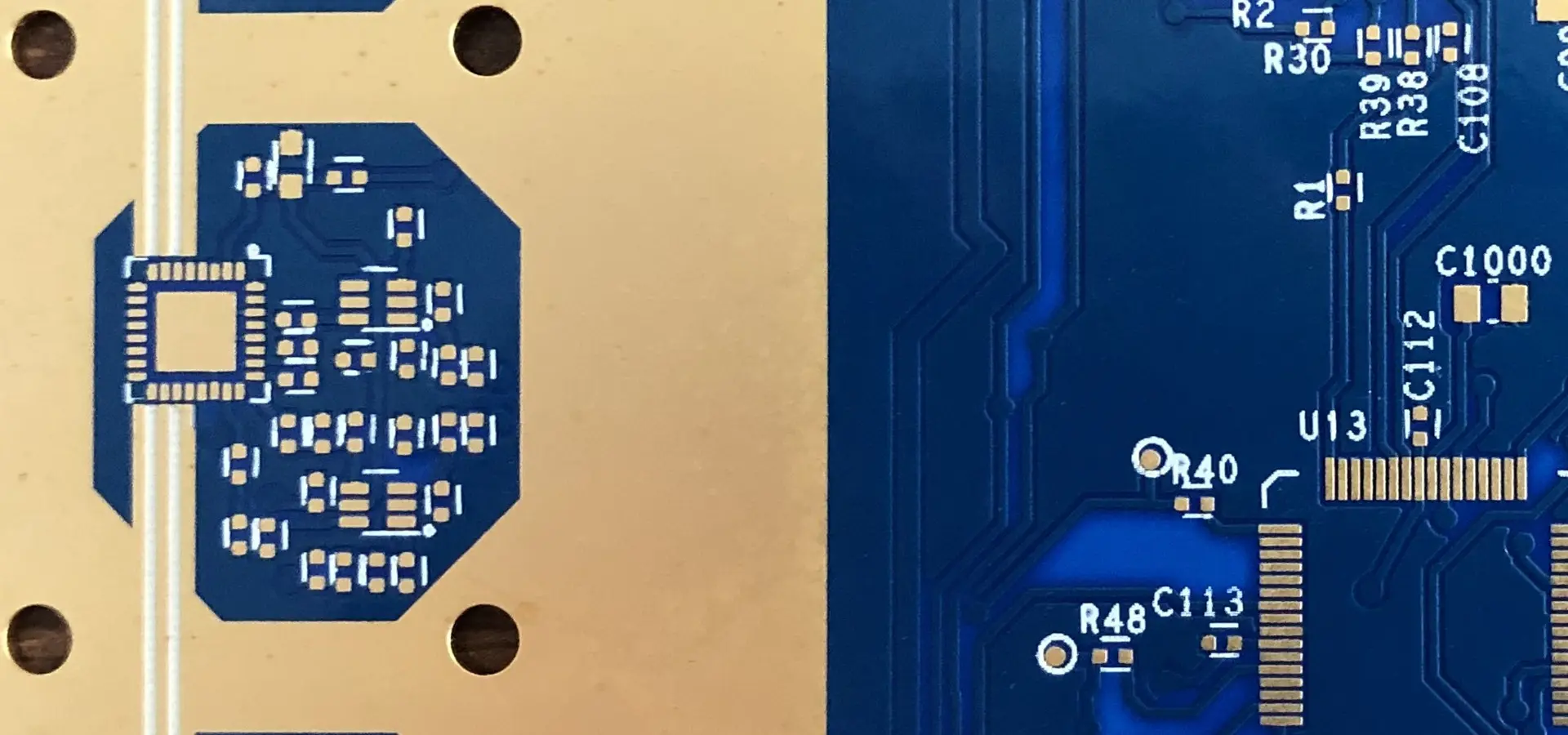

High performance and complex PCB designs often involve combining different laminate materials within a single circuit board stackup. A popular hybrid configuration uses standard FR-4 glass epoxy along with high frequency Rogers dielectric material in specific layers.

A 12 layer hybrid PCB with Rogers laminate and FR4 allows optimizing electrical performance and cost. This article provides an overview of hybrid 12 layer PCB stackups with Rogers and FR4 covering design, material selection, fabrication, applications and cost considerations.

Benefits of Rogers + FR4 Hybrid PCBs

Key advantages of using Rogers laminates selectively in a 12 layer FR4 PCB:

- Signal Integrity: Provides tightly controlled impedance for high speed signals on Rogers layers

- EMI Reduction: Rogers material has lower loss which improves signal quality and reduces EMI

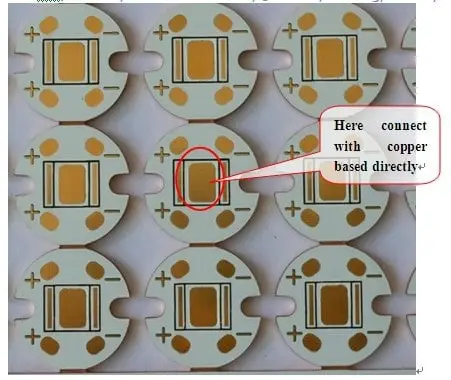

- Thermal Management: Higher thermal conductivity dissipates heat from high power components

- Mechanical Stability: Rogers material has a lower Z-axis CTE providing enhanced structural stability

- Selective RF Performance: High frequency analog circuits can be fabricated on Rogers layers

- Cost Savings: Using Rogers only in essential layers with FR4 for rest reduces cost versus full Rogers stackup

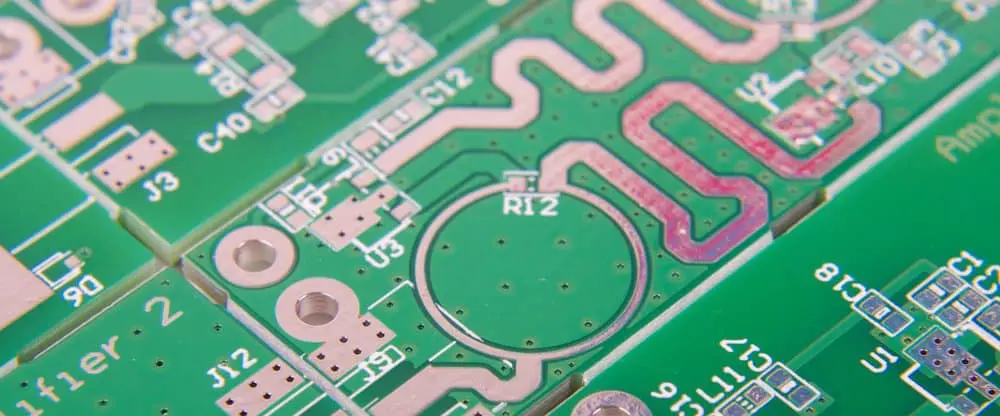

Typical Stackup Configuration

A common 12 layer hybrid PCB stackup configuration is:

- L1 to L4: FR-4 Dielectric

- L5: Rogers 4350B Dielectric

- L6 to L11: FR-4 Dielectric

- L12: Rogers 4350B Dielectric

The higher performance Rogers 4350B material is used in the critical signal layers at the center of the stackup while standard FR-4 handles the rest of the routing.<img src=”https://drive.google.com/uc?export=view&id=1PUosbPyuqbxT-ShQLuKNy Tem5MCyA4GX” alt=”Rogers FR4 Hybrid Stackup” style=”width:300px;height:400px;”>

The exact layer distribution can be adjusted based on high speed and RF routing needs. Additional Rogers layers can be added near the surface for RF components requiring tight impedance control. Simulations help optimize the hybrid stackup configuration.

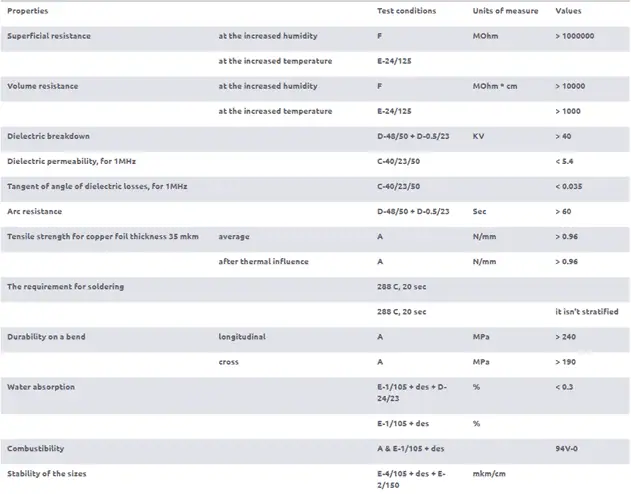

Rogers vs FR-4 Material Properties

Rogers 4350B offers better electrical and thermal performance than FR-4 but at a higher cost:

| Parameter | Rogers 4350B | FR-4 |

|---|---|---|

| Dielectric Constant | 3.66 | 4.5 |

| Loss Tangent | 0.0037 | 0.02 |

| Impedance Tolerance | ±5% | ±10% |

| Glass Transition Temp | >280°C | 130°C |

| Thermal Conductivity | 0.69 W/mK | 0.3 W/mK |

| Coefficient of Thermal Expansion | 40 ppm/°C | 14-18 ppm/°C |

| Moisture Absorption | 0.04% | 0.2% |

| Lead-free Process Compatible | Yes | Yes |

| Relative Cost | High | Low |

Rogers RF laminates allow reliable performance for circuits up to 77GHz. They are available in a range of dielectric constants from 2.2 to 10.2 to suit different applications. Popular alternatives are Rogers 4003C and 5880.

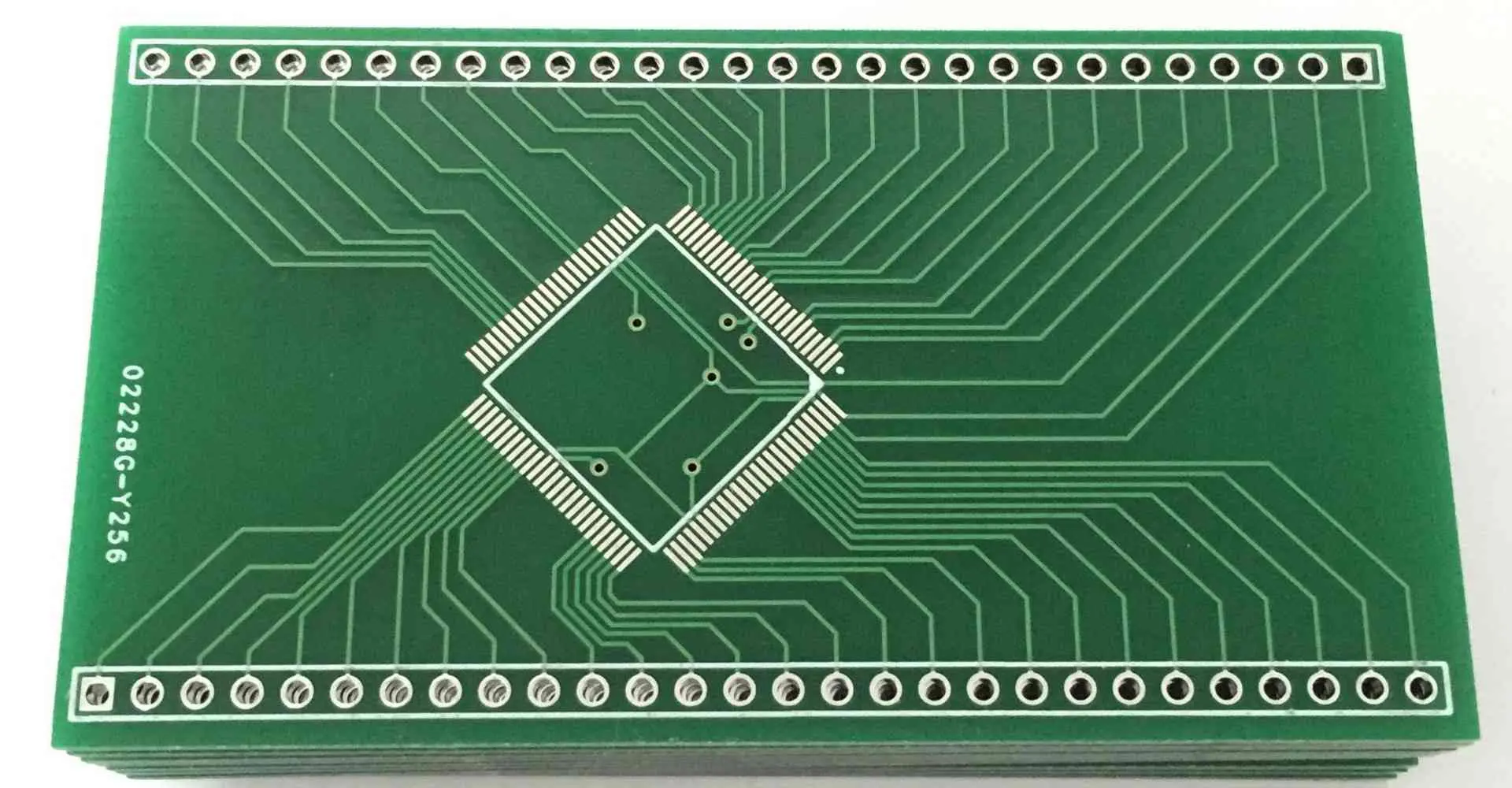

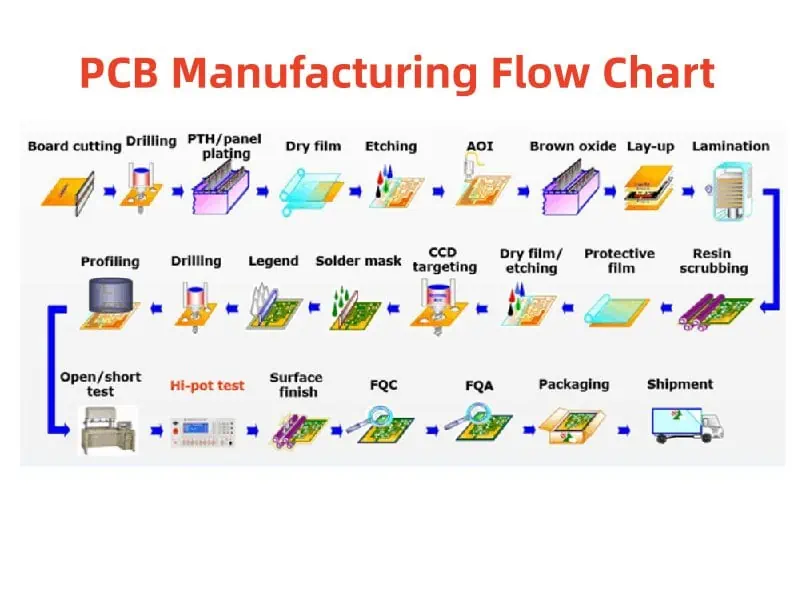

Hybrid PCB Fabrication Process

Fabricating a hybrid multilayer PCB with dissimilar materials involves additional steps compared to standard FR-4 boards:

- Materials from different suppliers are qualified for compatibility

- Separate layup stacks for Rogers and FR-4 multilayers

- Adhesion enhancers added at bonding interfaces

- Modified lamination profile to account for property mismatches

- Buried via formation requires staggered drilling and plating

- Multiple alignment steps are required when combining layers

- Bevel cutting bit used to avoid corner cracking

- Expanded testing to validate electrical performance

Only manufacturers with experience in hybrid constructions should be chosen to mitigate the fabrication risks.

Design Guidelines

Some key design aspects for hybrid Rogers + FR4 PCBs:

- Layer sequence: Order from middle outwards should progress from better to poorer performance

- Interfaces: No components recommended to straddle Rogers-FR4 junctions

- Transitions: Follow impedance transition rules when traces move between materials

- Thermal density: Spread heat generating components across layers to avoid hotspots

- Via transitions: Use annular rings when changing materials to avoid cracking

- Testpoints: Include pads on both Rogers and FR4 layers for characterization

- RoHS compliance: Both materials qualified for lead-free assembly

Simulations should account for the different dielectric constants between laminates while verifying impedance, timing, power integrity and EMI.

Applications

The capabilities of Rogers laminates make 12 layer hybrid boards suitable for:

- High speed digital circuits

- Serial bus interfaces like PCIe, USB 3.0

- Networking products like switches, routers

- Wireless communications infrastructure

- Radar and antenna systems

- Test and instrumentation

The integration of Rogers material in high layer count PCBs along with FR4 provides a robust solution for products requiring speed, precision and RF performance without the cost of using exotic dielectrics exclusively.

Cost Analysis

For a 300mm x 400mm board, a cost estimate comparison between full FR-4 and hybrid construction in 5000 piece prototype volumes:

| Configuration | 12L Full FR4 | 12L Hybrid (Rogers in L5/L12) |

|---|---|---|

| Fabrication | $130 | $160 |

| Material | $155 | $195 |

| PTH Plating | $210 | $250 |

| Mask +Legend | $130 | $145 |

| Handling | $55 | $60 |

| Test | $125 | $150 |

| Total/board | $805 | $960 |

The hybrid option with Rogers in 2 layers has around 20% higher cost. But the performance gain outweighs this cost premium in many high speed and RF applications.

Conclusion

Combining Rogers laminates and FR4 dielectric in a 12 layer PCB provides an optimized tradeoff between performance and cost. The integration of high frequency Rogers material in the core layers offers precision routing for signals demanding tight impedance control, low loss and crosstalk isolation within a reliable, industry-standard 12 layer FR4 multilayer board. With careful design planning andworking with fabricators experienced in hybrid multilayer constructions, the Rogers-FR4 hybrid approach enables modern PCBs to implement demanding applications in networking, communications, defense, instrumentation and other leading edge fields.

FAQs

What are some key benefits of using a hybrid PCB stackup?

Hybrid stackups allow optimizing electrical performance, thermal management, stability, density and cost by combining different materials selectively as per circuit needs.

What precautions are required when soldering hybrid PCBs?

Use a lower temperature solder alloy to avoid damaging the higher performance dielectric material. Ramp down temperatures slowly after reflow.

Can components be placed across Rogers-FR4 junctions?

This is not recommended as thermal stresses can induce cracks or delamination. Components should be fully placed over one material.

How are impedance matched traces implemented in hybrid PCBs?

Matching is achieved by using different trace widths on each dielectric layer according to the material dielectric constant. Transitions between widths can be tapering or abrupt.

What are thermal reliefs used for in hybrid boards?

Cutouts below pads and vias facilitate heat transfer into the higher thermal conductivity plane layers while limiting conduction into the outer layers.