If you’re unfamiliar with Unitech Corporation, you might wonder about its reputation. Established in 1994 by Chinese tech entrepreneurs, the company has diversified its business to include solar panels. In this article, we’ll delve into its history & current operations, as well as explore its offerings of rigid-flex printed circuit boards & double-sided printed circuit boards. By the end of this piece, you should be able to recognize a Unitech printed circuit board and understand how it can benefit you.

Solar cell business unit

Unitech Corporation will make more money by separating its solar cell enterprise into a new company. However, there was a report that Unitech’s founders took money from people who bought homes for other things. A giant electronics maker from Taiwan, called Inventec, is also a part owner of the new company. We don’t know how much money the new business will make yet, but there are some signs that it might be successful.

Chinese companies that make solar panels must reduce how much they produce, or they will keep losing money. Also, a new administration might focus on more reliable industries than solar. Lastly, the company might have to stop making solar panels because they don’t have enough money. However, this could be good for solar panel makers in Taiwan.

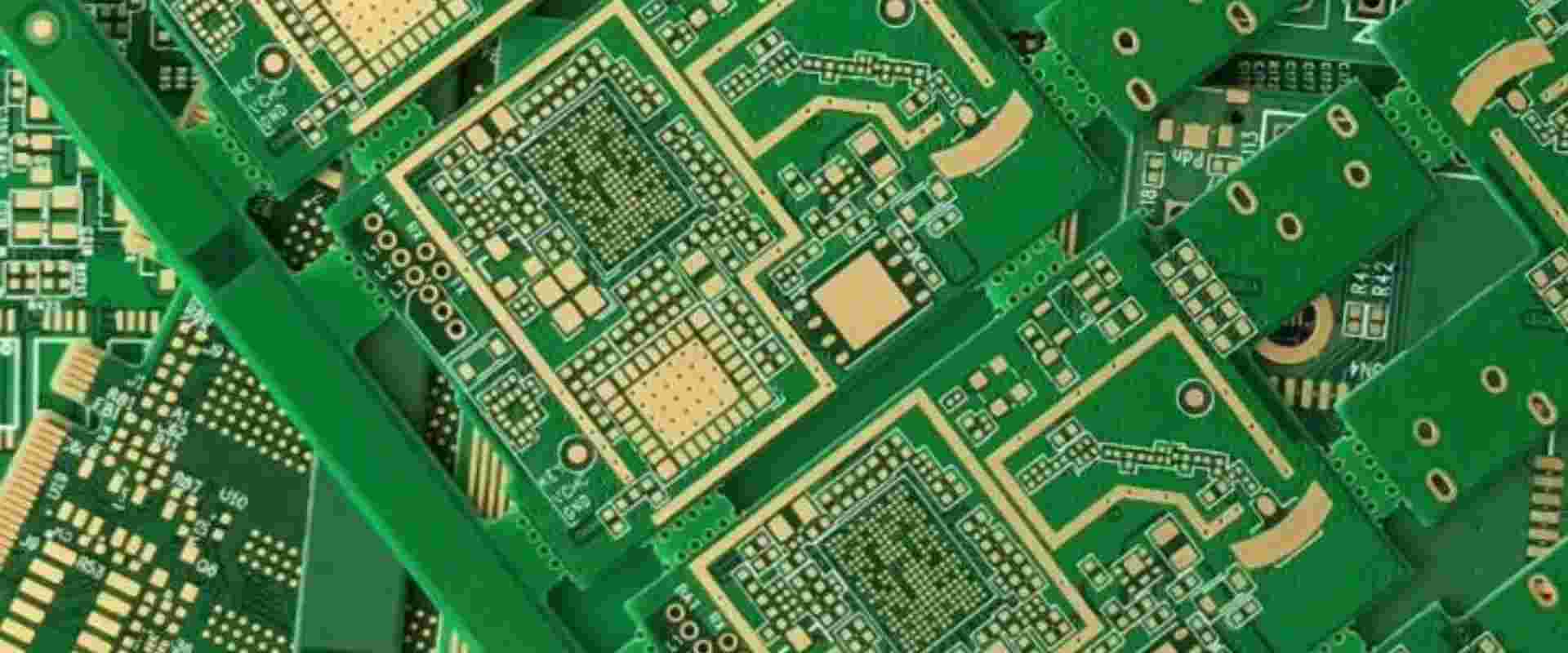

Multilayer PCBs

Multilayer PCBs by Unitech are gaining popularity in numerous industries due to their lightweight construction and impressive functionality. These boards are helpful in various high-tech applications, including X-ray equipment, optical fiber sensors, atomic accelerators, & weather analysis devices. Multilayer printed circuit boards offer several benefits to both manufacturers & end-users, including budget savings and improved functionality.

Multi-layer printed circuit boards, with their increased number of layers, require more design time and attention during manufacturing due to their complexity. Any imperfection can render multi-layer printed circuit boards unusable. However, the benefits of using these boards are significant. They are more effective than single-layer printed circuit boards and can withstand a range of humidity, temperatures, & pressure. Additionally, flexible multi-layer printed circuit boards are helpful for assemblies that require flexible construction methods or applications that involve bending.

With the increasing complexity and miniaturization of electronics, the internal elements must keep up with the trend. Double-sided printed circuit boards have proven insufficient in achieving a balance between size & functionality. However, multi-layer PCBs can overcome these challenges effectively. Unitech’s multi-layer printed circuit boards provide an ideal solution to meet this requirement, offering numerous advantages over traditional alternatives. Below are some benefits of utilizing multi-layer printed circuit boards.

Multilayer printed circuit boards are strong and protected, making them great for putting lots of electronic parts close together. The coatings are connected well and help control how electricity moves through the board. This lets people do more things with the board and saves money because it’s easier to put many parts on it.

Unitech’s multi-layer circuit boards are beneficial for cars. They can handle hot and wet conditions well and are solid and trustworthy. They also follow safety standards for the environment.

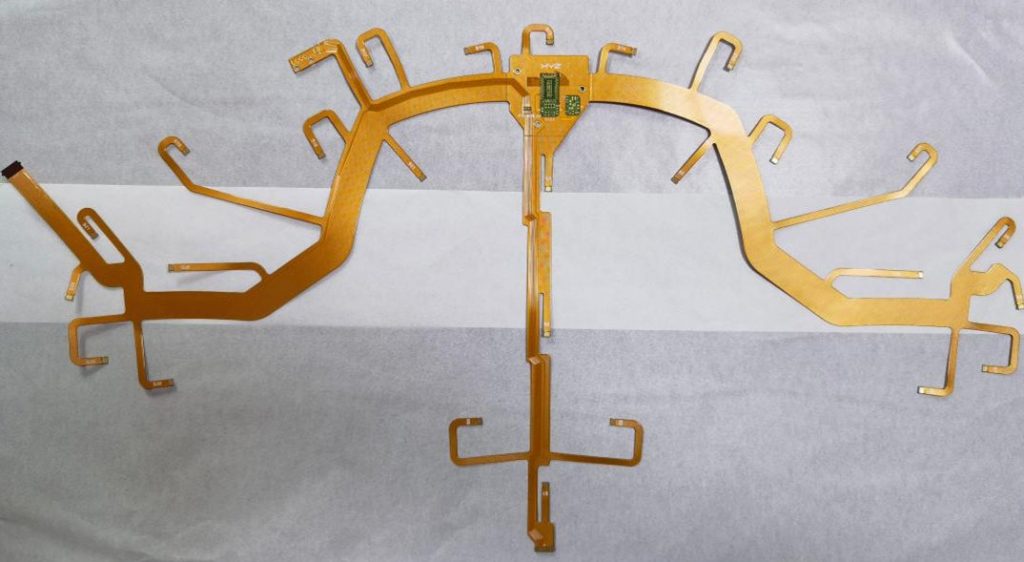

Rigid-flex PCBs

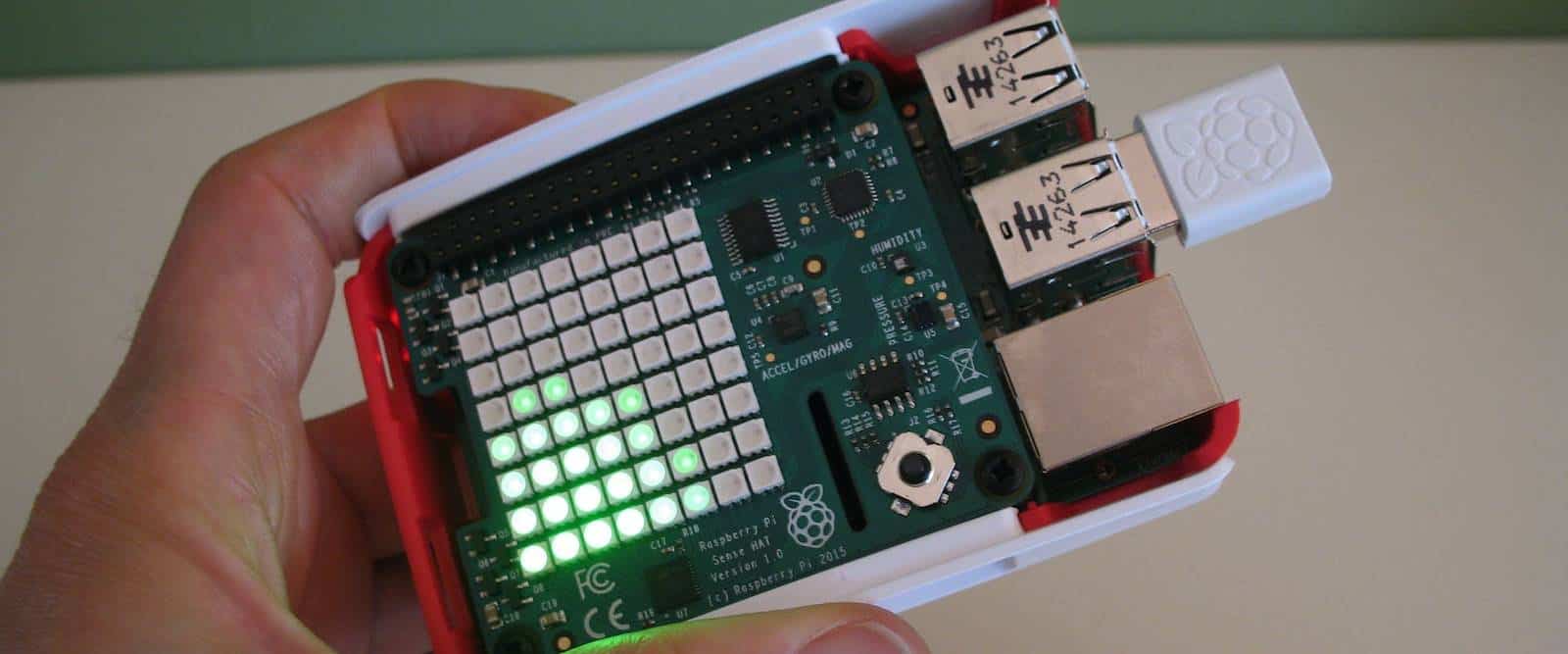

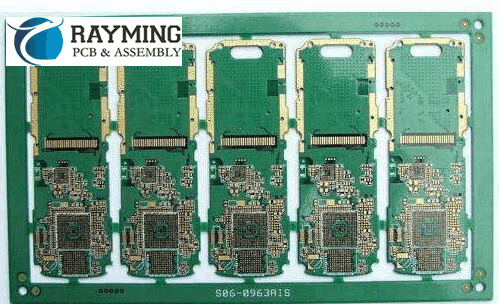

Unitech PCB is growing because more people want to buy electronics for cars and everyday life. They are making more “rigid-flex” circuit boards to meet this demand, which they think will help them send out many circuit boards to people who make electronics. They are also planning to use these circuit boards for phone parts and are working with other important circuit board companies like Rayming PCB and Assembly.

The new circuit board called a “rigid-flex printed circuit board,” has parts that are both hard and bendy. When it gets hot, it won’t get more extensive in some directions. This circuit board is better than other types because it doesn’t use things that get bigger or wet. They usually make these boards with stuff like sticky glue and a special kind of plastic that bends. However, these materials can make the board more extensive and cost more money.

Rigid-flex circuit boards benefit space and car technology because they make things more robust and reliable. They also eliminate the need for breakable wires and connections made with melted metal. People can use them in testing machines, tools, and cars too. So if you need a circuit board that can handle being hit, shaken, or put in hot or cold places, a rigid-flex board is a good choice.

Rigid-flex circuit boards cost more to create, but they save money when being made. This is because they can fit lots of parts on one board, so you don’t need to use lots of boards. This is cheaper. They can also be made special for different things and fit into different shapes. They are suitable for trying out new ideas because they are easy to test, even if they need to be small.

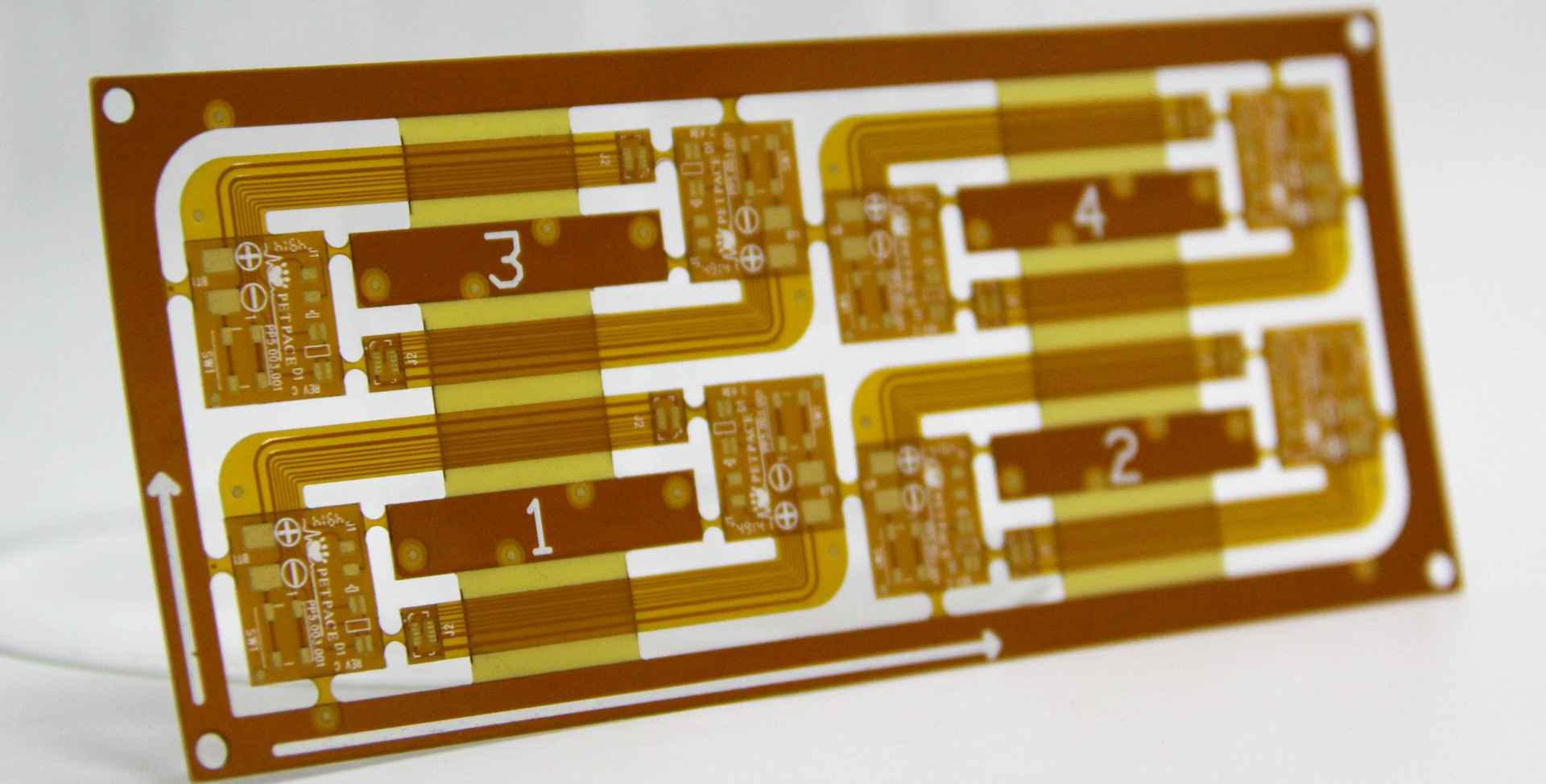

Double-sided PCBs

Unitech PCB Corp. is a company from Taiwan that makes circuit boards & solar panels. They make circuit boards that have circuits on both sides and also ones with lots of layers. They also make a particular solar panel called a “mono-crystalline silicon” panel. You can find their things in many places in Asia. If you want to know about their circuit boards, click the links below.

Many circuit boards only have circuits on one side, which means you can only put parts on one side too. But using a “double-sided” panel, you can put pieces on both sides. This is good because it makes the board smaller and takes up less space. When the board is being made, they can also put more metal on it, which can help it handle heat better. This means the board can be even smaller and cheaper to make.

Single-sided & double-sided circuit boards both have good things about them, but they aren’t identical. Double-sided boards are harder to make because you must put parts on both sides. This makes it cost more money to make. If you don’t have much money, you might want to use a single-sided board instead. This will be cheaper but may not be as flexible as needed for your job.

A single-sided PCB has metal lines on one side and is more affordable than double-sided boards. They are often used in things like electronics for regular people and factories. You can also order a “flexible” version of the board. This board is made from a flexible material, so you can bend it without breaking it.

Future of Unitech PCB

Unitech PCB has become more successful since it started. Customers & shareholders wonder how it will keep growing in the future. Many things make a business successful, so there isn’t just one answer. Unitech PCB has plans and a direction that links each project together. The business’s future looks good – what about yours?

Panasonic has announced that it will start making OLED television screens in 2020 at its factory in New Zealand’s Marlborough region. The manufacturing process will use both Japanese & Chinese techniques.

Conclusion

Unitech PCB is a company from Taiwan that specializes in making PCBs. Their goal is to offer high-quality products that are valuable to their customers. Unitech has many client options, like rigid-flex printed circuit boards, flexible printed circuit boards, and printable boards. They also allow you to choose the best PCB that fits your product.