Introduction

In the world of electronics and signal processing, few components are as fundamental and widely used as the low pass filter. These essential circuit elements play a crucial role in countless applications, from the audio systems in your home theater to life-saving medical devices. A low pass filter, as the name suggests, allows low-frequency signals to pass through while attenuating (reducing) signals with frequencies higher than a designated cutoff point. This seemingly simple function is the backbone of modern electronic systems, helping engineers and designers achieve cleaner signals, reduce noise, and extract only the information they need.

Whether you’re an electronics hobbyist, a student, or a seasoned engineer, understanding low pass filters is essential for designing effective electronic systems. This comprehensive guide explores everything you need to know about low pass filters in 2025, from basic principles to advanced design techniques, real-world applications, and emerging trends. We’ll break down the various types, explain how to design them for your specific needs, and provide practical tips to avoid common pitfalls.

What is a Low Pass Filter?

A low pass filter (LPF) is an electronic circuit designed to allow signals below a specific cutoff frequency to pass through while attenuating (reducing) signals above that frequency. This fundamental function makes it one of the most important components in signal processing and electronic design.

Basic Principles of Operation

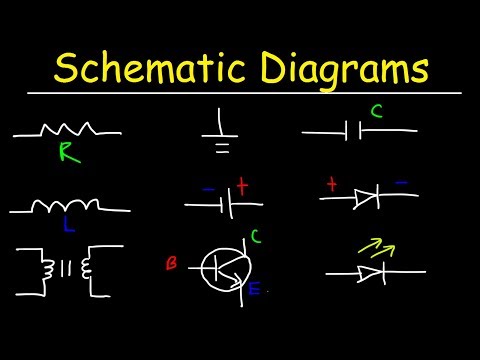

The operation of a low pass filter is based on the frequency-dependent behavior of capacitors and inductors. In simple terms, capacitors present high impedance (resistance) to low-frequency signals and low impedance to high-frequency signals. Inductors do the opposite, offering low impedance to lower frequencies and high impedance to higher frequencies. By strategically combining these components with resistors, engineers can create circuits that discriminate between signals based on their frequency content.

When a complex signal (containing multiple frequencies) enters a low pass filter, the circuit allows the low-frequency components to pass through relatively unchanged while progressively weakening higher-frequency components. The result is a “filtered” output signal that preserves the desired low-frequency information while reducing or eliminating unwanted high-frequency content.

Key Characteristics

Understanding the following key characteristics is essential for working with low pass filters:

- Cutoff Frequency (fc): This defines the boundary between the passband and the stopband. It’s typically defined as the frequency at which the output power drops to half (-3dB) of the input power. The cutoff frequency is the primary specification when designing or selecting a low pass filter.

- Roll-off Rate: This describes how quickly the filter attenuates frequencies above the cutoff point. It’s usually expressed in decibels per octave (dB/octave) or decibels per decade (dB/decade). A steeper roll-off means more effective filtering of unwanted frequencies.

- Passband Ripple: Ideally, a filter would pass all frequencies below the cutoff with identical gain, but real filters often exhibit some variation (ripple) in the passband response.

- Stopband Attenuation: This indicates how effectively the filter blocks frequencies in the stopband, typically measured in decibels.

- Phase Response: Low pass filters don’t just affect signal amplitude—they also introduce phase shifts that vary with frequency. This can be critical in applications where timing relationships between signals must be preserved.

- Filter Order: Higher-order filters (created by cascading multiple filter stages) provide steeper roll-off rates but introduce greater complexity, cost, and potential phase distortion.

Types of Low Pass Filters

Low pass filters come in various forms, each with distinct characteristics, advantages, and ideal use cases. Understanding these different types will help you select the right filter for your specific application.

1. Passive Low Pass Filter

Passive filters use only passive components—resistors, capacitors, and inductors—without any active elements like transistors or operational amplifiers. They’re the simplest form of filter and don’t require an external power supply.

Components and Structure

The basic passive low pass filters include:

- RC Filter: Combines a resistor and capacitor

- RL Filter: Uses a resistor and inductor

- LC Filter: Employs an inductor and capacitor

- RLC Filter: Incorporates all three components for more complex responses

Simple Circuit Example

The most basic passive low pass filter is the RC filter, consisting of just one resistor and one capacitor:

Input ---[Resistor]---+---Output

|

|

[Capacitor]

|

|

GNDIn this circuit, the resistor and capacitor form a voltage divider whose division ratio varies with frequency. At low frequencies, the capacitor has high impedance, so most of the input voltage appears at the output. As frequency increases, the capacitor’s impedance decreases, causing more signal to be shunted to ground.

Advantages and Limitations

Advantages:

- Simple and inexpensive

- No power supply required

- No active noise contribution

- Can handle relatively high power levels

- Reliable operation with minimal failure points

Limitations:

- Fixed gain (typically less than unity)

- Limited roll-off rate (usually 20 dB/decade per filter stage)

- Potential loading effects on connected circuits

- Less precise control over filter response

- Cannot amplify signals

2. Active Low Pass Filter

Active filters incorporate active components, typically operational amplifiers (op-amps), alongside passive elements. These filters can provide gain, improved performance, and better isolation between stages.

Using Op-Amps and Other Active Components

Active low pass filters typically use op-amps as the active element, providing benefits like:

- Signal amplification

- Impedance matching

- Isolation between filter stages

- More complex filter responses

Better Control Over Gain and Response

With active filters, designers can achieve:

- Precisely controlled filter characteristics

- Steeper roll-off rates

- Multiple filter responses (e.g., Butterworth, Chebyshev, Bessel)

- Gain at frequencies of interest

Typical Circuit Example

A basic active low pass filter using an op-amp might look like this:

+---[Resistor R2]----+

| |

Input---[Resistor R1]---+---[Capacitor]---+---Output

| |

| |

+----[Op-Amp]-----+This circuit can provide gain determined by the ratio of R2 to R1 while maintaining the filtering action of the RC network.

Advantages and Limitations

Advantages:

- Can provide signal gain

- Minimal loading effect on connected circuits

- Easily cascaded for higher-order filters

- More control over filter response

- Better performance at lower frequencies

Limitations:

- Requires power supply

- Bandwidth limitations of op-amps

- Introduces noise and potential distortion

- More complex design

- Limited power handling capability

3. Digital Low Pass Filter

Digital filters implement filtering functions through software algorithms rather than physical components. They operate on discrete samples of signals in the digital domain.

Algorithmic Approach

Digital low pass filters process signals using mathematical operations like:

- Convolution

- Difference equations

- Transfer functions

- Z-transform techniques

FIR and IIR Filters

Two primary categories of digital filters exist:

Finite Impulse Response (FIR) Filters:

- Use only current and past input values

- Always stable

- Linear phase response

- Higher computational requirements

Infinite Impulse Response (IIR) Filters:

- Use both input and output values

- More efficient computationally

- Potential stability issues

- Nonlinear phase response

- Can mimic analog filter responses

Used in DSP Systems

Digital filters are implemented in various systems:

- Digital signal processors (DSPs)

- Microcontrollers

- FPGAs

- Software applications

- Embedded systems

Advantages and Limitations

Advantages:

- Highly flexible and reconfigurable

- Precise and repeatable characteristics

- Immune to component tolerances

- Can implement complex filter responses

- Easily modified and updated

Limitations:

- Requires analog-to-digital and digital-to-analog conversion

- Processing delays

- Limited by sampling rate and quantization effects

- Higher power consumption for high-speed applications

- Potential for aliasing issues

4. RC (Resistor-Capacitor) Low Pass Filter

The RC filter is the simplest form of low pass filter, consisting of just one resistor and one capacitor.

Basic RC Circuit Explanation

In an RC low pass filter, the resistor is placed in series with the signal path, and the capacitor is connected between the signal path and ground. The time constant (τ = RC) determines the filter’s behavior:

- At low frequencies, the capacitor acts like an open circuit

- At high frequencies, the capacitor acts like a short circuit

- The cutoff frequency is given by: fc = 1/(2πRC)

Simple Design and Uses

An RC filter’s cutoff frequency is easily calculated using the formula above. For example:

- A 10kΩ resistor and a 0.1µF capacitor yield a cutoff frequency of approximately 159Hz

- A 1kΩ resistor and a 0.01µF capacitor result in a cutoff of about 15.9kHz

RC filters are commonly used in:

- Audio tone controls

- RF coupling circuits

- Power supply smoothing

- Anti-aliasing filters

- Simple noise suppression

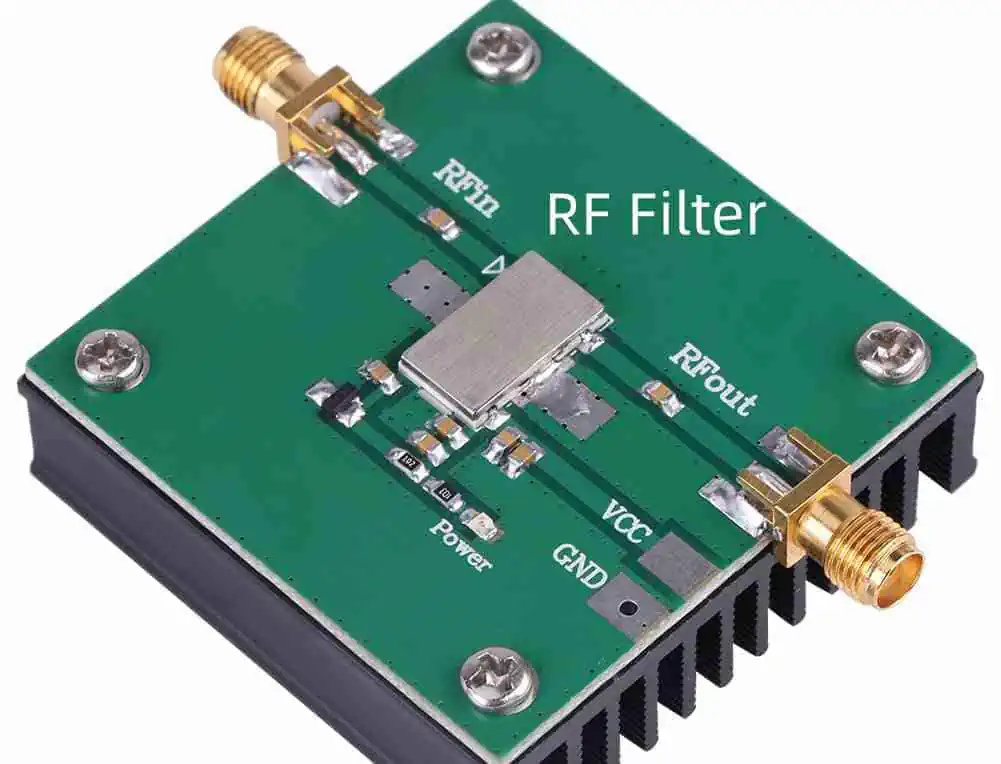

5. LC (Inductor-Capacitor) Low Pass Filter

LC filters use inductors and capacitors to form a resonant circuit that provides filtering action without the power losses associated with resistors.

Advantages in High-Frequency Applications

LC filters excel in high-frequency and high-power applications because:

- Lower power loss compared to RC filters

- Steeper roll-off characteristics

- Better performance at radio frequencies

- Can handle higher power levels

- Higher Q-factor (quality factor)

Example Schematic

A basic LC low pass filter might look like:

Input ---[Inductor]---+---Output

|

[Capacitor]

|

GNDThe cutoff frequency for this filter is given by: fc = 1/(2π√(LC))

Applications

LC filters are commonly found in:

- RF and microwave systems

- Power line filtering

- High-efficiency power supplies

- Antenna matching networks

- Audio crossover networks for speakers

6. RL (Resistor-Inductor) Low Pass Filter

RL filters use the frequency-dependent properties of inductors combined with resistors to create a low pass filter.

Basic Operation

In an RL low pass filter:

- The inductor is placed in series with the signal path

- The resistor is typically the load resistance or a parallel resistor

- Low frequencies encounter minimal opposition from the inductor

- High frequencies face increasing opposition from the inductor

Applications in Power Systems

RL filters are particularly useful in:

- Motor control circuits

- Power line conditioning

- Inductive load driving

- DC power supplies

- Current smoothing applications

Applications of Low Pass Filters

Low pass filters are ubiquitous in electronic systems, playing crucial roles across numerous fields and applications. Understanding these applications provides insight into the versatility and importance of these fundamental components.

Audio Processing

In audio systems, low pass filters serve multiple essential functions:

Speaker Crossover Networks: Low pass filters direct only the low-frequency components to subwoofers and bass speakers, ensuring each speaker reproduces only the frequencies it’s designed to handle efficiently. This improves sound quality and protects speakers from damage.

Audio Equalization: Low pass filters form the foundation of equalizers, allowing sound engineers and audiophiles to shape frequency response for optimal sound reproduction or creative effects.

Subwoofer Integration: Dedicated low pass filters ensure that subwoofers receive only low-frequency content, typically below 80-120Hz, optimizing bass reproduction in home theater and professional audio systems.

Noise Reduction: By filtering out high-frequency noise while preserving the audio spectrum, low pass filters can improve signal-to-noise ratio in recording and playback systems.

Radio Communications

Communication systems rely heavily on low pass filtering:

Channel Filtering: Low pass filters isolate specific frequency bands, helping receivers extract desired signals from crowded radio spectrums.

Bandwidth Limitation: Regulatory requirements often specify maximum bandwidths for transmissions; low pass filters ensure compliance by restricting the spectrum of transmitted signals.

Intermediate Frequency (IF) Processing: In superheterodyne receivers, low pass filters help process intermediate frequency signals before final demodulation.

Signal Demodulation: Many demodulation schemes require low pass filtering to extract the original information signal from the carrier wave.

Power Supplies and Noise Reduction

Power supply design frequently incorporates low pass filters:

Ripple Reduction: Low pass filters smooth the rectified AC in power supplies, reducing ripple voltage and providing cleaner DC output.

EMI/RFI Suppression: Filters prevent high-frequency noise from entering sensitive circuits or radiating from power lines, helping devices meet electromagnetic compatibility (EMC) requirements.

Power Line Conditioning: Low pass filters block high-frequency noise on power lines, protecting sensitive equipment and improving performance.

Transient Suppression: By attenuating high-frequency components, properly designed filters can help mitigate the effects of voltage spikes and transients.

Digital Signal Smoothing

In digital systems, low pass filtering plays a key role:

Anti-Aliasing: Before analog-to-digital conversion, low pass filters restrict the signal bandwidth to prevent aliasing artifacts.

Data Smoothing: Digital low pass filters can reduce noise and extract trends from noisy data streams, valuable in applications from weather prediction to stock market analysis.

Sensor Signal Conditioning: Low pass filters remove high-frequency noise from sensor outputs, producing cleaner signals for processing.

Image Processing: In digital image manipulation, low pass filtering produces blurring effects and removes high-frequency noise, useful for preprocessing in computer vision applications.

Biomedical Engineering

Medical devices rely extensively on low pass filtering:

ECG Signal Processing: Low pass filters remove high-frequency interference while preserving the critical cardiac waveform information.

EEG Monitoring: Brain activity monitoring systems use low pass filters to isolate specific frequency bands of interest.

Medical Imaging: MRI, ultrasound, and other imaging technologies employ sophisticated filtering to enhance image quality and diagnostic value.

Patient Monitoring: Vital signs monitors use low pass filters to stabilize readings and reduce false alarms from transient noise.

Everyday Examples

Low pass filters are present in many everyday consumer devices:

Smartphone Touchscreens: Low pass filtering algorithms help distinguish intentional touches from inadvertent contact or electrical noise.

Camera Stabilization: Digital cameras use low pass filtering to smooth out handheld camera movements.

Home Wi-Fi Routers: RF sections employ low pass filters to ensure transmissions remain within allocated frequency bands.

Automotive Electronics: From engine control modules to infotainment systems, vehicles use numerous low pass filters for signal conditioning and noise reduction.

Read more about:

Design Guide for Low Pass Filters

Creating an effective low pass filter requires careful planning and consideration of multiple factors. This step-by-step guide will help you design filters that meet your specific requirements.

1. Define Requirements

Before selecting components or drawing schematics, clearly establish what you need from your filter:

Cutoff Frequency

Determine the precise frequency boundary between signals you want to keep and those you want to attenuate. Consider:

- The highest frequency component in your desired signal

- The lowest frequency component you need to reject

- Any transition band requirements

Desired Roll-off Rate

Decide how rapidly the filter should attenuate signals above the cutoff frequency:

- Gentle roll-off (20 dB/decade): First-order filter, simpler but less effective

- Moderate roll-off (40 dB/decade): Second-order filter, good compromise

- Steep roll-off (60+ dB/decade): Higher-order filters, more complex but more effective

Passband and Stopband Specifications

Define the acceptable variation in your filter’s response:

- Passband ripple: Maximum allowable amplitude variation for frequencies you want to pass

- Stopband attenuation: Minimum required attenuation for frequencies you want to reject

- Transition band width: How quickly the filter transitions from pass to reject

2. Choose Filter Type

Based on your requirements, select the most appropriate filter category:

Analog vs. Digital

Consider:

- Operating environment (analog or digital domain)

- Available processing resources

- Required precision and flexibility

- Budget constraints

Active vs. Passive

Consider:

- Power availability

- Required gain

- Circuit complexity

- Noise sensitivity

- Available space

Filter Response Type

Different mathematical models offer different performance characteristics:

- Butterworth: Maximally flat passband, moderate roll-off

- Chebyshev: Steeper roll-off with some passband ripple

- Bessel: Linear phase response, minimal signal distortion

- Elliptic (Cauer): Sharpest transition but ripple in both passband and stopband

3. Select Components

Once you’ve decided on the filter type, select appropriate components:

How to Choose Capacitors

Consider these factors:

- Tolerance: Precision applications require tighter tolerances (±1% or better)

- Temperature coefficient: Choose stable types like NP0/C0G for critical applications

- Voltage rating: Should exceed maximum expected voltage by at least 2x

- ESR and ESL: Lower values improve high-frequency performance

- Dielectric: Different types (ceramic, film, electrolytic) suit different applications

Selecting Inductors

For LC filters, inductor selection is critical:

- Current rating: Must exceed maximum expected current

- DCR (DC resistance): Lower values reduce power loss

- Core material: Affects frequency response, saturation, and losses

- Shielding: May be necessary to prevent EMI issues

- Q factor: Higher values provide sharper resonance

Resistor Considerations

For RC and active filters:

- Power rating: Ensure adequate heat dissipation

- Noise characteristics: Critical in low-level signal processing

- Tolerance: Affects filter accuracy

- Temperature coefficient: Important for stable operation across temperatures

- Type: Thick film, thin film, wirewound, etc., each with different characteristics

Tolerances and Practical Tips

Real-world components differ from ideal:

- Use Monte Carlo analysis to evaluate the effect of component tolerances

- Consider using 1% or better tolerance components for critical filters

- Design with slightly adjusted values to accommodate standard component values

- For stringent requirements, consider tunable components

- Remember that capacitor values often drift with age and temperature

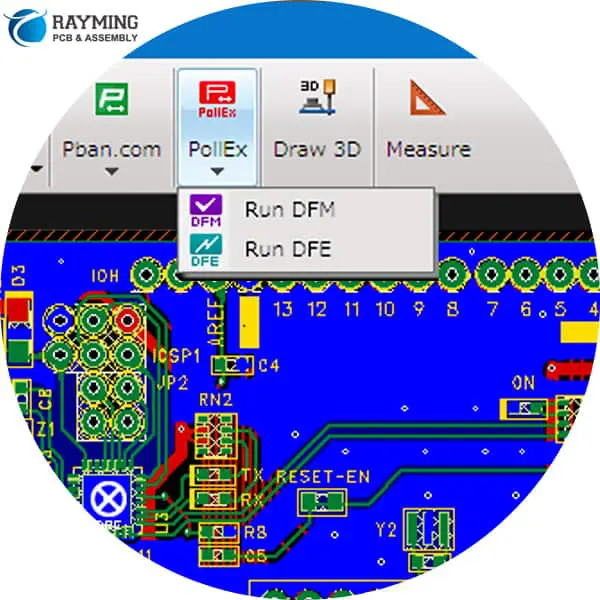

4. Simulate and Test

Before finalizing your design, verify its performance:

Tools for Simulation

Modern software makes filter design and verification accessible:

- LTspice: Free SPICE simulator excellent for analog filter design

- MATLAB/Simulink: Powerful platform for both analog and digital filter design

- FilterLab: Specialized for active filter design

- Python with SciPy: Excellent for digital filter prototyping

- Online calculators: Quick checks for simple filters

Importance of Testing Before Implementation

Simulation can reveal issues before you build:

- Verify actual cutoff frequency and roll-off

- Check for unexpected resonances or anomalies

- Assess sensitivity to component variations

- Verify phase response if timing is critical

- Estimate power consumption and thermal behavior

If possible, breadboard your design and test with real signals before final implementation.

5. Practical Design Tips

Theoretical design is just the beginning—practical implementation requires attention to detail:

Dealing with Parasitics

Real components have parasitic elements that can affect performance:

- Keep leads short to minimize inductance

- Consider capacitor ESR in high-frequency designs

- Be aware of inter-winding capacitance in inductors

- Use guard traces for sensitive nodes

- Consider shielding for high-precision filters

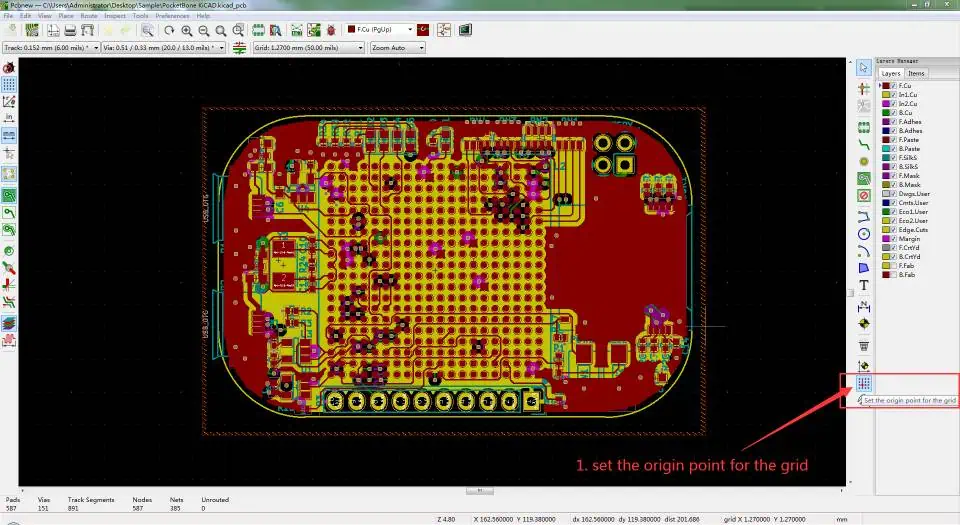

PCB Layout Considerations

Circuit board layout significantly impacts filter performance:

- Keep signal paths short and direct

- Use ground planes for low impedance returns

- Separate analog and digital grounds appropriately

- Orient components to minimize coupling

- Consider trace impedance at higher frequencies

Power Supply Decoupling

For active filters:

- Use local decoupling capacitors near op-amp power pins

- Employ multiple capacitor values for broadband decoupling

- Consider using ferrite beads for additional filtering

- Maintain low-impedance power supply paths

- Isolate sensitive analog sections from digital noise

Common Mistakes in Low Pass Filter Design

Even experienced designers can fall into these common pitfalls. Being aware of them can save you time and frustration.

Incorrect Cutoff Frequency

A frequent error is misinterpreting or miscalculating the cutoff frequency:

- Confusing -3dB point with other definitions of cutoff

- Using incorrect formulas for different filter topologies

- Failing to account for component tolerances

- Not considering loading effects of connected circuits

- Overlooking frequency shifts due to temperature variations

Overcomplicating the Design

Sometimes the simplest solution is the best:

- Using higher-order filters when not necessary

- Implementing active filters when passive would suffice

- Adding unnecessary features that introduce potential failure points

- Creating overly complex compensation networks

- Choosing exotic filter responses without clear benefits

Ignoring Component Non-Idealities

Real components differ from their idealized models:

- Capacitors have series resistance and inductance

- Inductors have parallel capacitance and series resistance

- Op-amps have limited bandwidth and slew rate

- Resistors generate noise and have parasitic capacitance

- All components have temperature coefficients and aging characteristics

Other Common Issues

Additional pitfalls to avoid:

- Neglecting input/output impedance matching

- Failing to consider the signal’s dynamic range

- Ignoring phase response when it matters

- Not validating designs with worst-case analysis

- Overlooking power supply noise effects on active filters

Latest Trends and Innovations in Low Pass Filters (2025)

The field of filter design continues to evolve rapidly. These recent developments represent the cutting edge of filtering technology in 2025.

MEMS-Based Filters

Micro-Electro-Mechanical Systems (MEMS) technology has revolutionized filter design:

- Microscopic mechanical resonators replace traditional LC components

- Exceptional performance at high frequencies

- Dramatically reduced size compared to conventional filters

- Improved temperature stability

- Integration with semiconductor manufacturing processes

These filters are increasingly found in wireless devices, offering superior performance while consuming less space and power than traditional designs.

AI-Enhanced Digital Filters

Artificial intelligence is transforming digital filter design and implementation:

- Neural networks adaptively optimize filter coefficients

- Machine learning algorithms predict and compensate for component aging

- Self-tuning filters adjust their characteristics based on real-time signal analysis

- AI-optimized filter architectures outperform traditionally designed filters

- Reduced computational requirements through intelligent algorithm selection

These smart filters are particularly valuable in applications with varying signal characteristics or challenging noise environments.

Integrated Solutions in ICs

Modern integrated circuit technology incorporates increasingly sophisticated filtering capabilities:

- Complete filter solutions in single-chip packages

- Programmable analog filters with digital control

- Switched-capacitor implementations with exceptional precision

- Software-defined filtering architectures

- Mixed-signal approaches combining the best of analog and digital techniques

These integrated solutions reduce component count, improve reliability, and lower system cost while offering performance that was previously unattainable.

Advanced Materials and Techniques

Novel materials and fabrication methods are expanding filter capabilities:

- High-Q ceramic resonators for RF applications

- Superconducting filters for quantum computing systems

- Metamaterial structures creating previously impossible frequency responses

- Carbon nanotube-based components with exceptional performance

- 3D-printed RF structures for custom filter responses

These advances particularly benefit specialized applications with extreme requirements for selectivity, power handling, or size constraints.

Conclusion

Low pass filters represent one of the fundamental building blocks of electronic systems, performing the crucial task of separating wanted signals from unwanted ones based on frequency content. From the simplest RC network to sophisticated digital implementations, these filters enable countless technologies that we rely on daily. As we’ve explored in this guide, low pass filters come in many forms, each with distinct advantages and ideal applications.

When designing or selecting a low pass filter, remember to clearly define your requirements first, then choose the appropriate filter type and topology that best matches those needs. Pay close attention to component selection, and always verify your design through simulation and testing before final implementation. By avoiding common pitfalls and staying aware of the latest developments in filter technology, you can create efficient, effective filtering solutions for even the most demanding applications.

As technology continues to advance, we can expect even more innovative approaches to filtering, with improvements in size, performance, and integration. However, the fundamental principles of low pass filtering will remain essential knowledge for anyone working with electronic systems and signal processing.

FAQs About Low Pass Filters

What is the best low pass filter for audio applications?

The “best” filter depends on your specific requirements, but Butterworth filters are often preferred for audio because they provide maximally flat frequency response in the passband, avoiding coloration of the audio. For crossovers, Linkwitz-Riley filters (which are cascaded Butterworth filters) are popular because they provide -6dB response at the crossover point when summed with their high-pass counterparts. For applications where phase response is critical, Bessel filters may be preferred due to their linear phase characteristics, which preserve the waveform shape.

Can I use a low pass filter for DC signals?

Yes, low pass filters work perfectly with DC signals since DC is essentially a signal with zero frequency, which falls well within the passband of any low pass filter. In fact, one common application of low pass filters is extracting the DC component from a mixed signal. However, if your signal is purely DC with no AC components, a filter wouldn’t be necessary unless you’re trying to remove noise or ripple.

How do I calculate the cutoff frequency?

The formula depends on the filter type:

- For RC filters: fc = 1/(2πRC)

- For RL filters: fc = R/(2πL)

- For LC filters: fc = 1/(2π√(LC))

- For active filters: depends on the specific topology, but many follow the RC formula

Where:

- fc is the cutoff frequency in Hz

- R is resistance in ohms

- C is capacitance in farads

- L is inductance in henries

Online calculators and design tools can simplify these calculations for more complex filter types.

Passive vs. active low pass filter: which is better?

Neither is inherently “better” as each has advantages for different situations:

Choose passive filters when:

- No power source is available

- Simplicity is paramount

- Working with high power levels

- High reliability is essential

- Working at very high frequencies

Choose active filters when:

- Signal amplification is needed

- Precise filter characteristics are required

- Multiple filter stages must be cascaded

- Input/output impedance matching is important

- Working with very low frequencies

For many modern applications, active filters are preferred due to their flexibility and performance, but passive filters remain important in power electronics, RF design, and other specialized fields.

How do I design a low pass filter for a specific application?

Start by defining your requirements precisely:

- Determine the required cutoff frequency

- Identify necessary attenuation rate (roll-off)

- Consider any phase response requirements

- Define acceptable passband ripple

- Consider physical constraints (size, cost, power)

Then: 6. Select an appropriate filter topology 7. Calculate component values using formulas or design tools 8. Choose actual components considering tolerances and non-idealities 9. Simulate your design with realistic component models 10. Build and test a prototype before final implementation

For complex filters, specialized design software can greatly simplify this process.