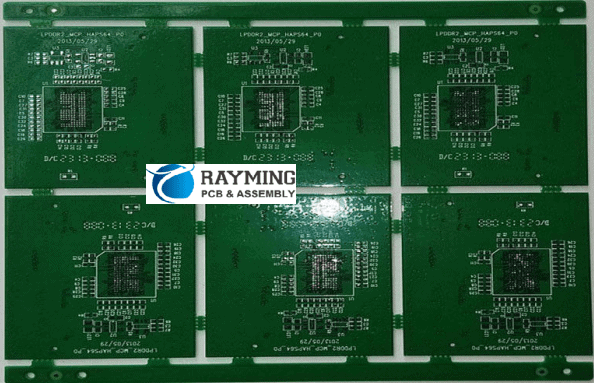

Printed Circuit Boards (PCBs) connect electronic components. PCBs are vital to the modern world. All electronic devices have PCBs.

A PCB is traditionally a dense and complex board with several layers. Standard PCBs have a layer of fiberglass. However, more sophisticated interconnect technology applies to PCBs.

As technology increases, so does the complexity of PCBs. This development has created new challenges for manufacturers. PCB manufacturers must keep up with industry trends.

The increasing functional complexity of devices is challenging manufacturers of PCBs. They are also experiencing challenges due to miniaturization. In addition, the growing number of components on a board leads to higher costs and lower reliability.

Lidar technology has revolutionized PCB design in several ways. It can provide more accurate measurements, faster production, and better quality.

Lidar technology is the process of using light to scan the environment. It is a popular method of surveying objects in three dimensions and can be helpful for many different purposes, such as mapping, navigation, and machine vision. Scientists working for the US military developed the first commercial Lidar system in the 1960s, which was applicable for artillery targeting and guided missile guidance.

Lidar helps PCB designers by providing them with more accurate data about the design layout. This improvement has led to a decrease in the time it takes for PCB design and an increase in efficiency.

Other industries, such as automotive manufacturing, aerospace engineering, and even architecture, have used lidar technology. In addition, Lidar systems are now helpful in many applications, including autonomous cars, drones, 3D printing, robotics, and more.

There are several different types of Lidar, such as sea-based, air-based, and ground-based. The kind used in autonomous cars is popular as laser radar.

Introduction to Lidar Technology, the Advanced Discovery and Inspection Solution for PCB Manufacturing

Lidar is an acronym for Light Detection and Ranging. We refer to Lidar as a remote-sensing technology making use of light as a pulsed laser to measure the properties of an object. It is a technology that uses light to detect objects, measure distances, and map surfaces. Lidar measures distance through the process of illuminating laser light to objects and evaluating reflected light. The Lidar systems can also scan objects and detect environmental changes by measuring light waves that bounce off them. We sometimes call it 3D or laser scanning.

Lidar technology has been in use for decades, but its recent developments have made it more accessible to PCB manufacturing companies. The latest advancements in lidars have made it possible for companies to inspect PCBs accurately at high speed.

Lidar uses light in the near-infrared region of the spectrum (wavelengths of 0.8 to 1.3 micrometers) to create a point cloud of measurements, which can help make 3D maps of inaccessible or dangerous areas.

Lidar is helpful in many fields, including astronomy, meteorology, geology, geography, automotive, aerospace, 3D printing, and robotics. It is also applicable in autonomous navigation in self-driving cars and drones.

What is a Lidar PCB?

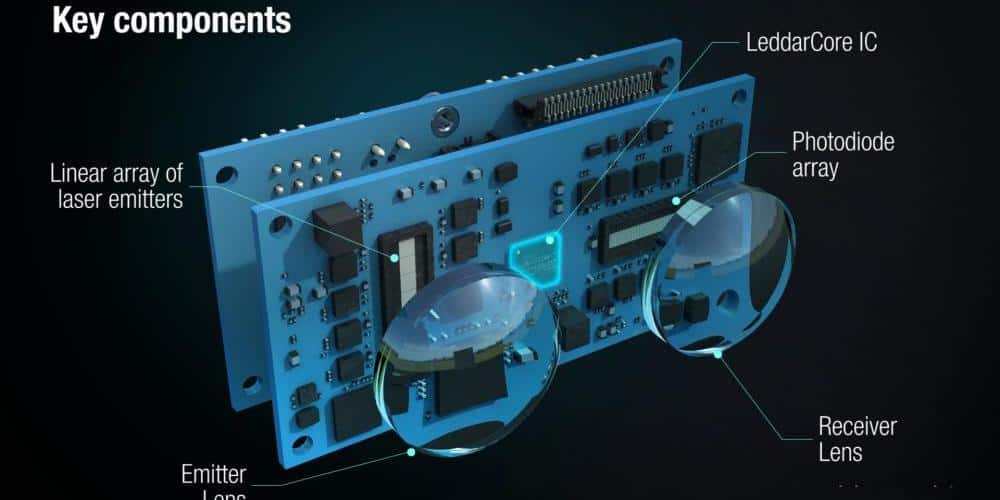

A lidar PCB is a printed circuit board containing a lidar sensor’s components, which is an essential part of the Lidar system.

Lidar PCBs typically consist of FR-4 glass epoxy laminate or copper-clad laminate. As a result, we can use them in all Lidar systems, such as range finders and scanners.

Lidar PCBs contain photodiodes, reflective elements, signal conditioning circuits, and amplifiers to convert light signals into electrical signals.

Using pulsed laser light, LiDAR sensors measure distances to detect objects in a range. The lidar PCB has an onboard processor that transmits and receives data. This feature allows for precise synchronization of the scanner’s movements. It also allows the computer to build a map of the area of data collection. It also includes point cloud maps, which reveal complex spatial relationships. These maps help identify objects like people, vehicles, and terrain.

PCB manufacturers have been using CO2 lasers for many years. They have shown that they are efficient in removing dielectric layers. However, they are not effective at drilling holes smaller than 75 mm.

How LiDAR works

You beam light toward a target and then measure the time it will take for the light to bounce back to the source. The lidar sensor records the time and uses such data to precisely calculate the distance between itself and the object/ground. The sensor then repeats the measurements million times and transmits the obtained information to a computer system that will create the area map related to the data collection criterion.

We refer to the 3D visual representations as Point Cloud maps. They include vital components and GPS identifying the transmitted light energy’s X, Y, and Z locations. In addition, onboard computers use the 3D map of the surrounding for navigation.

The lidar sensor fires a series of pulses between 8 to 108 laser beams. Each beam pulse can transmit billions of photons within a given second. There is simultaneous processing of data points and calculations, making the Lidar highlight objects accurately, determine their shape and display how they move. A computer algorithm will then simulate and assemble the figures to form a complete picture of the thing and its surroundings.

How to Use Lidar Technology in PCB Design

Lidar is a 3D imaging technology that works like radar. However, Lidar is 1 million times faster compared to sound waves you measure using sonar. So instead, you use light pulses to create a series of points in space suitable for making high-resolution images of objects.

Lidar technology has many use cases in PCB design. For example, it can help to generate CAD models, provide accurate geometry data and enable the production of 3D printed prototypes.

Lidar is an artificial intelligence (AI) tool that allows designers and engineers to create high-resolution designs for PCBs. Lidar AI design software scans the environment and creates CAD models based on the information gathered from the scanned environment.

Benefits of Lidar

Using LiDAR to map objects and create 3D models is an excellent idea for architects, engineers, landscape designers, and many other professions. The advantages of using LiDAR include speed, low-light performance, and high resolution and accuracy.

Resolution & Accuracy

We can use LiDAR (Light Detection and Ranging) technology to capture thousands of data points and produce reliable 3D representations of objects. The data helps to provide accurate ground truth, enabling safer navigation through diverse environments. It’s also valuable for construction, oceanography, agriculture, and transportation.

LiDAR sensors can scan millions of times per second. This trait allows LiDAR technology to provide reliable ranging over short ranges. In addition, we can combine the data with other sensory data to produce precise measurements.

LiDAR systems fall into two different types. Mechanical scanning LiDARs have some shortcomings. In contrast, solid-state designs are less expensive and more user-friendly. They also provide a path to mass-market automotive LiDAR solutions.

LiDAR also has applications in forestry. It allows forest management to determine the heights of the canopy. You can use it to interpret the shape of the trees and scan areas of high-risk flood risk.

3D mapping

Using LiDAR to map the environment is an excellent way to produce accurate and reliable 3D maps. We can use these for many applications, including classification, risk assessment, and disaster response. LiDAR mapping can map entire regions and specific objects and features. For example, liDAR can effectively map buildings, trees, and waterways. It also provides positional accuracy and georeferencing for each measurement.

LiDAR systems measure the height and width of a surface by using pulses of light. A plan then uses these measurements to create 3D mapping point clouds and register them with odometry. Next, you use this data to generate a Digital Elevation Model (DEM). The DEM usually has a 3-m horizontal resolution and a vertical precision of 0.1-m.

LiDAR is an ideal choice for mapping because it is accurate, reliable, and cost-effective. It helps to map large areas quickly and accurately. You can mount its sensors on cars or airborne.

Low Light Performance

Choosing the best sensor for your application requires understanding the trade-offs involved.

A suitable sensor must distinguish between different light intensities. This feature is essential for many applications, such as machine learning models.

The best sensors have large pixels to collect more photons. Consequently, it improves the dynamic pixel range and allows for better functioning in low-lighting conditions.

The best sensors also have a low cost, which is essential in many applications. This possibility is because the silicon-manufacturing process limits the silicon area required for a device. This is why high-quality, highly integrated CMOS sensors are more than a match for traditional charge-coupled device (CCD) sensors.

Speed

Since lidar data are distance measurements you obtain directly, there is no need to interpret or decipher them. This reason makes performance to be faster and reduces the need for processing.

Why is Lidar a Game-Changing Technology in the PCB Industry?

Lidar is a technology that has revolutionized the PCB industry. It has enabled PCB manufacturers to produce high-quality products with increased productivity and reduced costs.

Lidar technology benefits are numerous. For example, it can help in product design, testing and inspection of the product after production, and quality control to ensure that it meets all quality standards.

Laser scanning technology is applicable in companies like Apple, Microsoft, and Amazon to create 3D models of objects from different angles and distances to facilitate their design process.

Top 3 Ways to Use Lidar Technology in PCB Production

Lidar for PCB design: This technology can suit the design of PCBs. The Lidar scans the object from different angles to provide information about its shape and size. Consequently, designers can make better decisions when designing PCBs.

Lidar for PCB manufacturing: This can help create a highly accurate digital model of an object or product before its production using 3D printing technology. The Lidar scans the thing multiple times to create the digital model, which can then be converted into a physical prototype using 3D printing technology or CAD software.

Lidar for PCB print: Some companies use lidars to produce high-quality PCBs as part of their production process. It is an advanced version of the laser scanner, and it can record a digital image of objects in the form of light/radiation emitted from lasers.

Laser scanning: Laser scanning is similar to Lidar technology as it employs lasers to take a digital image of an object or environment. Lidar and laser scanning differ because while Lidar maps out 2-D surfaces, laser scanners map out 3-D surfaces.

Other LiDAR Applications

Using LiDAR technology has the following five applications:

- Woodland And Agriculture

Drones using LiDAR can help survey big farms to see how we can apply resources to boost output. They may also apply to such places to build 3D models illustrating how human activity has affected forest regions. Again, LiDAR’s capacity to pierce dense vegetation is a significant benefit.

- Land Surveying

Drones equipped with LiDAR sensors can rapidly, precisely, and affordably produce 3D digital terrain models (DTM) of difficult-to-reach places. UAVs are the best equipment for covering certain geographical regions when a human-crewed aircraft is an overkill. As opposed to helicopters or planes, drones are cheaper and faster to deploy, lowering costs and danger.

- Maintenance-Required Power Line Inspection

Huge safety risks arise from routine maintenance of electrical lines. LiDAR technology enables the early detection of problems with electricity lines. Utility firms can immediately analyze damage using UAVs and devise the least dangerous remedy.

- Advanced Transportation

LiDAR technology is an excellent resource for urban planners who want to increase the capacity of rail stations and mass transport networks. To develop plans for future transportation infrastructure, UAVs with LiDAR sensors can scan large regions and produce essential data.

- Minecraft Applications

For determining material quantities in open pit mines without interfering with work happening on the ground, LiDAR proves to be a superb tool. In addition, when we include drones in mining processes, it reduces time, money, and risk exposure.

Types of LiDAR Technologies and What They Do

There are many kinds of lidar systems on the market, each with unique qualities and uses.

1. Topographic LiDAR

The most popular Lidar is topographic, which creates high-resolution digital elevation models (DEMs) of the earth’s surface. This kind of Lidar can gather data at a high resolution and measure the distance to the ground using laser pulses. Maps of landscape features, including mountains, valleys, rivers, and coastlines, are created using topographic Lidar. Additionally, it helps to create digital terrain models and orthophotos (DTMs).

2. Mobile Mapping Lidar:

Mobile mapping lidar is a form of Lidar used to produce detailed 3D maps of a specific region. Usually installed on a vehicle, this kind of Lidar maps urban and rural areas. Applications for mobile mapping lidar include asset management, urban planning, and land surveying.

3. Airborne Lidar:

From the air, airborne Lidar helps to produce 3D maps of vast regions. Lidar can gather information over great distances and is generally part of airplanes. Applications of airborne Lidar include topography mapping, forest inventory, and archeological investigation.

4. Terrestrial Lidar:

This sort of Lidar helps to gather information from the ground. Typically installed on a tripod, this Lidar is suitable for topographical mapping features, including structures, highways, and rivers. In addition, land surveying, engineering, and archaeological investigation are a few terrestrial Lidar uses.

5. Scanning Lidar:

This Lidar helps to produce 3D maps of a specific area. This kind of Lidar scans a space in a spiral or raster pattern and is often part of a tripod. Applications for scanning lidar include 3D modeling, archeological investigation, and 3D printing.

6. Multi-beam Lidar:

This kind of Lidar helps to gather information from several laser beams. This kind of Lidar can concurrently collect data from several directions and is common in an airplane. There are several uses for multi-beam lidar, including 3D mapping, terrain modeling, and imaging.

7. Waveform Lidar:

This sort of Lidar helps to gather information from several laser beams. Lidar is suitable for many different purposes, including 3D mapping, terrain modeling, and imaging. It may concurrently collect data from numerous directions. For example, waveform lidar can easily determine the laser pulse strength and precise distance to a target.

8. Geodetic Lidar:

This form of Lidar helps to gather data over long distances. Applications for this kind of Lidar include asset management, engineering, and terrain mapping. For example, it is common in airplanes. Geodetic Lidar helps to create high-resolution DEMs and DTMs and can gather data across great distances.

9. Laser Scanning Microscopy Lidar:

This kind of Lidar helps to gather information from tiny things. Applications for this kind of Lidar include 3D modeling, 3D printing, and medical imaging. High-resolution 3D representations of small objects are easy to produce using laser scanning microscopy or Lidar.

10. LiDAR-based Photogrammetry:

We can gather data from aerial photographs using a Lidar called photogrammetry based on Lidar. Applications for this kind of Lidar include asset management, digital terrain modeling, and terrain mapping. Engineers create high-resolution DEMs and DTMs using LiDAR-based photogrammetry.

What Benefits Does Lidar Technology Have for PCB Manufacturing?

1. Increased Accuracy and Precision

The most significant benefit of lidar technology in PCB fabrication is greater precision and accuracy. Manufacturers can verify that each element is present by utilizing laser light to measure the distances between components. This check is crucial for complicated PCB designs because even the slightest misalignment might fail the entire board. In addition, Lidar can detect short circuits and verify that the PCB is adequately insulated.

2. Accelerating the manufacturing process

Additionally, the utilization of lidar technology significantly decreases the time required for PCB fabrication. Manual measurements are time-consuming and prone to human mistakes, whereas Lidar can finish the entire operation in a fraction of the time. This speed expedites manufacturing, resulting in potential cost savings for producers.

3. Cost Savings

Using lidar technology decreases costs in two ways: first, it reduces the time spent on production, hence decreasing labor costs; second, it helps to guarantee that PCBs are manufactured correctly, thereby eliminating the need for costly rework and repairs.

4. Enhanced Safety

Increased safety The use of lidar technology in PCB fabrication also boosts security. This removes the need for unsafe manual measurements that expose personnel to toxic chemicals. Additionally, Lidar may detect short circuits, which can cause significant harm if not discovered.

5. Environmental Impact Reduction

Lastly, applying lidar technology can lessen the environmental effect of PCB production. This is because the technology helps verify that all components are appropriately positioned, eliminating the need for rework, which may produce toxic emissions and waste.

What The Future Holds for LiDAR Technology in Printed Circuit Board (PCB) Manufacturing

In the PCB manufacturing sector, LiDAR (Light Detection and Ranging) technology is a fast-growing field. It can swiftly scan and measure distances, and its use in PCB creation and testing is rising. The technique has simplified production procedures and increased the accuracy and speed of PCB manufacturing.

In PCB manufacturing, manufacturers measure the size and form of a PCB before its fabrication. As a result, manufacturers can produce PCBs that fit the customer’s exact requirements.

In recent years, the usage of LiDAR technology in PCB manufacture has increased significantly since LiDAR offers several benefits over conventional PCB production processes. For example, it can scan and measure the precise size and form of a PCB in a considerably shorter length of time, which cuts production costs and improves productivity. It also enables the development of exact and accurate printed circuit boards, which enhances product performance and dependability.

Quality monitoring & inspection

LiDAR is useful for PCB production quality monitoring and inspection. The technique precisely and rapidly finds PCB faults, saving time and money in the long run. Additionally, it discovers and identifies design defects in PCBs, minimizing production mistakes and ensuring that the finished product fulfills client requirements.

Improved productivity

We anticipate that LiDAR technology will continue to expand in PCB manufacturing as manufacturers attempt to decrease costs and boost productivity. In the future, LiDAR may assist in automating the PCB creation process, substantially cutting the cost and time necessary to produce a PCB. In addition, LiDAR might aid in constructing highly accurate 3D representations of printed circuit boards (PCBs), which could facilitate virtual testing and prototyping.

Complex products

LiDAR might aid manufacturers in the production of PCBs with greater degrees of complexity. Therefore, it might enable manufacturers to produce PCBs with sophisticated features, like as integrated circuits, that are challenging to create using conventional methods. In addition, LiDAR can assist the fabrication of very accurate PCBs with several layers, which is suitable for applications such as smart gadgets and wearables.

LiDAR technology can change the PCB manufacturing process as a whole. It can decrease manufacturing processes’ complexity and improve PCB fabrication’s precision and speed. In addition, it might enable manufacturers to produce more sophisticated and accurate PCBs, enabling the development of several new applications and industries. As LiDAR technology continues to advance, we anticipate it will significantly influence the PCB manufacturing business.

Conclusion: Use the Future-Proofing Technology of Laser Scanners in Your Next PCB Production Run

Lidar uses time-of-flight measurements to create 3D representations of objects and scenes from data collected by scanning laser beams directed at targets.

We can use Lidar to distinguish between different materials and detect various types of radiation (such as infrared and ultraviolet). Moreover, we can measure atmospheric constituents such as temperature and humidity, map terrain elevation, estimate population density, and track moving objects such as vehicles.

Finally, LIDAR systems produce three-dimensional point cloud data that we can use for various applications, including mining site mapping; construction project planning; environmental monitoring; automotive design; robotics and autonomous systems; and navigation. Contact our company to get solutions to your PCB needs using lidar technology.