Internet of Things continues to tease us with a better and smarter future. Examples include fridges that can restock themselves by instantly ordering groceries from a nearby supermarket (in-fridge delivery available!), bridges that warn approaching vehicles of any frozen surface, as well as smart devices that track your health and wellness and send real-time data directly to your physician’s iPhone.

Even while all this might soon be in our hands, people still need to be conscious of the enormous apparatus working in close doors to make fantasies come true. These aspirations will never be realized without the numerous IoT technologies which are all around us.

IoT is Crucial, But Why?

People who use internet of things can work and live more intelligently and have total control and can take full charge of their lives.

IoT is crucial to business as well as providing smart home automation devices. With the help of IoT, organizations can see in real time how these systems actually function, gaining insights into anything from equipment performance to logistics and supply chain activities.

Businesses may automate procedures and save money on labor thanks to IoT device management. Additionally, it reduces waste, enhances service delivery, lowers the cost of manufacturing and delivering items, and provides transparency to customer transactions.

Due to this reason, IoT is among the most significant technologies of modern life, and will gain momentum as more companies recognize how linked gadgets can help them stay competitive.

What Advantages Does IoT offer Businesses and Organizations?

Organizations can gain a number of advantages from internet of things. Some advantages are unique to certain businesses, while others apply to many other industries.

IoT equips organizations with the resources they need to enhance their business strategy and challenges them to reevaluate how they conduct their operations.

However, this has found uses for organizations only within agriculture, infrastructure, as well as industries for home automation, leading some of the organizations towards digital transformation. In general, IoT is prevalent in transportation, manufacturing, as well as utility organizations, using iot sensors as well as other different consumer IoT devices.

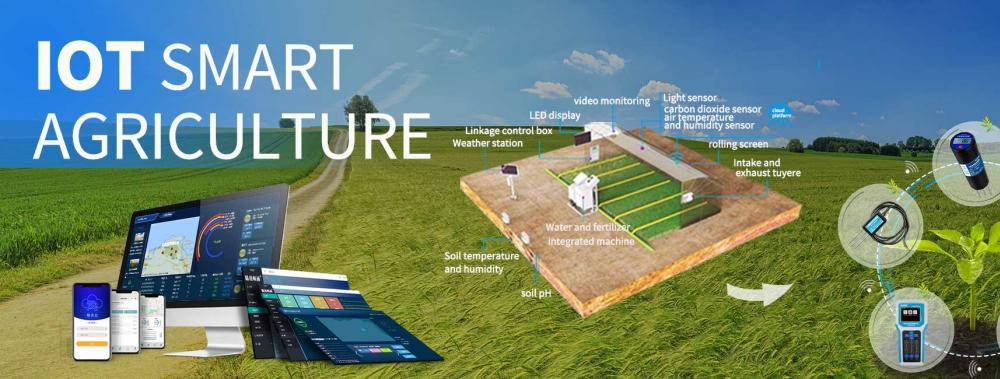

The use of IoT in agriculture can help farmers in simplifying their work. Sensors can gather information on soil composition, temperature, humidity, rainfall, and other variables that would aid in automating farming practices.

IoT can also assist with the capacity to monitor infrastructure-related operations. For instance, sensors could be employed to track developments or changes in the structural elements of bridges, buildings, as well as other infrastructure. Benefits associated with this include time savings, cost savings, changes to the workflow’s quality of life, including paperless workflow.

IoT can be used by the home automation company to monitor and control a building’s electrical and mechanical systems. On a larger scale, the smart cities could assist residents in using less garbage and energy.

Every industry, including those in healthcare, banking, retail, including manufacturing, is impacted by IoT.

What is the Excitement Surrounding IoT Technology?

Since mid 20th century, we have used computers and their technology. Internet of Things’ underlying technology, however, existed for long before everyone had access to PCs. Since the 2nd part of 19th century, telemetry, the first predecessor to the Internet of Things, has been utilized to collect and measure data as well as follow wildlife using wired phone lines, satellite communications, and radio waves.

Despite its technical shortcomings, it helped establish the idea of one machine to another machine communication, which progressively developed along with improvements in different connectivity solutions to give rise to the modern Internet of Things.

IoT can be described as a network of linked digital items, including machines, people, animals, and objects, that may exchange data over a network without any of the requirements for human-to-computer nor human-to-human interaction.

By bridging this gap between our real world as well as the digital one, the Internet of Things (IoT) strives to build intelligent settings where people can live more comfortably and intelligently, both as individuals and as a society as a whole.

Despite how pompous this may sound, Internet of Things has already ingrained itself into our daily lives and will undoubtedly remain there. Keeping this in mind, let’s take a quick look at the technology that powers the Internet of Things.

What Materials Make Up IoT Technology?

Given the complexity and sheer quantity of technology solutions which surrounds the IoT, it might be challenging to navigate your way all through it. However, in order to keep things simple, we may divide Internet of Things technological stack to four fundamental technology layers. These are listed below:

Device Hardware

In internet of Things, the devices are the physical things that make up the “things.” They serve as a bridge between the physical and digital worlds, and based on whatever function they are needed to carry out within the given IoT deployment, they might take various shapes, sizes, and technological complexity levels.

Almost any material object, including animate ones such as humans or other animals, can be made together into a specific connected device through the inclusion of the required instrumentation (by introducing actuators or sensors along with all the necessary software) in measuring and collecting the required data. This includes microscopic devices or large construction equipment.

Of course, actuators, sensors, as well as other telemetry equipment can also function as independent smart devices. The exact IoT application and requirements of the hardware are the only restriction that can be experienced here (size, deployment ease as well as management, useful lifetime, reliability, cost-effectiveness).

Device Software

The ‘smartness’ of connected gadgets is actually due to their device software. The implementation of connectivity with its cloud, coupled with data collection, device integration, and real-time analysis of data within are all handled by software.

Additionally, it is a device software which supports application level features for individuals to communicate with its IoT system as well as visualize data.

Communications

Once the software and hardware for the device are in place, another layer must be added to give smart objects ways to communicate with the remainder of an IoT ecosystem. It is important to think of communications mechanisms as a standalone system despite the fact that they are closely related to the software and hardware of devices. Physical connectivity options (LAN, satellite, cellular) and particular protocols utilized in various IoT contexts are both included in the communication layer (Thread, ZigBee, MQTT, Z-Wave, LwM2M). One key components in building all the IoT technology stacks is selecting the appropriate communications solution.

The technology selected will influence how data is transferred to and received out from Cloud, as well as how these devices are maintained and interact with other devices. Later in this article, we shall go into specifics of a few modern communications technologies for the sake of the current essay.

Platform

As was already established, the gadget can “feel” what is happening around it, then it will transmit that information to these user over a particular communications channel because of the “smart” software and hardware installed. All of this data is collected, handled, processed, analyzed, and then presented in such a user-friendly manner on the IoT platform.

The capacity of such a system to analyze and derive value from the sections of data given by these devices through the communication layer, rather than just its data gathering and IoT management skills, is what makes it particularly valuable.

Once more, there are a lot of different IoT platforms available, and this choice will depend on the needs of the individual IoT project as well as criteria like architecture as well as the IoT technology stack, customization options, reliability, used protocols, hardware independence, security, as well as cost-effectiveness. Also it’s important to note that platforms could either be installed locally or be hosted in the cloud. A nice illustration of this type of platform is the Coiote IoT Device platform, which can be set up both locally and in the cloud.

IoT technology Stack Connectivity Options

The connectivity solutions that support IoT technologies are as many just like the potential real-world applications for them. Each communication solution may offer various service enablement possibilities while offering tradeoffs between the power consumption, bandwidth and range based on the requirements of a specific IoT Application.

For example, if you’re designing your smart home, then you might want to interface your heating controller and indoor temperature sensor with your phone so you will be able to remotely monitor these temperatures in every room as well as modify them as needed. The suggested remedy in this situation would be Thread, an IP-based networking protocol created specifically for different home automation environments.

Given the variety as well as multiplicity of the communication protocols and standards, it is reasonable to question the necessity of creating new technologies when there are already existing tried-and-true Internet protocols in use. This is due to the fact that current Internet protocols, including Transmission Control Protocol and Internet Protocol, frequently aren’t efficient enough but need too much power to function effectively in the growing applications of IoT technology. The primary alternative protocols for the internet specifically created for usage by IoT systems will be briefly discussed in this section.

The overview focuses on the most widely used Internet of Things radio technologies, split down by the radio-frequency range each of these solutions achieves: short-range, medium-range, and long-range WAN solutions.

Short-range Network Solutions for IoT

Bluetooth

Given its extensive integration with phones, Bluetooth is regarded as the go-to short-range communication technology, especially for the market future of wearable electronics, including wireless headphones and geolocation sensors.

Bluetooth Low-Energy protocol uses a negligibly small amount of the device’s power and was created with cost efficiency and minimal power usage in mind. The trade-off is that BLE might not be the best option when exchanging larger volumes of data often.

RFID

Radio-frequency identification, one of the earliest IoT applications originally developed, provides positioning solutions to serve IoT applications, particularly in the logistics and management of the supply chain, which need the capability of establishing the position of the object inside buildings.

RFID technology obviously has a bright future beyond basic localization services, including potential uses including patient tracking in hospitals, increased healthcare productivity, and real-time product location data in order to reduce out-of-stock situations present in retail establishments.

Wifi

It was built on the foundation of IEEE 802.11, and it is still the most popular and well-known wireless communications. The IoT industry’s capacity to use it widely is mostly constrained by its higher-than-average power consumption, which is a byproduct of the necessity to maintain high signal strength and quick data transfer for improved connectivity and reliability.

Although WiFi is a significant technology for the advancement of the Internet of Things, it also must be managed as well as utilized in marketing in order to generate revenue to users and service providers.

Linkify is a great illustration of a unique platform for WiFi management that provides the value-added services enabling open access points for WiFi. Linkify, one of the cutting-edge technologies of the AVSystem, offers nearly infinite marketing as well as customization possibilities for guest WiFi.

ZIGBEE

The most common industries in which this well-liked wireless mesh standard is used are the machine sector, home electronics, and systems for traffic management. Zigbee, which is based just on IEEE 802.15.4 standard, provides low data transfer rates, low energy consumption, security, and dependability.

THREAD

Thread, which was created expressly for home products, uses IPv6 connection to let connected devices talk to one another, have access to cloud services, or engage with users through the Thread mobile application.

Given the saturation of the market, Thread’s critics have argued that adding another wireless protocol for communication will only further fracture its IoT technology stacks.

Solutions for Long Range WAN (Wide Area Network)

NB-IOT

Narrowband IoT can be described as a new radio technology that is a derivative of 3GPP technologies, which is now in use. It guarantees exceptionally low consumption of power (A decade of operation of the battery power) and connection with a signal strength that is roughly 23 dB less than that of 2G. Additionally, it makes use of current network infrastructure, guaranteeing both assured signal quality and global coverage for LTE networks. This aspect often makes it possible to use NB-IoT in place of technologies like Sigfox or LoRa that require the creation of different local networks.

LTE-CAT M1

M2M and IoT devices having medium requirements for the data rate can be connected using the low-power wide-area standard for connection known as LTE-Cat M1. Relative to other cellular technologies like LTE-Cat 1, 2G, or 3G, it has extended battery lifecycles as well as provides improved in-building range.

Because CAT M1 is applicable to the present LTE network, carriers do not need to invest in the new infrastructure before they can use it. LTE Cat M1 is superior to the NB-IoT for the mobile applications since it handles hand-over between the cell sites more better and is also more comparable to the high-speed LTE.

LORAWAN

This is known as the long-range low power Wide-Area Networking that supports massive networks containing millions of phones and devices and is designed for low energy consumption. In order to provide low-cost, and ensure bi-directional communication in M2M, IoT, smart city, as well as industrial applications, this LoRaWAN is built with wide-area network applications in mind.

SIGFOX

The idea underlying Sigfox is offering an efficient connection option for M2M applications of low power that need low amounts of transfer of data but can’t use cellular service since it costs too much and uses too much power and WiFi range seems too short for them. UNB is a technology used by Sigfox, allowing it to be able to handle slow data transfer rates between 10 to about 1,000 bits each second.

It offers a stand-by time for a battery of 2.5Ah of 20 years while using approximately 100 times lesser energy than cellular communication systems.

Sigfox confirms that it is suitable for different M2M applications, which includes intelligent meters, smart street lighting, security devices, patient monitors as well as environmental sensors. It provides a reliable, energy-efficient, as well as scalable network that can support communication in-between millions of devices that are battery-operated over some several square kilometer areas. A rising number of Internet of Things (IoT) technological solutions, including Coiote, to name just one, currently use Sigfox.

What are Benefits and Drawbacks of the IoT Technology?

IoT has several benefits, some of which are listed below:

- Better communication between the connected devices

- The ability to obtain details from anywhere and at all times on all devices

- The ability to transfer data packets across a unique and connected network thereby saving money and time

- Ability to automate tasks enhancing the caliber of the services of a business as well as reduce the requirement for intervention of humans

The following are some drawbacks of IoT:

- As the connected devices available increases and information is transferred more often between different devices, the risk that any hacker may steal sensitive data rises as well.

- Enterprises may someday have to manage enormous numbers of different IoT devices—possibly millions—and it will be difficult to collect and manage this data from these devices.

- It’s conceivable that every linked device would become corrupted whenever the system has a problem.

- Since there is no global IoT interoperability standard, it is challenging for devices got from various manufacturers to connect devices with one another.

IoT Applications for Consumers and Businesses

The IoT technology has many practical uses, from consumer and business IoT through manufacturing as well as industrial IoT. Numerous industries, including the automotive, communication, and energy sectors, use IoT applications.

In consumer markets, for instance, smart houses with networked heating, lighting, electronic equipment as well as smart appliances can be operated remotely using smartphones and computers.

In order to make users’ life more comfortable and easier, wearable technologies with software and sensors may gather and analyze data of users. They can also send messages onto other technologies concerning the users. In order to improve first responders’ reaction times during different emergencies, wearable gadgets are also employed in public safety. Take for instance, they can provide efficient routes to the location as well as monitor the vital signs of firemen or construction workers at potentially fatal work sites.

IoT in healthcare has several advantages, one of which is the capacity to track patients very closely by analyzing the data produced. IoT devices are frequently used in hospitals to carry out activities like managing the inventory of drugs and medical equipment.

Utilizing sensors that determine the number of inhabitants inside a room, smart buildings for example, can lower energy expenditures. Automatic temperature adjustments can be made, such as turning on air conditioners if sensor senses that there’s a full conference room or reducing the heat when everyone has left the workplace.

IoT Privacy and Security Issues

IoT uses data points (billions) to connect billions of different devices onto the internet, and all must be protected. Also, IoT privacy and IoT security are identified as important problems due to the larger attack surface.

Since IoT devices remain interconnected, a hacker only needs to take advantage of one weakness to change all the entire data and make it useless. Devices made by manufacturers who don’t update them frequently or never leave them open to hackers.

Additionally, users of linked devices are frequently prompted to provide personal data such as names, addresses, ages, phone numbers, as well as social network accounts. This data is useful to hackers.

The IoT technology is also threatened by privacy issues, which are a top priority for the IoT users. manufacturers and distributors of customer IoT devices might utilize those gadgets to collect and market the personal information of customers.

Conclusion

Given the rapid pace of the IoT development as well as the fact that it has already established a comfortable presence in different homes, workplaces, public spaces, and manufacturing facilities, it appears that the clichéd IoT adage “anything that could be connected would be connected” is rapidly approaching becoming our everyday reality. So, rather than asking when this would happen, the actual question ought to be ways in connecting everything in a way that maximizes efficiency while maintaining essential elements like cost-effectiveness and security. IoT is useful for data processing, data encryption, wireless network, smart home devices, health monitoring devices, and more.