Thermal management is a critical aspect of printed circuit board (PCB) design, especially as electronic devices become more powerful and compact. Effective thermal design ensures optimal performance, reliability, and longevity of electronic components and systems. This comprehensive guide explores the principles, techniques, and best practices for thermal design in PCBs, covering everything from basic concepts to advanced strategies.

Understanding Heat Generation and Transfer in PCBs

Sources of Heat in PCBs

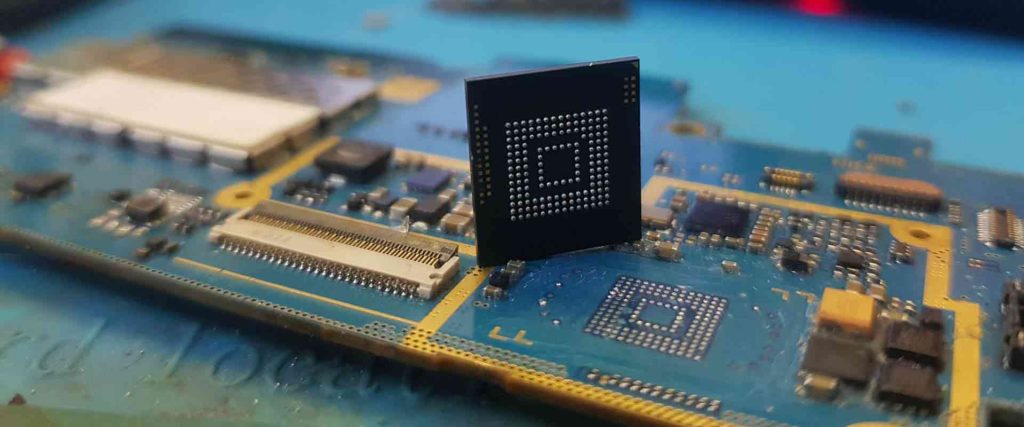

Heat generation in PCBs primarily comes from active components such as:

- Integrated circuits (ICs)

- Power semiconductors

- Resistors

- LEDs

Heat Transfer Mechanisms

There are three main heat transfer mechanisms in PCBs:

- Conduction

- Convection

- Radiation

Heat Transfer Coefficients

| Mechanism | Typical Range (W/m²K) |

| Conduction (through PCB) | 0.3 – 0.8 |

| Natural Convection (air) | 5.-25 |

| Forced Convection (air) | 10 – 300 |

| Radiation | 5.-8 |

Thermal Management Strategies

Component Selection and Placement

Thermal Considerations for Component Selection

- Maximum operating temperature

- Thermal resistance (junction-to-case, junction-to-ambient)

- Power dissipation

Component Placement Guidelines

- Place high-power components away from heat-sensitive devices

- Allow adequate spacing for airflow

- Consider thermal coupling between adjacent components

PCB Material Selection

The choice of PCB material significantly impacts thermal performance.

Thermal Conductivity of Common PCB Materials

| Material | Thermal Conductivity (W/mK) |

| FR-4 | 0.3 – 0.5 |

| Aluminum PCB | 1.0 – 3.0 |

| Ceramic PCB | 20 – 270 |

| Copper | 400 |

Copper Pour and Plane Design

Copper planes and pours play a crucial role in heat distribution across the PCB.

Copper Thickness and Thermal Performance

| Copper Weight | Thickness (µm) | Relative Thermal Performance |

| 0.5 oz | 17.5 | 1.0 (baseline) |

| 1 oz | 35 | 2 |

| 2 oz | 70 | 4 |

| 3 oz | 105 | 6 |

Thermal Vias

Thermal vias enhance heat transfer between PCB layers.

Thermal Via Design Guidelines

- Use multiple small vias instead of fewer large vias

- Place vias in a grid pattern under hot components

- Fill vias with thermally conductive material when possible

Thermal Relief and Starved Thermal Pads

Balancing thermal performance with manufacturability is crucial.

Thermal Relief Design

- Use thermal relief connections for easier soldering

- Adjust spoke width and count based on thermal requirements

- Consider direct connections for high-power components

Advanced Thermal Management Techniques

Heat Sinks and Spreaders

Heat sinks and spreaders increase the surface area for heat dissipation.

Heat Sink Selection Factors

- Thermal resistance

- Size and weight constraints

- Airflow characteristics

- Attachment method

Forced Air Cooling

Implementing forced air cooling can significantly enhance thermal performance.

Airflow Design Considerations

- Fan placement and orientation

- Duct design for directed airflow

- Impedance matching for optimal air movement

Liquid Cooling Systems

For high-power applications, liquid cooling offers superior heat dissipation.

Liquid Cooling Methods

- Cold plates

- Immersion cooling

- Spray cooling

Thermoelectric Cooling (Peltier Devices)

Thermoelectric coolers can provide active cooling for specific components.

Peltier Device Considerations

- Power consumption

- Heat dissipation requirements

- Temperature differential capabilities

Thermal Analysis and Simulation

Thermal Modeling Techniques

Accurate thermal modeling is essential for predicting PCB thermal performance.

Common Thermal Modeling Approaches

- Lumped parameter models

- Computational Fluid Dynamics (CFD)

- Finite Element Analysis (FEA)

Thermal Resistance Calculations

Understanding thermal resistance helps in estimating component temperatures.

Thermal Resistance Network

| Path | Symbol | Description |

| Junction to Case | θJC | Internal component resistance |

| Case to Heat Sink | θCS | Interface material resistance |

| Heat Sink to Ambient | θSA | Heat sink efficiency |

Total thermal resistance: θJA = θJC + θCS + θSA

CFD Simulation for PCB Thermal Analysis

CFD simulations provide detailed insights into thermal behavior.

Key Parameters for CFD Simulation

- Component power dissipation

- PCB material properties

- Ambient conditions (temperature, airflow)

- Enclosure geometry

Thermal Management for High-Density Designs

3D Packaging Thermal Considerations

3D packaging introduces unique thermal challenges.

Thermal Management Strategies for 3D Packages

- Through-Silicon Vias (TSVs) for heat extraction

- Interposer layers with high thermal conductivity

- Microchannel cooling within the package

Thermal Design for Flex and Rigid-Flex PCBs

Flexible circuits require special thermal management approaches.

Thermal Considerations for Flex PCBs

- Limited heat spreading due to thin copper layers

- Use of polyimide or other high-temperature materials

- Implementation of stiffeners for improved heat dissipation

Thermal Testing and Validation

Temperature Measurement Techniques

Accurate temperature measurement is crucial for thermal design validation.

Common Temperature Measurement Methods

- Thermocouples

- Infrared thermography

- Temperature-sensitive paints

- On-chip temperature sensors

Thermal Cycling and Reliability Testing

Thermal cycling tests assess long-term reliability under varying temperature conditions.

Thermal Cycling Test Parameters

| Parameter | Typical Range |

| Temperature Range | -40°C to +85°C (or application-specific) |

| Dwell Time | 15 – 30 minutes |

| Ramp Rate | 10°C – 20°C per minute |

| Number of Cycles | 500 – 1000 (or more) |

Regulatory Compliance and Thermal Design

Thermal Requirements in Industry Standards

Various industry standards specify thermal requirements for electronic equipment.

Key Thermal Standards

- IPC-2152: Standard for Determining Current-Carrying Capacity in Printed Board Design

- JEDEC JESD51: Standards for Thermal Measurement of Semiconductor Devices

- MIL-STD-810: Environmental Engineering Considerations and Laboratory Tests

Safety Considerations in Thermal Design

Thermal design must address safety concerns to prevent hazards.

Thermal Safety Considerations

- Maximum touch temperature limits

- Fire prevention and containment

- Thermal runaway protection

Emerging Trends in PCB Thermal Management

Advanced Materials for Thermal Management

New materials offer improved thermal performance for PCBs.

Emerging Thermal Management Materials

- Graphene-based thermal interface materials

- Carbon nanotube-enhanced composites

- Phase change materials for thermal energy storage

AI and Machine Learning in Thermal Design

Artificial intelligence is increasingly used to optimize thermal designs.

AI Applications in Thermal Management

- Predictive thermal modeling

- Automated component placement optimization

- Real-time thermal management in adaptive systems

Frequently Asked Questions

Q1: What are the primary goals of thermal management in PCB design?

A1: The primary goals of thermal management in PCB design are:

- Maintaining component temperatures within their specified operating ranges

- Ensuring overall system reliability and longevity

- Preventing thermal-induced failures or performance degradation

- Optimizing power efficiency

- Meeting regulatory and safety requirements related to temperature

Q2: How do I determine if my PCB requires active cooling?

A2: To determine if your PCB requires active cooling:

- Calculate the total power dissipation of all components

- Estimate the PCB’s ability to dissipate heat passively (through conduction, natural convection, and radiation)

- Compare the estimated component temperatures with their maximum operating temperatures

- Consider environmental factors such as ambient temperature and airflow

- If passive cooling is insufficient to maintain safe operating temperatures, active cooling methods (e.g., fans, heat sinks, or more advanced cooling systems) should be considered

Q3: What are some common mistakes in PCB thermal design?

A3: Common mistakes in PCB thermal design include:

- Underestimating component power dissipation

- Neglecting thermal coupling between adjacent components

- Insufficient copper pour or improper use of thermal vias

- Ignoring the effects of enclosures on heat dissipation

- Failing to consider worst-case scenarios or environmental conditions

- Overlooking the impact of thermal design on EMI/EMC performance

Q4: How can I improve the thermal performance of an existing PCB design?

A4: To improve the thermal performance of an existing PCB design:

- Add or enhance heat sinks on critical components

- Implement forced-air cooling if not already present

- Increase copper weight or add additional copper pours

- Add thermal vias under hot components to improve heat transfer to other layers

- Use thermal interface materials to improve heat transfer to enclosures or heat sinks

- Consider component upgrades to more thermally efficient alternatives

- Optimize component placement to reduce thermal coupling and improve airflow

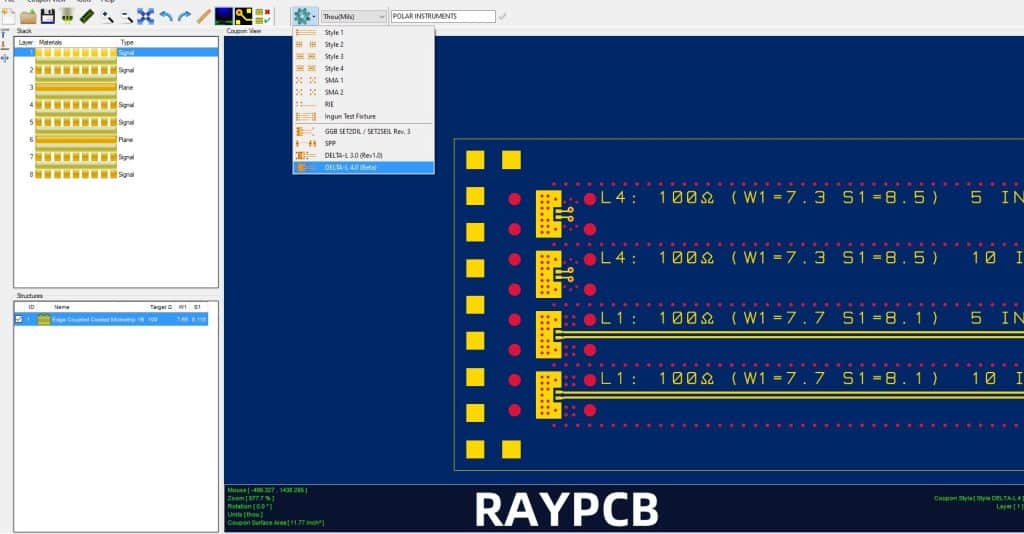

Q5: What role does PCB stack-up play in thermal management?

A5: PCB stack-up plays a significant role in thermal management:

- The number and thickness of copper layers affect heat spreading capability

- Inner ground and power planes can act as heat spreaders

- The choice of dielectric materials impacts overall thermal conductivity

- Stack-up symmetry helps prevent board warpage due to thermal stress

- The position of high-power components relative to thermal layers affects heat dissipation efficiency