How to Fabricate a PCB With DIY Methods?

Method 1#:

- Cut the copper-clad laminate to the size required by the pcb fabrication

- Put the stencilpaper on the steel plate, use a pen to draw the circuit diagram on the stencil paper (diagram size should be 1:1), cut it out according to the PCB size, and place it on the copper-clad laminate. Take a small amount of paint and talcum powder into a suitable printing material, dip the printing material with a brush, and evenly apply it to stencil paper. Repeat it several times. Then the circuit can be printed on the printed board. This printed board can be used repeatedly and is suitable for small batch production.

- Use 1g of potassium chlorate and 40ml of 15% hydrochloric acid to prepare a corrosive solution, and then apply it to the printed board where it needs to be corroded for corrosion.

- Wash corroded printed boards repeatedly with water. Wipe off the paint with banana oil, and then wash it several times to clean theprinted board without leaving corrosive liquids. Apply a layer of rosin solution. Let it dry before drilling.

PCB fabrication Method 2#:

There are many ways amateurs can create PCB, but they are either time-consuming, complex in “craftsmanship,” or low quality. My method of making PCB is one of the methods with a better overall effect. The method is as follows:

- Printed circuit board diagram. The pads in the figure are represented by dots, and the connection can be a single line, but the position and size must be accurate.

- Cut the printed circuit board according to the circuit diagram’s sizeand clean the surface of the copper foil.

- Use carbon paper to copy the diagram to the printing board. If the circuit is simple and the producer has extensive board-making experience, this step can be omitted.

- Depending on the components, paste standard pre-cut symbols (pads) with different inner and outer diameters. Then stick tape lines of different widths according to the current. Electronic stores provide standard pre-cut symbols and tape. Common specifications of pre-cut symbols include basic materials such as D373 (0D-2.79, ID-0.79), D266 (0D-2.00, ID-0.80), D237 (OD-3.50, ID-1.50). Try not to use (black) and plastic (red) materials. The general specifications of tape are 0.3, 0.9, 1.8, 2.3, 3.7, etc. The unit is millimeters.

- Use a softer hammer, such as smooth rubber, plastic, etc.,to hit the sticker to make it fully adhere to the copper foil. Focus on the turning and overlapping of the line. It is best to use a heater in cold weather to heat the surface to enhance the adhesion effect.

- Put it in ferric chloride to start the corrosionprocess. Be noted that the liquid temperature cannot be higher than 40° After corrosion, it should be taken out and rinsed at the correct time, especially if there are thin lines.

- Make holes, polish the copper foil with fine sandpaper, apply rosin alcohol solution, and let it dry. The quality of this printed board is very close to that of a conventional printed board. The 0.3 mm tape can be passed between the two legs of the IC, which can greatly reduce the short jumpers on the front of the circuit board, thus saving trouble and time.

PCB fabrication Method 3#:

- Dissolve lacquer flakes (namely shellac, available from chemical stores) in three parts of absolute alcohol, and stir appropriately. After all the flakes dissolve, add a few drops of medical purple potion (gentian violet) to make it show a particular After evenly mixing, it can be used as protective paint for the pcb fabrication.

- First,polish the copper-clad board with fine sandpaper. Then use the duckbill pen in the drawing instrument (or the ink duckbill pen used to draw graphics on the compass) for drawing. There are nuts on the duckbill pen to adjust the thickness of the stroke. You can also use a triangle ruler to draw thin straight lines. The drawn line should be smooth, uniform, without jagged edges, giving people a smooth and fluent feeling. You can also write Chinese characters, English, pinyin, and symbols in the free space of the circuit board.

- If the drawing line penetrates the surrounding environment, the concentration is too small,and you can add some paint chips. If the drawing line does not stretch smoothly and becomes too thick, you need to drop a few drops of absolute alcohol. It doesn’t matter if you make a mistake. Just wipe it off with a small cotton swab dipped in absolute alcohol, and then redraw. After drawing the circuit board, it may corrode in the ferric chloride solution. After the circuit board is corroded, it is very convenient to remove the paint. Dip a cotton ball in absolute alcohol to wipe the protective paint to dry, and then apply rosin.

- Because the alcohol evaporates quickly, the prepared protective paint should be sealed and stored in a small bottle,such as an ink bottle. Cover the bottle cap after use. If the concentration becomes thicker in the next use, add the appropriate amount of anhydrous alcohol to dilute the solution.

Fabrication PCB Method 4#:

- Paste the self-adhesive labels on the copper foil of the copper-clad laminate, then draw the circuit on the veneer. Use a cutter to cut the veneer to form the required circuit prototype, remove the non-circuit parts, and finally use ferric chloride to corrode theideal circuit board.

- The corrosion temperature can be performed at about 55°C, and the corrosion rate is more rapid. Rinse the corroded circuit board with clean water, remove the self-adhesive labels on the circuit board, make holes, wipe clean, and then apply rosin alcohol solution prior to

Method 5#:

- Arrange the components’ density and positionaccording to the shape of the components used in the schematic circuit diagram and the size of the printed board area. The components‘ location should be determined according to the principle of large first, then small, first overall, and then local. The adjacent components in the circuit are placed nearby and arranged neatly and evenly.

- The connecting tracebetween components cannot be bent at right angles at the corners or intersections of the two traces. They must transition through a curve, and they cannot cross each other and turn too far. When certain traces cannot achieve this, you can consider placing printed trace on the back of the printed board and then using stud bolts to connect to the front circuit. Another solution is to use insulated trace when soldering components.

- The distance between the input part and the output part is better to avoid mutual interference.

Method 6#:

- Print the circuit board diagram on the printer at a ratio of 1:1 on 80 grams of copy paper. Hand drawing is also possible, but the bottom paper should be flat.

- Find a fax machine, take out the fax paper from the machine, and replace it with a hot-melt plastic film. Put the circuit diagram into the fax machine’s outgoing fax trayand use the copy button to copy the circuit diagram on the hot-melt plastic film. At this time, the “printed manuscript” of the printed circuit board is ready.

- Use double-sided adhesive tape to affix the drawn plastic film to the copper-clad board evenly. The plastic film and board shouldbe flat and not wrinkled. The tape paper can not cover the melted part. Otherwise, it will affect the production quality of the circuit board.

- Use a paintbrush to brush the paint on the plastic film evenly. Note: Only brush in one direction. Otherwise,the plastic film will wrinkle, and the lines on the copper plate will overlap. After the circuit diagrams have been brushed, carefully remove the plastic film. At this time, a printed circuit board is finished. After drying, it can be corroded.

- If you want to print manypieces, you can make a wooden frame that is a little larger than the circuit board, lay the PCB stencil (our company sells it) flat on the wooden frame, and fix it. Then use double-sided tape to stick the fixed plastic film under the screen. Put the copper-clad board on the table, close the screen frame (the printed image and the copper-clad board should be aligned left and right), use a paintbrush to paint in one direction, and remove the screen frame. The printed circuit board is printed. If there is any defect, it can be modified with paint and bamboo.

Pay attention to the above process. When painting, the hand force should be light and heavy. If there is too much paint or the film is too thick, the lines will be smudged. If the force is too light, the lines will break. And the plastic film must face up.

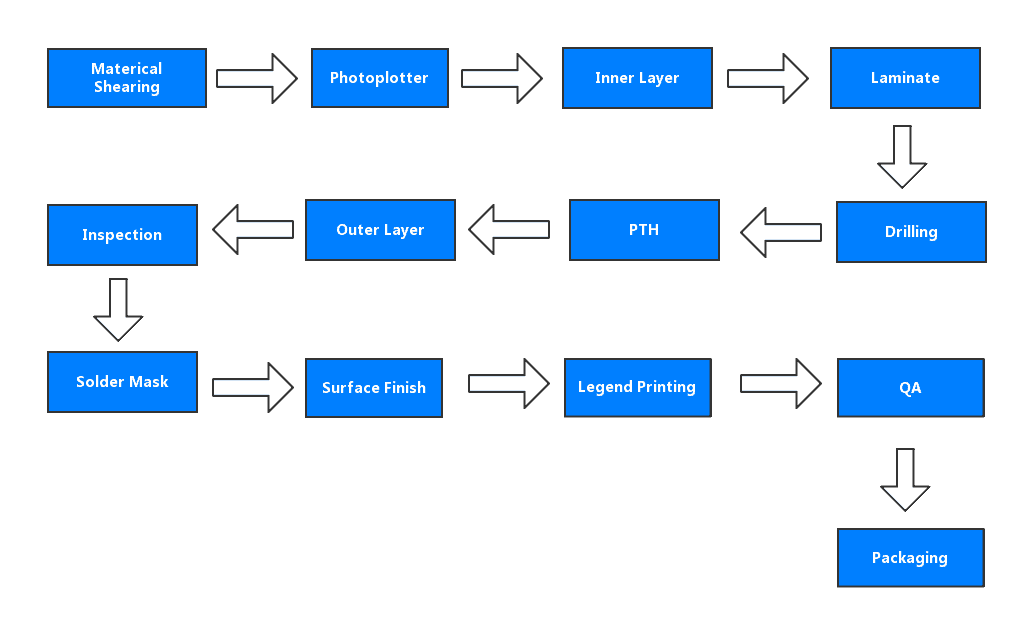

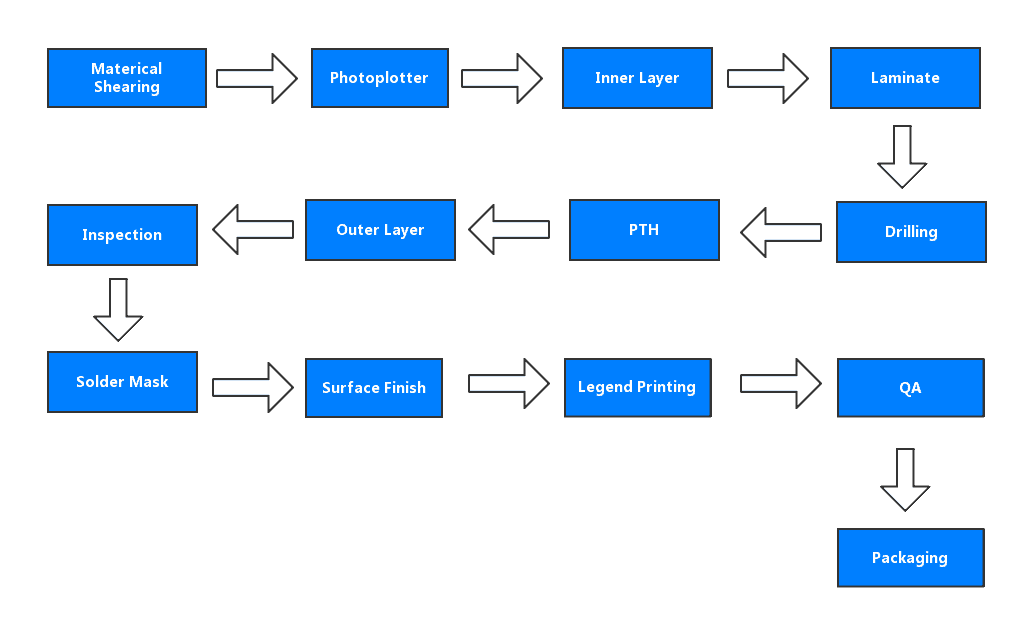

What is the Industrial PCB fabrication Process?

- Board cut

Board cutting is the process of cutting the original copper-clad laminate into boards that can be made on the production line.

First, let’s understand a few concepts:

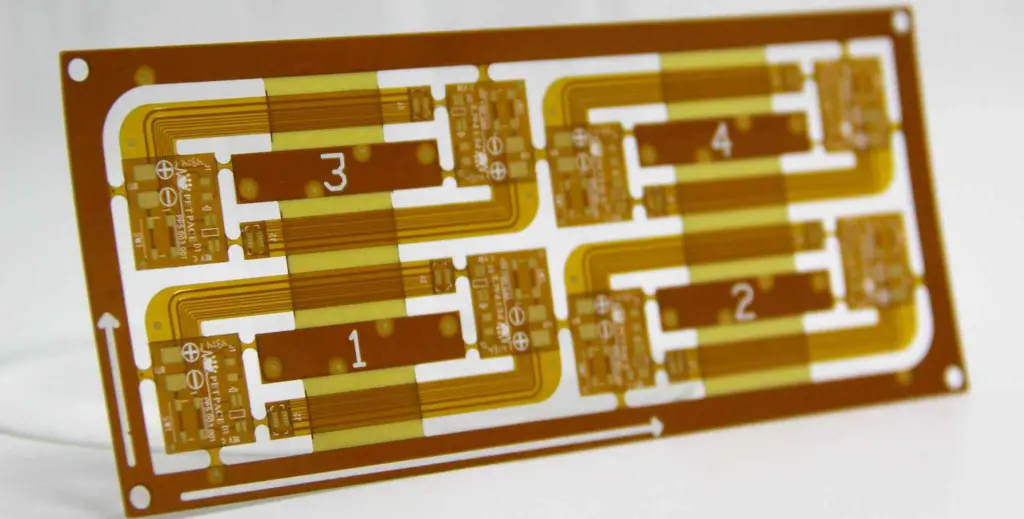

- UNIT: Refers to the unit graphics designed by PCB design engineers.

- SET: Refers to multiple units that engineers put together to improve production efficiency and facilitate production. This is what we often call the puzzle, which includes unit graphics, process edges,etc.

- PANEL: Refers to a pcb fabrication composed of multiple sets. It is added with tool board edges to improve efficiency and facilitate production when PCB manufacturers producethe product.

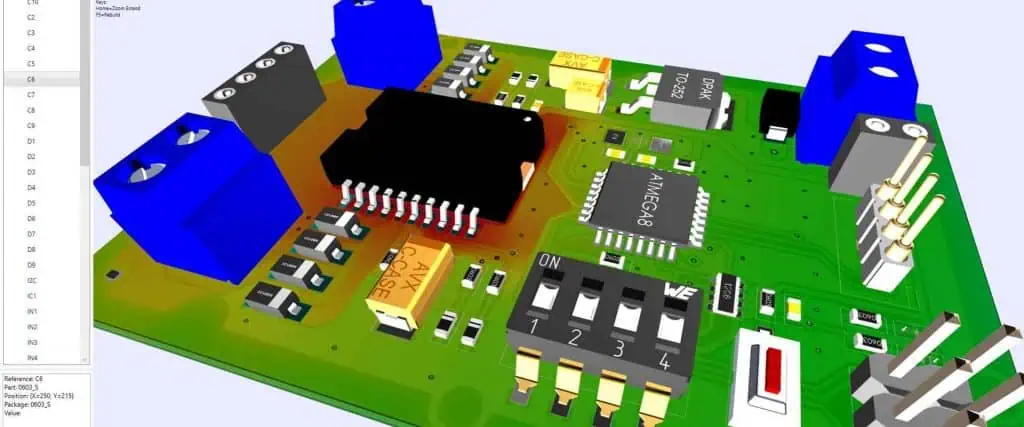

- Innerdry film

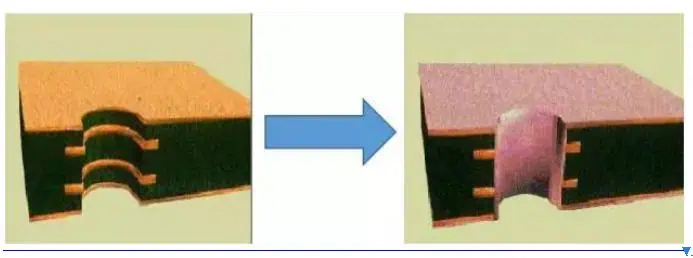

The inner layer dry film is the process of transferring the inner layer circuit pattern to the pcb manufacturing board.

In PCB production, we will mention the concept of graphics transfer because the production of conductive graphics is the basis of PCB production. Therefore, the graphics transfer process is of great significance to pcb fabrication process.

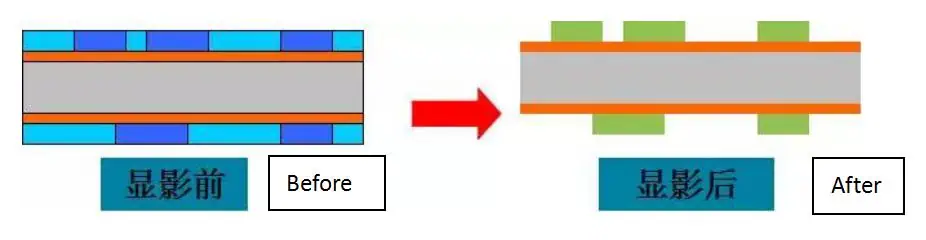

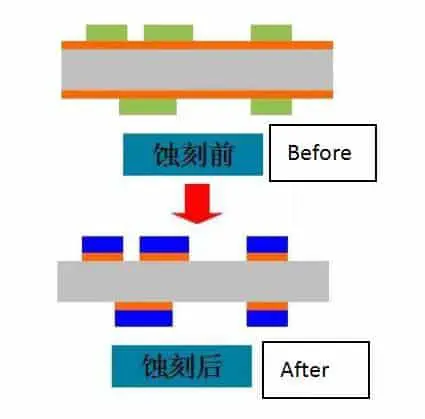

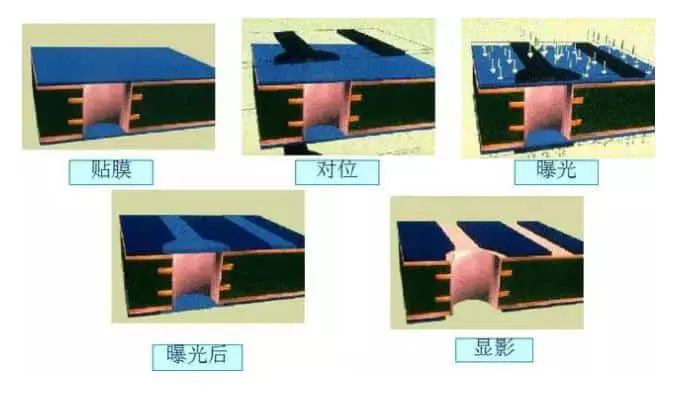

The inner dry film application includes many processes such as inner layer filming, exposure, development, and etching. The inner film is to paste a special photosensitive film on the copper plate’s surface, which we call a dry film. This film will cure when exposed to light, forming a protective film on the board. Exposure and development expose the board with the film, the transparent part is cured, and the non-transparent part is still the dry film. After developing, the uncured dry film is removed, and the board with the cured protective film is etched. After removing the film, the inner circuit pattern is transferred to the board. The whole process flow is shown in the picture below.

For designers, our main consideration is the minimum line width, spacing control, and wiring uniformity. If the distance is too small, it will cause film clamping. If this occurs, the film cannot be removed entirely and will cause a short circuit. If the line width is too small, the film’s adhesion is insufficient, resulting in an open circuit. Therefore, the safety spacing during circuit design (including line to line, line to pad, pad to pad, line to the copper surface, etc.) must be considered during pcb manufacturing.

- Grinding board

The primary function of the grinding plate: The basic pretreatment is mainly to solve the problems of surface cleanliness and roughness. Remove oxidation and increase the copper surface’s roughness, which will increase the film’s adhesion effect to the copper surface.

- Filming

Paste the processed substrate with dry film or wet film by hot pressing or coating to facilitate subsequent exposure production.

- Exposure

Align the negative film with the substrate on which the dry film is pressed, and use ultraviolet light on the exposure machine to transfer the negative film pattern to the photosensitive dry film.

- Development

Use the weak alkalinity of sodium carbonate to dissolve and rinse the unexposed dry film/wet film, leaving the exposed part.

- Etching

After the unexposed dry film and wet film are removed, the copper surface will be exposed. Use acid copper chloride to dissolve and corrode the exposed copper surface to obtain the required circuit.

- Film stripping

Use sodium hydroxide solution to peel off the exposed dry film that protects the copper surface to expose the circuit pattern.

3. Brown oxidation

Purpose: To form a microscopic roughness and organic metal layer on the inner copper surface to enhance the adhesion between the layers.

Process principle: Through chemical treatment, a uniform and good adhesion characteristic of the organic metal layer structure is produced. The copper layer’s surface, which is before the inner layer, is roughened in a controlled matter. This is to strengthen the inner copper layer and the prepreg after pressing the plate strength.

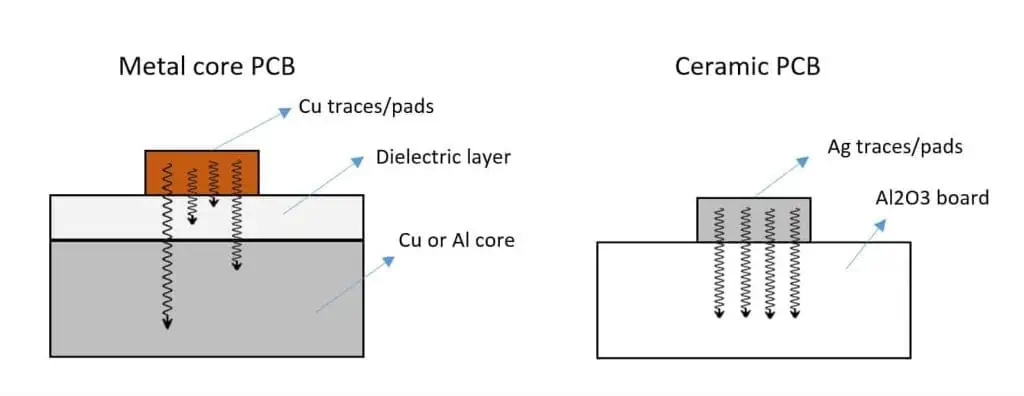

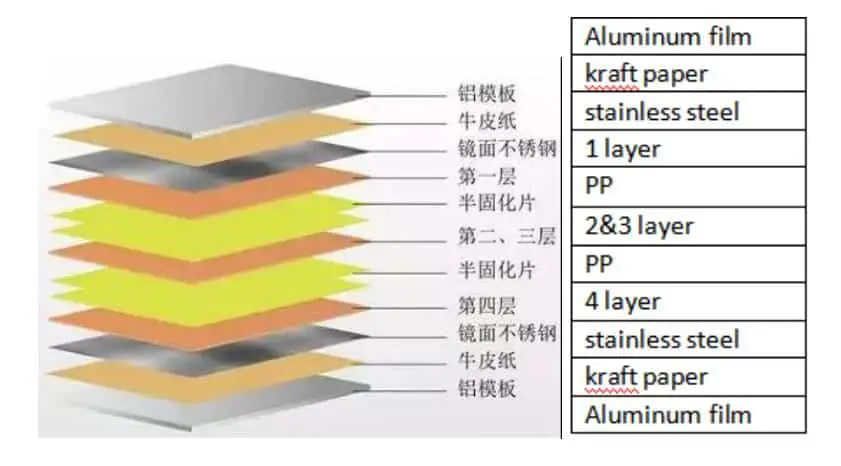

4.Stack up

Stack up is the process of bonding each layer into a whole utilizing the PP sheet’s adhesiveness. This bonding is achieved by mutual diffusion, penetration between macromolecules on the interface, and interweaving. The multi-layer pcb manufacturing and PP sheets are pressed together to form a multi-layer board with the required number of layers and thickness. In actual operation, the copper foil, bonding sheet (prepreg), inner layer, stainless steel, isolation board, kraft paper, outer layer, and other materials are laminated according to the process requirements.

For designers, the first consideration for stack up is symmetry. Because the pcb fabrication will be affected by pressure and temperature during the lamination process, stress will remain on the board after the lamination is completed. Therefore, if the two sides of the laminated board are not uniform, the stress on the two sides will be different, causing the board to bend to one side, which greatly affects the PCB’s performance.

In addition, even in the same layer, if the copper distribution is uneven, the resin flow rate at each point will be different. As a result, the area with less copper will be slightly thinner, and the area with more copper will be slightly thicker.

In order to avoid these problems, various factors such as the uniformity of the copper distribution, the symmetry of the stack, the design and layout of the blind and buried holes, etc., must be considered in detail during the design.

5.Drilling

Drilling is the process of creating through-holes between the layers to connect the layers.

6.Plated through holes(PTH) and plating

- Plated through holes(PTH)

Plated through-holes are also called chemical copper. After drilling, the PCB board undergoes redox reactions in the sinking copper cylinder to form a copper layer to metalize the holes. Copper is deposited on the surface of the original insulating substrate to achieve an interlayer electrical connection.

- Plating

Plating creates the PCB board surface that has just been copper-immersed. The copper in the hole is thickened to 5-8um to prevent the thin copper in the hole from being oxidized or micro-etched and leaking the substrate before pattern plating.

(1) Outer dry film

The process is the same as the inner dry film.

8.Outer layer pattern plating, SES

The copper layer of the hole and circuit is plated to a specific thickness (20-25um) to meet the copper thickness requirements of the final PCB board. The useless copper on the board surface is etched away, exposing useful circuit patterns.

9. Solder mask

Solder mask, also called and green oil, is one of the most critical PCB fabrication processes. Solder mask is achieved mainly through screen printing or coating solder mask ink, coating a layer of solder mask on the board surface, and developing through exposure. The processes also expose the disk and hole to be soldered and cover other areas with solder mask to prevent short circuit during soldering.

10. Silkscreen

The required text, trademark, or part symbol is printed on the board surface by screen printing. Afterward, it is exposed on the board surface by ultraviolet radiation.

11. Surface treatment

The solderability of bare copper itself is very good, but long-term exposure to the air can cause oxidation and saturation. It tends to exist in the form of oxides and is unlikely to remain as the original copper for an extended period. Therefore, surface treatment of the copper surface is required. The primary purpose of surface treatment is to ensure good solderability or electrical properties.

Regular surface treatments: HASL, immersion gold(ENIG), OSP, immersion tin, immersion silver, electric hard gold, electric gold fingers, etc.

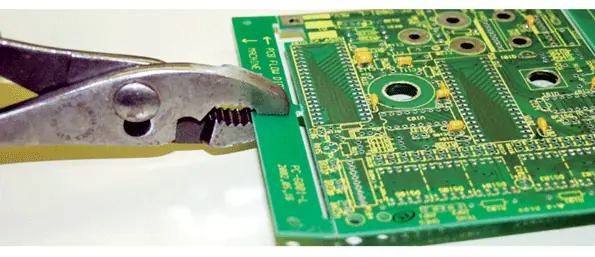

12. Forming

The pcb fabrication process is cut into the required dimensions with a CNC molding machine.

13. Electrical test(E-test)

Simulate the status of the pcb fabrication and check the electrical performance after power on to see if there is an open or short circuit.

14. Final inspection, sampling test, packaging

Check the appearance, size, hole diameter, thickness, and marking of the pcb fabrication process to meet customer requirements. The qualified products are packed into bundles, which are easy to store and transport.