In the competitive landscape of electronics manufacturing, companies are constantly seeking ways to reduce costs while maintaining or improving product reliability. Visual inspection, often overlooked in favor of more advanced automated testing methods, remains a crucial shortcut to achieving both cost reduction and reliability improvement. This article explores the significance of visual inspection in electronics manufacturing, its implementation strategies, and the tangible benefits it brings to the production process.

The Importance of Visual Inspection in Electronics Manufacturing

Definition and Scope

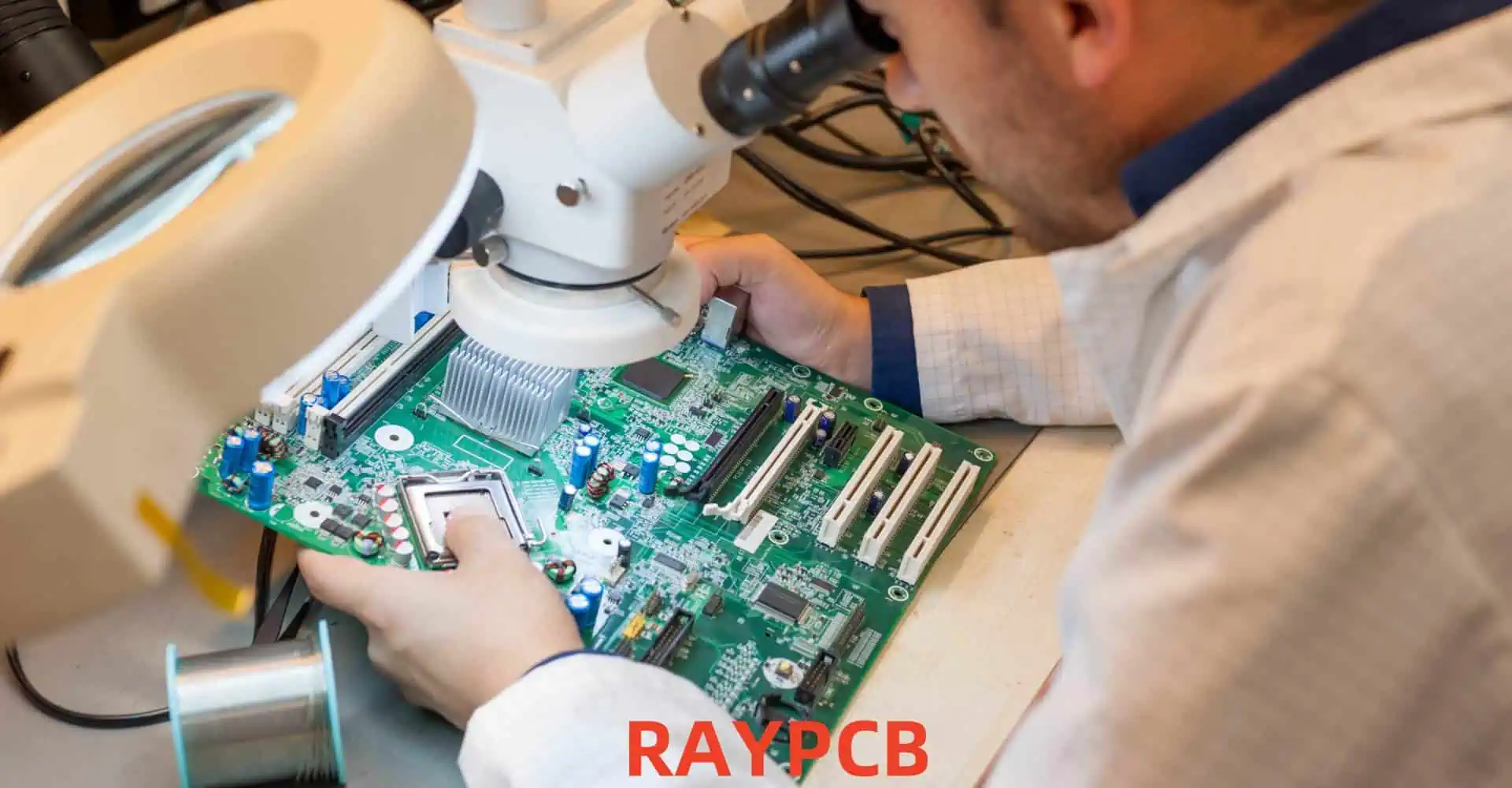

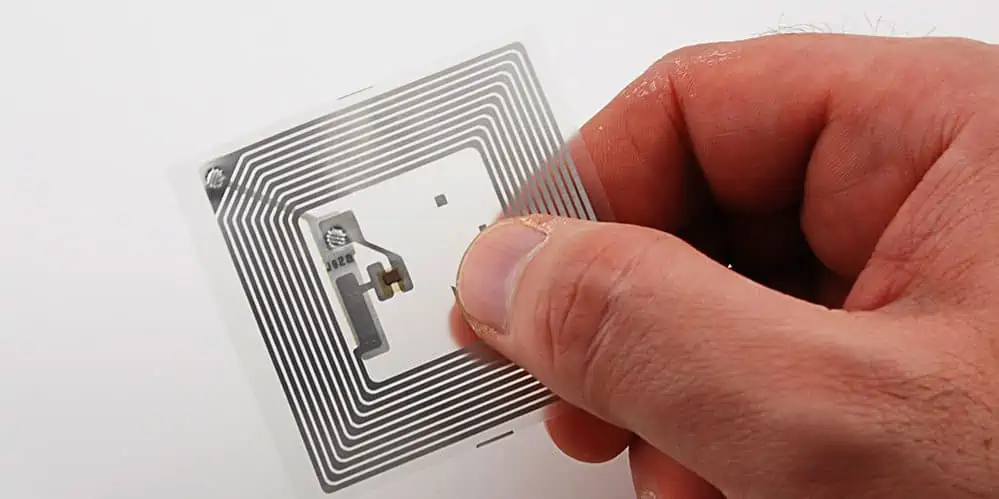

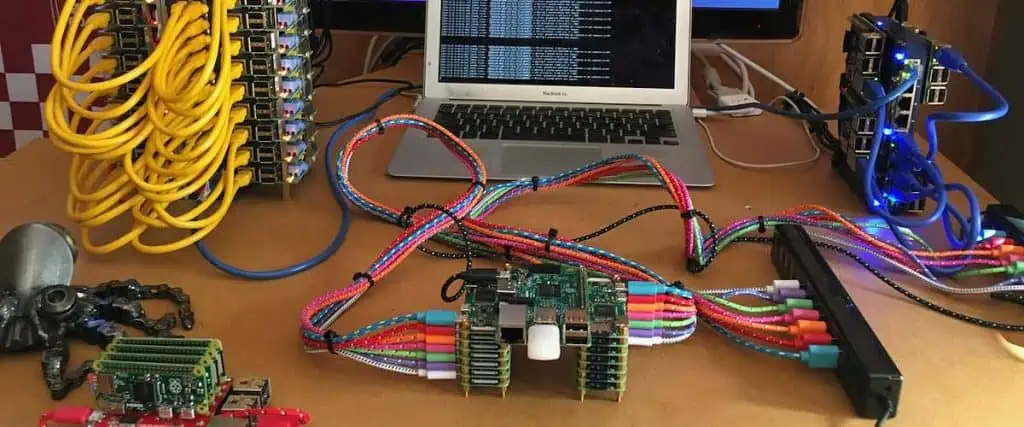

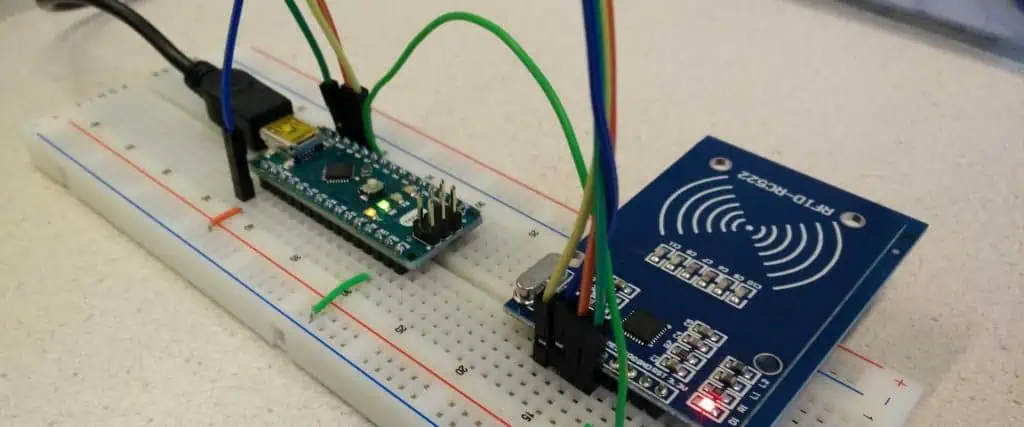

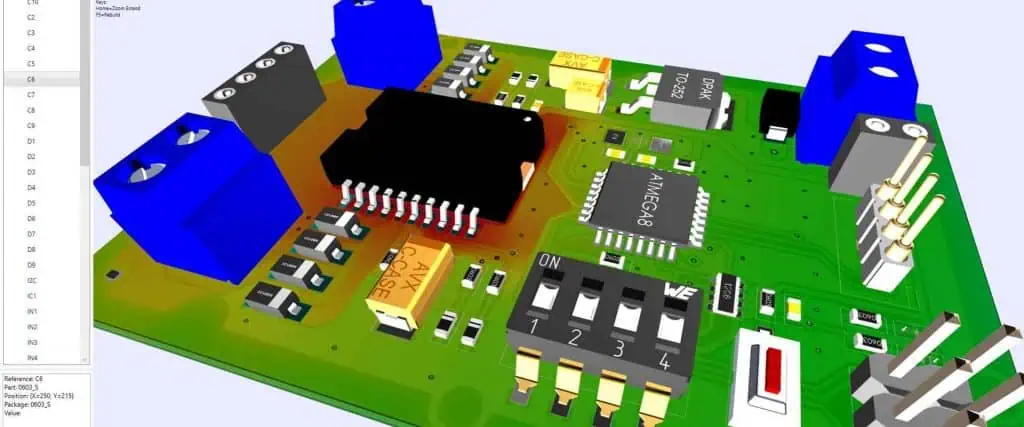

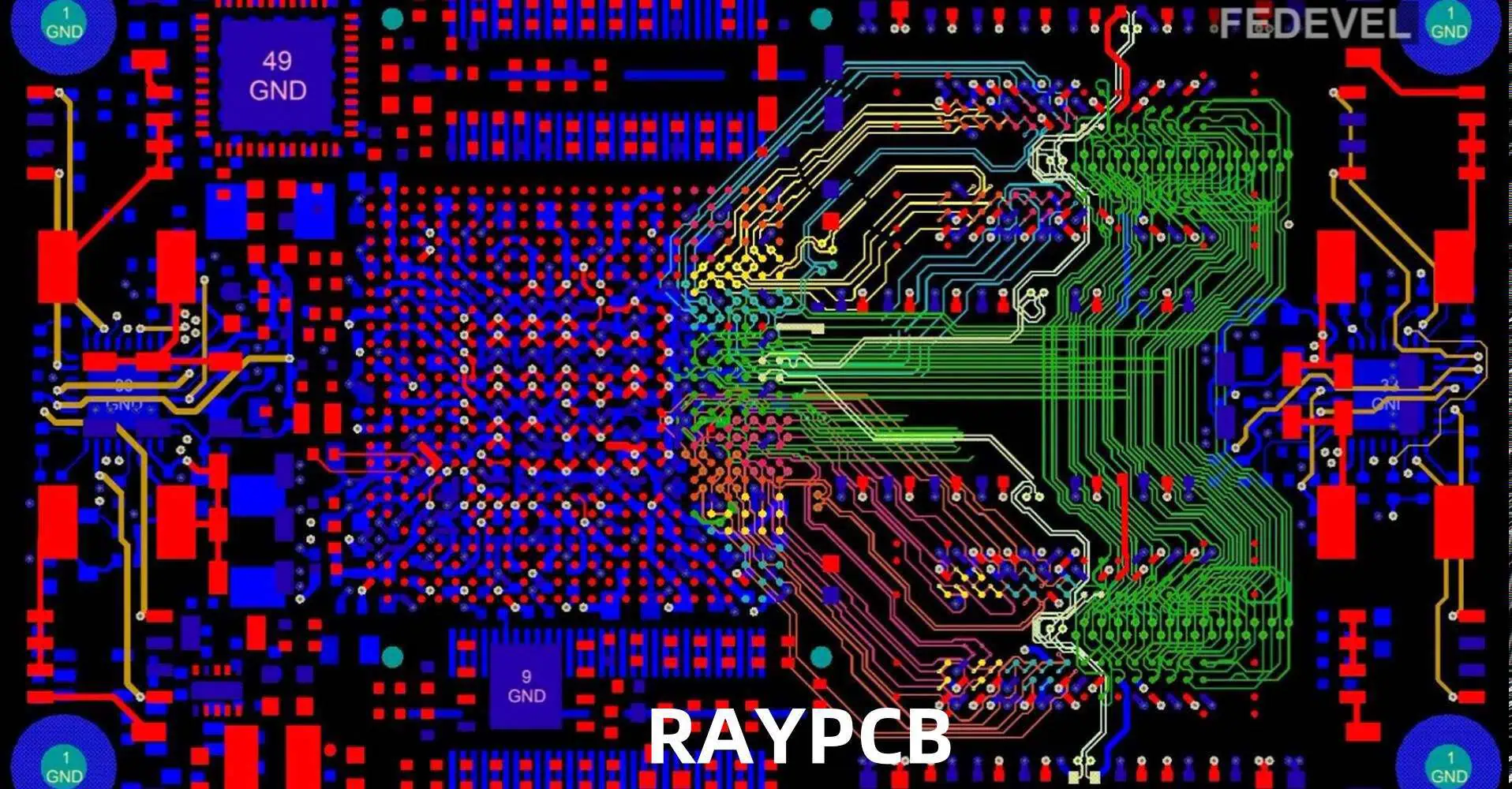

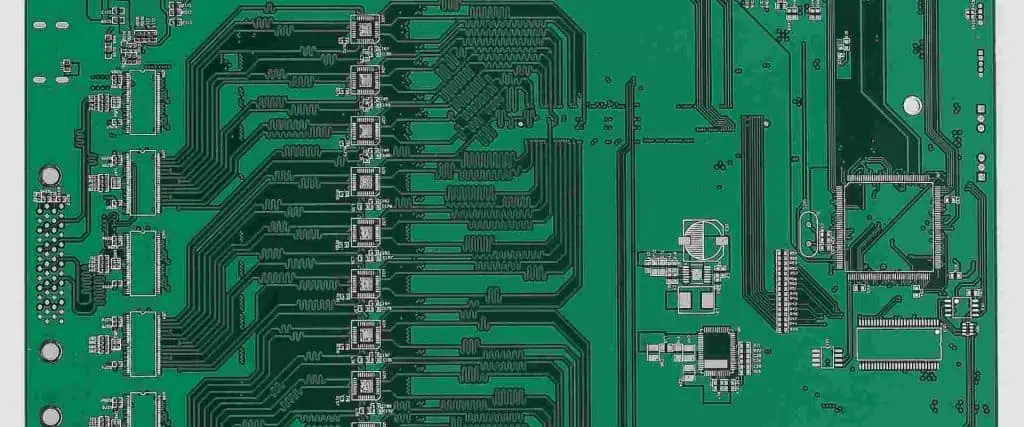

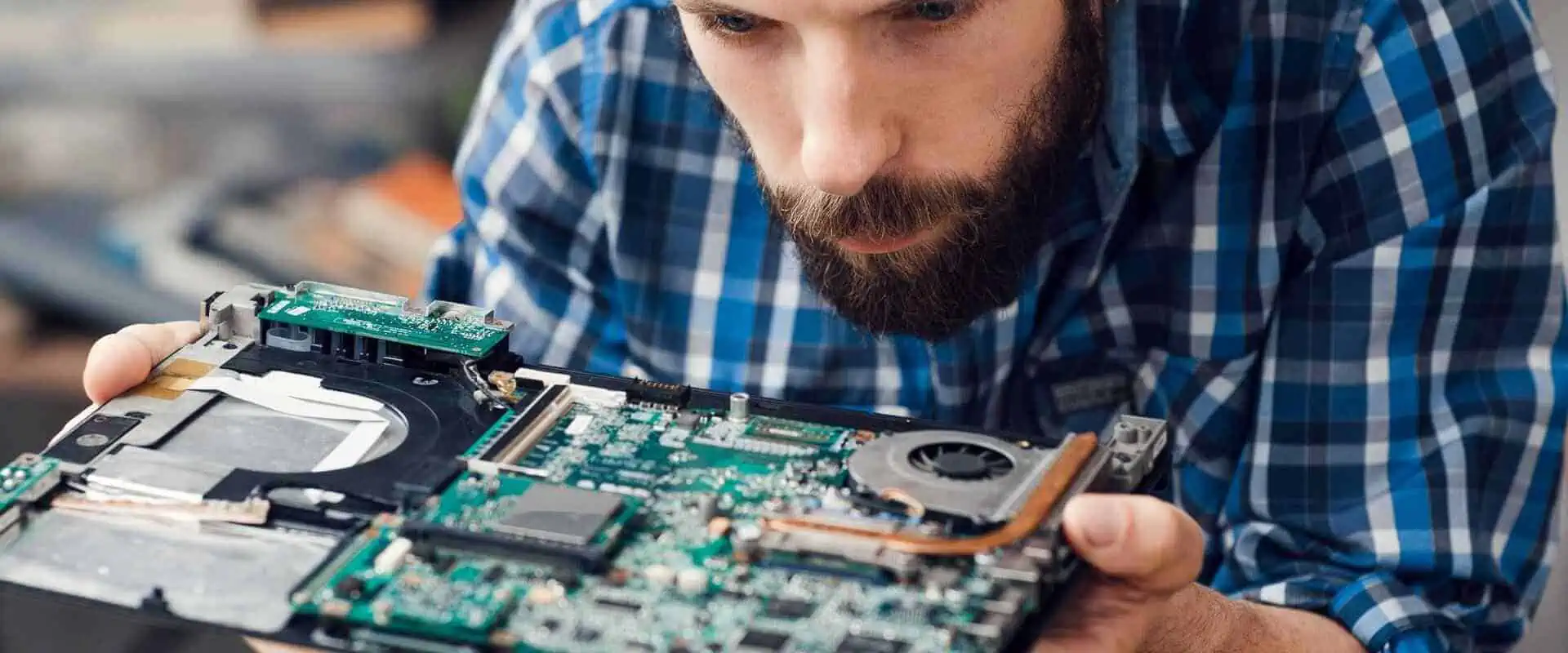

Visual inspection in electronics manufacturing refers to the process of examining components, printed circuit boards (PCBs), assemblies, and finished products using the human eye, often aided by magnification tools. It encompasses various stages of production, from incoming component inspection to final product evaluation.

Role in Quality Assurance

Visual inspection serves as a critical first line of defense in quality assurance, capable of detecting a wide range of defects that may be missed by automated testing systems.

Types of Defects Detectable by Visual Inspection

| Defect Category | Examples |

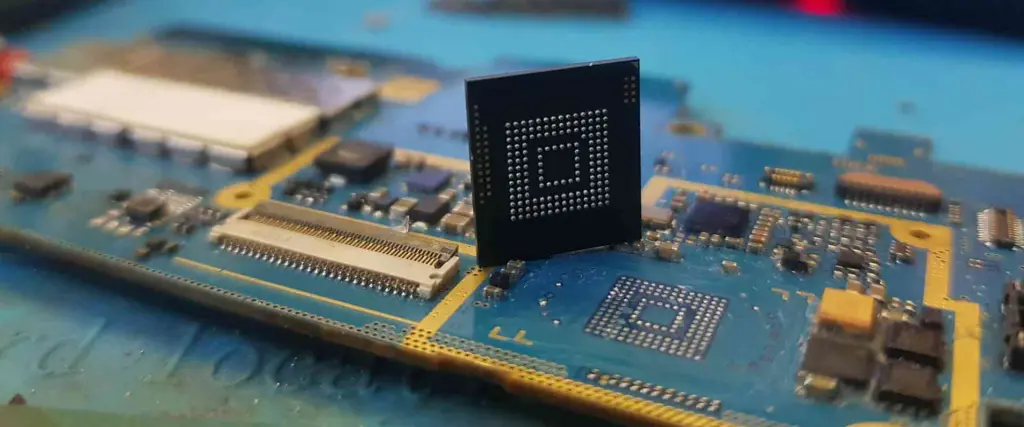

| Component Defects | Misalignment, wrong polarity, missing components |

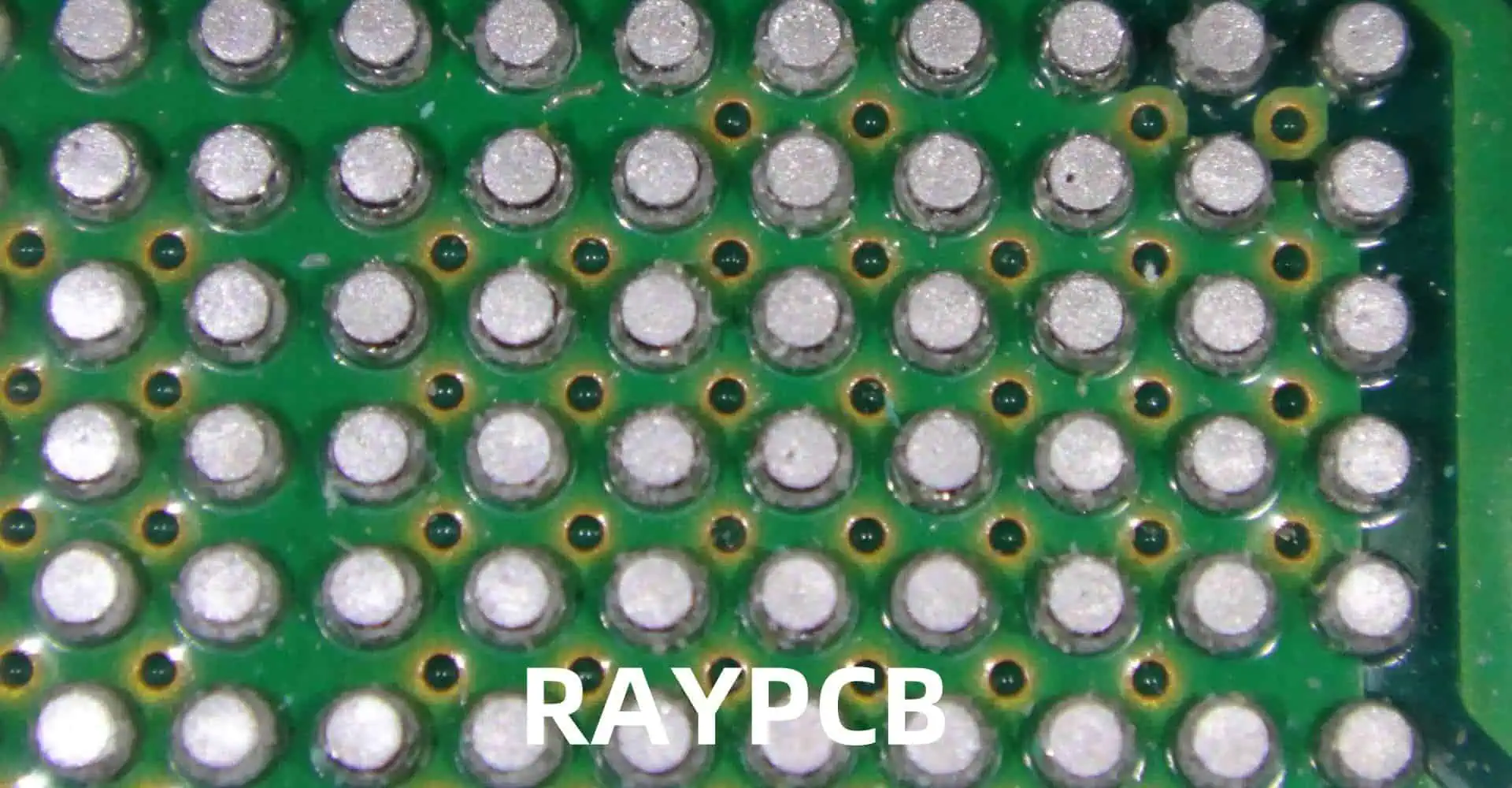

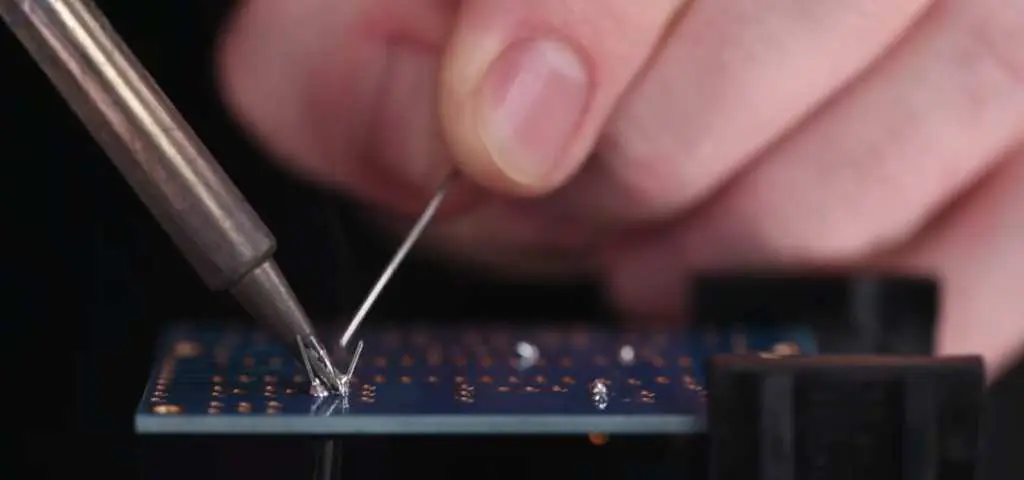

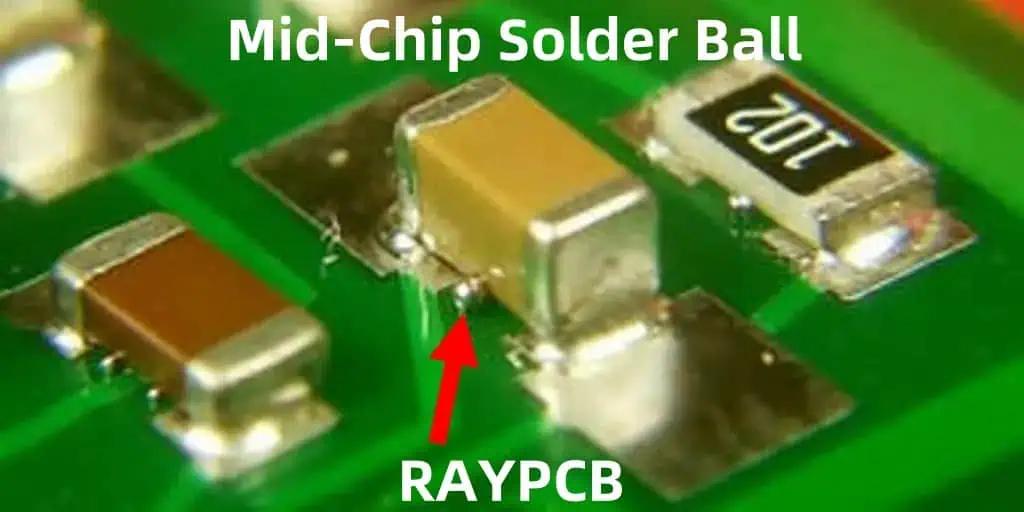

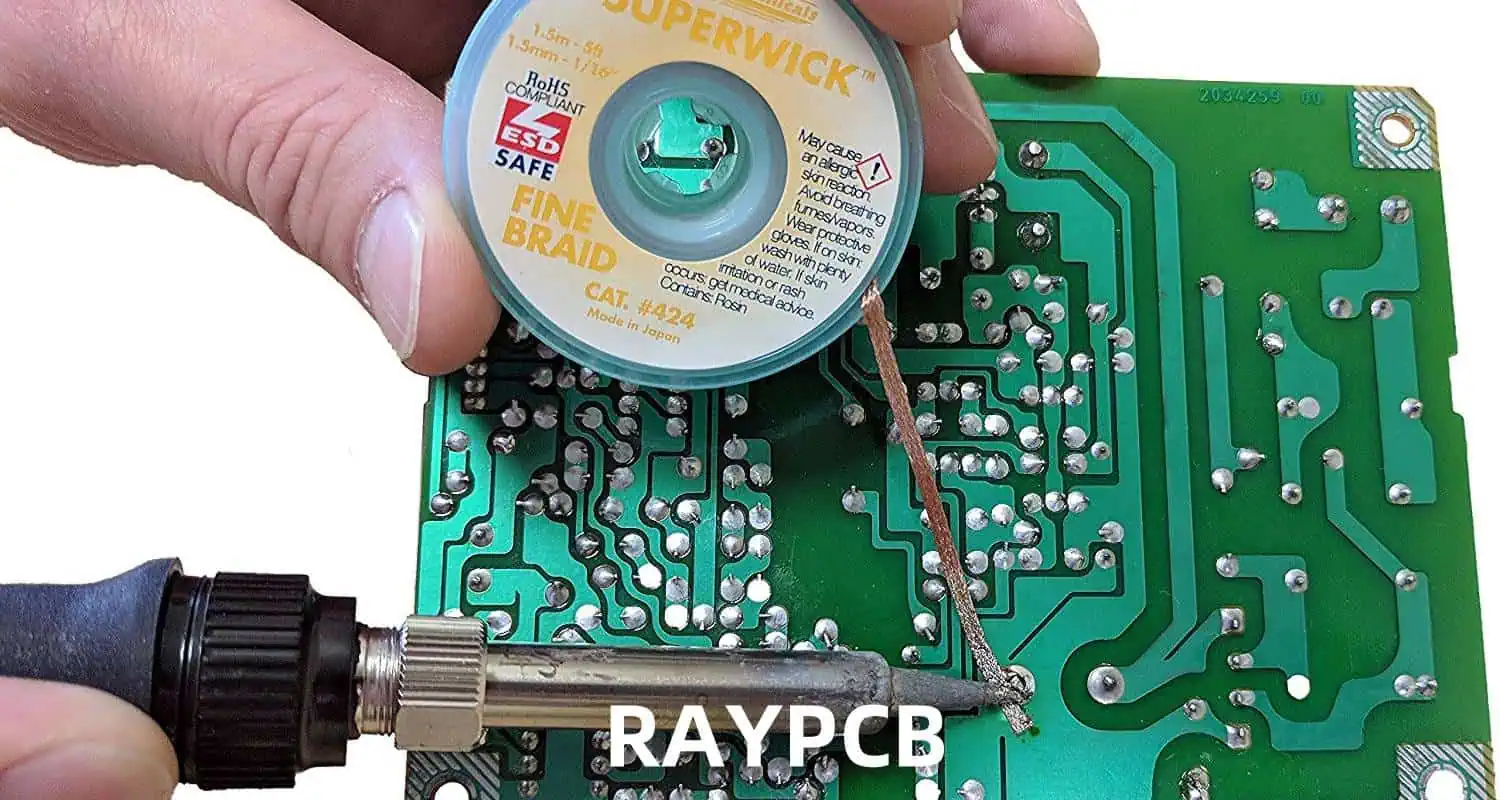

| Soldering Issues | Insufficient solder, solder bridges, cold joints |

| PCB Defects | Scratches, delamination, copper exposure |

| Assembly Problems | Bent pins, lifted leads, foreign material |

| Cosmetic Issues | Discoloration, surface damage, label errors |

Implementing Effective Visual Inspection Processes

Training and Qualification of Inspectors

Developing a skilled workforce of visual inspectors is crucial for the success of the inspection process.

Key Elements of Inspector Training

- Understanding of product specifications and quality standards

- Familiarity with common defect types and their visual characteristics

- Proper use of inspection tools and equipment

- Ergonomics and eye strain prevention techniques

- Documentation and reporting procedures

Inspection Environment and Tools

Creating an optimal inspection environment enhances the accuracy and efficiency of visual inspections.

Essential Elements of an Inspection Workstation

| Element | Purpose |

| Lighting | Proper illumination to reveal defects |

| Magnification | Detailed examination of small components |

| Ergonomic Seating | Comfort for extended inspection periods |

| Anti-static Equipment | Prevention of ESD damage |

| Documentation Access | Quick reference to specifications |

Inspection Criteria and Checklists

Developing clear, standardized inspection criteria ensures consistency across inspectors and shifts.

Sample Visual Inspection Checklist

- Component presence and orientation

- Solder joint quality and uniformity

- PCB surface condition

- Dimensional accuracy of assemblies

- Labeling and marking accuracy

- Cleanliness and absence of foreign materials

Integration with Production Workflow

Seamless integration of visual inspection into the production process maximizes its effectiveness without compromising efficiency.

Strategic Inspection Points

- Incoming component inspection

- Post-placement inspection (before reflow)

- Post-reflow inspection

- Final assembly inspection

- Pre-packaging inspection

Cost Reduction Through Visual Inspection

Early Defect Detection

Identifying defects early in the production process significantly reduces the cost of rework and scrap.

Cost Savings Example

| Stage of Detection | Relative Cost to Correct |

| Component Level | 1x |

| PCB Assembly | 10x |

| Final Product | 100x |

| Field Failure | 1000x |

Reduction in Automated Testing Time

Effective visual inspection can reduce the reliance on time-consuming automated testing procedures.

Minimization of Customer Returns

Catching cosmetic and functional defects before shipment reduces costly customer returns and warranty claims.

Process Improvement Insights

Visual inspection provides valuable feedback for continuous improvement of manufacturing processes.

Reliability Improvement Through Visual Inspection

Prevention of Latent Defects

Many reliability issues stem from defects that are not immediately apparent but can be detected through careful visual inspection.

Examples of Latent Defects Detectable by Visual Inspection

- Insufficient solder on critical connections

- Microscopic cracks in PCB traces

- Improper component placement leading to stress

- Contamination that could cause long-term corrosion

Enhanced Process Control

Regular visual inspections help maintain tight control over manufacturing processes, ensuring consistent quality.

Identification of Systemic Issues

Patterns observed during visual inspection can reveal systemic problems in design or production processes.

Compliance with Industry Standards

Visual inspection plays a crucial role in meeting industry standards and regulatory requirements.

Relevant Industry Standards

| Standard | Focus Area |

| IPC-A-610 | Acceptability of Electronic Assemblies |

| J-STD-001 | Requirements for Soldered Electrical and Electronic Assemblies |

| MIL-STD-883 | Test Method Standard for Microcircuits |

Advanced Visual Inspection Techniques

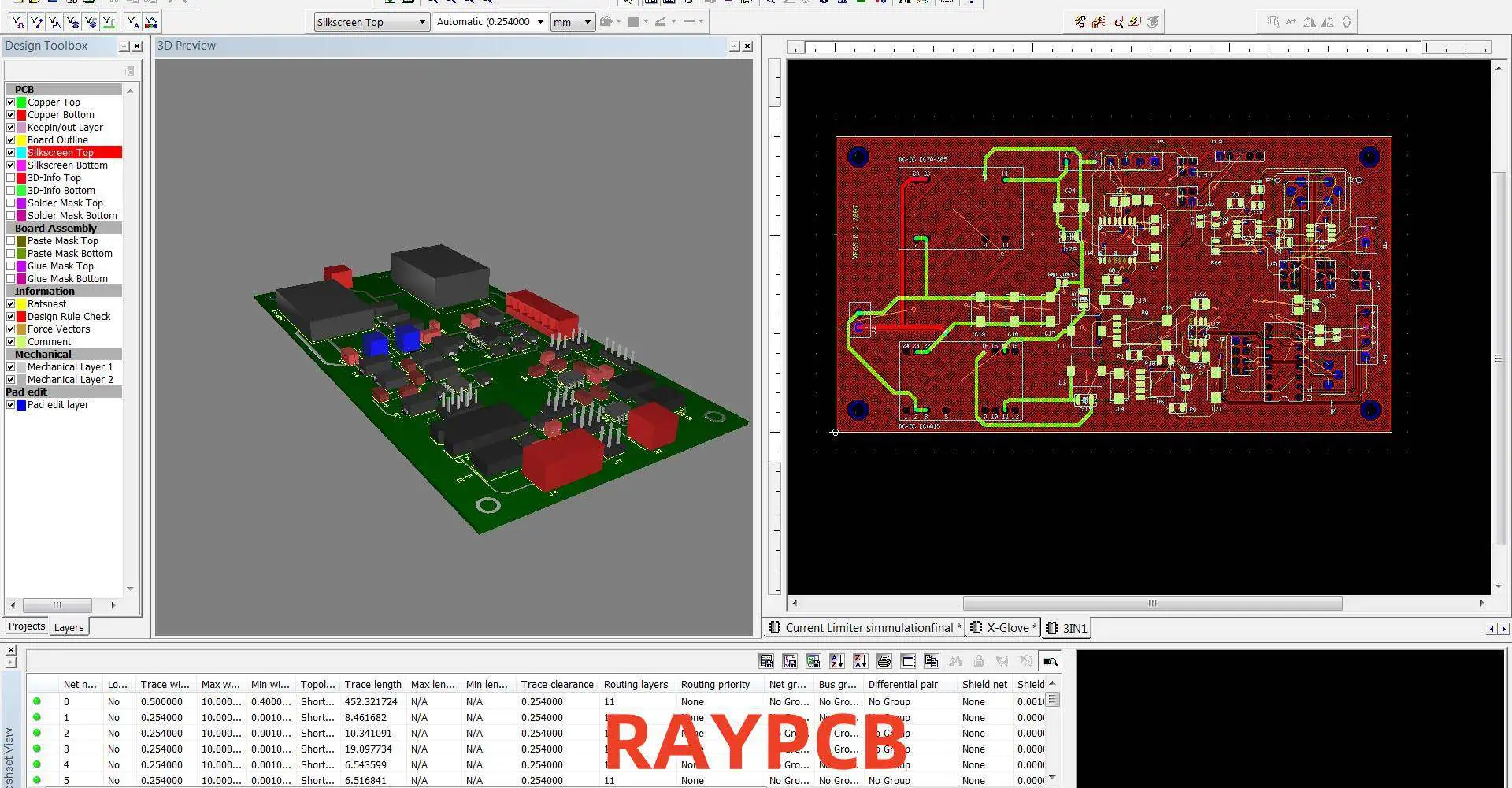

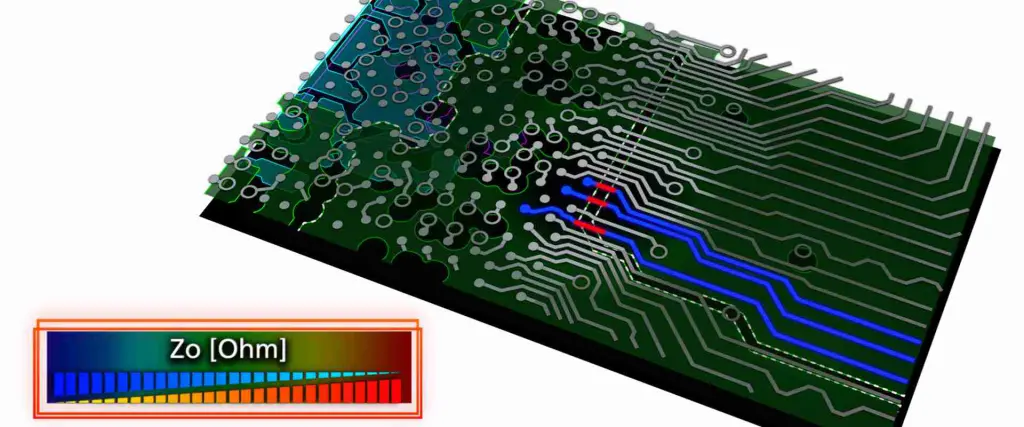

Automated Optical Inspection (AOI)

While not strictly “visual” in the traditional sense, AOI systems complement manual inspection processes.

Benefits of AOI Integration

- High-speed inspection of large production volumes

- Consistent application of inspection criteria

- Digital documentation of inspection results

- Ability to detect defects beyond human visual acuity

Machine Learning in Visual Inspection

Emerging AI technologies are enhancing the capabilities of both manual and automated visual inspection processes.

Applications of Machine Learning in Visual Inspection

- Defect classification and categorization

- Predictive maintenance of inspection equipment

- Optimization of inspection parameters

- Anomaly detection in complex assemblies

3D Inspection Technologies

Advanced 3D inspection systems provide additional dimensions of analysis for complex assemblies.

Types of 3D Inspection Technologies

- Laser triangulation

- Structured light scanning

- Computed tomography (CT) scanning

Challenges and Limitations of Visual Inspection

Human Factors

Visual inspection is subject to human limitations and variability.

Common Human Factor Challenges

- Fatigue and attention span

- Subjective interpretation of defects

- Inconsistency between inspectors

- Eye strain and ergonomic issues

Scalability Concerns

As production volumes increase, maintaining thorough visual inspection becomes challenging.

Invisible Defects

Some defects may not be visible even with magnification, requiring additional testing methods.

Best Practices for Implementing Visual Inspection

Standardization and Documentation

Develop and maintain detailed inspection standards and procedures.

Continuous Training and Certification

Implement ongoing training programs to maintain and improve inspector skills.

Regular Audits and Calibration

Conduct periodic audits of the inspection process and calibrate inspection equipment regularly.

Integration of Multiple Inspection Methods

Combine visual inspection with other testing methods for comprehensive quality assurance.

Feedback Loop Implementation

Establish a system for inspectors to provide feedback on recurring issues or process improvements.

Future Trends in Visual Inspection for Electronics Manufacturing

Augmented Reality (AR) in Inspection

AR technologies promise to enhance inspector capabilities by overlaying digital information onto physical products.

Collaborative Robotics

Cobots may assist human inspectors in handling and manipulating products during inspection.

Big Data Analytics

Leveraging big data from inspection processes can provide insights for predictive quality management.

Conclusion

Visual inspection remains a powerful tool in the arsenal of electronics manufacturers seeking to reduce costs and improve reliability. By implementing robust visual inspection processes, companies can catch defects early, streamline production, and ensure the delivery of high-quality products to their customers. As technology advances, the integration of visual inspection with automated systems and AI promises to further enhance its effectiveness, cementing its role as a critical component of modern electronics manufacturing.

Frequently Asked Questions

Q1: How does visual inspection compare to automated testing methods in terms of cost-effectiveness?

A1: Visual inspection is often more cost-effective than automated testing methods for several reasons:

- Lower initial investment: Visual inspection requires minimal equipment compared to complex automated systems.

- Flexibility: Inspectors can quickly adapt to new products or quality criteria without reprogramming.

- Early defect detection: Visual inspection can catch issues earlier in the production process, reducing costly rework.

- Comprehensive defect detection: Human inspectors can often spot unusual or unexpected defects that automated systems might miss.

However, for high-volume production, a combination of visual and automated inspection often provides the best balance of cost-effectiveness and thoroughness.

Q2: What are the key factors in training effective visual inspectors?

A2: Training effective visual inspectors involves several key factors:

- Product knowledge: Thorough understanding of the products and their specifications.

- Defect recognition: Ability to identify and classify various types of defects.

- Attention to detail: Developing keen observational skills and focus.

- Consistency: Training in applying standards uniformly across different products and situations.

- Tool proficiency: Proper use of magnification and other inspection tools.

- Ergonomics: Techniques to maintain focus and prevent fatigue during long inspection sessions.

- Documentation: Skills in accurately recording and reporting inspection results.

- Continuous learning: Ongoing training to keep up with new technologies and standards.

Q3: How can companies measure the ROI of implementing or improving visual inspection processes?

A3: Companies can measure the ROI of visual inspection improvements through several metrics:

- Defect escape rate: Reduction in defects caught by customers or later testing stages.

- Rework costs: Decrease in expenses related to fixing defects later in production.

- Customer returns: Reduction in product returns due to quality issues.

- Production yield: Increase in first-pass yield rates.

- Inspection time: Efficiency improvements in the inspection process itself.

- Warranty claims: Reduction in long-term reliability issues caught by customers.

- Customer satisfaction: Improvements in customer feedback and ratings.

By tracking these metrics before and after implementing visual inspection improvements, companies can quantify the financial benefits and calculate ROI.

Q4: What are the limitations of visual inspection, and how can they be mitigated?

A4: Visual inspection has several limitations:

- Subjectivity: Different inspectors may interpret defects differently.

- Fatigue: Long inspection sessions can lead to decreased accuracy.

- Speed: Manual inspection can be slower than automated methods for high volumes.

- Invisible defects: Some issues may not be detectable by eye.

These limitations can be mitigated by:

- Implementing standardized inspection criteria and regular calibration exercises.

- Rotating inspectors and providing ergonomic workstations to reduce fatigue.

- Using a hybrid approach combining visual and automated inspection methods.

- Supplementing visual inspection with other testing techniques (e.g., X-ray, in-circuit testing) for comprehensive quality assurance.

Q5: How is artificial intelligence (AI) changing the landscape of visual inspection in electronics manufacturing?

A5: AI is transforming visual inspection in several ways:

- Automated defect detection: AI algorithms can analyze images to identify defects with high accuracy and speed.

- Consistency: AI systems apply consistent criteria across large volumes of products.

- Learning and adaptation: Machine learning models can improve over time, learning to detect new types of defects.

- Data analysis: AI can process vast amounts of inspection data to identify trends and predict quality issues.

- Augmented human inspection: AI can assist human inspectors by highlighting potential defects or providing decision support.

- Integration with other systems: AI can combine visual data with other sensor inputs for more comprehensive quality assessment.

While AI is enhancing visual inspection capabilities, it’s important to note that human expertise remains valuable, especially for complex or novel defect types. The future of visual inspection likely lies in the effective collaboration between human inspectors and AI systems.