Introduction

Electronic control boards are at the heart of systems across industrial, automotive, medical, aerospace, and consumer product applications. Control boards process inputs from sensors then output commands to actuators in order to regulate operation. Designing reliable, manufacturable control boards requires cross-discipline collaboration and applying specialized design-for-manufacturing techniques. This article explores best practices for control board development, from product requirements down to volume fabrication.

Defining Product Requirements

The first step is gathering key requirements that drive the control board implementation:

- Functional Requirements – Define exactly what the system must sense, process, and control. This includes parameters like voltage, current, speed, temperature, pressure, etc.

- Performance Requirements – Specify metrics like accuracy, precision, resolution, sampling rate, control latency, control loop stability, etc. needed for proper operation.

- Operating Environment – Will the system be exposed to temperature extremes, vibration, humidity, dirt, weather, shock, etc.? What enclosure, sealing, and ruggedizing is needed?

- Certifications – List any safety, regulatory, or compliance approvals required like UL, CE, FCC, ISO, etc. applicable to the industry.

- Interfaces – Detail the types of sensors, actuators, communication buses, and user interfaces the control board must connect with. Quantify electrical interfaces and data rates.

- Power – Define available power sources like 24VDC or 120VAC along with backup needs like batteries for hold-up. Specify minimum lifecycle duration before power maintenance.

- Physical Constraints – Set mechanical form factor limits including maximum dimensions (LxWxH), mounting requirements, connectors locations, durability, etc.

Documenting these needs upfront ensures the control board design addresses all product requirements necessary for successful operation in the field.

Control System Architecture

The electronics architecture can now be partitioned based on functional requirements:

- Sensors Interface – Condition and acquire all sensor signals like voltage, current loops, thermocouples, RTDs, strain gauges, encoders, etc. This requires respective signal conditioning, filtering, sampling, isolation.

- Control Logic – Microcontroller(s) or FPGA(s) implement digital control logic, sensor fusion, actuation waveforms, timing control, communication protocols, and supervisory functions. Sufficient processing power, memory, storage, and redundancy should be incorporated to execute required control algorithms.

- Actuators Interface – Power drivers, SSRs, contactors, relays, valves, switches, indicators etc. interface to external components under system control. Electrical isolation and protection must be provided.

- Communications – Interfaces like USB, Ethernet, RS-485, RS-232, CAN, Bluetooth etc. enable local or remote monitoring, configuration, data logging, and integration with other systems. Cybersecurity should be addressed.

- User Interface – Inputs like buttons, switches, touchscreens and outputs like buzzers, lights, graphical displays provide user interaction with the control system. UX design practices should optimize these interfaces.

- Power Supplies – Step down and regulate available power sources to generate needed DC voltages for electronics with appropriate hold-up, redundancy, sequencing, and protection.

Proper subsystem partitioning with well-defined internal interfaces enables effective implementation by a multi-disciplinary engineering team.

Control Board Electronics Design

With architecture defined, PCB layout and electronic circuit design takes place:

- Schematic Capture – Develop detailed schematics for power, sensors, logic, actuation, and I/O subsystems showing all discrete components. Simulation and calculations should validate operation.

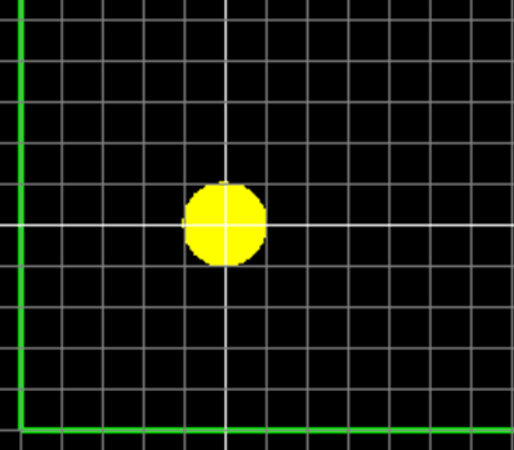

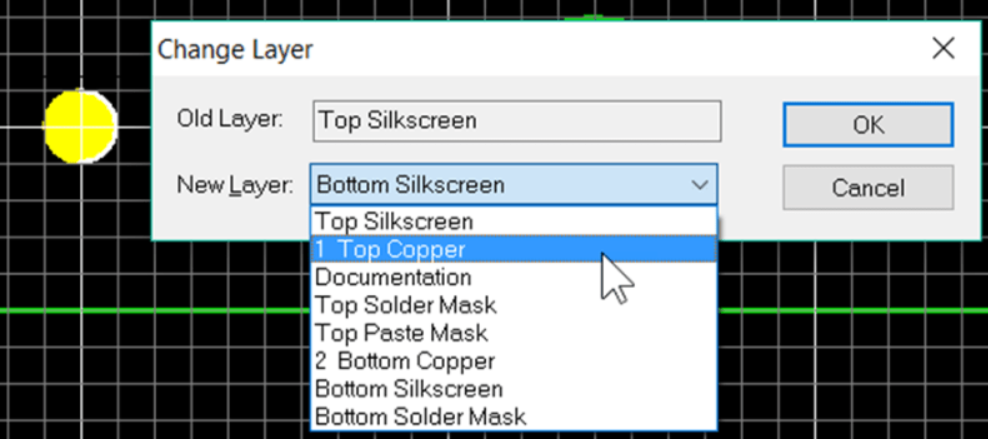

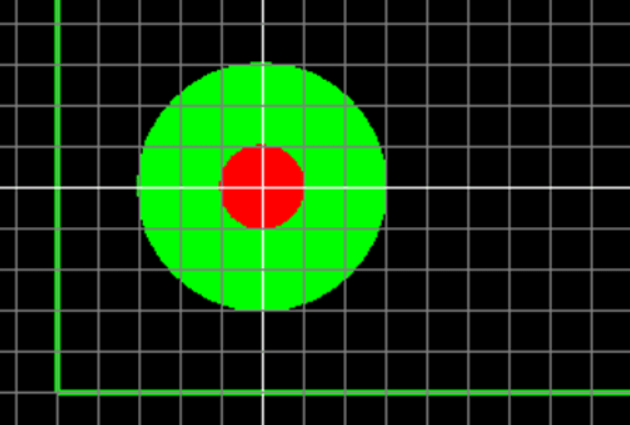

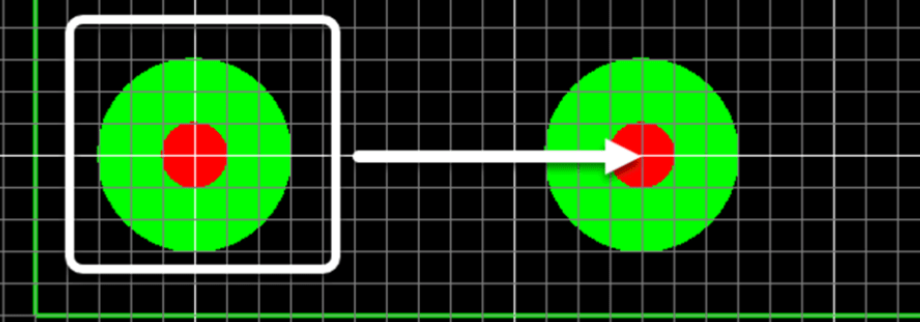

- PCB Layout – Lay out printed circuit board routing each net, ensuring signal integrity and manufacturability. Utilize appropriate high-speed, mixed-signal, and power supply layout practices. Verify critical dimensions, spacing, fab tolerances met.

- Component Selection – Research and select all ICs, passive parts, connectors etc. ConfirmEnvironmental ratings like temperature range, packaging type, qualifications, and availability match design needs.

- Simulations – Perform circuit, thermal, vibration, and other physics simulations to virtually validate performance under operating conditions prior to prototyping.

- DFx Analysis – Apply design-for-manufacturing (DFM), design-for-assembly (DFA), and design-for-testability (DFT) analysis to ensure quality and optimize producibility.

Applying best practice design principles tailored for control systems helps avoid issues and ensures the electronics meet functional requirements prior to physical prototyping.

Prototyping and Validation

Before committing to production, prototypes validate the design:

- Board Fabrication – Produce prototypes using same materials, finishes, tolerances, and fabricator as production to avoid issues replicating design.

- Component Procurement – Source prototype quantities and required technical documentation for all components. Avoid difficult-to-acquire parts without multiple qualified vendors.

- Assembly – Have prototyping shop assemble boards and inspect for errors. Fixture boards as needed for automated assembly. Programmable components should be flashed with current firmware.

- Testing – Verify board operation across temperature, voltage, vibration, EMI, age testing, and other qualifications identified. Debug design issues through multiple prototype revs.

- Compliance – Test prototypes for relevant safety, EMC emissions, regulatory, environmental compliance certifications. Retroactive fixes can be costly.

- Process Validation – Audit assembly process capability and yields. Perform test coverage and capability analysis. The assembly line must support building boards correctly in volume.

Thorough prototyping and process validation reduces the risk of issues arising during ramp to mass production.

Design for Manufacturing

Specialized DFM techniques optimize manufacturability:

Component Selection

- Prefer standard footprints that match manufacturer’s placement libraries

- Avoid complex, connector-less modules which challenge assembly

- Select parts qualified for any lead-free soldering or other processes

- Check minimum feature sizes can be reliably assembled

PCB Layout

- Provide sufficient clearance between traces, pads, vias, drill holes, cutouts etc.

- Verify minimum annular ring dimensions for vias can be achieved

- Include text labels with minimum readable font size for identification

- Allow adequate panelization routing space for breakout tabs

Thermal Management

- Ensure components are within thermal dissipation limits

- Avoid placing heat sources near temperature-sensitive devices

- Incorporate thermal vias, pads, and internal copper planes to spread heat

- Model airflow and enclosure thermal performance

Test and Inspection

- Include testpoints to access key signals

- Enable automated optical inspection (AOI)

- Add mounting points for fixture during test

- Minimize overlapping components which block AOI scanning

Following DFM guidelines avoids issues during manufacturing and improves yield. DFM analysis tools like design rule checking should be used to verify adherence.

Design Tools Overview

Key software tools aid electronic control board development:

- Schematic Capture – Creation of multi-page schematics with part libraries defining circuit connectivity

- PCB Layout – Convert schematics into routed board layout files with all component placements and traces

- Simulation – Model, analyze, and verify circuit, thermal, vibration, and other physics performance

- DFx Analysis – Perform automated design rule, DFM, signal integrity, power integrity checking

- MCAD – Develop mechanical enclosure models and integrate board models to check fit

- CAM and Documentation – Generate manufacturing and assembly data like Gerbers, bill of materials, assembly drawings

- Version Control – Manage multiple design revisions and enable team collaboration

Leveraging these electronic design automation (EDA) tools improves engineering efficiency, design quality, and reduces errors.

Low Volume Production

For limited quantity board builds:

- Fabrication – Leverage quick-turn assembly services to build prototypes and low volume production using supplied Gerber fabrication and assembly files.

- Manual Assembly – For very low quantities, hand assembly or manual production lines may be viable using paste stencils and inspection microscopes.

- Box Build – Utilize contract manufacturers to procure all components, load software, perform final assembly, test, inspect, and ship integrated systems.

- Supply Chain – Work with distributors like Digikey or Arrow providing easy small quantity purchases of many electronic components.

- Test and Debug – Develop production test procedures and fixture boards as needed. Perform failure analysis on defects.

Low volume techniques allow iteratively building, testing, and refining the design until ready for mass production.

High Volume Manufacturing

Transitioning to large scale production requires alignment across the supply chain:

Contract Manufacturing

Engage a contract manufacturer early to provide DFM guidance, prototyping, then ramp high volume SMT assembly, test, procurement, and system build. They become an extension of the internal team.

Component Engineering

Work with suppliers to qualify components for automotive, industrial temperature ranges, lead-free soldering, or other needs. Setup long term supply agreements and component lifecycle management.

Process Capability

Perform process capability analysis like Cpk studies for assembly, test, inspection, and other process yield indicators. Verify consistent 6-sigma quality capability.

Testing Strategy

Implement structural test coverage of functional paths, automated in-circuit and functional testing, ICT fixture design, and probe testing of bare boards to comprehensively screen defects.

Change Control

Institute formal configuration management and engineering change control processes to manage revisions, deviations, exceptions, and firmware version control over product lifecycles.

Investments into workflow, testing, data management, and supply chain integration support the volumes, quality, and responsiveness needed in mass production.

Key Manufacturing Defect Risks

Common defects threatening production yield include:

- Components missing, incorrectly inserted, or mixed up due to assembly errors

- PCB defects like opens, shorts, drilling errors, poor pad adhesion causing functionality issues

- Poor soldering workmanship resulting in cold joints, bridges, or excessive voids

- Damage like board cracks, broken connectors, or loose parts from handling

- Contamination from dirt, debris, or foreign objects present on boards or the assembly line

- Electrostatic discharge (ESD) or power surges damaging sensitive components

- Firmware not flashing properly or version control errors

In-process inspection, test coverage at multiple stages, and tightly controlled assembly environments aim to minimize these and other defect risks.

Electronic Control Board Manufacturing – FAQs

What standards apply to control board design?

Key standards include IPC-2221 and IPC-2222 covering generic and rigid printed board fabrication, along with IPC-A-610 describing acceptance criteria for electronic assemblies.

What types of simulations are performed?

Typical simulations include circuit (SPICE), thermal, structural (vibration), computational fluid dynamics (CFD), electromagnetic (EMI), and environmental (drop, UV, humidity).

What data should be requested from electronics suppliers?

Items like specification datasheets, qualification reports, material declarations, longevity guarantees, EOL notifications, model libraries, and application notes.

What types of testing screen for defects?

Testing spans in-circuit test (ICT), flying probe, boundary scan, automated optical inspection (AOI), x-ray, functional test, burn-in, environmental stress screening, and power/signal integrity.

What are some common DFM checks?

Rules exist for trace width, hole annular rings, spacing, mask expansion, via geometry, solder masks, fillets, text legibility, and more based on fabrication process capabilities.

Conclusion

Successfully designing, validating, and manufacturing electronic control boards requires early cross-discipline collaboration and applying specialized techniques tailored for control systems. Following best practices for requirements definition, architecture partitioning, design reviews, simulation, prototyping, DFM analysis, supply chain integration, and defect-screening testing will optimize development efficiency and reduce risks as products transition into volume production. Investments made upfront in engineering rigor pay dividends through accelerated time-to-market, improved quality, and lower overall product lifecycle cost.

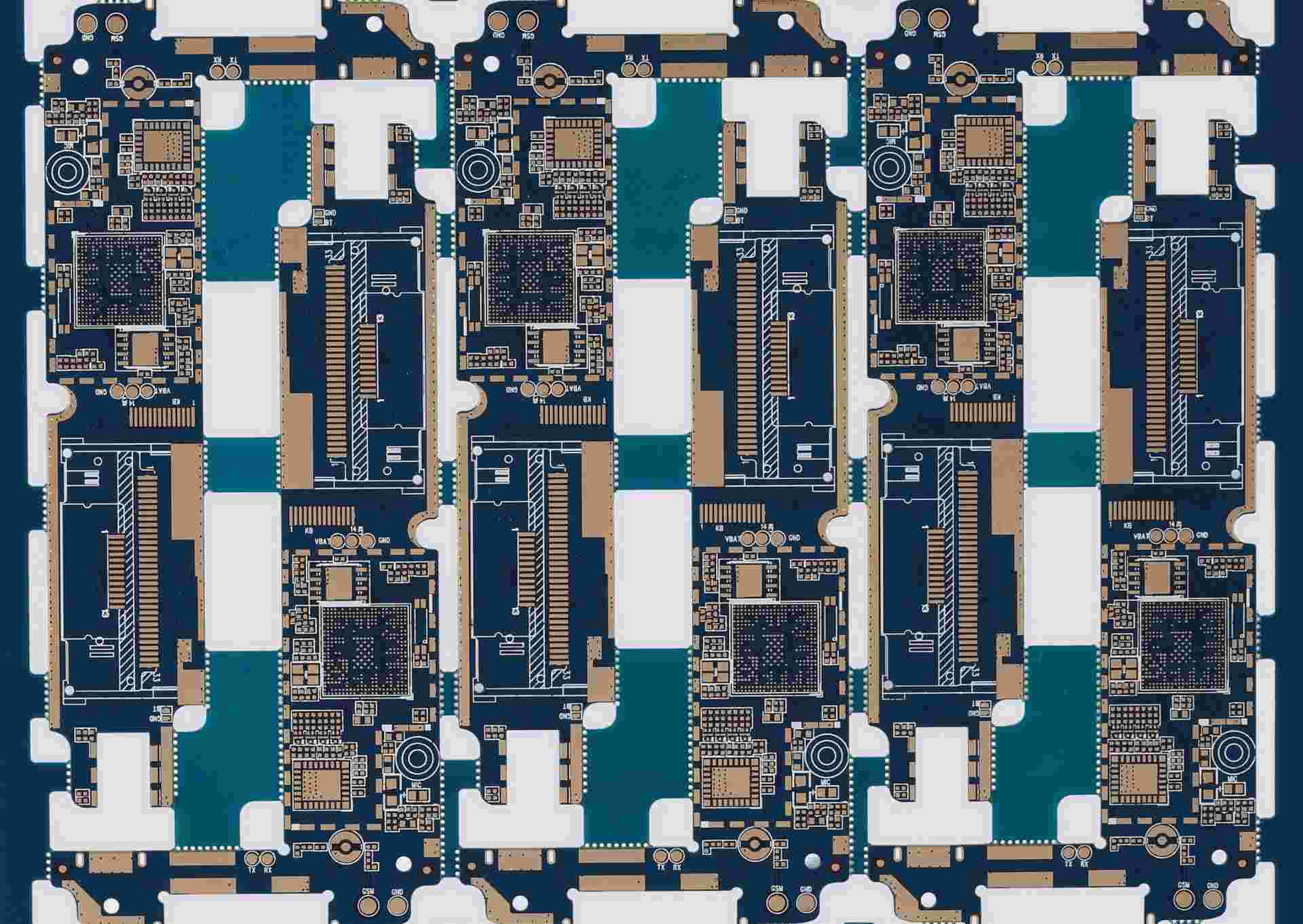

How Many Layer PCB: 10 layer PCB

Surface Process: Immersion Gold

PCB Testing : Yes

Provide PCB Manufacturing : Yes

Full electronic components procurement : Yes

PCBA Testing : Yes

If you need full PCB assembly services , you can send your PCB File and Bom list to sales@raypcb.com

whatever prototype boards or volume boards.