Building a GPS tracker with cellular communication capabilities and a companion Flutter mobile app is an exciting project that combines hardware engineering, embedded programming, and mobile app development. This comprehensive guide will walk you through the entire process, from selecting components to deploying your finished tracking system.

Project Overview and Requirements

A GPS tracker with cellular communication consists of three main components: the hardware device that captures location data, the cellular communication system that transmits this data, and the mobile application that displays and manages the tracking information. The device needs to be power-efficient, weather-resistant, and capable of maintaining reliable communication in various environments.

The core functionality includes real-time location tracking, geofencing capabilities, historical route storage, battery monitoring, and remote configuration options. The system should provide accurate positioning data, send alerts for specific events, and maintain a user-friendly interface for monitoring tracked assets or individuals.

Hardware Components and Architecture

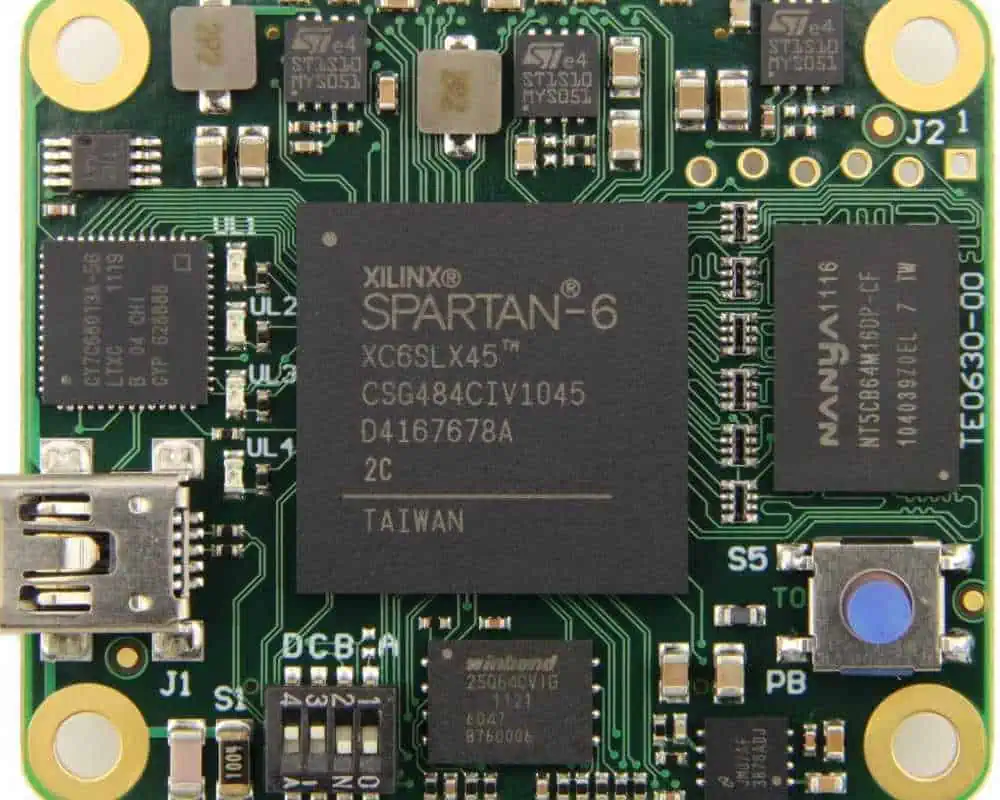

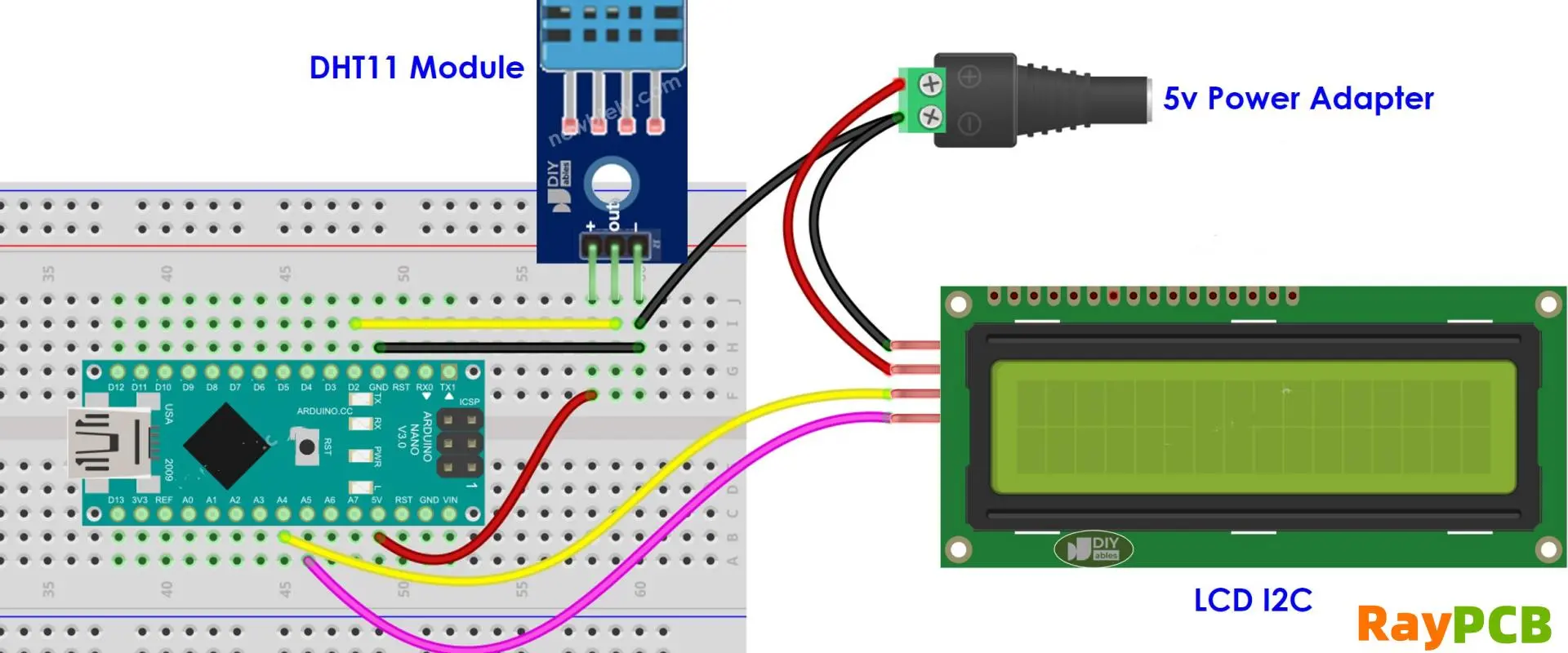

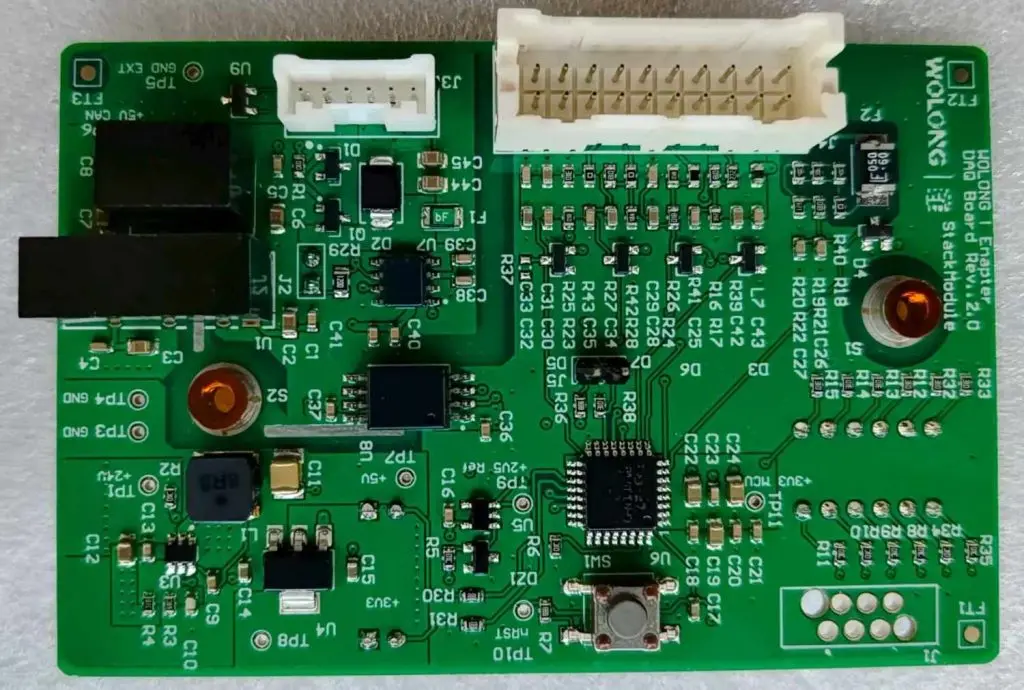

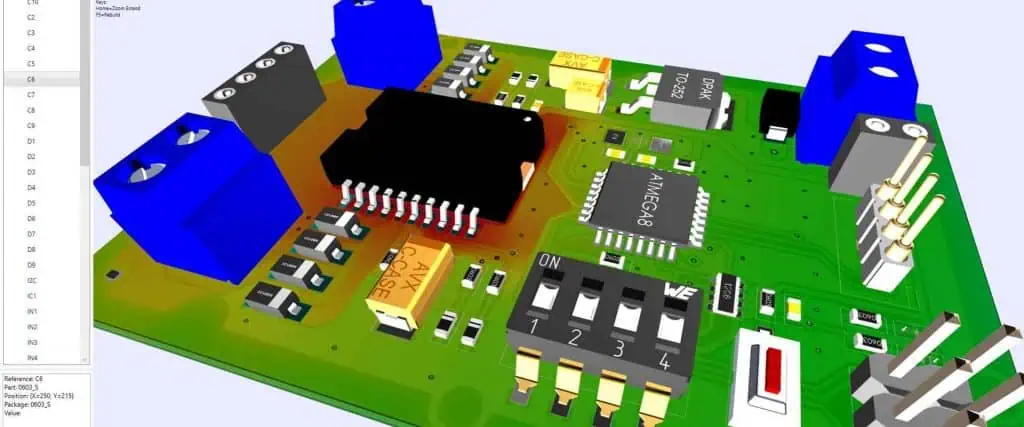

The foundation of your GPS tracker requires several key components working in harmony. The microcontroller serves as the brain of the device, with popular choices including the ESP32 for its built-in WiFi capabilities, Arduino-compatible boards for ease of programming, or specialized IoT development boards that integrate multiple communication protocols.

For GPS functionality, modules like the NEO-8M or NEO-6M from u-blox provide reliable positioning data with good accuracy and reasonable power consumption. These modules communicate via UART and can achieve cold start times under 30 seconds while maintaining hot start capabilities in under one second.

Cellular communication requires a GSM/GPRS module such as the SIM800L, SIM7600, or more advanced LTE modules like the SIM7000 series. These modules handle the data transmission to your backend servers and support various cellular standards depending on your regional requirements and data needs.

Power management is crucial for portable tracking devices. Include a lithium-ion battery with appropriate capacity for your use case, a charging circuit for easy maintenance, and consider solar panels for extended outdoor deployments. Implement sleep modes and efficient power management to maximize battery life between charges.

Additional components include a robust enclosure rated for your intended environment, LED indicators for status feedback, optional buzzers for audio alerts, and mounting hardware appropriate for your tracking application.

Firmware Development and GPS Integration

The firmware development process begins with setting up your development environment and initializing the core systems. Start by configuring the GPS module to receive NMEA sentences, which contain standardized location data including latitude, longitude, altitude, speed, and timestamp information.

Implement a GPS parsing library or create your own parser to extract meaningful data from NMEA sentences. Focus on GGA (Global Positioning System Fix Data) and RMC (Recommended Minimum) sentences, which provide the essential positioning information needed for tracking applications.

Create a location data structure that stores coordinates, timestamps, accuracy measurements, and satellite count. Implement validation logic to ensure GPS fixes are reliable before transmitting data, including checks for minimum satellite count and position accuracy thresholds.

Develop a state machine that manages different operational modes: initialization, GPS acquisition, data transmission, sleep mode, and error handling. This approach ensures reliable operation and efficient power management throughout the device lifecycle.

Cellular Communication Implementation

Establishing cellular communication requires configuring your GSM/GPRS module with the appropriate APN settings for your cellular provider. Implement AT command sequences to initialize the module, establish network connectivity, and manage data transmission sessions.

Design a robust communication protocol that handles network interruptions gracefully. Implement retry mechanisms, data queuing for offline periods, and connection monitoring to ensure reliable data delivery. Consider using MQTT for efficient bidirectional communication, allowing both data transmission and remote configuration capabilities.

Create data packets that include essential tracking information: device ID, timestamp, GPS coordinates, battery level, and any sensor data. Optimize packet size to minimize cellular data usage while maintaining necessary information density.

Implement security measures including data encryption, device authentication, and secure communication protocols. Use TLS/SSL for data transmission and consider implementing device certificates for enhanced security in commercial deployments.

Backend Infrastructure and API Development

The backend infrastructure serves as the central hub for receiving, processing, and storing tracking data from your devices. Design a scalable architecture using cloud services like AWS, Google Cloud Platform, or Azure to handle multiple devices and users efficiently.

Develop RESTful APIs that handle device registration, location data ingestion, user authentication, and data retrieval. Implement endpoints for real-time tracking, historical data queries, geofence management, and device configuration updates.

Choose an appropriate database solution for storing location data. Time-series databases like InfluxDB excel at handling GPS tracking data, while traditional SQL databases can manage user accounts and device relationships. Consider implementing data retention policies to manage storage costs and comply with privacy regulations.

Implement real-time notification systems using WebSockets or Server-Sent Events to provide instant updates to connected mobile applications. This enables live tracking capabilities and immediate alert delivery for geofence violations or emergency situations.

Flutter Mobile Application Development

Flutter provides an excellent framework for creating cross-platform mobile applications that work seamlessly on both iOS and Android devices. Begin by setting up your Flutter development environment and creating a new project with the necessary dependencies for mapping, HTTP communication, and local storage.

Design an intuitive user interface that displays maps, device lists, and tracking information clearly. Implement a main dashboard showing device status, battery levels, and last known positions. Create detailed views for individual devices with historical tracking data and route visualization.

Integrate mapping functionality using packages like Google Maps for Flutter or open-source alternatives like Flutter Map with OpenStreetMap data. Implement features for displaying current device locations, drawing historical routes, and managing geofences with visual boundary indicators.

Develop real-time tracking capabilities by establishing WebSocket connections to your backend services. Implement efficient state management using providers or bloc patterns to handle live location updates and maintain responsive user interfaces.

Create user account management features including registration, authentication, device association, and profile management. Implement secure token-based authentication and consider biometric authentication options for enhanced security.

Advanced Features and Optimization

Enhance your tracking system with advanced features that provide additional value to users. Implement geofencing capabilities that trigger alerts when devices enter or exit predefined areas. Create customizable notification systems that support SMS, email, and push notifications for various tracking events.

Develop offline mapping capabilities for areas with limited internet connectivity. Cache map tiles locally and implement data synchronization when connectivity is restored. This ensures continuous functionality even in remote locations.

Optimize power consumption through intelligent tracking algorithms that adjust GPS sampling rates based on movement patterns. Implement accelerometer-based motion detection to trigger active tracking only when movement is detected, significantly extending battery life during stationary periods.

Create comprehensive analytics dashboards that provide insights into tracking patterns, device usage statistics, and system performance metrics. These analytics help users understand tracking data better and identify optimization opportunities.

Testing and Deployment Strategies

Thorough testing is essential for reliable GPS tracking systems. Conduct extensive field testing in various environments including urban areas with tall buildings, rural locations, and indoor spaces to evaluate GPS performance and cellular connectivity reliability.

Implement automated testing procedures for both firmware and mobile applications. Create unit tests for GPS parsing functions, communication protocols, and API endpoints. Develop integration tests that verify end-to-end functionality from device to mobile application.

Test power consumption extensively under different operational scenarios. Measure battery life during active tracking, sleep modes, and various cellular signal conditions to provide accurate battery life estimates to users.

Consider implementing over-the-air update capabilities for firmware updates and remote configuration changes. This enables bug fixes and feature updates without physical access to deployed devices, significantly reducing maintenance overhead.

Plan your deployment strategy considering regulatory requirements for GPS tracking devices in your target markets. Ensure compliance with privacy laws and consider implementing features that support legal requirements for tracking consent and data management.

Conclusion

Building a comprehensive GPS tracker with cellular communication and Flutter app integration requires careful planning, attention to detail, and thorough testing. The combination of reliable hardware, efficient firmware, robust backend infrastructure, and intuitive mobile applications creates a powerful tracking solution suitable for various applications from personal asset tracking to commercial fleet management.

Success in this project depends on understanding the interconnections between all system components and optimizing each element for reliability, efficiency, and user experience. With proper implementation, your GPS tracking system will provide accurate, real-time location data while maintaining the flexibility and scalability needed for long-term success.