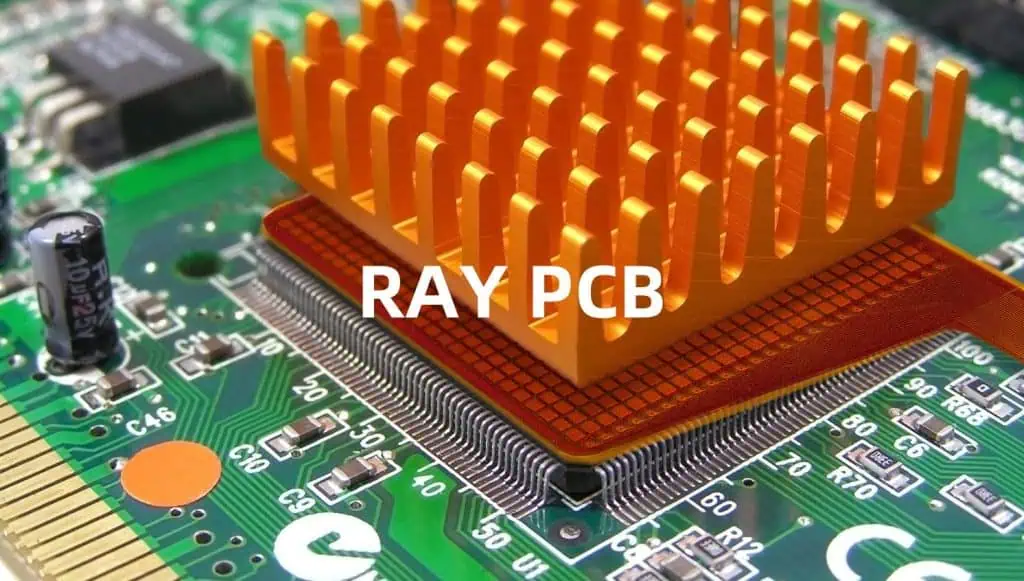

Active components can serve as significant heat sources in your PCB, directly influencing the board’s equilibrium temperature. Repeated thermal cycling (high-to-low transitions) and prolonged high-temperature operation degrade system longevity, often leading to premature component or trace failures. Implementing an effective thermal management strategy is critical to mitigating these risks.

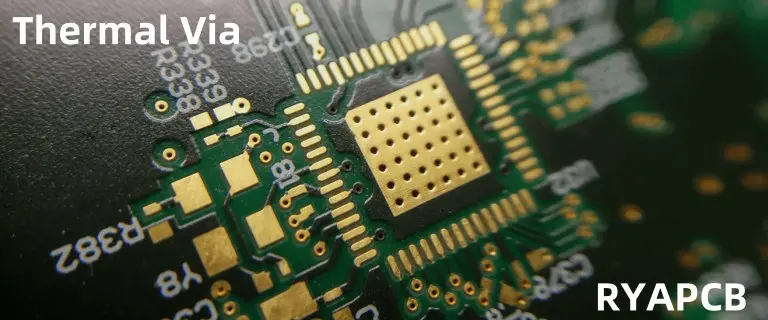

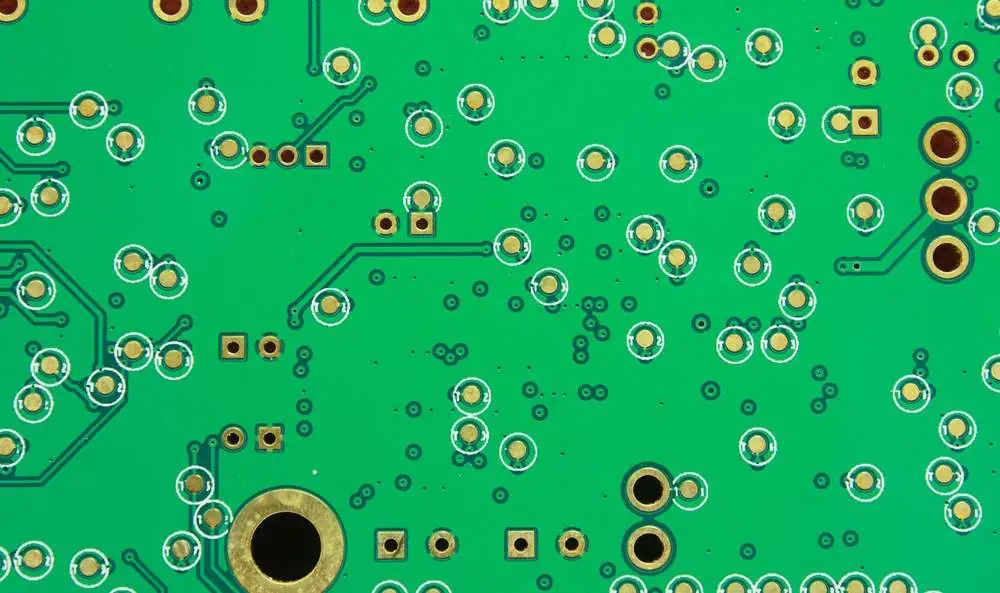

A key element of this strategy is the strategic placement of thermal vias. These vias enhance heat dissipation away from high-power components such as processors, FPGAs, and power electronics. By optimizing thermal via placement in your PCB layout, you can reduce peak temperatures, eliminate hot spots, and significantly improve system reliability.

What Are Thermal Vias?

Thermal vias are specialized through-hole connections in a PCB designed primarily for heat transfer. Unlike standard vias used for electrical connections between layers, thermal vias are strategically placed to conduct heat away from components and distribute it more effectively across the board or to dedicated heat sinking layers.

Key Characteristics of Thermal Vias:

- Typically smaller in diameter than standard vias

- Often clustered in arrays beneath heat-generating components

- May be filled with thermally conductive materials

- Can span multiple layers of the PCB

Read more about:

How Thermal Vias Dissipate Heat

Understanding the mechanism behind heat dissipation through thermal vias is crucial for effective implementation. Thermal vias work on the principle of conduction, one of the three primary heat transfer methods (along with convection and radiation).

The Heat Dissipation Process:

- Heat Generation: Electronic components, such as power transistors or high-speed processors, generate heat during operation.

- Conduction to PCB: This heat is initially conducted to the PCB surface directly beneath the component.

- Thermal Via Network: An array of thermal vias beneath the component provides multiple pathways for heat to travel.

- Vertical Heat Transfer: Heat moves vertically through the vias, utilizing the high thermal conductivity of copper.

- Layer-to-Layer Spread: As heat travels through the vias, it spreads laterally at each layer, increasing the effective heat dissipation area.

- Heat Sinking: In many designs, thermal vias connect to internal ground planes or dedicated heat sinking layers, further enhancing heat distribution.

- External Dissipation: Finally, heat is dissipated to the environment through the PCB surfaces or additional heat sinking structures.

Types of Thermal Vias in PCBs

Thermal vias come in various configurations, each with its own set of advantages and use cases. Understanding these types can help designers choose the most appropriate solution for their specific thermal management needs.

1. Standard Thermal Vias

Standard thermal vias are the most basic and common type. They are essentially normal plated through-holes used for thermal purposes.

Characteristics:

- Unfilled

- Typically 0.3mm to 0.5mm in diameter

- Used in arrays for increased thermal conductivity

Advantages:

- Cost-effective

- Easy to manufacture

- Suitable for moderate heat dissipation needs

Disadvantages:

- Less efficient than filled vias

- Can trap air, reducing thermal performance

2. Via-in-Pad

Via-in-pad technology integrates thermal vias directly into the component’s solder pad, allowing for more efficient heat transfer and space-saving designs.

Characteristics:

- Vias placed within the component’s footprint

- Often used with BGAs and other dense packages

Advantages:

- Improved thermal performance

- Reduced PCB real estate usage

- Shorter electrical paths

Disadvantages:

- More complex manufacturing process

- Risk of solder wicking during assembly

3. Filled and Capped Vias

Filled and capped vias represent the most advanced thermal via technology, offering superior heat dissipation capabilities.

Characteristics:

- Vias filled with thermally conductive material (e.g., copper, silver, or thermal epoxy)

- Capped with copper for a smooth surface

Advantages:

- Excellent thermal conductivity

- Prevents solder wicking

- Allows for component placement over vias

Disadvantages:

- Higher manufacturing costs

- Requires specialized production processes

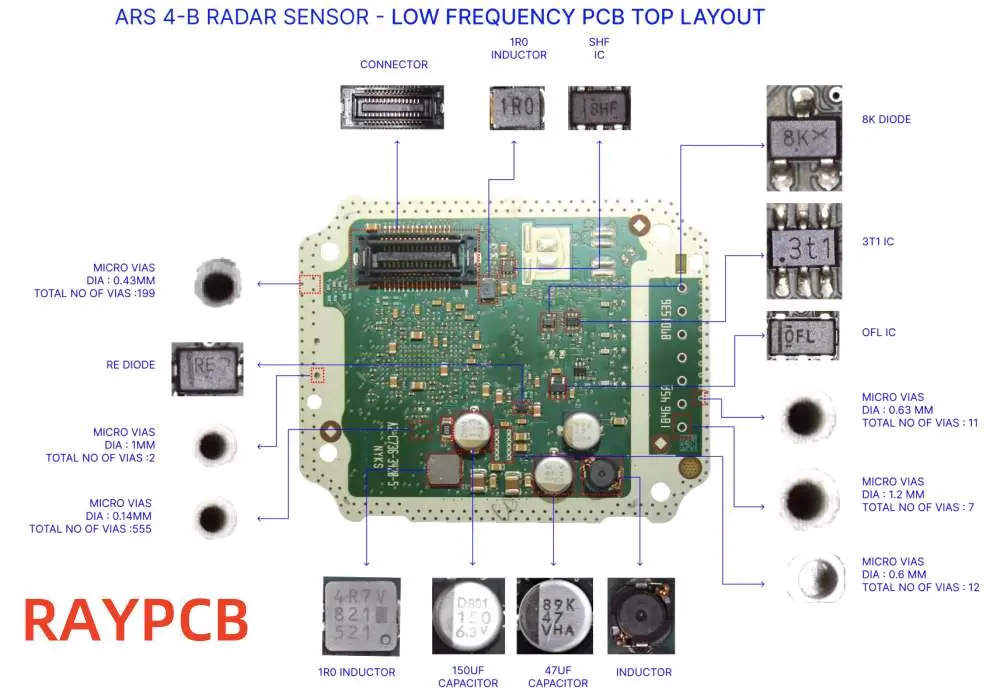

4. Micro Vias

Micro vias are extremely small thermal vias, typically used in high-density interconnect (HDI) boards.

Characteristics:

- Diameter less than 0.15mm

- Often laser-drilled

- Can be stacked or staggered

Advantages:

- Enables very high via density

- Suitable for fine-pitch components

- Improved signal integrity

Disadvantages:

- More expensive to manufacture

- May have limited depth due to aspect ratio constraints

How to Maximize the Effectiveness of Thermal Vias

To achieve optimal heat dissipation using thermal vias, designers must consider various factors and implement best practices. Here are key strategies to maximize the effectiveness of thermal vias:

1. Optimize Via Placement

- Place vias as close to the heat source as possible

- Use arrays of vias rather than single, larger vias

- Consider the direction of heat flow when placing vias

2. Choose Appropriate Via Size and Spacing

- Balance via diameter with manufacturing capabilities

- Space vias close enough for effective heat spread, but not so close as to compromise board integrity

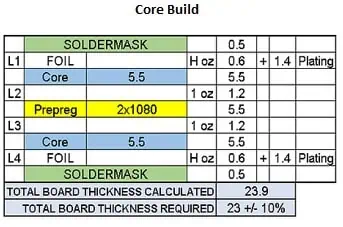

3. Utilize Multiple Layers

- Connect thermal vias to internal ground planes and power planes

- Use dedicated thermal layers in multi-layer designs

4. Consider Thermal Via Filling

- For high-power applications, use filled vias for improved thermal conductivity

- Choose filling materials based on thermal requirements and budget constraints

5. Implement Proper PCB Stackup

- Place high-conductivity layers closer to heat-generating components

- Use thicker copper layers for improved heat spreading

6. Combine with Other Cooling Techniques

- Integrate thermal vias with heat sinks or cooling fans

- Use thermal vias in conjunction with thermally conductive PCB materials

6 Benefits of Using Thermal Vias in Your PCBs

Incorporating thermal vias into PCB designs offers numerous advantages:

- Enhanced Heat Dissipation: Thermal vias significantly improve the board’s ability to remove heat from components.

- Improved Component Reliability: By reducing operating temperatures, thermal vias can extend the lifespan of electronic components.

- Space Efficiency: Thermal vias allow for more compact designs by reducing the need for large heat sinks or spacing between components.

- Flexibility in Component Placement: Effective heat management through thermal vias enables more freedom in component placement on the PCB.

- Cost-Effective Thermal Management: Compared to other cooling solutions, thermal vias are relatively inexpensive to implement.

- Compatibility with High-Density Designs: Thermal vias are crucial for managing heat in densely packed, high-performance PCBs.

Combining Thermal Vias with Other Thermal Management Strategies

While thermal vias are highly effective, they are often most powerful when used in conjunction with other thermal management techniques. Here are some complementary strategies:

1. Heat Sinks

- Attach heat sinks to components or PCB surfaces

- Use thermal vias to enhance heat transfer to the heat sink

2. Thermal Interface Materials (TIMs)

- Apply TIMs between heat-generating components and the PCB

- Use in combination with thermal vias for improved heat conduction

3. Forced-Air Cooling

- Implement fans or blowers for active cooling

- Design thermal via patterns to work with airflow patterns

4. Liquid Cooling

- For extreme thermal requirements, consider liquid cooling solutions

- Use thermal vias to efficiently transfer heat to liquid cooling channels

5. Thermally Conductive PCB Materials

- Select base materials with higher thermal conductivity

- Combine with thermal vias for optimal heat spreading

6. Power Plane Design

- Optimize power and ground plane design for heat distribution

- Connect thermal vias to these planes for enhanced thermal performance

16 Thermal Via Design Tips for Efficient Heat Management

- Conduct Thermal Simulations: Use thermal modeling software to optimize via placement and size.

- Consider Manufacturability: Design thermal via patterns that are feasible to produce with available technology.

- Use Larger Diameter Vias for High-Power Components: Increase via size for components with higher heat output.

- Implement Redundancy: Design with extra thermal vias to account for potential manufacturing defects.

- Balance Thermal and Electrical Requirements: Ensure thermal via placement doesn’t compromise signal integrity.

- Adhere to IPC Standards: Follow industry guidelines, such as IPC-2221, for thermal via design.

- Optimize Via Aspect Ratio: Maintain appropriate depth-to-diameter ratios for effective plating and heat transfer.

- Consider Thermal Expansion: Account for differences in thermal expansion between PCB materials and components.

- Use Thermal Relief Patterns: Implement thermal relief connections to balance heat dissipation and solderability.

- Avoid Voids in Filled Vias: Ensure proper filling techniques to prevent air pockets that reduce thermal efficiency.

- Implement Teardrop Connections: Use teardrop patterns to strengthen via connections and improve heat spread.

- Design for Even Heat Distribution: Spread thermal vias evenly to avoid hot spots on the PCB.

- Consider Top and Bottom Layer Heat Dissipation: Utilize both sides of the PCB for maximum thermal performance.

- Optimize Copper Weight: Use heavier copper weights on layers connected to thermal vias for better heat spreading.

- Implement Thermal Fences: Create barriers of thermal vias to isolate heat-sensitive components.

- Document Thermal Design Intent: Clearly communicate thermal via requirements in PCB design files and documentation.

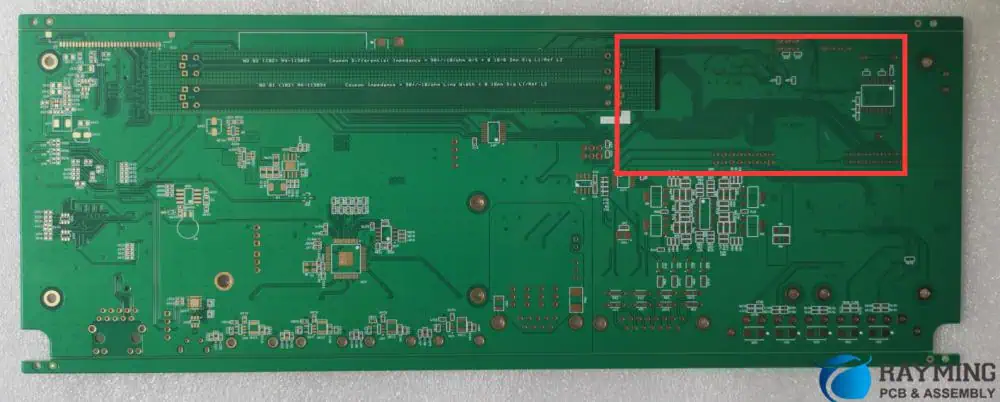

Thermal Vias Simulation and PCB Examples

To illustrate the effectiveness of thermal vias, let’s explore some simulation results and real-world PCB examples.

Thermal Simulation Example

A thermal simulation of a high-power LED module demonstrates the impact of thermal vias:

- Without Thermal Vias: Peak temperature of 85°C at the LED junction

- With Thermal Vias: Peak temperature reduced to 65°C

- Result: 23.5% reduction in peak temperature, significantly improving LED lifespan and performance

PCB Design Example: Power Supply Board

In a 4-layer power supply PCB design:

- Thermal Challenge: High-power MOSFETs generating significant heat

- Solution: Array of 20 thermal vias (0.3mm diameter) under each MOSFET

- Implementation: Vias connected to internal ground plane and bottom-layer copper pour

- Outcome: 30% reduction in MOSFET operating temperature, enabling higher power output

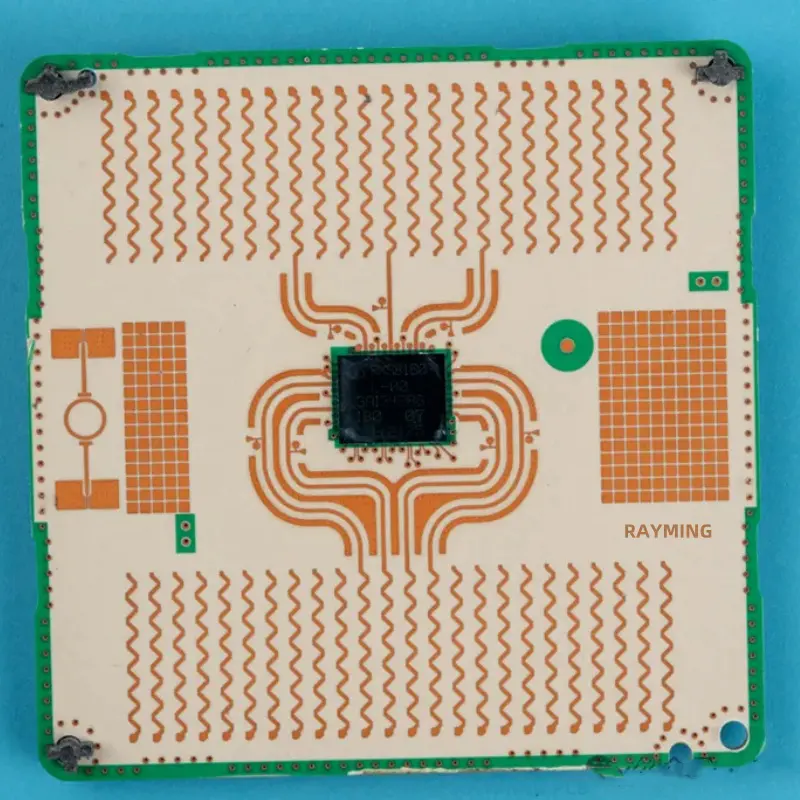

High-Frequency RF Board Example

For a high-frequency RF amplifier board:

- Thermal Challenge: Maintaining low temperatures while preserving signal integrity

- Solution: Micro vias (0.1mm diameter) in via-in-pad configuration

- Implementation: Stacked micro vias connecting to buried heat-spreading layer

- Outcome: Achieved required thermal performance without compromising RF characteristics

Conclusion: The Critical Role of Thermal Vias in Modern PCB Design

As electronic devices continue to shrink in size while increasing in power and complexity, effective thermal management becomes ever more crucial. Thermal vias represent a powerful, flexible, and cost-effective solution for addressing these challenges in PCB design.

By understanding the principles behind thermal vias, their various types, and best practices for implementation, PCB designers can create more efficient, reliable, and high-performing electronic products. Whether you’re working on a simple consumer device or a complex industrial system, integrating thermal vias into your PCB design strategy can lead to significant improvements in thermal performance and overall product quality.

As technology evolves, we can expect to see further innovations in thermal via design and implementation. Staying informed about these developments and continuing to refine thermal management techniques will be essential for PCB designers aiming to push the boundaries of electronic design and meet the demands of future technologies.

Remember, effective thermal management is not just about preventing failure—it’s about optimizing performance, extending product lifespan, and enabling the next generation of electronic innovations. Thermal vias are a key tool in achieving these goals, and mastering their use is a valuable skill for any PCB designer in today’s fast-paced technological landscape.