As a leading provider of cost-effective and high-quality PCB fabrication and assembly services, we support over 1000+ engineers in their research and development projects. Every day, we address questions from customers worldwide about our PCB and assembly solutions. To help new customers better understand our products and services, we’ve compiled these frequently asked questions for your reference.

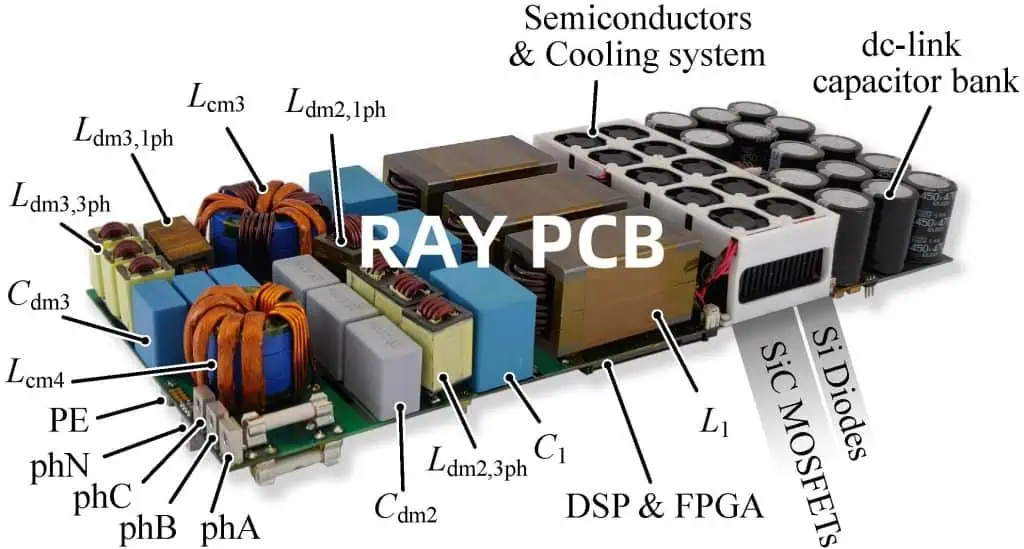

RayMing PCB is a trusted and professional provider of PCB fabrication and PCBA services. With years of experience in the industry, RayMing specializes in delivering high-quality, cost-effective solutions for a wide range of applications, including consumer electronics, industrial equipment, medical devices, and research projects.

The company is known for its commitment to precision, reliability, and customer satisfaction. RayMing PCB offers comprehensive services, from PCB prototyping to full-scale production, including turnkey assembly, component sourcing, and testing. Their advanced manufacturing facilities, skilled engineering team, and dedication to innovation make them a preferred partner for engineers, businesses, and researchers worldwide.

Whether you’re working on a small prototype or a large-scale production run, RayMing PCB provides tailored solutions to meet your specific needs, ensuring high-quality results and on-time delivery.

Generally, there is no minimum order quantity (MOQ) requirement for the pcb assembly order.

At this time, we do not offer assembly services for PCBs manufactured by other companies. Our process is designed to provide a seamless and integrated experience, combining PCB fabrication, component sourcing, and assembly under one roof. This approach ensures efficiency, quality control, and cost-effectiveness, ultimately saving our customers time and money. By handling the entire production process internally, we can guarantee consistent results and a smoother workflow for your projects.

For your PCBA orders, we require the following files: Gerber files, Centroid data, and a BOM (Bill of Materials). If you’ve already placed your PCB order with us and your Gerber files include the essential layers—silkscreen, copper track, and solder paste—you only need to provide the Centroid data and BOM.

However, if your Gerber files are missing any of these three critical layers, please resend the updated files, as these are the minimum requirements for assembly.

For the best possible results, we also recommend submitting additional documents such as assembly drawings, special instructions, and photos of your project. While these are not mandatory, they help us better understand your requirements, avoid ambiguities, and prevent potential errors in component placement. Providing these details ensures a smoother and more accurate assembly process.

A Centroid file is a specialized file used in the assembly process to program automated assembly machines efficiently. It is also referred to as Insertion, Pick-and-Place, or XY Data. This file provides detailed information about the placement and orientation of all surface-mount components on the PCB.

The Centroid file includes:

Reference Designator

X and Y Coordinates (position on the board)

Rotation (orientation of the component)

Board Side (Top or Bottom)

While some CAD tools automatically generate this file, others may require manual adjustments before the Centroid file can be created. It’s important to note that only surface-mount components are listed in the Centroid file, as it is specifically designed for automated placement of these parts.

Providing an accurate Centroid file ensures precise and efficient assembly of your PCB.

For consigned or kitted orders, we kindly request that you mark each individual package or box with the following details:

Line Number (as listed in the BOM)

Manufacturer’s Part Number or Customer’s Part Number

Quantities

Additionally, please include a detailed packing list with your shipment. This list will help us efficiently count, verify, and organize the parts upon receipt. Clear labeling and documentation ensure a smooth and accurate assembly process, minimizing delays or errors.

For consigned or kitted PCBA orders, please note the following guidelines regarding parts overages:

Return of Unused Parts:

Unused or excess parts provided by you or purchased by us will not be returned by default. If you wish to have these parts returned with your assembled boards, please inform your service representative or add a note to your order specifying which parts should be sent back.

Packaging for SMT Parts:

SMT parts not supplied on reels must be provided on one continuous strip of tape.

If the same SMT part is used across multiple boards, do not cut them into strips. Keep them on a continuous strip of tape or on reels.

Minimum and Excess Quantities for Common Components:

Resistors, Capacitors, Diodes (0603, 0805, 1206, 2225, SOT, SOD, MELF packages):

Minimum: 50 pieces

Excess: 30 pieces over the required quantity

Example: For an assembly quantity of 40 pieces, provide 70 pieces (50 minimum + 30 excess).

Resistors, Capacitors, Diodes (0201, 0402, miniMelf, miniature packages):

Minimum: 100 pieces

Excess: 50 pieces over the required quantity

Example: For an assembly quantity of 80 pieces, provide 130 pieces (100 minimum + 50 excess).

Expensive Components (ICs, BGAs, QFPs, Connectors, etc.):

A small excess (1-5 pieces, depending on the total assembly quantity) is recommended to ensure smooth assembly and timely delivery of your boards.

If you are unsure about the quantity, feel free to provide additional extras or contact us for clarification.

Adhering to these guidelines helps us maintain efficiency and ensures your project is completed on time and to the highest standards. If you have any questions, please don’t hesitate to reach out to us.

Yes, we can! This service is known as Partial Turn-Key. You have the option to supply some of the components yourself, and we will source the remaining parts on your behalf. During the process, if we encounter any uncertainties regarding part specifications or availability, we will seek your approval before proceeding.

In cases where parts are unavailable or substitutions are required, we will contact you for final confirmation to ensure the selected alternatives meet your requirements. This approach allows us to maintain transparency and ensures your assembly aligns with your expectations.

Yes, we are fully equipped to assemble BGAs, including those with a fine pitch of 0.25mm, and we provide X-ray testing to ensure quality and reliability.

For BGA assembly, there are two common design approaches: via on pad and via near pad (connected by shorter traces). Each design has specific requirements to ensure optimal soldering quality:

Via Near Pad:

Vias located near the BGA pads must be tented and filled with solder mask to prevent solder wicking and ensure proper soldering.

Via on Pad:

Vias directly on the BGA pads must be filled with resin to create a flat surface, ensuring excellent soldering quality and preventing voids or defects.

By adhering to these guidelines, we guarantee high-quality BGA assembly and reliable performance for your PCBs. If you have any specific requirements or questions, feel free to reach out to us!

Excess parts are common because we typically request a percentage of overage for consigned/kitted orders or purchase additional quantities for Turn-Key orders to ensure smooth assembly. Once your order is complete, you have two options for handling the unused parts:

Ship them back to you: We can return the unused parts along with your assembled boards.

Store them for future use: We can keep the parts in our inventory for your next order.

The choice is entirely yours! Let us know your preference, and we’ll accommodate accordingly.

Our online instant quote system provides a preliminary estimate of the PCBA cost, covering essential elements such as tooling, laser-cut steel stencils, and labor. For Turn-Key or Partial Turn-Key PCBA services, the cost of components will also be included in the final price. This ensures transparency and helps you understand the breakdown of expenses for your project.

Determining the turnaround time for PCBA services can be complex due to various factors. As per our policy, the turnaround time officially begins only after the following conditions are met:

All required parts and PCBs are ready.

All necessary files and documents are submitted, including:

PCB files (Gerber files or other formats)

Centroid file (Pick & Place/PNP file, XY Data, or equivalent)

BOM (Bill of Materials)

Any additional data, documents, images, or photos essential for the assembly process.

Once all these elements are complete and in place, we initiate the assembly process and the turnaround time starts. This ensures a smooth and efficient workflow for your project.

Yes, our assembly services are RoHS compliant, ensuring adherence to environmental and safety standards. However, we also provide leaded PCBA services for projects that require traditional soldering methods. Let us know your specific requirements, and we’ll accommodate accordingly!

Panelization is required in the following scenarios:

If your PCB dimensions are smaller than 50mm x 100mm.

If your PCB has a non-rectangular shape (e.g., circular or irregular).

In such cases, your boards must be arranged in an array (panelized) to facilitate the assembly process. Since we also handle PCB fabrication, once we begin manufacturing your boards, we will generate the panelization file (including solder paste data). This file is then shared with our PCBA department to create a stencil that matches the panelized PCB layout, ensuring precise and efficient assembly. Panelization streamlines production and ensures consistency across your boards.

Break-away rails (or tabs) are necessary in the following situations:

If the clearance between the board’s edge and copper features is less than 3.5mm (138 mil).

If your boards require panelization for assembly or other reasons.

These rails must be added along the two longer parallel edges of the boards to ensure they can be properly handled and processed by the SMT (Surface Mount Technology) machines. Break-away rails provide structural support during assembly, enabling smooth machine processing and ensuring the boards remain stable throughout the manufacturing process. Once assembly is complete, the rails can be easily removed.

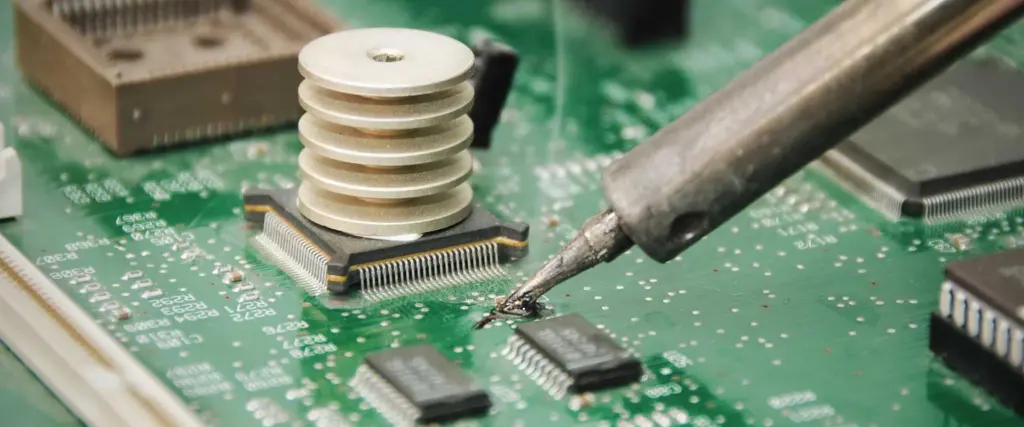

While PCBA is a complex process involving numerous details, defects or issues can occasionally occur. If you encounter any problems, please notify us immediately. We will thoroughly evaluate and review the situation to determine the best course of action. Depending on the issue, we will either repair/rework the boards or remake them entirely.

In some cases, we may request that you return the defective boards to us for further analysis. Rest assured, our goal is to ensure you receive fully functional boards, and we stand by our commitment to resolving any issues promptly and effectively. Your satisfaction is our priority!

Our PCB assembly services adhere to the IPC-A-610 Class 2 standard. This ensures that your boards meet high-quality reliability and performance criteria, suitable for a wide range of applications where extended product life and uninterrupted service are essential.

For Turn-Key orders, the turnaround time primarily depends on the time required to source all the necessary components. We will keep you updated through daily email communications regarding the progress of part sourcing and overall timelines.

While waiting for the parts to arrive, we will proceed with PCB fabrication and stencil preparation. This allows us to begin the assembly process immediately once all components are in hand, ensuring an efficient and streamlined workflow. Rest assured, we prioritize minimizing delays and keeping you informed every step of the way.

You can share your special instructions by either:

Sending us an email detailing your requirements, or

Including a readme file with your specifications when submitting your order.

This ensures we clearly understand your needs and can accommodate any specific requests during the assembly process.

a) Visual Inspection b) AOI Inspection c) X-Ray inspection (for BGA’s and fine pitch parts) d) Functional testing (if required by customer)

Yes, we offer both IC programming and functional testing.

For IC programming, we will need the hex file.

For functional testing, please provide the test procedure and the required hardware.

Yes, we offer conformal coating services. For further details, feel free to reach out to us at: Sales@raypcb.com.

Several key factors directly affect the cost of PCB assembly, such as the technology employed, whether the board is single or double-sided, the number of component placements, coating requirements, testing procedures, shipping needs, and more.