Flexible Printed Circuit Boards (PCBs) have revolutionized the electronics industry, offering numerous advantages such as reduced weight, space savings, and improved reliability. However, like any technology, they also come with their own set of drawbacks. This article delves into the various disadvantages of flexible PCBs, providing a comprehensive overview of the challenges faced by manufacturers, designers, and end-users when working with this technology.

Understanding Flexible PCBs

Before we explore the disadvantages, let’s briefly recap what flexible PCBs are and their basic characteristics.

Definition and Basic Characteristics

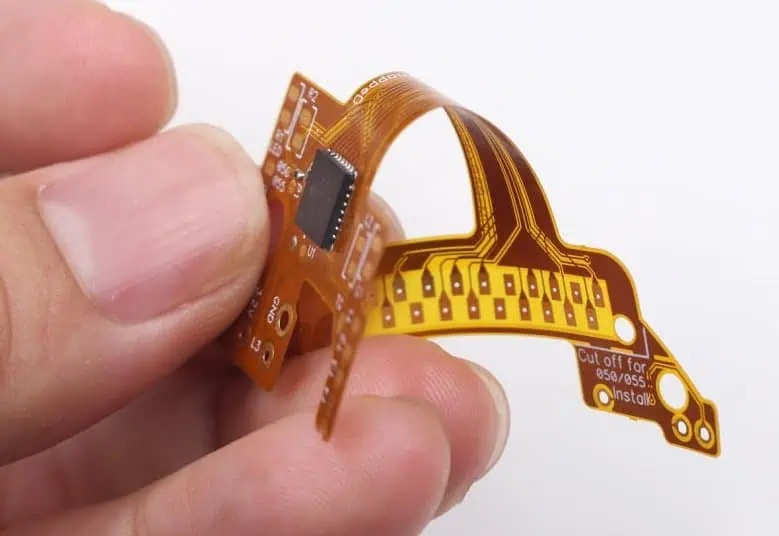

Flexible PCBs, also known as flex circuits, are electronic circuits mounted on flexible substrate materials. Unlike rigid PCBs, these circuits can bend, fold, and conform to various shapes, making them ideal for applications where space is at a premium or where the circuit needs to flex during use.

Key Components

The typical components of a flexible PCB include:

- Flexible substrate (usually polyimide or polyester)

- Conductive layers (typically copper)

- Coverlay or cover coat

- Adhesives

- Stiffeners (in some designs)

Now that we have a basic understanding, let’s explore the disadvantages of flexible PCBs.

Learn more about:

Cost Considerations

Higher Initial Costs

One of the most significant disadvantages of flexible PCBs is their higher initial cost compared to rigid PCBs.

Table 1: Cost Comparison – Flexible vs. Rigid PCBs

| Factor | Flexible PCBs | Rigid PCBs |

|---|---|---|

| Raw Material Cost | Higher | Lower |

| Manufacturing Complexity | Higher | Lower |

| Specialized Equipment | Required | Standard |

| Design Time | Longer | Shorter |

| Overall Initial Cost | Higher | Lower |

The higher costs associated with flexible PCBs stem from several factors:

- Expensive raw materials: The polyimide or polyester substrates used in flexible PCBs are more expensive than the FR-4 material commonly used in rigid PCBs.

- Complex manufacturing process: Producing flexible PCBs requires specialized equipment and more intricate processes, increasing production costs.

- Design complexity: Designing flexible PCBs often takes more time and expertise, adding to the overall cost.

Limited Cost-Effectiveness for Low-Volume Production

While flexible PCBs can be cost-effective for high-volume production, they may not be economically viable for low-volume or prototype runs.

Design and Manufacturing Challenges

Complex Design Process

Designing flexible PCBs presents unique challenges that can be time-consuming and require specialized expertise.

Bend Radius Considerations

One of the critical aspects of flexible PCB design is accounting for the bend radius. Designers must ensure that the circuit can flex without damaging the conductive traces or components.

Table 2: Typical Minimum Bend Radii for Flexible PCBs

| Number of Layers | Minimum Bend Radius (mm) |

|---|---|

| Single-sided | 0.8 – 1.5 |

| Double-sided | 1.5 – 2.5 |

| Multilayer | 3.0 – 6.0 |

Limited Layer Count

Flexible PCBs typically have fewer layers than their rigid counterparts, which can limit circuit complexity and functionality.

Table 3: Typical Layer Count Comparison

| PCB Type | Typical Maximum Layers |

|---|---|

| Flexible PCBs | 4-6 |

| Rigid PCBs | 16-32 (or more) |

This limitation can force designers to make trade-offs between flexibility and circuit complexity.

Manufacturing Challenges

Handling and Processing Difficulties

The flexible nature of these PCBs can make them more challenging to handle during the manufacturing process. Issues such as warping, twisting, or folding can occur, potentially leading to defects or reduced yield rates.

Specialized Equipment Requirements

Manufacturing flexible PCBs requires specialized equipment, which can be a significant investment for PCB fabricators. This requirement can limit the number of manufacturers capable of producing flexible PCBs, potentially affecting lead times and costs.

Performance and Reliability Concerns

Thermal Management Issues

Flexible PCBs face unique challenges when it comes to heat dissipation.

Limited Heat Dissipation

The thin, flexible nature of these PCBs means they have less mass to absorb and dissipate heat compared to rigid PCBs. This can lead to potential overheating issues, especially in high-power applications.

Table 4: Thermal Conductivity Comparison

| Material | Thermal Conductivity (W/mK) |

|---|---|

| FR-4 (typical rigid PCB) | 0.3 – 0.8 |

| Polyimide (typical flex PCB) | 0.12 – 0.46 |

| Copper (for reference) | 385 |

Mechanical Stress and Fatigue

While flexibility is a key advantage of these PCBs, it also introduces potential reliability issues.

Repeated Flexing

In applications where the PCB needs to flex repeatedly, there’s a risk of mechanical fatigue. This can lead to cracked traces, delamination, or component failure over time.

Table 5: Flex Life of Different Flexible PCB Constructions

| Construction Type | Typical Flex Life (number of flexes) |

|---|---|

| Single-layer | 1,000,000+ |

| Double-layer | 100,000 – 500,000 |

| Multilayer | 10,000 – 100,000 |

Environmental Sensitivity

Flexible PCBs can be more sensitive to environmental factors compared to rigid PCBs.

Moisture Sensitivity

The polyimide material commonly used in flexible PCBs can absorb moisture, potentially leading to delamination or changes in electrical properties.

Temperature Extremes

While flexible PCBs can generally withstand a wide range of temperatures, extreme conditions can cause issues such as dimensional changes or adhesive degradation.

Limited Repairability and Modification

Difficulty in Rework and Repair

Flexible PCBs present unique challenges when it comes to rework and repair.

Delicate Nature

The thin, flexible structure of these PCBs makes them more susceptible to damage during rework attempts. Standard repair techniques used for rigid PCBs may not be suitable or may risk further damage.

Limited Access

In applications where the flexible PCB is tightly integrated into a product, accessing the PCB for repairs can be extremely difficult or impossible without disassembling the entire product.

Challenges in Post-Production Modifications

Making changes to a flexible PCB after production can be more challenging compared to rigid PCBs.

Limited Real Estate

The compact nature of flexible PCB designs often means there’s little to no extra space for additional components or traces, making modifications difficult.

Maintaining Flexibility

Any modifications must be carefully considered to ensure they don’t compromise the PCB’s ability to flex as required in the application.

Component and Assembly Limitations

Restricted Component Selection

Not all electronic components are suitable for use with flexible PCBs.

Size and Weight Constraints

Larger or heavier components may not be suitable for flexible PCBs as they can create stress points and limit flexibility.

Table 6: Component Suitability for Flexible PCBs

| Component Type | Suitability | Reason |

|---|---|---|

| SMD (small) | Excellent | Low profile, lightweight |

| SMD (large) | Fair | May limit flexibility |

| Through-hole | Poor | Can create stress points, limit flexibility |

| Ball Grid Array (BGA) | Good | Depends on size and pitch |

Assembly Challenges

Prototype Assembling components onto flexible PCBs can be more challenging than with rigid PCBs.

Specialized Equipment

Standard pick-and-place machines may struggle with the flexible nature of the PCB, requiring specialized equipment or processes.

Soldering Difficulties

The heat-sensitive nature of flexible substrates can make soldering more challenging, requiring precise temperature control to avoid damaging the PCB.

Regulatory and Compliance Issues

EMI/EMC Challenges

Flexible PCBs can face unique challenges in meeting electromagnetic interference (EMI) and electromagnetic compatibility (EMC) requirements.

Limited Shielding Options

The thin, flexible nature of these PCBs can make it more difficult to incorporate effective EMI shielding compared to rigid PCBs.

Signal Integrity Issues

The flexible structure can potentially lead to signal integrity issues, especially in high-frequency applications, making it more challenging to meet EMC standards.

Environmental Compliance

While flexible PCBs themselves are often compliant with environmental regulations, the overall product may face challenges.

End-of-Life Considerations

The integrated nature of flexible PCBs in some applications can make them more difficult to separate and recycle at the end of a product’s life, potentially impacting compliance with e-waste regulations.

Conclusion

While flexible PCBs offer numerous advantages and have enabled many innovative product designs, it’s crucial to consider their disadvantages when deciding whether to use them in a particular application. From higher costs and design complexities to performance limitations and regulatory challenges, flexible PCBs present a unique set of trade-offs.

By understanding these disadvantages, engineers and product designers can make informed decisions about when and how to use flexible PCBs, balancing their benefits against their drawbacks to create optimal solutions for their specific applications.

Frequently Asked Questions (FAQ)

Q1: Are flexible PCBs more expensive than rigid PCBs?

A1: Yes, flexible PCBs typically have higher initial costs than rigid PCBs due to more expensive raw materials, complex manufacturing processes, and specialized design requirements. However, they can be cost-effective in high-volume production or where their unique properties provide significant advantages.

Q2: Can flexible PCBs handle high-power applications?

A2: Flexible PCBs generally have more limited heat dissipation capabilities compared to rigid PCBs, which can make them less suitable for high-power applications. However, design techniques such as using thicker copper layers or incorporating thermal management solutions can help mitigate this limitation in some cases.

Q3: How many times can a flexible PCB be bent?

A3: The number of times a flexible PCB can be bent depends on factors such as the PCB’s construction, the bend radius, and the specific materials used. Single-layer flex PCBs can often withstand over a million flexes, while multilayer designs may be limited to tens or hundreds of thousands of flexes.

Q4: Are all components compatible with flexible PCBs?

A4: Not all components are suitable for use with flexible PCBs. Small surface-mount devices (SMDs) are generally the most compatible, while larger or heavier components may be problematic. Through-hole components are typically avoided in flexible PCB designs as they can create stress points and limit flexibility.

Q5: Can flexible PCBs be repaired easily?

A5: Repairing flexible PCBs is generally more challenging than repairing rigid PCBs. Their delicate nature and often tightly integrated designs can make access difficult and increase the risk of damage during repair attempts. In many cases, it may be more practical to replace the entire flexible PCB rather than attempt a repair.