The RO3000 series laminates are high-frequency circuit materials designed for demanding RF and microwave applications. This family includes RO3003, RO3006, RO3010, and RO3035, each offering different dielectric constants ranging from 3.0 to 3.5. These materials provide excellent electrical and mechanical stability, low loss, and consistent dielectric constant across a wide frequency range, making them ideal for high-performance RF/microwave circuits.

Powered By EmbedPress

RO3003 – RO3006 – RO3010 – RO3035

The Rogers RO3000 series represents a family of high-performance ceramic-filled PTFE composite laminates specifically engineered for demanding RF and microwave applications. This comprehensive analysis examines the four primary variants in the series: RO3003, RO3006, RO3010, and RO3035, each offering distinct dielectric properties while maintaining consistent mechanical characteristics that make them ideal for commercial microwave and RF circuit designs.

Series Overview and Core Technology

The RO3000 series utilizes ceramic-filled polytetrafluoroethylene (PTFE) composite technology, which provides the foundation for exceptional electrical and mechanical stability across all frequency ranges. This family was specifically designed to deliver outstanding performance at competitive prices, making high-frequency circuit design more accessible for commercial applications. The ceramic filling in the PTFE matrix ensures dimensional stability while maintaining the excellent electrical properties that PTFE is known for.

What sets the RO3000 series apart from other high-frequency laminates is the consistent mechanical properties across all dielectric constant variants. This uniformity allows designers to develop complex multilayer board constructions using different dielectric constant materials for individual layers without encountering warpage or reliability issues that typically plague mixed-material designs.

Individual Material Specifications

RO3003 Laminates

RO3003 represents the lowest dielectric constant option in the series, featuring a dielectric constant (εr) of 3.0 ± 0.04. This material exhibits exceptionally low dielectric loss, with a dissipation factor (tan δ) of only 0.0013 at 10 GHz, making it suitable for applications extending up to 30-40 GHz. The low dielectric constant and minimal loss characteristics make RO3003 particularly valuable for millimeter-wave applications, precision stripline circuits, and high-performance antenna systems where signal integrity is paramount.

The material demonstrates excellent thermal stability with a coefficient of thermal expansion (CTE) in the X and Y directions of 17 ppm/°C, which precisely matches that of copper. This matching ensures exceptional dimensional stability during thermal cycling, with typical etch shrinkage after etching and baking of less than 0.5 mils per inch. The Z-axis CTE of 24 ppm/°C provides outstanding plated through-hole reliability even in severe thermal environments.

RO3006 Laminates

RO3006 features a dielectric constant of 6.15, positioning it as the mid-range option for applications requiring higher capacitance per unit area while maintaining low loss characteristics. Like its RO3003 counterpart, RO3006 exhibits a dissipation factor of 0.0013 at 10 GHz, ensuring minimal signal degradation across the frequency spectrum. The higher dielectric constant makes RO3006 particularly suitable for compact circuit designs where size reduction is critical without compromising electrical performance.

The thermal stability coefficient in the Z-direction reaches an impressive -3 ppm/°C when measured over the temperature range from -50°C to +150°C at 10 GHz. This exceptional temperature stability eliminates the step-change phenomenon in dielectric constant that occurs in traditional PTFE glass materials near room temperature, ensuring consistent performance across varying environmental conditions.

RO3010 Laminates

RO3010 offers a dielectric constant of 10.2, representing the highest value in the series for applications requiring maximum miniaturization and high capacitance density. This material maintains the same excellent loss characteristics as other series members while providing the electrical properties needed for extremely compact antenna designs and high-density filter applications. The higher dielectric constant enables significant size reduction in circuit designs, particularly valuable in space-constrained applications such as automotive radar systems and portable communication devices.

The material maintains the same mechanical stability characteristics as other RO3000 series members, ensuring that the benefits of higher dielectric constant don’t come at the expense of mechanical reliability or processing difficulties.

RO3035 Laminates

RO3035 features a dielectric constant of 3.5, providing a middle ground between RO3003 and RO3006 for applications requiring specific impedance characteristics. This variant maintains the excellent electrical performance standards of the series while offering designers additional flexibility in circuit design optimization. The material demonstrates the same exceptional temperature stability as RO3003, making it suitable for applications where environmental conditions may vary significantly.

Mechanical and Thermal Properties

All RO3000 series materials share identical mechanical properties, which represents a significant advantage for multilayer circuit design. The coefficient of thermal expansion in the X and Y directions of 17 ppm/°C matches copper exactly, ensuring that the substrate and conductor expand at the same rate during temperature changes. This matching prevents stress-related failures and maintains circuit integrity over extended temperature cycling.

The Z-axis CTE of 24 ppm/°C provides exceptional reliability for plated through-hole connections, even under severe thermal stress conditions. This property is particularly important for applications in automotive, aerospace, and industrial environments where temperature extremes are common.

The dielectric constant versus temperature relationship for all RO3000 materials is remarkably stable, eliminating the performance variations that can plague other high-frequency materials. This stability ensures predictable circuit performance across the entire operating temperature range, reducing the need for temperature compensation in critical applications.

Processing and Manufacturing Considerations

RO3000 series laminates can be processed using standard PTFE circuit board fabrication techniques with minor modifications outlined in Rogers Corporation’s fabrication guidelines. The materials are compatible with conventional drilling, etching, and plating processes, though special handling procedures are required due to the PTFE content.

The ceramic filling in the PTFE matrix provides improved dimensional stability compared to unfilled PTFE materials while maintaining the excellent electrical properties. This enhancement allows for tighter tolerance control during manufacturing and improved yield rates in production environments.

Standard thickness tolerances are maintained across the series, with typical values of ±0.0013 inches (±0.033 mm) for most standard thicknesses. The materials are available in various copper cladding weights, including 0.5 oz, 1 oz, and 2 oz configurations, providing flexibility for different application requirements.

Applications and Performance Advantages

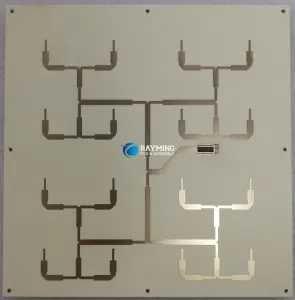

The RO3000 series finds extensive application in automotive collision avoidance systems, GPS satellite antennas, cellular and pager telecommunications systems, patch antennas for wireless communications, direct broadcast satellites, cable system datalinks, remote meter reading systems, and power backplane applications. The consistent mechanical properties across dielectric constants make the series particularly valuable for complex multilayer designs that require different electrical characteristics in different layers.

The series offers significant cost advantages compared to traditional PTFE-based microwave laminates while maintaining comparable electrical performance. This cost-effectiveness makes high-frequency design more accessible for commercial applications where budget constraints are significant factors.

The low dielectric loss characteristics enable the materials to be used effectively in applications up to 30-40 GHz, covering most commercial RF and microwave frequency bands. The stable dielectric constant across temperature and frequency ranges ensures predictable performance in varying environmental conditions.

Conclusion

The RO3000 series represents a mature and well-optimized family of high-frequency circuit materials that successfully balance performance, reliability, and cost-effectiveness. The four variants – RO3003, RO3006, RO3010, and RO3035 – provide designers with a comprehensive range of dielectric constants while maintaining consistent mechanical properties that simplify multilayer design challenges.

The exceptional thermal stability, low loss characteristics, and processing compatibility make the RO3000 series an excellent choice for demanding RF and microwave applications. The materials’ proven track record in commercial applications, combined with their competitive pricing, positions them as industry standards for high-frequency circuit design where reliability and performance are essential requirements.