In today’s rapidly evolving electronics landscape, flexible printed circuit boards (flex PCBs) have become essential components for innovative product design. Sourcing these vital components from Canadian manufacturers offers significant advantages for businesses seeking quality, speed, and cost-effectiveness. This comprehensive guide explores why flex PCB Canada suppliers are increasingly becoming the preferred choice for companies needing reliable prototyping and production solutions.

Understanding Flexible PCBs and Their Applications

What Exactly Is a Flexible PCB?

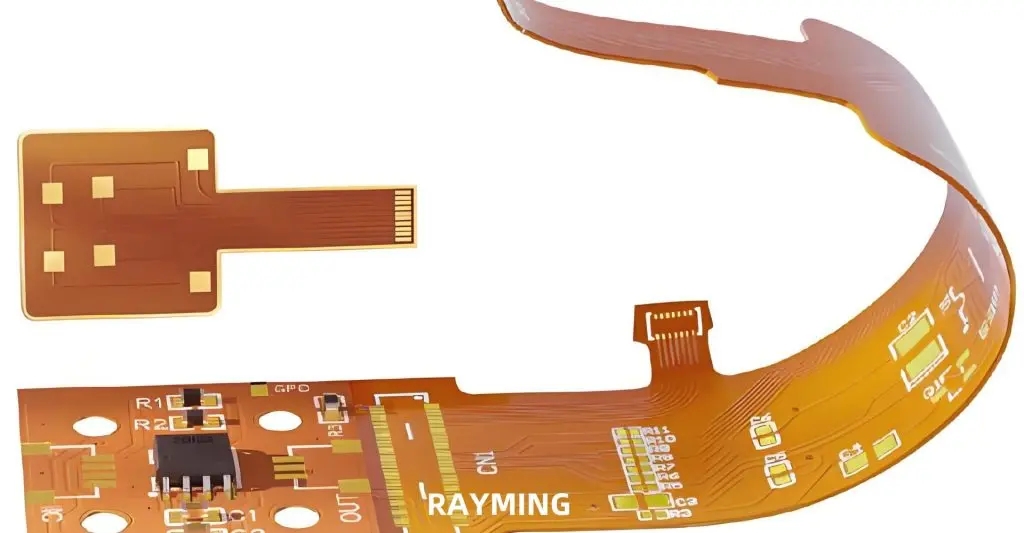

Flexible PCBs are circuit boards manufactured using pliable materials that allow them to bend, fold, and conform to three-dimensional shapes. Unlike traditional rigid PCBs, flex PCBs utilize thin, flexible substrate materials—typically polyimide or polyester films—that maintain electrical connectivity while accommodating movement and vibration. This fundamental difference enables product designs that would be impossible with conventional rigid boards.

The core structure of a flex PCB typically includes:

- A flexible polyimide base material (most commonly Kapton®)

- Conductive copper traces for electrical pathways

- Protective coverlay or solder mask layers

- Various surface finish options (ENIG, immersion tin, etc.)

These specialized circuit boards can range from simple single-sided designs to complex multi-layer configurations, depending on the application requirements.

Critical Applications Across Industries

The versatility of flex PCBs has made them indispensable across numerous sectors:

Medical Devices: Canadian-manufactured flex PCBs power life-saving medical equipment where reliability is non-negotiable. From hearing aids and pacemakers to wearable health monitors, these flexible circuits enable miniaturization while maintaining durability in critical applications.

Automotive Electronics: Modern vehicles incorporate dozens of flex PCBs in dashboard displays, engine management systems, and advanced driver assistance systems (ADAS). The ability to withstand vibration, temperature fluctuations, and tight space constraints makes flex PCBs ideal for automotive applications.

Aerospace and Defense: Canadian flex PCB manufacturers support the aerospace industry with lightweight, reliable circuits for satellite systems, aircraft instrumentation, and defense applications where failure is not an option.

Consumer Electronics: Smartphones, tablets, digital cameras, and wearable technology all depend on flex PCBs to achieve their sleek, compact designs while maintaining functionality.

Why Flexibility Matters in Modern Electronics

The demand for flex PCB Canada solutions continues to grow because flexibility offers distinct advantages:

- Space Optimization: Flex PCBs can fold into compact spaces, enabling 3D packaging that reduces overall device size.

- Weight Reduction: Critical for aerospace and portable electronics, flex PCBs are significantly lighter than rigid alternatives.

- Dynamic Applications: Components that must withstand repeated bending or movement during operation require flexible circuits.

- Improved Reliability: Fewer connectors mean fewer potential points of failure, enhancing overall system reliability.

- Thermal Management: Flexible circuits can distribute heat more effectively across confined spaces.

Advantages of Choosing Flex PCB Manufacturing in Canada

Quality Standards and Regulatory Compliance

Canadian flex PCB manufacturers operate under stringent quality control systems and regulatory frameworks. Most maintain ISO 9001 certification at minimum, with many also holding specialized certifications for aerospace (AS9100), automotive (IATF 16949), and medical device (ISO 13485) manufacturing.

This commitment to quality translates into several tangible benefits:

- Consistent manufacturing processes with documented quality controls

- Regular third-party audits ensuring compliance

- Traceability of materials and processes

- Lower defect rates and higher reliability

- Adherence to international standards like IPC-6013 for flexible circuits

Geographic Proximity and Communication Benefits

For North American companies, partnering with a flex PCB Canada manufacturer offers significant practical advantages:

- Time Zone Alignment: Real-time communication during standard business hours

- Reduced Language Barriers: Clear technical discussions without misinterpretations

- Shorter Shipping Distances: Faster delivery times and lower shipping costs

- Easier Site Visits: The ability to visit manufacturing facilities for critical projects

- Cultural Business Alignment: Similar business practices and expectations

Intellectual Property Protection

Intellectual property protection represents another crucial advantage of manufacturing flex PCBs in Canada. Canadian laws provide robust IP safeguards, giving businesses confidence that their proprietary designs and technologies remain secure throughout the manufacturing process.

Fast Prototyping Capabilities for Flexible PCBs in Canada

Accelerating the Design-to-Production Cycle

Canadian flex PCB manufacturers have developed streamlined processes specifically for rapid prototyping. These accelerated services typically include:

- Online quoting systems for instant pricing

- Design for manufacturability (DFM) reviews within 24 hours

- Expedited material procurement for common substrates

- Dedicated prototyping lines separate from volume production

- Advanced digital manufacturing techniques

The result is a significantly compressed timeline from concept to functional prototype, with many Canadian suppliers offering turnaround times as quick as 3-5 business days for standard flex PCB prototypes.

Typical Lead Times for Canadian Flex PCB Prototyping

Lead times vary based on design complexity, but general expectations include:

- Simple single-sided flex PCBs: 3-5 business days

- Double-sided flex PCBs: 5-7 business days

- Multi-layer flex circuits: 7-10 business days

- Rigid-flex hybrid designs: 10-15 business days

These timelines represent a substantial improvement over offshore manufacturing options that often require 3-4 weeks for comparable prototyping services.

Iterative Design Support

Beyond speed, Canadian flex PCB manufacturers typically offer enhanced engineering support during the prototyping phase. This collaborative approach includes:

- Design optimization suggestions

- Material recommendations based on application requirements

- Manufacturability enhancements

- Testing and validation services

- Rapid iteration capabilities for design refinements

This level of support proves invaluable for companies developing innovative products with tight market windows.

Read more about:

Cost-Effective Flex PCB Production in Canada

Long-Term Value Proposition

While unit costs for flex PCBs manufactured in Canada may initially appear higher than overseas alternatives, the total cost of ownership often proves more favorable when considering all factors:

- Reduced Quality Issues: Lower defect rates mean fewer costly reworks and field failures

- Faster Time-to-Market: Compressed development cycles translate to earlier revenue generation

- Inventory Management: Shorter lead times allow for leaner inventory practices

- Supply Chain Resilience: Reduced vulnerability to international shipping disruptions

- Simplified Logistics: Lower shipping costs and fewer customs complications

Balancing Quality with Affordability

Canadian flex PCB manufacturers have implemented several strategies to remain cost-competitive while maintaining quality:

- Advanced automation reducing labor costs

- Lean manufacturing principles minimizing waste

- Strategic material sourcing and inventory management

- Specialized equipment optimized for flexible circuit production

- Energy efficiency initiatives reducing overhead costs

Volume Production Economics

As production volumes increase, Canadian manufacturers offer increasingly competitive pricing structures:

- Volume discount tiers beginning at modest quantities (often 100+ units)

- Panel optimization for higher-volume runs

- Material quantity discounts passed through to customers

- Dedicated production cells for recurring orders

- Just-in-time delivery options reducing inventory carrying costs

For many companies, the sweet spot for Canadian flex PCB manufacturing lies in low to medium production volumes (100-10,000 units), where quality, speed, and total cost align optimally.

Essential Selection Criteria for Flex PCB Manufacturers in Canada

Technical Capabilities Assessment

When evaluating potential flex PCB Canada partners, consider these technical capabilities:

- Layer Count Capacity: Maximum number of layers they can reliably produce

- Minimum Feature Sizes: Trace width/spacing limitations and via technology

- Material Options: Range of base materials, adhesives, and surface finishes available

- Special Processes: Capabilities for selective stiffeners, shielding, or embedded components

- Testing Infrastructure: In-house electrical testing capabilities and quality verification

Certifications and Standards

Look for manufacturers maintaining relevant certifications:

- ISO 9001 (Quality Management)

- ISO 13485 (Medical Devices)

- AS9100 (Aerospace)

- IATF 16949 (Automotive)

- IPC Member certification

- UL certification for materials

Design Support Services

Evaluate the manufacturer’s ability to support your design process:

- Design rule checking and optimization

- Material selection guidance

- Stack-up recommendations

- Design for manufacturing (DFM) reviews

- Design for testing (DFT) strategies

Customer Experience Factors

Beyond technical capabilities, consider these operational factors:

- Communication responsiveness

- Project management processes

- Online ordering and tracking systems

- Documentation and traceability

- Technical support availability

Emerging Trends in Flex PCB Technology in Canada

Material and Manufacturing Innovations

Canadian flex PCB manufacturers are advancing the field through several innovations:

- Ultra-Thin Substrates: Development of reliable circuits using substrates under 25μm

- Embedded Components: Integrating passive and active components within the flex layers

- Advanced Adhesiveless Laminates: Improving thermal performance and reliability

- Additive Manufacturing: Exploring printed electronics for specialized applications

- Green Manufacturing: Reducing environmental impact through material and process improvements

Growing Demand Across Canadian Industries

Several sectors are driving increased demand for flex PCB Canada solutions:

- Clean Energy Technologies: Solar panels, wind turbines, and battery management systems

- IoT Devices: Smart home technology, industrial sensors, and connected infrastructure

- Advanced Manufacturing: Robotics, automation systems, and smart factories

- Digital Health: Wearable medical devices and remote monitoring solutions

Canadian manufacturers are well-positioned to support these growth areas with specialized flex PCB capabilities.

Integration with Advanced Electronics

The future of flex PCB development in Canada includes deeper integration with:

- Microelectromechanical Systems (MEMS): Combining flex PCBs with tiny mechanical elements

- Printed Electronics: Incorporating printed components directly onto flexible substrates

- Advanced Interconnect Technologies: Developing high-density, reliable connections between flex and rigid elements

- 5G and RF Applications: Specialized flex PCBs optimized for high-frequency performance

Conclusion: Making the Right Choice for Flex PCB Canada Manufacturing

The Canadian flexible PCB manufacturing landscape offers compelling advantages for companies seeking reliable, high-quality circuit solutions with fast turnaround times. By balancing quality, speed, and cost-effectiveness, Canadian manufacturers provide a valuable alternative to overseas production, particularly for prototyping and low to medium volume requirements.

When selecting a flex PCB Canada partner, conduct thorough due diligence on their technical capabilities, quality systems, and support services. The right manufacturing relationship can significantly enhance your product development process and contribute to market success.

To begin exploring Canadian flex PCB manufacturing options, request quotes from several qualified suppliers, review their capabilities against your specific requirements, and consider starting with a prototype project to evaluate their performance firsthand.

Frequently Asked Questions

Q: What is the typical turnaround time for flex PCB prototypes in Canada?

A: Most Canadian manufacturers can deliver simple flex PCB prototypes in 3-7 business days, with more complex designs requiring 7-15 business days.

Q: Are Canadian-manufactured flex PCBs more expensive than Asian alternatives?

A: While unit costs may be higher, the total cost of ownership often favors Canadian manufacturing when considering quality, lead time, shipping, and support factors.

Q: What minimum feature sizes can Canadian flex PCB manufacturers achieve?

A: Leading Canadian manufacturers can typically achieve trace/space widths down to 3mil/3mil (0.076mm) and via holes as small as 0.2mm.

Q: Can Canadian manufacturers handle both prototyping and volume production?

A: Yes, most established Canadian flex PCB manufacturers offer seamless scaling from prototype to production volumes, with optimal economics in the low-to-medium volume range.

Q: What design file formats do Canadian flex PCB manufacturers accept?

A: Most accept standard industry formats including Gerber files, ODB++, and native CAD files from common design platforms like Altium, Eagle, and OrCAD.