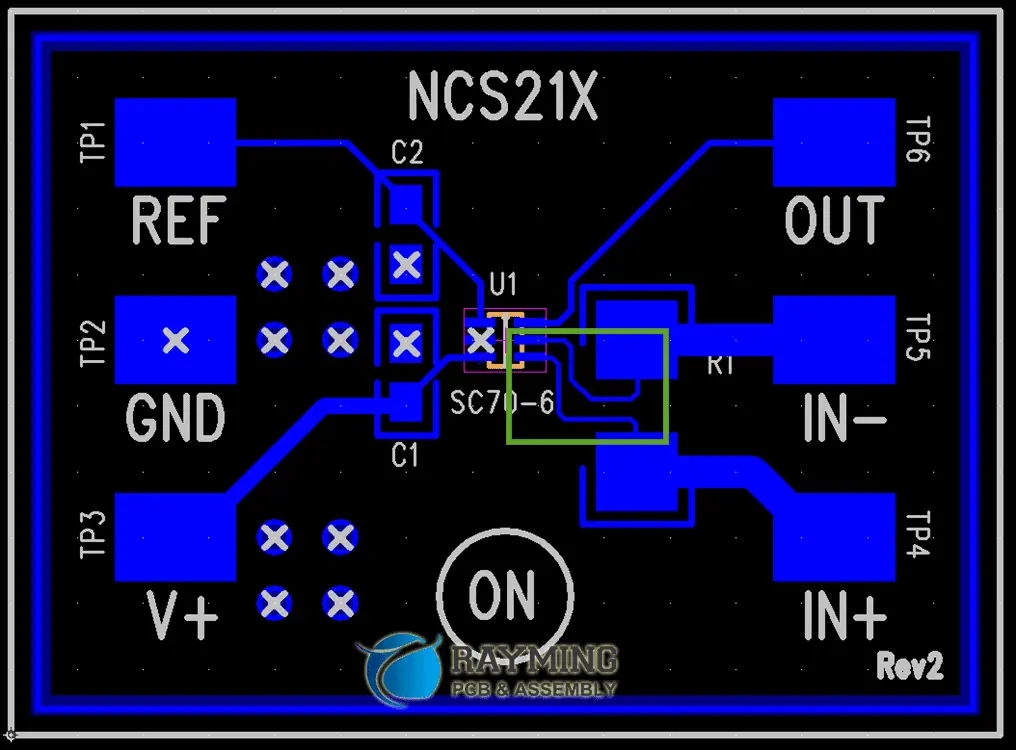

In the intricate world of Printed Circuit Board (PCB) manufacturing, the solder mask layer plays a crucial role in protecting and enhancing the functionality of electronic components. This article delves deep into the design guidelines of the solder mask layer, providing comprehensive insights for both novice and experienced PCB designers. By understanding and implementing these guidelines, you can significantly improve the quality, reliability, and longevity of your PCB designs.

Understanding the Solder Mask Layer

Before we dive into the design guidelines, it’s essential to grasp what exactly a solder mask layer is and why it’s so important in PCB manufacturing.

What is a Solder Mask Layer?

The solder mask layer is a thin, lacquer-like layer of polymer that is applied to the copper traces of a printed circuit board, excluding areas where components will be soldered. It’s typically green in color, although other colors are available for aesthetic or functional purposes.

The Importance of Solder Mask in PCB Design

The solder mask layer serves several critical functions:

- Protection: It shields the copper traces from oxidation and other environmental factors.

- Insulation: It prevents short circuits between closely spaced conductive areas.

- Solder control: It helps control the flow of solder during the assembly process.

- Visual aid: It improves the visibility of the circuit layout for inspection and repair.

Key Design Guidelines for Solder Mask Layer

Now that we understand the basics, let’s explore the essential design guidelines for the solder mask layer in PCB manufacturing.

1. Solder Mask Clearance

One of the most critical aspects of solder mask design is ensuring proper clearance around pads and vias.

Pad Clearance

- For through-hole components, maintain a clearance of 50-75 μm (2-3 mils) between the pad edge and the solder mask.

- For surface mount devices (SMDs), the clearance should be 25-50 μm (1-2 mils).

Via Clearance

- For vias that will be tented (covered by solder mask), ensure the solder mask opening is 50-75 μm (2-3 mils) larger than the via pad.

- For exposed vias, maintain a clearance of 75-100 μm (3-4 mils) around the via pad.

2. Solder Mask Dam

A solder mask dam is the area of solder mask between two adjacent pads or between a pad and a via. Proper dam width is crucial for preventing solder bridges.

Minimum Dam Width

- For fine-pitch components (0.5 mm pitch or less), maintain a minimum dam width of 75 μm (3 mils).

- For standard components, aim for a dam width of 100-150 μm (4-6 mils).

Read more about:

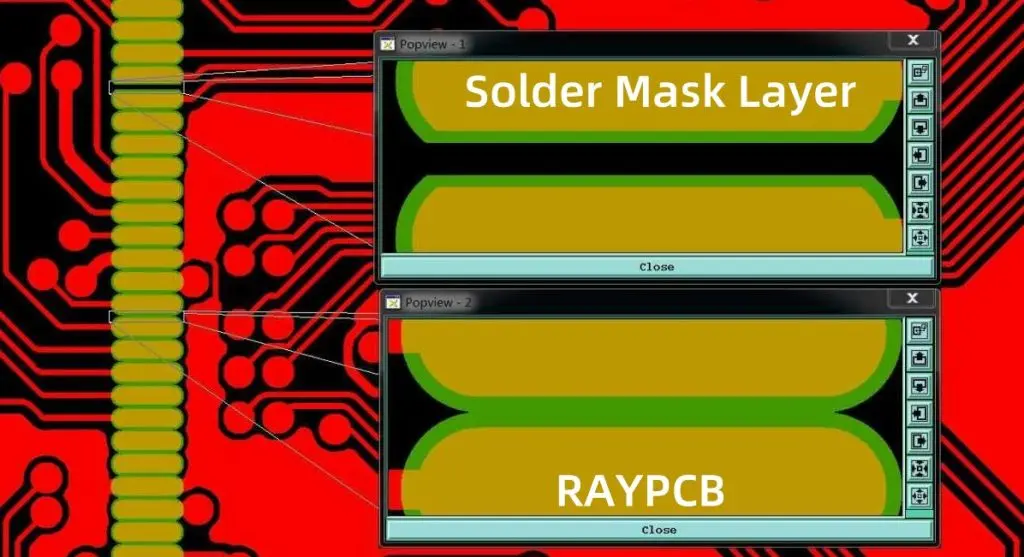

3. Solder Mask Defined (SMD) vs. Non-Solder Mask Defined (NSMD) Pads

The choice between SMD and NSMD pads can significantly impact the reliability of your PCB.

SMD Pads

- The solder mask opening is smaller than the copper pad.

- Provides better adhesion between the pad and the board.

- Suitable for fine-pitch components and areas with high mechanical stress.

NSMD Pads

- The solder mask opening is larger than the copper pad.

- Allows for better solder joint formation and inspection.

- Preferred for most applications due to improved reliability.

4. Solder Mask on Vias

Proper handling of vias in solder mask design is crucial for preventing solder wicking and ensuring reliable connections.

Tented Vias

- Cover small vias (0.3 mm or less) with solder mask to prevent solder from flowing through during assembly.

- Ensure the solder mask opening is slightly larger than the via to account for registration tolerances.

Exposed Vias

- For vias that need to be exposed, maintain a clearance of 75-100 μm (3-4 mils) around the via pad.

- Consider using via plugging for critical applications to prevent solder wicking.

5. Solder Mask Color Selection

While green is the most common color for solder mask, other colors can be used for specific purposes.

Considerations for Color Selection

- Green: Standard color, provides good contrast for visual inspection.

- Red or Blue: Often used for prototype boards or to distinguish different PCB versions.

- White: Provides excellent contrast but may yellow over time.

- Black: Offers a sleek appearance but can make visual inspection challenging.

6. Solder Mask Thickness

The thickness of the solder mask layer can impact both the protection it provides and the manufacturing process.

Recommended Thickness

- Aim for a solder mask thickness between 0.5 and 1.5 mils (12.7-38.1 μm).

- Thicker solder mask provides better protection but may cause issues with fine-pitch components.

- Thinner solder mask may not provide adequate protection against environmental factors.

Advanced Considerations for Solder Mask Design

As PCB designs become more complex, additional considerations come into play for solder mask design.

1. High-Frequency Applications

In high-frequency PCB designs, the solder mask layer can impact signal integrity.

Design Tips for High-Frequency PCBs

- Consider selective removal of solder mask in critical areas to reduce parasitic capacitance.

- Use solder mask materials with low dielectric constants for improved performance.

- Maintain consistent solder mask coverage to ensure uniform impedance across the board.

2. Flex and Rigid-Flex PCBs

Flexible and rigid-flex PCBs present unique challenges for solder mask design.

Solder Mask Considerations for Flex PCBs

- Use flexible solder mask materials that can withstand bending without cracking.

- Avoid solder mask in areas of maximum flex to prevent cracking and peeling.

- Consider selective solder mask application to balance protection and flexibility.

3. High-Temperature Applications

For PCBs that will operate in high-temperature environments, special considerations are necessary for the solder mask layer.

High-Temperature Solder Mask Design

- Use high-temperature solder mask materials rated for the expected operating temperature.

- Ensure proper curing of the solder mask to prevent degradation under heat stress.

- Consider thicker solder mask application for improved thermal protection.

4. Fine-Pitch and BGA Components

As component sizes shrink and pin counts increase, solder mask design becomes increasingly critical.

Solder Mask Design for Fine-Pitch Components

- Use NSMD pads for improved solder joint reliability.

- Maintain strict control over solder mask registration to prevent bridging.

- Consider laser-defined solder mask openings for the highest precision.

5. Solder Mask Registration

Proper registration of the solder mask layer is crucial for ensuring accurate coverage and preventing manufacturing defects.

Tips for Improving Solder Mask Registration

- Use fiducial marks to aid in aligning the solder mask layer.

- Consider adding local fiducials near critical components for improved accuracy.

- Maintain consistent clearances and dam widths to account for registration tolerances.

Common Pitfalls in Solder Mask Design

Even experienced PCB designers can fall into common traps when designing the solder mask layer. Being aware of these pitfalls can help you avoid costly mistakes.

1. Insufficient Clearance

Not providing enough clearance around pads and vias can lead to solder bridges and other assembly issues.

2. Inconsistent Dam Widths

Varying dam widths across the board can lead to inconsistent solder paste application and potential bridging.

3. Ignoring Thermal Considerations

Failing to account for thermal expansion in high-temperature applications can result in solder mask cracking or peeling.

4. Overlooking Manufacturing Tolerances

Designing to the edge of manufacturing capabilities without considering tolerances can lead to yield issues.

5. Neglecting Via Protection

Failing to properly tent or plug vias can result in solder wicking and unreliable connections.

Conclusion: Mastering Solder Mask Layer Design

Designing an effective solder mask layer is a critical aspect of PCB manufacturing that requires careful consideration and attention to detail. By following these design guidelines and being aware of common pitfalls, you can significantly improve the quality, reliability, and manufacturability of your PCB designs.

Remember that while these guidelines provide a solid foundation, each PCB design is unique and may require specific adjustments. Always consult with your PCB manufacturer to ensure your design aligns with their capabilities and processes.

By mastering the art and science of solder mask layer design, you’ll be well-equipped to create high-quality PCBs that meet the demanding requirements of modern electronic devices. Whether you’re working on simple two-layer boards or complex multi-layer designs, a well-designed solder mask layer is key to achieving optimal performance and longevity in your PCB projects.