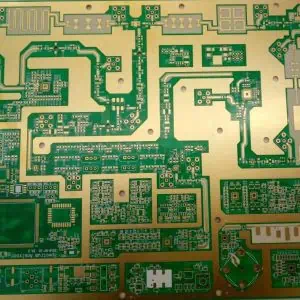

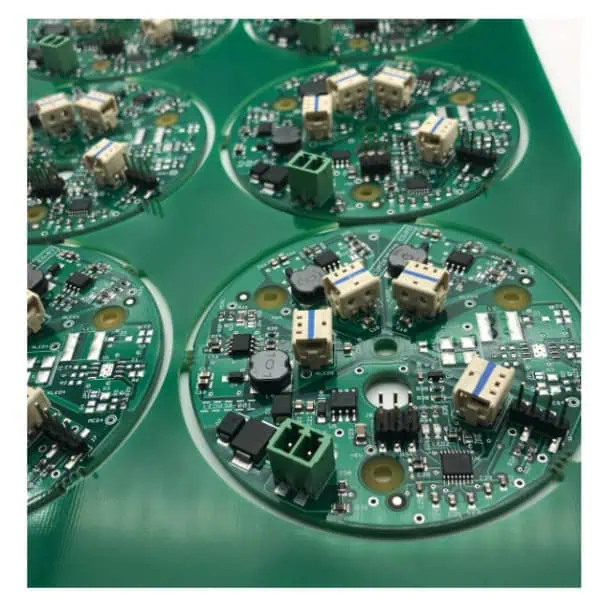

Get your PCBs manufactured in as little as 24 hours without compromising quality. RayMing delivers rapid PCB prototyping and small-volume production services with over 20 years of manufacturing excellence, helping engineers accelerate their time-to-market while maintaining the highest quality standards.

Whether you need emergency prototypes, pre-production testing, or full-scale manufacturing with tight deadlines, our quick turn PCB services provide the speed and reliability your projects demand. Experience the perfect balance of rapid turnaround, superior quality, and competitive pricing that has made RayMing a trusted partner for thousands of engineers worldwide.

What is Quick Turn PCB Manufacturing?

Quick turn PCB manufacturing is a specialized fabrication process that delivers printed circuit boards in dramatically reduced timeframes—typically 24 to 72 hours—compared to standard manufacturing cycles that can take weeks. This accelerated approach revolutionizes product development by enabling rapid prototyping, faster design iterations, and emergency production runs without sacrificing quality or reliability.

Quick Turn vs Standard PCB Fabrication

Standard PCB Manufacturing:

- Lead times: 2-4 weeks

- Optimized for large volume production

- Lower per-unit costs for high quantities

- Less flexibility for design changes

Quick Turn PCB Services:

- Lead times: 24-72 hours

- Optimized for prototypes and urgent orders

- Premium pricing for expedited service

- High flexibility for rapid iterations

- Same quality standards as standard production

The key difference lies in manufacturing prioritization and streamlined processes. Quick turn PCB manufacturers like RayMing maintain dedicated production lines, pre-stocked materials, and optimized workflows specifically designed for rapid fabrication without compromising on quality control measures.

Industries That Benefit from Fast PCB Services

Consumer Electronics: Smartphone manufacturers, wearable device companies, and IoT developers rely on quick turn PCB services for rapid prototyping and market testing of new products.

Medical Devices: Medical equipment manufacturers require fast PCB prototyping for life-critical devices where rapid development cycles can bring life-saving technologies to market sooner.

Automotive & Aerospace: These industries use quick turn services for testing advanced driver assistance systems (ADAS), electric vehicle components, and avionics prototypes.

Telecommunications: 5G infrastructure development, network equipment prototyping, and communication device testing demand rapid PCB fabrication capabilities.

Quick Turn PCB Capabilities & Specifications

Turnaround Time Options

24-Hour Express Service:

- Simple 1-2 layer boards

- Standard FR-4 materials

- HASL or ENIG surface finish

- Prototype quantities (1-50 pieces)

48-Hour Fast Track:

- Up to 6-layer boards

- Multiple material options

- Various surface finishes

- Small production runs (1-200 pieces)

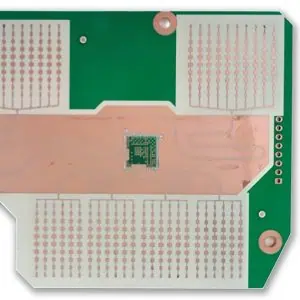

72-Hour Standard Quick Turn:

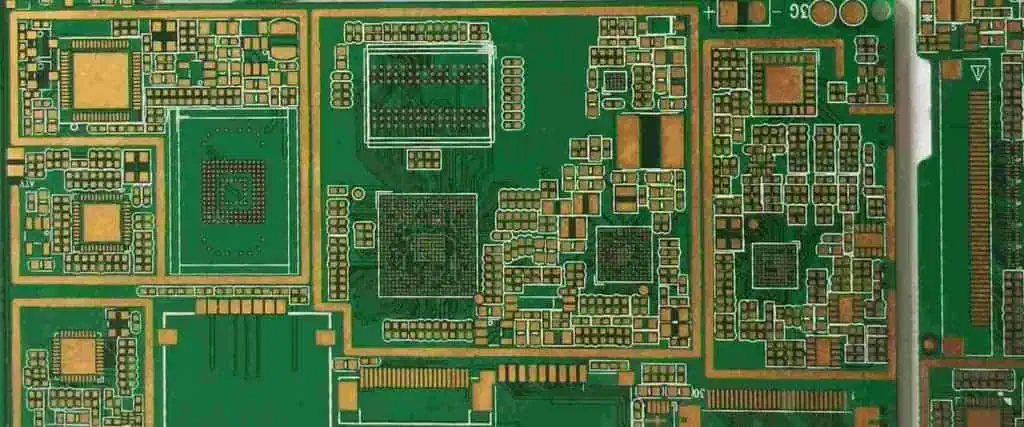

- Complex multilayer boards (up to 16 layers)

- Specialized materials (Rogers, Polyimide)

- Advanced surface finishes

- Medium production volumes (1-500 pieces)

Layer Count & Complexity Handling

| Layer Count | Quick Turn Capability | Typical Applications |

| 1-2 Layers | 24-48 hours | Simple prototypes, LED boards |

| 4-6 Layers | 48-72 hours | Consumer electronics, IoT devices |

| 8-12 Layers | 72 hours – 5 days | Telecommunications, computing |

| 14-16 Layers | 5-7 days | High-speed digital, servers |

Material Options for Rapid Fabrication

Standard Materials (24-48 hour capability):

- FR-4 Standard and High-Tg

- CEM-1 and CEM-3

- Aluminum-backed boards

- Standard prepreg options

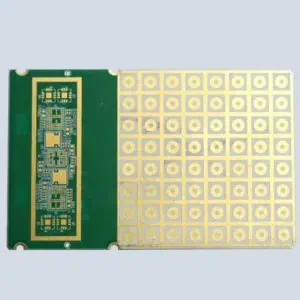

Specialized Materials (48-72 hour capability):

- Rogers RT/duroid series

- Polyimide flexible materials

- PTFE-based substrates

- High-frequency materials

Technical Specifications:

- Minimum trace width: 0.1mm (4 mil)

- Minimum via size: 0.2mm (8 mil)

- Layer count: 1-16 layers

- Board thickness: 0.4mm – 3.2mm

- Maximum board size: 610mm x 1220mm

Quick Turn PCB Manufacturing Process

Design File Submission & DFM Review

The quick turn PCB process begins when you submit your design files through our secure online portal. Our engineering team performs a comprehensive Design for Manufacturability (DFM) review within 2 hours of file submission, ensuring your design meets all technical requirements for rapid fabrication.

Required Files:

- Gerber files (RS-274X format)

- Excellon drill files

- Pick and place files (for assembly)

- Bill of Materials (BOM)

- Assembly drawings and specifications

Our automated DFM software instantly checks for potential manufacturing issues while our experienced engineers verify design intent, material compatibility, and manufacturability constraints. Any concerns are immediately communicated to prevent delays in the production process.

Rapid Prototyping Stage

Quick turn PCB prototyping serves as the critical first step in validating your design before committing to larger production runs. During this stage, we manufacture small quantities (typically 5-50 pieces) that exactly represent your final product specifications.

Prototype Validation Benefits:

- Early detection of design flaws

- Functional testing capabilities

- Component fit verification

- Signal integrity validation

- Thermal performance assessment

Our prototype PCBs undergo the same rigorous quality control procedures as production boards, including automated optical inspection (AOI), electrical testing, and dimensional verification. This ensures that prototype results accurately predict production performance.

Pre-Production Testing & Validation

The pre-production phase involves manufacturing larger quantities (100-1000 pieces) to validate manufacturing processes and identify any potential issues before full-scale production. This critical stage helps optimize manufacturing parameters and ensures consistent quality across production volumes.

Key Pre-Production Activities:

- Manufacturing process optimization

- Yield analysis and improvement

- Quality system validation

- Supply chain verification

- Cost optimization strategies

During pre-production, we conduct comprehensive electrical testing, including flying probe testing for prototype quantities and bed-of-nails testing for larger volumes. This thorough testing approach ensures that every board meets your specifications before moving to full production.

Full Production & Quality Control

Full production quick turn PCB manufacturing maintains the same accelerated timeline while scaling to meet your volume requirements. Our production facilities operate 24/7 to ensure rapid delivery of high-volume orders without compromising quality standards.

Production Quality Controls:

- 100% AOI inspection

- Statistical process control monitoring

- IPC-A-600 compliance verification

- Final electrical testing

- Packaging and shipping verification

Advanced Technologies for Quick Turn Assembly

Surface Mount Technology (SMT) for Fast Assembly

Our state-of-the-art SMT lines feature high-speed pick-and-place machines capable of placing over 50,000 components per hour with placement accuracy of ±25 microns. This advanced equipment enables rapid assembly of complex PCBs while maintaining exceptional quality standards.

SMT Capabilities:

- Component sizes: 01005 to large BGAs

- Fine-pitch components: 0.3mm pitch and smaller

- High-speed placement: Up to 50,000 CPH

- Placement accuracy: ±25 microns

- Component types: Resistors, capacitors, ICs, connectors

Our quick turn SMT assembly process includes automated solder paste printing, component placement, reflow soldering, and comprehensive quality inspection—all optimized for rapid turnaround without sacrificing reliability.

Through-Hole Assembly Capabilities

For components requiring through-hole assembly, our selective soldering systems and wave soldering equipment provide precise, reliable connections for quick turn projects. Our skilled technicians also perform hand soldering for prototype quantities and specialized components.

Through-Hole Services:

- Automated selective soldering

- Wave soldering for high volumes

- Hand soldering for prototypes

- Mixed technology assembly

- Component lead forming and preparation

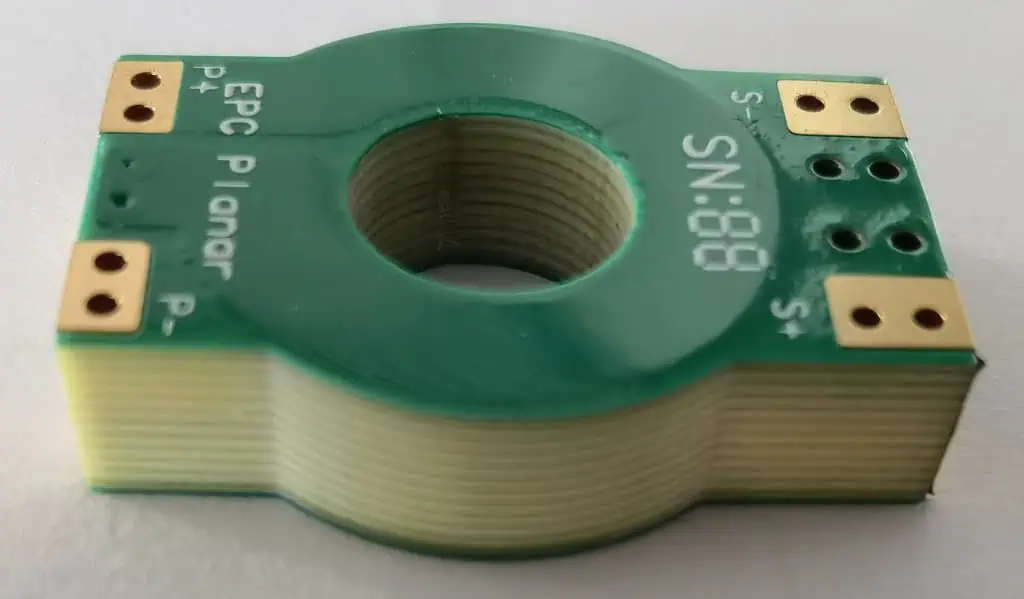

Mixed Technology PCB Assembly

Many modern PCBs require both surface mount and through-hole components. Our mixed technology assembly capabilities seamlessly integrate both mounting methods in a single, streamlined process optimized for quick turn production.

Mixed Assembly Advantages:

- Single-pass manufacturing process

- Reduced handling and potential damage

- Optimized thermal profiles

- Comprehensive testing procedures

- Faster overall assembly times

Quality Assurance in Quick Turn Manufacturing

IPC Standards Compliance

All quick turn PCB manufacturing at RayMing strictly adheres to IPC standards, ensuring that accelerated production timelines never compromise quality or reliability. Our quality management system maintains compliance with IPC-A-600 (acceptability standards) and IPC-6012 (qualification standards).

Key IPC Standards:

- IPC-A-600: PCB acceptability standards

- IPC-6012: Qualification and performance specifications

- IPC-2221: Generic standard for PCB design

- IPC-A-610: Electronic assemblies acceptability

- J-STD-001: Soldering requirements

Our quality engineers continuously monitor compliance through statistical process control, ensuring that every quick turn PCB meets or exceeds industry standards regardless of production timeline.

AOI and Electrical Testing Procedures

Automated Optical Inspection (AOI) systems provide 100% inspection coverage for all quick turn PCBs, detecting manufacturing defects that could affect performance or reliability. Our advanced AOI systems use high-resolution cameras and sophisticated algorithms to identify issues invisible to manual inspection.

Testing Procedures:

- Pre-etch AOI for substrate quality

- Post-etch AOI for trace integrity

- Solder mask inspection

- Silkscreen verification

- Final dimensional inspection

Electrical Testing:

- Flying probe testing for prototypes

- Bed-of-nails testing for production

- In-circuit testing (ICT) when required

- Boundary scan testing capabilities

- Functional testing for assemblies

Materials Certification & Traceability

Every quick turn PCB project includes complete materials certification and traceability documentation. We maintain detailed records of all materials used, including substrate certifications, solder certifications, and component traceability for aerospace and medical applications.

Certification Documentation:

- Material test certificates (MTCs)

- RoHS compliance certificates

- UL recognition documentation

- IPC test coupons and reports

- Statistical process control data

Quick Turn PCB Pricing & Cost Factors

Factors Affecting Quick Turn Costs

Quick turn PCB pricing reflects the premium value of accelerated manufacturing while remaining competitive within the rapid fabrication market. Several key factors influence pricing for expedited orders:

Primary Cost Factors:

- Turnaround time requirements (24hr premium vs 72hr)

- Board complexity and layer count

- Panel utilization efficiency

- Material requirements and availability

- Surface finish specifications

- Testing and inspection requirements

Volume-Based Pricing:

- Prototype quantities (1-50): Premium pricing

- Small production (51-250): Moderate premium

- Medium volumes (251-1000): Reduced premium

- Higher volumes: Near-standard pricing

Cost Comparison: Quick Turn vs Standard

| Service Type | Lead Time | Cost Multiplier | Best For |

| 24-Hour Express | 1 day | 3.0-4.0x | Emergency prototypes |

| 48-Hour Fast | 2 days | 2.0-2.5x | Urgent testing needs |

| 72-Hour Quick | 3 days | 1.5-2.0x | Accelerated development |

| Standard Production | 2-3 weeks | 1.0x | High-volume production |

Volume Pricing for Rapid Orders

Our transparent pricing structure ensures competitive costs even for expedited orders. Volume discounts apply to quick turn services, making rapid fabrication economical even for larger prototype runs.

Price Match Guarantee: If you find a lower price for equivalent quick turn PCB services, we’ll match or beat that price while maintaining our superior quality standards and reliable delivery performance.

Industries & Applications for Quick Turn PCBs

Consumer Electronics Prototyping

The consumer electronics industry drives significant demand for quick turn PCB services, particularly for smartphone accessories, wearable devices, and smart home products. Rapid prototyping enables faster product development cycles and quicker market entry.

Typical Applications:

- Smartphone and tablet prototypes

- Wearable device PCBs

- IoT sensor boards

- Consumer audio equipment

- Gaming peripherals and accessories

Medical Device Development

Medical device manufacturers rely on quick turn PCB services for life-critical applications where rapid development can accelerate the delivery of life-saving technologies to market. Our medical-grade quality standards ensure reliability for healthcare applications.

Medical Applications:

- Patient monitoring equipment

- Diagnostic instrument PCBs

- Implantable device prototypes

- Surgical equipment controllers

- Telemedicine device boards

Medical Certifications:

- ISO 13485 quality management

- FDA-compliant documentation

- Biocompatibility testing support

- IPC-6012 Class 3 manufacturing

Automotive & Aerospace Applications

Automotive and aerospace industries utilize quick turn PCB services for advanced driver assistance systems (ADAS), electric vehicle components, and avionics prototypes. These applications demand the highest reliability standards and comprehensive testing.

Automotive Applications:

- ADAS sensor boards

- Electric vehicle charging systems

- Infotainment system prototypes

- Engine control modules

- Battery management systems

Aerospace Applications:

- Avionics prototypes

- Satellite communication boards

- Navigation system PCBs

- Flight control electronics

- Ground support equipment

IoT and Communications Equipment

The explosive growth of IoT devices and 5G infrastructure creates substantial demand for quick turn PCB manufacturing. These applications often require rapid prototyping to test new communication protocols and device functionality.

Communication Applications:

- 5G infrastructure equipment

- Wireless sensor networks

- Bluetooth and WiFi modules

- Cellular communication boards

- Network switching equipment

Choosing a Quick Turn PCB Manufacturer

Key Capabilities to Evaluate

When selecting a quick turn PCB manufacturer, several critical capabilities determine whether a supplier can meet your rapid development needs while maintaining quality standards.

Essential Capabilities:

- Proven track record of on-time delivery

- Advanced manufacturing equipment and automation

- Comprehensive quality control systems

- Technical support and design assistance

- Flexible capacity for varying order sizes

- Global shipping and logistics capabilities

Technical Considerations:

- Maximum layer count capabilities

- Minimum feature sizes and tolerances

- Material options and availability

- Surface finish capabilities

- Testing and inspection equipment

Certifications & Quality Standards

Industry certifications provide confidence that your quick turn PCB manufacturer maintains consistent quality standards and can meet the requirements of regulated industries.

Critical Certifications:

- ISO 9001:2015 quality management

- IPC-A-600 and IPC-6012 compliance

- UL recognition for safety standards

- RoHS and REACH compliance

- ITAR registration for defense applications

Industry-Specific Standards:

- AS9100 for aerospace applications

- ISO 13485 for medical devices

- TS 16949 for automotive applications

- IPC-6013 for flexible circuits

Customer Support & Communication

Effective communication becomes even more critical in quick turn manufacturing where timelines are compressed and there’s little margin for error. Choose manufacturers that provide dedicated support throughout the entire process.

Support Features:

- 24/7 customer service availability

- Dedicated project management

- Real-time order status updates

- Technical design support

- Rapid quote turnaround

- Proactive issue communication

RayMing’s Quick Turn PCB Services

24-Hour Express PCB Fabrication

RayMing’s 24-hour express service represents the pinnacle of rapid PCB manufacturing, delivering prototype and small production quantities in just one day after design approval. This industry-leading capability enables emergency prototyping and critical project rescue scenarios.

Express Service Features:

- Guaranteed 24-hour delivery for qualified designs

- Real-time production status updates

- Priority queue positioning

- Expedited shipping options

- Emergency customer support hotline

Design Qualifications for 24-Hour Service:

- 1-4 layer boards

- Standard FR-4 materials

- HASL or ENIG surface finish

- Standard via sizes (≥0.2mm)

- Minimum trace width ≥0.1mm

Advanced Manufacturing Equipment

Our state-of-the-art manufacturing facility features the latest PCB fabrication equipment specifically configured for rapid production without compromising quality. Advanced automation and process optimization enable consistent delivery of quick turn orders.

Key Equipment:

- Laser Direct Imaging (LDI) systems for precise patterning

- High-speed drilling equipment with micro-via capabilities

- Advanced plating lines with precise thickness control

- Automated optical inspection (AOI) systems

- Flying probe and bed-of-nails testing equipment

Quality Control Technology:

- Statistical process control monitoring

- Real-time defect detection systems

- Automated thickness measurement

- Impedance testing and verification

- Environmental stress testing capabilities

Customer Success Stories & Testimonials

Automotive Tier 1 Supplier: “RayMing’s 48-hour quick turn service saved our ADAS project timeline when we discovered a critical design issue just days before the customer delivery deadline. Their engineering team worked with us through the weekend to optimize the design and deliver perfect boards on Monday morning.”

Medical Device Startup: “The 24-hour PCB service was crucial for our FDA submission timeline. RayMing delivered prototype boards that passed all our testing requirements, enabling us to meet our regulatory milestones and secure additional funding.”

IoT Technology Company: “We’ve used RayMing’s quick turn services for over 50 prototype iterations. Their consistent quality and reliable delivery have accelerated our product development by at least 6 months compared to traditional PCB suppliers.”

Telecommunications Equipment Manufacturer: “RayMing’s quick turn assembly services enabled us to rapidly test multiple antenna configurations for our 5G equipment. Their technical expertise and rapid turnaround were instrumental in optimizing our design performance.”

Frequently Asked Questions (FAQ)

Q: What’s the fastest turnaround time available for PCB fabrication? A: RayMing offers 24-hour express fabrication for qualified designs, including simple 1-4 layer boards with standard materials and finishes. More complex designs typically require 48-72 hours.

Q: Do quick turn PCBs maintain the same quality as standard production boards? A: Yes, all quick turn PCBs undergo the same rigorous quality control procedures as standard production, including AOI inspection, electrical testing, and IPC compliance verification.

Q: What file formats do you accept for quick turn orders? A: We accept standard Gerber files (RS-274X), Excellon drill files, and native CAD files from major design software packages. Our engineering team can also work with PDF drawings for simple designs.

Q: Can you source components for quick turn assembly projects? A: Yes, we maintain inventory of common components and have established relationships with distributors for rapid component procurement. For optimal speed, customer-supplied components are recommended.

Q: What payment terms are available for quick turn orders? A: We accept major credit cards for immediate processing, wire transfers, and offer net payment terms for qualified customers. Express orders typically require advance payment or credit card authorization.

Q: Do you provide design support for quick turn projects? A: Our engineering team offers comprehensive design support including DFM analysis, impedance calculations, stack-up recommendations, and design optimization for rapid manufacturing.

Get Your Quick Turn PCB Quote Today

Ready to accelerate your product development with industry-leading quick turn PCB manufacturing? Contact RayMing today for an instant quote and experience the perfect combination of speed, quality, and competitive pricing.

Start Your Quick Turn Project:

- Email: sales@raypcb.com

- Phone: Contact our express hotline for urgent projects

- Online Quote: Upload your files for instant pricing

- 24/7 Support: Emergency project assistance available

Transform your development timeline with RayMing’s proven quick turn PCB capabilities. Join thousands of satisfied customers who trust us for their most critical rapid manufacturing needs.