In today’s fast-paced electronics industry, the demand for Printed Circuit Boards (PCBs) continues to grow exponentially. As the backbone of electronic devices, PCBs play a crucial role in everything from smartphones to industrial machinery. Amidst this increasing demand, China has emerged as the undisputed leader in PCB manufacturing, offering high-quality products at surprisingly low costs. But what exactly makes China PCB circuit boards so affordable compared to those produced in other countries? This article delves into the factors behind China’s competitive edge in the PCB industry.

1. The Scale of China’s PCB Manufacturing Industry

1.1 China as the World’s PCB Manufacturing Hub

China’s dominance in the PCB manufacturing industry is undeniable. According to recent statistics, China accounts for over 50% of the global PCB production, with an annual output value exceeding $30 billion. This massive scale of production is largely concentrated in manufacturing hubs like Shenzhen, Guangzhou, and Dongguan in the Pearl River Delta region.

The clustering effect in these areas has created a robust ecosystem of suppliers, manufacturers, and supporting industries, all working in close proximity. This geographical concentration facilitates rapid communication, efficient logistics, and knowledge sharing, contributing significantly to cost reduction.

1.2 Economies of Scale

One of the primary reasons for China’s low-cost PCB production is the economies of scale achieved through mass production. When manufacturers produce PCBs in large quantities, the fixed costs associated with production (such as equipment, facilities, and setup) are spread across a greater number of units, effectively lowering the cost per unit.

Moreover, bulk purchasing of raw materials allows Chinese manufacturers to negotiate better prices with suppliers. This cost advantage is then passed down the supply chain, ultimately resulting in lower prices for customers.

2. Access to Raw Materials at Lower Costs

2.1 Local Availability of Core Materials

China’s vast manufacturing sector has fostered the growth of a comprehensive supply chain for PCB production. Core materials such as FR4 (the most common base material for PCBs), copper foils, and various laminates are readily available locally. This local availability eliminates the need for costly imports and reduces transportation expenses.

2.2 Vertical Integration of Supply Chains

Many Chinese PCB manufacturers have adopted a vertically integrated business model. This means they not only produce PCBs but also manufacture or source key components and materials within their own network. Such integration allows for better control over costs and quality, leading to more competitive pricing.

2.3 Lower Material Transportation Costs Within China

The strategic location of PCB factories near raw material suppliers significantly reduces transportation costs. The well-developed transportation infrastructure within China’s manufacturing hubs further enhances this advantage, allowing for quick and cost-effective movement of materials and finished products.

Read more about:

3. Advanced Manufacturing Technology and Automation

3.1 Investment in Modern PCB Manufacturing Equipment

Chinese PCB manufacturers have made substantial investments in state-of-the-art manufacturing equipment. Advanced technologies such as CNC drilling machines, laser cutting systems, and Automated Optical Inspection (AOI) systems have become standard in many Chinese factories. These technologies not only improve precision and quality but also increase production efficiency, thereby reducing costs.

3.2 High Throughput Production Lines

The implementation of high-throughput production lines in Chinese PCB factories has dramatically increased production speed and efficiency. Automated systems handle various aspects of PCB production, from material handling to testing, minimizing human error and reducing labor costs.

3.3 PCB Manufacturing Machine Costs in China

Interestingly, the cost of PCB manufacturing equipment in China is often lower than in other countries. This is partly due to local production of such machinery and partly due to government incentives for upgrading manufacturing technology. Lower equipment costs translate to lower overhead for manufacturers, contributing to the overall low cost of PCBs.

4. Government Policies and Industrial Support

4.1 Incentives and Subsidies for Electronics Manufacturing

The Chinese government has long recognized the importance of the electronics manufacturing sector and has implemented various policies to support its growth. These include tax incentives, subsidies for research and development, and financial support for companies investing in advanced technologies.

4.2 Infrastructure Development

Significant investments in infrastructure, including modern ports, efficient road networks, and reliable power supply, have greatly benefited the PCB industry. This well-developed infrastructure reduces logistical costs and improves overall operational efficiency.

4.3 Export-Friendly Trade Policies

China’s export-oriented policies have created a favorable environment for PCB manufacturers to sell their products globally. Various trade agreements and export incentives have made it easier and more cost-effective for Chinese companies to reach international markets.

5. Lower Labor Costs Compared to Other Countries

5.1 Skilled but Cost-Effective Workforce

While labor costs in China have been rising in recent years, they remain significantly lower than in many developed countries. The PCB industry in China benefits from a large pool of skilled workers who are proficient in various aspects of PCB manufacturing, yet command wages that are competitive on a global scale.

5.2 Specialized Training Programs

Many regions in China have implemented specialized training programs focused on PCB assembly and testing. These programs ensure a steady supply of skilled workers, reducing training costs for manufacturers and maintaining a high level of expertise in the workforce.

5.3 Labor Cost Comparison

When compared to countries like the USA, Japan, or those in Europe, China’s labor costs in the PCB industry can be 50-70% lower. This significant difference in labor expenses plays a crucial role in keeping overall production costs down.

6. Highly Competitive Domestic Market

6.1 Intense Competition Among PCB Manufacturers

The PCB industry in China is characterized by intense competition among numerous manufacturers. This competitive environment leads to continuous price wars, forcing companies to optimize their processes and reduce costs to remain viable. While challenging for the manufacturers, this competition ultimately benefits customers through lower prices.

6.2 Impact of Competition on Innovation and Efficiency

The fierce competition in China’s PCB market has spurred innovation and efficiency improvements. Manufacturers constantly seek ways to streamline their processes, reduce turnaround times, and offer value-added services like rapid prototyping. This drive for efficiency further contributes to cost reduction and improved service quality.

7. Specialization in Different PCB Types

7.1 Standard PCB vs. Custom PCB Manufacturing

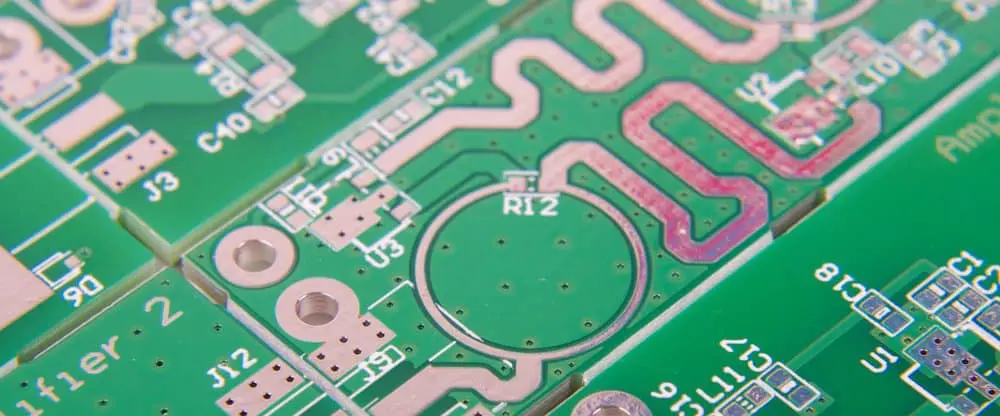

Chinese manufacturers have become highly efficient in producing standard PCBs, such as 2-layer and 4-layer boards. The streamlined processes for these common configurations allow for faster production and lower costs. However, many Chinese manufacturers also excel in custom PCB production, offering competitive prices for specialized designs.

7.2 Diverse PCB Offerings at Low Prices

The specialization extends to various PCB types, including flexible PCBs, LED PCBs, and amplifier PCBs. By focusing on specific niches, manufacturers can optimize their processes and offer these specialized products at surprisingly low prices. This specialization allows for economies of scale even in more complex PCB types.

8. Efficient Logistics and Global Shipping

8.1 Strategic Location of PCB Factories

Many PCB factories in China are strategically located near major ports and transportation hubs. This proximity reduces domestic transportation costs and facilitates quick and easy shipping to international markets.

8.2 Partnered Logistics Companies

Chinese PCB manufacturers often have partnerships with logistics companies that offer competitive shipping rates. These partnerships, combined with the high volume of shipments, allow for significant cost savings in international shipping.

8.3 Role of Online PCB Services

Companies like PCBWay and JLCPCB have revolutionized the global distribution of PCBs from China. These online platforms offer user-friendly interfaces for ordering custom PCBs, provide instant quotes, and manage the complexities of international shipping, making it easier than ever for global customers to access low-cost Chinese PCBs.

9. Common Misconceptions About Cheap China PCBs

9.1 Is Lower Price Equal to Lower Quality?

A common misconception is that low-cost PCBs from China are of inferior quality. While it’s true that some low-end manufacturers may cut corners, many Chinese PCB manufacturers produce high-quality boards that meet or exceed international standards. The key is to choose reputable suppliers with proper certifications and quality control processes.

9.2 Risks to Watch Out For

While the Chinese PCB market offers excellent opportunities for cost savings, buyers should be aware of potential risks. These include the possibility of counterfeit components in some supply chains and inconsistent quality from less reputable manufacturers. Due diligence in supplier selection is crucial to mitigate these risks.

10. How to Leverage China’s PCB Market Effectively

10.1 Tips for Choosing a Good Manufacturer

When selecting a Chinese PCB manufacturer, consider the following:

- Look for relevant certifications (ISO 9001, UL, RoHS, etc.)

- Check customer reviews and testimonials

- Verify their testing standards and quality control processes

- Request samples before placing large orders

- Assess their communication responsiveness and English proficiency

10.2 Balancing Cost, Quality, and Lead Time

While low cost is attractive, it’s important to balance it with quality requirements and lead times. Sometimes, paying a slightly higher price can result in better quality, more reliable delivery, or enhanced customer service, which can save money and headaches in the long run.

Conclusion

The low cost of China PCB circuit boards is the result of a complex interplay of factors, including economies of scale, advanced manufacturing technologies, lower labor and material costs, government support, and intense market competition. These elements combine to create an environment where high-quality PCBs can be produced at remarkably low prices.

For startups and established companies alike, China remains a smart choice for PCB sourcing. The country’s PCB industry offers a compelling combination of cost-effectiveness, quality, and production capacity that is hard to match elsewhere in the world.

However, it’s crucial to approach PCB sourcing from China with due diligence. By carefully selecting manufacturers, understanding the market dynamics, and balancing cost considerations with quality requirements, businesses can fully leverage the advantages of China’s PCB industry while mitigating potential risks.

As the global electronics industry continues to evolve, China’s position as a leader in low-cost, high-quality PCB manufacturing seems secure for the foreseeable future. Whether you’re working on a small prototype or planning large-scale production, China’s PCB industry offers solutions that can significantly impact your project’s success and bottom line.