The selection of appropriate materials for high-frequency printed circuit boards (PCBs) is a critical decision that directly impacts signal integrity, performance, and reliability in modern electronic systems. As operating frequencies continue to increase in applications ranging from 5G communications to radar systems, understanding the nuances of high-frequency PCB material selection becomes increasingly important for engineers and designers.

Understanding High-Frequency Challenges

High-frequency circuits present unique challenges that don’t exist at lower frequencies. As signals approach gigahertz frequencies, traditional PCB materials like standard FR-4 begin to exhibit significant limitations. Signal attenuation increases dramatically, dielectric losses become pronounced, and impedance control becomes more critical. The skin effect causes current to flow primarily on the surface of conductors, increasing resistance and heat generation. Additionally, electromagnetic interference (EMI) and crosstalk between traces become more problematic, requiring careful material selection and design considerations.

Key Material Properties for High-Frequency Applications

Dielectric Constant (Dk)

The dielectric constant, also known as relative permittivity, fundamentally affects signal propagation speed and impedance characteristics. For high-frequency applications, materials with lower and more stable dielectric constants are generally preferred. A lower Dk results in faster signal propagation and reduced signal delay, which is crucial for maintaining timing integrity in high-speed digital circuits. More importantly, the stability of the dielectric constant across frequency, temperature, and humidity variations ensures consistent performance. Materials like PTFE-based substrates typically offer Dk values ranging from 2.1 to 2.6, compared to standard FR-4’s typical range of 4.2 to 4.8.

Dissipation Factor (Df)

The dissipation factor, or loss tangent, quantifies the material’s ability to convert electrical energy into heat. In high-frequency applications, minimizing signal loss is paramount, making low dissipation factor materials essential. While standard FR-4 might have a dissipation factor of 0.02 or higher, specialized high-frequency materials can achieve values as low as 0.001 to 0.004. This dramatic reduction in loss translates directly to improved signal integrity and reduced power consumption, particularly important in battery-powered devices or high-power RF applications.

Thermal Stability

High-frequency circuits often generate significant heat, and thermal management becomes crucial for maintaining performance and reliability. The coefficient of thermal expansion (CTE) must be carefully matched between the substrate and copper conductors to prevent stress-related failures. Additionally, the thermal conductivity of the substrate affects heat dissipation capabilities. Materials with good thermal stability maintain their electrical properties across wide temperature ranges, ensuring consistent performance in varying environmental conditions.

Moisture Absorption

Water absorption can significantly alter a material’s dielectric properties, leading to performance degradation in high-frequency applications. Hydrophobic materials like PTFE-based substrates typically exhibit very low moisture absorption rates, maintaining stable electrical characteristics even in humid environments. This property is particularly important for outdoor applications or devices operating in challenging environmental conditions.

Common High-Frequency PCB Materials

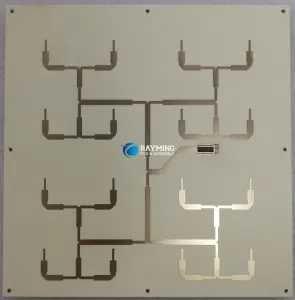

PTFE-Based Materials

Polytetrafluoroethylene (PTFE) based materials represent the gold standard for many high-frequency applications. Rogers RT/duroid series, including RT/duroid 5870 and 5880, offer excellent electrical properties with dielectric constants around 2.33 and extremely low dissipation factors. These materials provide exceptional stability across frequency and temperature ranges, making them ideal for microwave and millimeter-wave applications. However, PTFE materials can be challenging to process, requiring specialized drilling and plating techniques due to their chemical inertness.

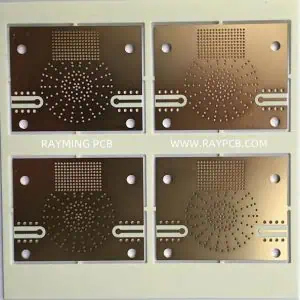

Hydrocarbon Ceramic Materials

Materials like Rogers RO4000 series combine the processability of traditional epoxy-glass systems with enhanced high-frequency performance. These materials use hydrocarbon ceramic technology to achieve lower dielectric constants and dissipation factors compared to standard FR-4, while maintaining compatibility with conventional PCB manufacturing processes. This balance makes them attractive for applications requiring good high-frequency performance without the processing complexities of pure PTFE systems.

Low-Loss Glass Weave Materials

Advanced glass weave constructions help minimize the “glass weave effect,” where the periodic structure of glass fabric can cause impedance variations and skew in differential pairs. Materials using spread glass or low dielectric constant glass weaves help maintain signal integrity in high-speed digital applications. Some manufacturers offer materials with specialized glass constructions designed specifically for high-frequency performance.

Liquid Crystal Polymer (LCP)

LCP materials offer unique advantages for certain high-frequency applications, particularly in flexible circuits. They provide low dielectric constants, excellent dimensional stability, and good processability. LCP’s inherent flexibility makes it suitable for applications requiring bendable high-frequency circuits, though its use is more specialized compared to traditional rigid substrates.

Selection Criteria and Trade-offs

Performance Requirements

The first step in material selection involves clearly defining performance requirements. Operating frequency range, acceptable insertion loss, return loss specifications, and impedance tolerance all influence material choice. Applications operating above 10 GHz typically require specialized low-loss materials, while applications in the 1-5 GHz range might be adequately served by enhanced FR-4 materials or entry-level high-frequency substrates.

Manufacturing Considerations

Processing compatibility with standard PCB manufacturing equipment significantly impacts material selection. Pure PTFE materials may require specialized drilling techniques and surface treatments for reliable plating adhesion. Materials that can be processed using conventional FR-4 manufacturing methods often provide cost advantages and shorter lead times, making them attractive for commercial applications.

Cost Analysis

High-frequency materials typically cost significantly more than standard FR-4, sometimes by factors of five to ten or more. This cost impact extends beyond just material costs to include potential manufacturing complications, yield considerations, and inventory management. Engineers must balance performance requirements against budget constraints, often leading to hybrid designs where high-frequency materials are used only in critical circuit sections.

Environmental and Reliability Factors

Operating environment significantly influences material selection. Applications exposed to extreme temperatures, humidity, or mechanical stress require materials with appropriate environmental ratings. Space and military applications may require materials meeting specific outgassing, flammability, or radiation resistance standards.

Design Guidelines and Best Practices

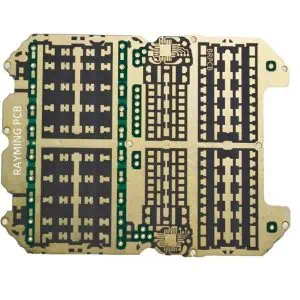

Stackup Design

Proper stackup design works hand-in-hand with material selection to achieve optimal high-frequency performance. Controlled impedance requirements often dictate minimum substrate thicknesses and copper weights. Mixed-material stackups can optimize cost by using high-performance materials only where needed, though this approach requires careful attention to interface effects and thermal expansion matching.

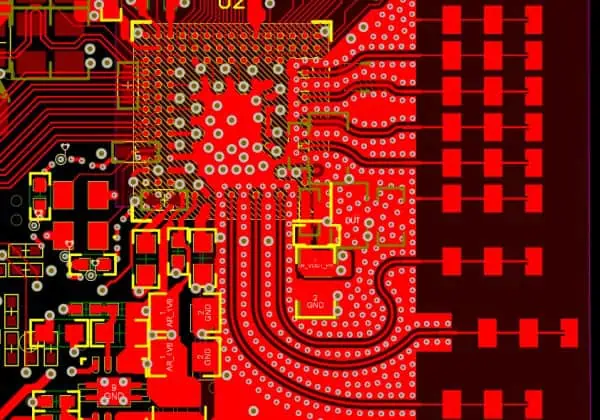

Via and Transition Design

High-frequency signals are particularly sensitive to discontinuities, making via design critical. Material selection affects via aspect ratios, drill sizes, and plating requirements. Some high-frequency materials may limit via options or require special processing techniques to maintain signal integrity through layer transitions.

Testing and Validation

Material selection should be validated through both simulation and measurement. S-parameter measurements, time-domain reflectometry, and eye diagram analysis help verify that chosen materials meet performance requirements. Early prototyping with candidate materials can identify potential issues before committing to full production.

Future Trends and Considerations

As frequencies continue to increase and new applications emerge, material technology continues evolving. Nanotechnology-enhanced materials, advanced polymer systems, and novel ceramic compositions promise improved performance characteristics. The growing importance of 5G, automotive radar, and satellite communications drives continued innovation in high-frequency PCB materials.

Environmental considerations are also becoming increasingly important, with lead-free, halogen-free, and recyclable materials gaining attention. Balancing environmental responsibility with performance requirements represents an ongoing challenge for material developers and circuit designers.

The selection of high-frequency PCB materials requires careful consideration of multiple interrelated factors. Success depends on understanding the fundamental trade-offs between electrical performance, manufacturing practicality, cost, and reliability requirements. As technology continues advancing, staying informed about new material developments and their practical implications remains essential for engineers working in high-frequency applications.

Related posts:

- Copper Foils for High Frequency Circuit Materials

- Fabrication Guidelines RO3000 and RO3200 Series High Frequency Circuit Materials

- Rogers Dielectric Materials: A Guide to High-Frequency PCB Laminates for RF & Microwave Applications

- Fabrication Guidelines RT/duroid 5870-5880 High Frequency Circuit Materials (PDF Download)