In the world of electronics, electromagnetic compatibility (EMC) is a critical aspect that ensures the proper functioning of electronic devices and systems. EMC refers to the ability of electrical and electronic equipment to operate as intended, without causing unacceptable electromagnetic interference (EMI) to other devices or systems, and without being unduly affected by EMI from external sources.

EMC issues can arise from various sources, including internal circuit design, power supply noise, external electromagnetic fields, and even environmental factors. Failure to address EMC concerns can lead to malfunctions, decreased performance, and even safety hazards in some cases.

This comprehensive article aims to provide you with a comprehensive guide to troubleshooting EMC issues from your workbench. Whether you’re a hobbyist, engineer, or technician, understanding and addressing EMC problems is essential for ensuring the reliable operation of your electronic projects and systems.

Understanding EMC Basics

Before delving into troubleshooting techniques, it’s crucial to understand the fundamental concepts of EMC and the potential sources of EMI.

What is EMI?

Electromagnetic interference (EMI) refers to the unwanted electromagnetic energy that can disrupt or degrade the performance of electronic devices and systems. EMI can be caused by various sources, including:

- Radiated emissions: These are electromagnetic waves emitted by devices or circuits, which can interfere with the operation of other electronics in the vicinity.

- Conducted emissions: Conducted emissions refer to electrical noise or disturbances that travel along power lines, signal cables, or other conductive paths, affecting connected devices.

- Electrostatic discharge (ESD): ESD events occur when static electricity is discharged, potentially causing damage or disruption to sensitive electronic components.

EMC Compliance and Standards

Depending on the application and industry, electronic devices and systems may be subject to various EMC standards and regulations. These standards aim to ensure that products meet certain EMI emission limits and immunity levels, minimizing the risk of electromagnetic interference.

Some commonly encountered EMC standards include:

- FCC (Federal Communications Commission) regulations: These apply to electronic devices sold in the United States and cover both radiated and conducted emissions.

- CISPR (International Special Committee on Radio Interference): This international body develops EMC standards for various product categories, such as CISPR 11 for industrial, scientific, and medical (ISM) equipment, and CISPR 32 for multimedia equipment.

- IEC (International Electrotechnical Commission) standards: These include IEC 61000 series standards, which cover EMC testing and measurement techniques, as well as immunity requirements for different environments.

- Automotive EMC standards: Vehicles and automotive components must comply with standards like CISPR 25 and ISO 7637 to ensure EMC in harsh automotive environments.

While compliance with relevant EMC standards is essential for commercial products, understanding and applying EMC principles can also benefit hobbyists and engineers working on personal projects or prototypes assembly pcb.

Identifying EMC Issues

Before attempting to troubleshoot EMC problems, it’s crucial to identify the signs and symptoms of EMI. Some common indicators of EMC issues include:

- Intermittent or erratic behavior: If your electronic device or system exhibits unexplained glitches, freezes, or resets, EMI could be the culprit.

- Noise or interference on displays or audio outputs: The presence of visible or audible noise, such as static, hum, or flickering, can be a sign of EMI affecting the device.

- Data corruption or communication errors: EMI can corrupt data transmissions or cause communication failures between devices or systems.

- Proximity effects: If the behavior of your device changes when it’s brought near other electronic equipment or sources of electromagnetic fields, EMI could be the underlying issue.

- Environmental factors: Changes in temperature, humidity, or other environmental conditions can sometimes exacerbate or reveal EMC problems.

If you suspect EMC issues in your electronic project or system, it’s time to start troubleshooting.

Troubleshooting EMC from Your Workbench

Troubleshooting EMC problems can be a complex process, as the sources of EMI can be numerous and sometimes difficult to pinpoint. However, by following a systematic approach and employing various techniques, you can often identify and mitigate EMC issues effectively.

Workbench Setup and Best Practices

Before diving into specific troubleshooting methods, it’s essential to ensure that your workbench environment is optimized for EMC testing and debugging. Here are some best practices to consider:

- Grounding and shielding: Ensure that your workbench surface is properly grounded, and consider using conductive mats or shielding materials to minimize the impact of external EMI sources.

- Power supply isolation: Use isolated power supplies or line filters to minimize conducted EMI from the mains power supply.

- Cable management: Properly route and shield cables to minimize radiated and conducted emissions, and avoid excessive cable lengths or tight bends.

- Equipment placement: Arrange your test equipment and devices strategically, separating potential EMI sources from sensitive components or circuits.

- Minimizing external interference: Identify and minimize potential sources of external EMI, such as nearby wireless transmitters, high-voltage lines, or machinery.

Troubleshooting Techniques

Once you’ve optimized your workbench environment, you can apply various troubleshooting techniques to identify and mitigate EMC issues. Here are some effective methods to consider:

1. Visual Inspection

Begin by carefully inspecting your circuit or system for potential EMC issues. Look for:

- Improper grounding or shielding: Ensure that all ground connections are secure and that shielding materials are properly implemented.

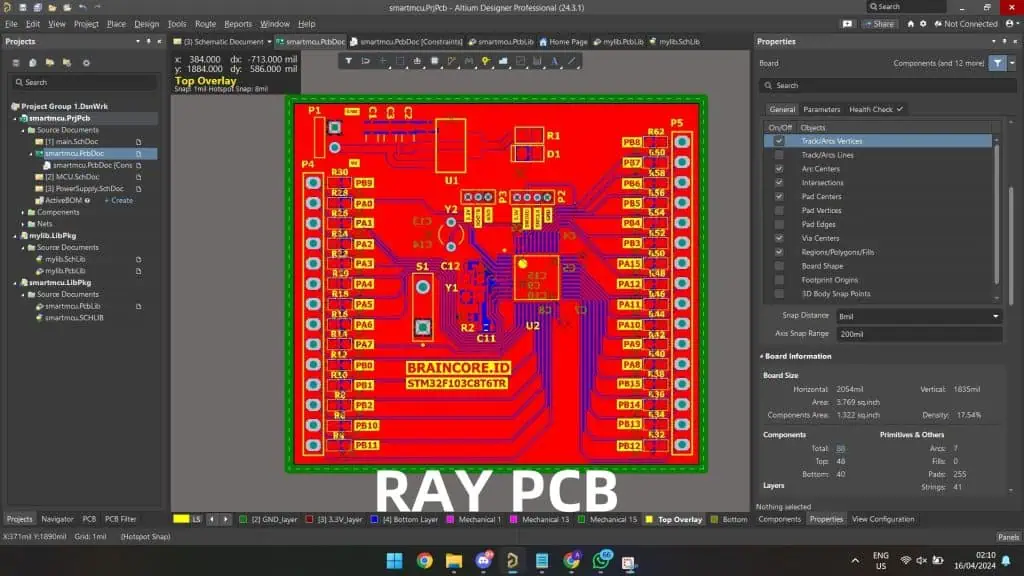

- Poor layout or component placement: Identify areas where sensitive components or traces are in close proximity to potential EMI sources, such as high-frequency oscillators, switching power supplies, or high-current traces.

- Unshielded cables or openings: Check for unshielded cables or openings in enclosures that could allow EMI to penetrate or escape.

- Potential ESD sources: Identify components or assemblies that may be susceptible to electrostatic discharge (ESD) events.

2. Near-Field Probing

Near-field probing is a powerful technique for locating sources of radiated EMI within your circuit or system. This method involves using a small loop or monopole antenna to detect and measure electromagnetic fields in the near-field region.

By systematically probing different areas of your circuit or system, you can identify hot spots or components that are generating excessive EMI. This information can guide you in implementing targeted shielding, filtering, or layout modifications to mitigate the identified EMI sources.

3. Conducted EMI Measurements

In addition to radiated EMI, conducted EMI can also be a significant source of interference. Conducted EMI measurements involve monitoring and analyzing the noise or disturbances present on power lines, signal cables, or other conductive paths.

Use a spectrum analyzer or EMI receiver, along with appropriate probes or current clamps, to measure conducted EMI levels. By identifying frequency ranges or components contributing to excessive conducted EMI, you can implement appropriate filtering or suppression techniques.

4. Shielding and Filtering

Once you’ve identified the sources of EMI, you can apply shielding and filtering techniques to mitigate the interference. Shielding involves enclosing sensitive components or circuits within conductive enclosures or using shielding materials to block or attenuate electromagnetic fields.

Filtering, on the other hand, involves using passive or active filters to suppress conducted EMI on power lines, signal cables, or other conductive paths. Common filtering components include ferrite beads, capacitors, and inductor-capacitor (LC) filters.

5. Layout Optimization

In some cases, optimizing the layout of your circuit or system can significantly improve EMC performance. This may involve separating sensitive components or traces from potential EMI sources, implementing proper grounding and shielding techniques, and minimizing loop areas or high-current paths.

Additionally, consider using multi-layer printed circuit boards (PCBs) with dedicated ground and power planes, as well as careful trace routing and component placement to minimize EMI coupling and crosstalk.

6. Software and Firmware Modifications

In certain situations, EMC issues may arise due to software or firmware implementations. For example, improper timing or control of high-speed digital signals, inefficient power management algorithms, or inadequate error handling routines can contribute to EMI problems.

Analyze your software and firmware code for potential areas of improvement, and consider implementing techniques such as spread-spectrum clocking, optimized interrupt handling, or power supply sequencing to mitigate EMC issues.

7. Environmental Testing

Environmental factors, such as temperature, humidity, and electromagnetic fields, can influence the EMC performance of your electronic devices or systems. To ensure reliable operation in various conditions, it’s essential to