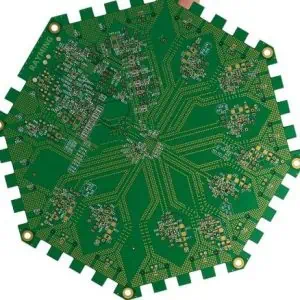

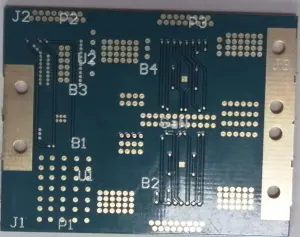

Understanding PCB pricing can be complex due to the numerous variables involved in the manufacturing process. RAYMING provides a comprehensive price comparison system that helps customers make informed decisions. This guide will walk you through the various factors affecting PCB costs and how to effectively compare prices using RAYMING‘s platform.

PCB Price Components

Base Material Costs

| Material Type | Cost Factor | Typical Applications |

| FR-4 | 1.0x (Base) | Standard electronics |

| High Tg FR-4 | 1.2-1.5x | Industrial equipment |

| Rogers | 3-5x | RF/Microwave |

| Polyimide | 2-3x | Flex circuits |

| Metal Core | 2-2.5x | High-power applications |

Layer Count Impact

| Number of Layers | Price Multiplier | Complexity Level |

| 1-2 layers | 1.0x | Basic |

| 4 layers | 1.8-2.2x | Standard |

| 6 layers | 2.5-3.0x | Moderate |

| 8 layers | 3.2-3.8x | Complex |

| 10+ layers | 4.0x+ | Advanced |

Understanding RAYMING’s Pricing Structure

Basic Price Factors

Board Specifications

| Specification | Price Impact | Notes |

| Board Size | Direct correlation | Price per square inch |

| Thickness | 10-30% per mm | Above standard 1.6mm |

| Copper Weight | 5-15% per oz | Above standard 1oz |

| Surface Finish | Varies by type | HASL as baseline |

Quantity Discounts

| Quantity Range | Discount Level | Lead Time Impact |

| 1-10 pcs | Base price | Standard |

| 11-50 pcs | 10-15% off | +0 days |

| 51-100 pcs | 20-25% off | +1-2 days |

| 101-500 pcs | 30-35% off | +3-5 days |

| 500+ pcs | Custom quote | Custom |

Special Features and Their Cost Impact

Surface Finish Options

| Finish Type | Cost Addition | Durability |

| HASL Lead | Base price | Standard |

| HASL Lead-Free | 4.9 | Standard |

| ENIG | 14.8 | High |

| Immersion Silver | 9.85 | Moderate |

| Immersion Tin | 7.88 | Moderate |

| Hard Gold | 24.7 | Very High |

Additional Features

| Feature | Cost Impact | Processing Time |

| Controlled Impedance | 14.8 | +1-2 days |

| Via-in-pad | 19.75 | +1-2 days |

| Blind/Buried Vias | 29.6 | +2-3 days |

| Heavy Copper | 24.65 | +2-3 days |

How to Use RAYMING’s Price Comparison Tool

Basic Steps

- Enter board specifications

- Select material options

- Choose quantity

- Add special requirements

- Compare instant quotes

Advanced Features

Technical Parameters for Comparison

| Parameter | Options Available | Impact on Quote |

| Min Track Width | 3-50 mil | Affects yield rate |

| Min Spacing | 3-50 mil | Affects yield rate |

| Min Hole Size | 0.2-6.0 mm | Affects drilling cost |

| Aspect Ratio | Up to 10:1 | Affects pricing tier |

Manufacturing Options and Cost Implications

Production Speed Options

| Service Level | Lead Time | Price Premium |

| Standard | 5-7 days | Base price |

| Expedited | 3-4 days | 30% |

| Super Rush | 24-48 hours | 100% |

| Custom | Negotiable | Quote based |

Quality Testing Options

| Test Type | Cost Addition | Time Added |

| Basic E-Test | Included | None |

| Flying Probe | 10% | +1 day |

| AOI | 5% | +0.5 day |

| X-ray | 15% | +1 day |

| Multiple Tests | Custom | Custom |

Cost Optimization Strategies

Design Optimization

| Strategy | Potential Savings | Implementation Time |

| Panel Optimization | 5-15% | Design phase |

| Layer Reduction | 20-40% | Design phase |

| Via Optimization | 5-10% | Design phase |

| Material Selection | 10-30% | Design phase |

Volume Optimization

| Strategy | Savings Range | Conditions |

| Bulk Orders | 20-40% | Longer lead time |

| Panel Sharing | 15-25% | Similar specs |

| Regular Orders | 10-20% | Annual contract |

| Prototype assembly Bundles | 5-15% | Multiple designs |

Industry-Specific Considerations

Market Segment Pricing

| Industry | Price Premium | Special Requirements |

| Consumer | Base | Standard specs |

| Industrial | 9.8 | Enhanced durability |

| Medical | 19.7 | Certification needed |

| Aerospace | 29.6 | High reliability |

| Military | 39.5 | Special certification |

Environmental and Compliance Factors

Compliance Requirements

| Standard | Cost Impact | Documentation |

| RoHS | Included | Included |

| REACH | 5% | Additional |

| UL | 10% | Additional |

| IPC Class 3 | 15% | Additional |

| AS9100 | 20% | Additional |

Frequently Asked Questions

Q1: How accurate are RAYMING’s instant quotes compared to final pricing?

A1: RAYMING’s instant quotes are typically accurate within 5-10% of final pricing for standard specifications. Complex designs may require manual review for final pricing accuracy.

Q2: What factors can cause the biggest price variations in PCB manufacturing?

A2: The most significant price variations come from layer count, board size, material selection, and quantity. Special requirements like controlled impedance or blind/buried vias can also substantially impact pricing.

Q3: How does RAYMING handle price comparisons for non-standard specifications?

A3: For non-standard specifications, RAYMING provides initial estimates through the comparison tool and follows up with a detailed manual quote within 24 hours.

Q4: Can I get better pricing by combining different PCB designs in one order?

A4: Yes, RAYMING offers panel sharing options for multiple designs with similar specifications, potentially reducing costs by 15-25%.

Q5: What is RAYMING’s policy on price matching with competitors?

A5: RAYMING offers competitive price matching for identical specifications and quality levels, requiring documentation of the competitor’s quote for verification.

Conclusion

RAYMING’s PCB price comparison system provides a comprehensive tool for understanding and optimizing PCB manufacturing costs. By considering all variables and utilizing the available optimization strategies, customers can achieve the best balance of cost, quality, and delivery time for their specific needs.