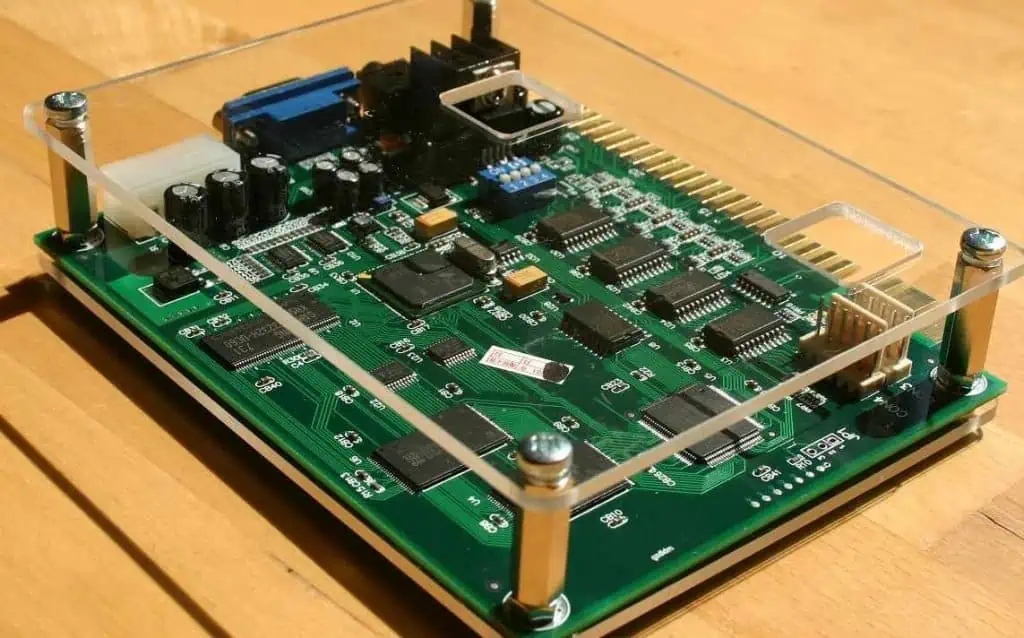

An arcade PCB (printed circuit board) is the main electronic circuit board used to operate and control an arcade or coin-operated amusement machine. Arcade PCB boards contain the core processing components, memory, graphics and sound chips, power regulation, and other supporting circuitry that brings the arcade game to life.

Custom designed for each game title, the arcade PCB allows the unique software, electronic features, and gameplay elements envisioned by the game creators to be faithfully implemented in the final product through intricate electrical engineering and specialized manufacturing.

Understanding what these complex boards comprise of, how they function, and key design differentiators across classic and modern arcade platforms lays the foundation for operating, repairing, collecting, or even developing new coin-op games.

Electrical Components

Arcade PCBs house a variety of electronic components that work in conjunction to run the arcade game machine.

CPU (Central Processing Unit)

The CPU chip or processor executes the program code and software for the game. Classic arcade CPU’s ranged from simple 8-bit microprocessors to more powerful 16-bit and later 32-bit chips. High-end modern arcade boards may use advanced multi-core PC processors.

RAM (Random Access Memory)

Volatile RAM provides active working memory for real-time program operations and data storage/access during gameplay. RAM capacity and speed impacts game performance.

Graphics Processor & Support Chips

Specialized graphics chips render sprite, polygon, and other visuals to screens while support chips handle audio, input/output, protection, and more. Custom chipsets lend unique personality to many classic arcade titles.

ROM (Read Only Memory)

Non-volatile ROM chips contain the game software, audio, program data like character sprites permanently stored for access during power-up. Types include EPROM, EEPROM, and flash memory.

Regulators

Voltage regulator ICs and power management circuitry generate required voltage/current levels from the AC or DC input power bus to supply the sensitive digital logic chips and components on board.

Connectors

Edge connectors and wiring harnesses provide physical interfaces for buttons/joysticks, displays, speakers and power input. Communication buses link multiple boards together in multi-PCB systems.

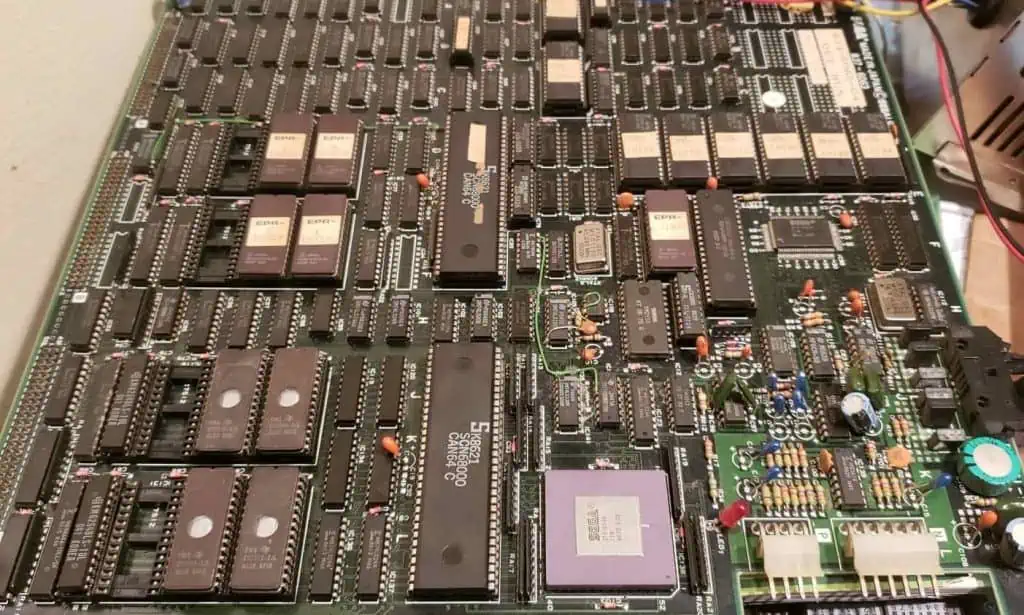

While the above represents core components, arcade PCBs utilize many other supporting resistors, capacitors, crystals, fuses, transistors etc. in their circuit design. Component types and counts vary considerably based on era and game complexity.

| Component | Description |

|---|---|

| CPU (Processor) | Executes game program code |

| RAM | Working memory during gameplay |

| Graphics & Audio Chips | Renders visuals & audio output |

| ROM | Stores game software/data |

| Regulators | Generates required voltages for components |

| Connectors | Interface for controls, I/O, power |

Table: Major electrical components on arcade PCB board designs

PCB Architecture & Layout

The printed circuit board serving as the foundation consists of electrical conductor traces laminated onto an insulating substrate that interconnect the populated components per the schematic layout. The PCB assembly and architecture varies across arcade platforms.

Single Board

Early arcade PCBs utilized a single large board integrating all active and passive components with edge connectors for wiring harnesses to controls/displays. Lower complexity games may still rely on single board construction today.

Multi-Board Stack

Larger form factor arcade platforms link multiple smaller stacked PCBs together communicating over bus architecture. Allows segmenting functions across boards for easier assembly/maintenance.

Daughterboards

Dedicated functional daughterboards housing specialty processors, graphics chips and/or memory modules may be used in conjunction with a main CPU board to allow customization and upgrades.

Backplanes

Passive backplane boards with multi-slot card cages and bus architecture enable modular plug-in designs using interchangeable cards for discrete subsystems like CPU, video, sound etc. This supports repair/replacement.

Arcade PCB layouts strategically place components based on connection paths and critical signal timing considerations required for proper synchronization and operation. additionally, form factor constraints, connector placement, electromagnetic compatibility (EMC) and heat dissipation for thermally significant chips guide board geometries.

While early boards were often wired by hand, today’s PCBs leverage sophisticated autorouting and optimization software ensuring clean routing among dense electronics package configurations. They may also utilize advanced techniques like multi-layer boards and surface mounts for miniaturization.

| PCB Style | Description | Key Traits |

|---|---|---|

| Single Board | All components on one board | Simple design, difficult maintenance |

| Multi-Board Stack | Functions segmented on linked boards | Easier assembly/access, bus communication |

| Daughterboards | Specialty boards to supplement main PCB | Allows upgrades and customization via modular approach |

| Backplanes | Passive backplane with plugin cards for subsystems | Enables easy card swapping for repairs/replacement |

Table: Overview of common architectural styles employed in arcade PCB designs

Era Comparison

Arcade PCB technological capabilities, complexity, and approaches varied considerably across different era’s from the dawn of coin-op games in the early 1970s to state-of-the art modern boards driving the latest game software and arcade experiences:

1970s Arcade PCBs

The earliest arcade boards were primitive dedicated logic boards hard-wired to run single game software titles via a few simple CPUs and support chips. They relied heavily on discrete components with graphics generated using basic TTL, CRT controllers, and clever analogue circuit techniques.

1980s Arcade PCBs

The classic ‘golden age’ of arcade gaming saw advancement to more standardized CPUs like M6502, Z80 paired with specialized graphics and sound processors like Yamaha FM synth chips along with proprietary chipsets. Larger code capacities on 16-bit through early 32-bit processors supported greater complexity.

1990s Arcade PCBs

This period marked a leap to advanced 32-bit CPUs and the emergence of 3D sprite-scaling graphics. CD-ROMs appeared as storage to allow far more extensive software assets. Some platforms adopted backplane designs supporting interchangeable subsystem cards as well.

Modern Arcade PCBs

Cutting-edge modern arcade boards employ multi-core PC processors, high-capacity solid state storage, discrete or integrated graphics chipsets, and even network connectivity supporting remote software updates/monitoring. Increasing convergence with PC computing hardware using customized OS environments.

While simple electromechanical games still retain charm, evolution in processing power, graphics and storage tech continues enabling unprecedented arcade experiences from virtual reality games to highly immersive multiplayer interactive environments undreamt of by early video amusement pioneers.

| Era | CPU Class | Graphics Chip | Memory Medium | Networking | Key Traits |

|---|---|---|---|---|---|

| 1970s | 4 and 8 bit Microprocessors | TTL Circuits, CRT Controllers | Small ROMs, SRAMs | None | Discrete component logic |

| 1980s | 8 and 16 bit Processors | Custom Graphics & Sound Processors | ROMs, SRAMs | None | Special co-processors |

| 1990s | 32 bit Processors | Sprite/3D Graphics Cards | Larger ROMs, CD-ROMs | None | 3D rendering, CD-Audio |

| Modern | Multi-Core PC CPUs | Discrete/Integrated GPUs | Solid State Drives | Yes | Commodity computing hardware, remote communication capabilities |

Table: Comparison snapshot of PCB electronics across arcade history

Interestingly, while underlying technology has radically changed, the concept of customized electronic boards driving interactive amusement persists as a vibrant global phenomenon across generations – a testament both to skilled arcade PCB designers as well as engaged participants simply seeking fun, challenge, and community around games.

Arcade Genres & PCB Distinctions

Beyond chronological capabilities, arcade game genres themselves impose unique technical demands influencing PCB designs across eras.

Classic 2D Platformers

Responsive controls, color palettes, scrolling capabilities defined platformers like Mario Bros requiring optimized sprite graphics handling and processes synchronization.

Classic Fighters

Isometric screens, animation Ahigh speed input processing was critical for fighters like Street Fighter II achieved via graphics co-processors integrated into CPU boards.

Classic Shmups

Scrolling shooters like Gradius relied on similar rapid background rendering techniques coupled with dynamic audio tied closely to actions.

Light Gun Games

Specialized light gun boards accurately timed screen output to gun input sensing using timing ICs or auxiliary controllers connected to main PCB system.

3D Racing

Sprite scaling graphics engines on pseudo-3D racers modeled smoothly animating visual perspectives responsive to quick player inputs.

Modern Emulation Platforms

Hardware emulating legacy original boards in FPGA or ARM SoC designs recreate authentic play while simplifying repair/updates.

This small sample illustrates how distinct goals prompted engineers to craft customized PCB solutions tailored to game concepts, spawning diverse electronic architectures over the history of the industry.

Key Design Considerations

Several unique factors beyond standard computing applications guide development of high performance, reliable arcade PCBs:

Harsh Operating Conditions

Coins, dust, drinks etc. and constant user interactions mandate protection for electronics along with resilience to drops, debris, even intentional abuse.

Hardware Longevity

With expected multi-year lifecycles maintaining acceptable failure rates necessitates quality boards, connectors, and components selected/tested conservative derating.

Software Protection

Risk of board compromise or game cloning led many manufacturers utilizing encryption chips, potting compounds and creative electrical defenses against unauthorized duplication.

Play Responsiveness

Input timing varies considerably across games but maintaining precise software control to action delays through the entire sensor-processor-output chain remains critical for playable, competitive experiences.

Power Protection

Uncontrolled power disruptions could corrupt memory or damage electronics. Robust regulation, electrical spike/surge suppression and battery backup of instability proved essential.

Serviceability

From component labeling to safe sectional power distribution enabling rapid diagnostics and simple sectional replacement served to maximize uptime with easier maintainability.

Cooling Management

Many high density boards demanded small fans, vents, heat pipes and even liquid cooling to discharge thermal loads when air convection proved insufficient to mitigate risks to delicate board electronics operating almost continually.

By considering combinations of the above factors among safety, security, reliability, performance, maintenance, and user engagement goals, arcade PCB shapes directly impacted the holistic game experience and perception of creators’ brands overall.

Manufacturing Process

Producing a new arcade PCB entails sophisticated electronic design automation (EDA), rigorous testing, and advanced manufacturing techniques ensuring the final boards meet stringent technical requisites and quality standards.

Schematic Capture

Engineers draft complex circuit schematics with components interconnect into specialized CAD software suites detailing electrical functionality driving layout.

PCB Layout

Board geometries are laid out for manufacturability specifying conductor paths, layers, finishes, silkscreening, and electrical rules checks to verify trace clearances after initial testing on prototyping boards.

Fabrication

Final board designs get transferred to board houses for generating photo tools used to chemically etch copper foil laminates into desired conductor patterns on the insulating substrate. Components are machine-placed and wave soldered.

Testing & Validation

Assembled boards undergo meticulous inspection and electrical testing against acceptance criteria with iterative correction of any fabrication or design issues on new revisions until conforming to specifications.

Enclosures & Branding

Rugged enclosures securely mount boards then get customized with art, decals, warning labels. Careful manual attention finishes cable dressing.

The rigorous process combines technical engineering disciplines with practical design for environment considerations tailored for the harsh, insensitive operating conditions endemic to unattended amusement equipment deployed among general public locations.

Thousands of intricate custom electronic boards arose from global arcade factories through such methodology enabling wonderful game concepts to engage millions pursuing pleasant diversions from daily stresses – an enduring legacy still inspiring surprise and joy inside aging cabinet frames to latest immersive VR experiences or competitive eSports arena attractions.

Failure Analysis & Repair

Despite following robust design guidelines and manufacturing procedures, arcade boards inevitably still face service issues across long service lifetimes from user-induced damage, electrical failures, damaged traces, or faulty components. Professional repair technicians leverage specialized tools and techniques to diagnose issues and undertake restorative repairs.

Visual Inspection

Close examination under magnification checks for things like damaged conductors, burnt spots, debris accumulation, damaged joints/connectors that provide failure clues guiding deeper electronic testing.

Cleaning

Removal of corrosion, leaked battery residues, soda residues or other conductive contaminants using solvents can often restore compromised boards to functional state after proper drying.

Power Sequencing

Systematically testing regulation and power delivery at each stage quickly isolates bulk failures to specific subsections for more focused analysis using breakout test setups.

Signal Injection

Feeding simulated ‘test software command pulses’ substitutes control side for software errors allowing ‘listen mode’ monitoring of expected electronic feedbackulo scopes, logic probes, and analyzers.

Component Testing

Confirms units like transistors, memory ICs, crystal oscillators and other parts still deliver expected performance versus baselines using Curve tracers and Parameter analyzers.

Signal Tracing

Following the path of compromised signals triggered by designed inputs characterizes issues across function blocks down to specific blown IC or passive elements.

Repairs & Reworks

After root cause identification, issues get resolved through replacement sockets, cables, ICs then retesting boards fully before carefully restoring to arcade cabinet.

Though complex, clearly defined electronic assembly and troubleshooting principles make restoring operation feasible in most cases – a skill essential not just to maintain availability of cherished vintage games but also ensuring the rich knowledge behind electrical designs endures into the future.

FQA

What are some key components found on most arcade PCB boards?

Typical arcade boards include a CPU processor, graphics chips, memory (RAM and ROM), regulators, custom I/O controllers, connectors and various supporting passive components like resistors and capacitors that implement the signal processing required for game software.

How did arcade platforms in the 1990s era differ from earlier decades?

By the 1990s, arcade PCBs transitioned to more powerful 32-bit CPUs, 3D graphics accelerators, and began leveraging storage mediums like CD-ROMs for far greater data capacities compared to earlier ROM cartridges and diskettes, enabling enhanced visuals and gameplay complexity.

Why might a multi-board stack architecture be used instead of a single PCB?

Stacking functionally segmented PCBs together reduces complexity of any single board assembly for manufacturing, also allows easier access or replacements of specific boards during service while enabling high speed parallel communication between boards.

How are modern arcade platforms evolving relative to past dedicated hardware?

Modern coin-op boards leverage powerful standard computing hardware like multi-core PC processors and GPUs just like the latest consoles. They increasingly use solid state disks for software and storage and may incorporate ethernet connectivity for remote reporting and software updates departing from fully proprietary designs.

What are some key considerations for engineers designing arcade PCB boards?

Long term reliability and protection of electronics against liquids, debris and abuse along with ensuring responsiveness and precision timing of all sensor and output sequences are critical. Maintainability to component level and effective heat dissipation also guide board layouts and enclosure integration for the harsh operating conditions and 24/7 runtimes.