Introduction

In the rapidly evolving world of electronics, flexible printed circuit boards (flex PCBs) have gained significant popularity due to their versatility, space-saving capabilities, and ability to conform to complex shapes. As engineers, startups, and manufacturers increasingly turn to flex PCBs for their projects, understanding the costs associated with these innovative components becomes crucial. This comprehensive guide will take you on a journey from initial design considerations to final production pricing, helping you navigate the intricacies of flex PCB costing.

1. What is a Flex PCB?

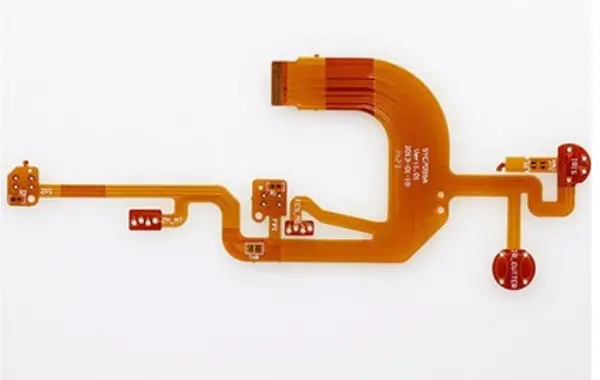

1.1 Definition and Structure of a Flexible PCB

Flex PCBs are circuit boards that can bend, flex, or conform to a desired shape. Unlike their rigid counterparts, flex PCBs are constructed using flexible base materials, typically polyimide or polyester films. This unique structure allows them to be:

- Bent or folded to fit into tight spaces

- Dynamically flexed during operation

- Shaped to follow contours of product designs

The key differences between flex PCBs and rigid PCBs lie in their materials, manufacturing processes, and applications. While rigid PCBs use stiff substrates like FR-4, flex PCBs employ thin, pliable materials that enable their characteristic flexibility.

1.2 Common Applications of Flex PCBs

Flex PCBs have found their way into numerous industries and applications, including:

- Wearable technology (smartwatches, fitness trackers)

- Automotive (dashboard displays, sensor connections)

- Aerospace (satellite components, aircraft control systems)

- Medical devices (hearing aids, implantable devices)

- Consumer electronics (smartphones, cameras)

- Industrial equipment (robotics, automated systems)

The ability of flex PCBs to save space, reduce weight, and withstand mechanical stress makes them ideal for these applications where traditional rigid PCBs would be impractical or impossible to use.

2. Overview of Flex PCB Costing

2.1 Why Flex PCBs are Generally More Expensive than Rigid PCBs

Flex PCBs typically come with a higher price tag compared to their rigid counterparts. This cost difference stems from several factors:

- Specialized materials: Flex PCBs require more expensive base materials like polyimide.

- Complex manufacturing processes: Producing flex PCBs involves more intricate steps and specialized equipment.

- Stringent quality control: Flex PCBs often need more rigorous testing to ensure reliability under bending and flexing conditions.

- Lower production volumes: Flex PCBs are often produced in smaller quantities, leading to higher per-unit costs.

2.2 Flex PCB Cost vs. Rigid PCB Cost: Quick Comparison

To give you a general idea of the cost difference, here’s a quick comparison:

| Factor | Rigid PCB | Flex PCB |

|---|---|---|

| Base material cost | Lower | Higher |

| Manufacturing complexity | Lower | Higher |

| Tooling costs | Lower | Higher |

| Minimum order quantities | Often lower | Often higher |

| Per-unit cost (small volumes) | Lower | Significantly higher |

| Per-unit cost (large volumes) | Lower | Moderately higher |

The most significant cost differences come from:

- Material expenses (flex materials can be 2-3 times more expensive)

- Manufacturing process complexity

- Specialized handling and quality control requirements

Read more about:

3. Key Factors Affecting Flex PCB Cost

3.1 Design Complexity

The complexity of your flex PCB design plays a crucial role in determining its cost. Key aspects include:

Number of Layers

- Single-layer flex: Simplest and most cost-effective

- Double-layer flex: Moderate complexity and cost

- Multilayer flex: Most complex and expensive

Trace Width and Spacing

Finer traces and tighter spacing require more advanced manufacturing processes, increasing costs.

Via Structures

- Through-hole vias: Standard and less expensive

- Microvias: More complex and costly

- Blind and buried vias: Most expensive due to additional processing steps

Bending Requirements

Designs that require tight bending radii or frequent dynamic flexing may need special materials or manufacturing techniques, increasing costs.

3.2 Material Selection

The choice of materials significantly impacts flex PCB cost:

Base Materials

- Polyimide: More expensive but offers better performance and temperature resistance

- Polyester: Less expensive but with limitations in performance and durability

Adhesive Types

- Adhesive-based: Traditional and less expensive

- Adhesiveless: More expensive but offers better electrical and thermal performance

Coverlay vs. Solder Mask

- Coverlay: More expensive but provides better protection and flexibility

- Solder mask: Less expensive but may crack under extreme bending

Material Grade

- Standard-grade materials: Suitable for most applications

- High-temperature materials: More expensive but necessary for certain high-reliability applications

3.3 Size and Shape of the PCB

The physical dimensions and outline of your flex PCB affect its cost:

- Larger boards require more material and processing time

- Irregular or complex shapes necessitate advanced cutting techniques and may result in more material waste

3.4 Manufacturing Process Complexity

Additional manufacturing steps can significantly increase costs:

Stiffeners

Adding rigid areas (e.g., FR4 or polyimide stiffeners) for component mounting increases complexity and cost.

Shielding Requirements

Incorporating EMI shielding films or layers adds to material and processing costs.

Surface Finishes

Different finishes impact both cost and performance:

- ENIG (Electroless Nickel Immersion Gold): More expensive but offers excellent surface protection

- OSP (Organic Solderability Preservative): Less expensive but with shorter shelf life

- Immersion Silver: Moderate cost with good solderability

3.5 Quantity and Volume

Order quantity plays a significant role in per-unit costs:

- Prototyping (1-10 pieces): Highest per-unit cost due to setup fees and minimum order quantities

- Small production runs (100-1000 pieces): Moderate per-unit cost

- Mass production (10,000+ pieces): Lowest per-unit cost due to economies of scale

3.6 Testing and Quality Assurance

Rigorous testing requirements add to the overall cost:

- Electrical testing: Ensures proper connectivity and functionality

- Dynamic flex testing: Verifies durability under repeated bending

- Environmental reliability testing: Assesses performance under various conditions (temperature, humidity, etc.)

More stringent QA requirements increase labor and equipment costs, reflecting in the final price.

3.7 Lead Time and Turnaround Speed

Faster production times come at a premium:

- Standard lead times (2-3 weeks): Most economical option

- Expedited services (3-5 days): Can increase costs by 50-100%

- Super rush (24-48 hours): Highest premium, often 2-3 times the standard price

4. Typical Flex PCB Cost Breakdown

Understanding the cost components helps in identifying areas for potential savings:

4.1 Material Costs (30-40% of total cost)

- Base materials (polyimide, polyester)

- Copper foils

- Adhesives or bonding films

- Coverlay or solder mask materials

4.2 Labor and Processing Costs (25-35%)

- Machine operation

- Handling and assembly

- Engineering and design review

4.3 Tooling and Setup Charges (10-20%)

- Photomasks

- Drill files

- Machine setup and calibration

4.4 Testing and Inspection Fees (10-15%)

- Electrical testing equipment usage

- Visual inspection

- Reliability testing

4.5 Logistics and Shipping Costs (5-10%)

- Packaging materials

- Shipping fees

- Import/export charges for international orders

5. Cost Estimation at Different Project Stages

5.1 Early Design Phase: Ballpark Estimates

At this stage, focus on:

- Approximate board size

- Estimated layer count

- Rough idea of design complexity

- Projected production volume

Use online calculators or consult with manufacturers for initial estimates, but expect these to be within ±30-50% of the final cost.

5.2 After Finalizing the Stackup and BOM (Bill of Materials)

With detailed specifications, you can get more accurate quotes:

- Precise dimensions and layer stackup

- Specific material requirements

- Detailed via structures and trace/space requirements

- Finalized component list and placement

Expect these estimates to be within ±10-20% of the final cost.

5.3 Manufacturing Phase: True Final Costs

Final costs are determined after:

- DFM (Design for Manufacturability) review

- Any necessary design modifications

- Confirmation of all manufacturing processes

- Finalization of testing requirements

At this stage, you should have a precise cost figure, barring any unforeseen issues during production.

6. How to Reduce Your Flex PCB Costs

6.1 Simplify the Design Where Possible

- Minimize the number of layers

- Use standard trace widths and spacings

- Avoid unnecessary use of advanced via structures

6.2 Use Standard Materials and Standard Sizes

- Opt for commonly used polyimide thicknesses

- Choose standard copper weights

- Design within standard panel sizes to minimize waste

6.3 Consolidate Orders (Batch Production Strategies)

- Combine multiple designs into a single order

- Plan for larger production runs to benefit from economies of scale

6.4 Work with Manufacturers Early During Design (DFM: Design for Manufacturability)

- Consult with manufacturers about design choices

- Implement DFM guidelines to avoid costly revisions later

6.5 Choose the Right Manufacturer Specializing in Flex PCBs

- Look for manufacturers with experience in flex PCB production

- Consider the balance between cost, quality, and capabilities

7. Flex PCB Cost Estimator Tools and Services

7.1 Online Flex PCB Quote Calculators

Many PCB manufacturers offer online quote calculators, including:

- JLCPCB

- PCBWay

- ALLPCB

- Flexible Circuit Technologies

These tools provide instant estimates based on basic design parameters.

7.2 How to Use Instant Pricing Tools Accurately

To get the most accurate quotes:

- Input exact specifications (dimensions, layers, materials)

- Specify all special requirements (stiffeners, surface finish)

- Include quantity and lead time preferences

- Check for any design rule violations flagged by the tool

7.3 Factors to Double-Check Before Finalizing an Estimate

Be aware of potential hidden costs:

- Setup fees or tooling charges

- Testing and inspection costs

- Shipping and handling fees

- Import duties for international orders

- Taxes (VAT, sales tax)

8. Examples: Flex PCB Cost Scenarios

8.1 Small Batch Prototype (10 pieces, 2-layer flex PCB)

- Size: 50mm x 100mm

- Material: Standard polyimide

- Finish: ENIG

- Estimated cost range: 300−300−500 total (30−30−50 per piece)

8.2 Mid-Sized Production (500 pieces, multilayer flex PCB with stiffeners)

- Size: 75mm x 150mm

- Layers: 4 layers with FR4 stiffeners

- Material: High-temp polyimide

- Finish: Immersion gold

- Estimated cost range: 7,500−7,500−10,000 total (15−15−20 per piece)

8.3 High-Volume Production (10,000+ pieces, single-layer flex)

- Size: 25mm x 50mm

- Material: Standard polyimide

- Finish: OSP

- Estimated cost range: 30,000−30,000−40,000 total (3−3−4 per piece)

Note: These examples are for illustration purposes only. Actual costs can vary significantly based on specific design details and manufacturer pricing.

Conclusion

Understanding the intricacies of flex PCB costing is crucial for anyone involved in electronic product development. From the initial design phase to final production, numerous factors influence the overall cost of flexible circuit boards. By carefully considering elements such as material selection, design complexity, manufacturing processes, and production volume, you can make informed decisions that balance performance, reliability, and budget.

Remember that while flex PCBs may come with a higher upfront cost compared to rigid PCBs, they often offer significant advantages in terms of space savings, weight reduction, and design flexibility. These benefits can lead to overall cost savings in your final product design and assembly.

As you embark on your flex PCB project, keep these key takeaways in mind:

- Start with a clear understanding of your project requirements and constraints.

- Engage with manufacturers early in the design process for DFM guidance.

- Consider the total cost of ownership, not just the initial PCB price.

- Leverage online tools and expert consultations for accurate cost estimates.

- Look for opportunities to optimize your design for cost-effectiveness without compromising performance.

By applying the knowledge and strategies outlined in this guide, you’ll be well-equipped to navigate the flex PCB costing landscape, make informed decisions, and achieve the best possible balance between performance and budget for your flexible circuit board projects.

FAQs: Common User Questions about Flexible PCB Pricing

- Q: How much more expensive are flex PCBs compared to rigid PCBs? A: Flex PCBs can be 2-5 times more expensive than rigid PCBs, depending on complexity and volume.

- Q: What’s the minimum order quantity for flex PCBs? A: This varies by manufacturer, but many offer prototyping services with MOQs as low as 1-5 pieces.

- Q: How can I reduce the cost of my flex PCB design? A: Simplify the design, use standard materials, increase order quantity, and work closely with manufacturers for DFM optimization.

- Q: Are there any hidden costs I should be aware of when ordering flex PCBs? A: Watch for tooling charges, testing fees, expedited service costs, and shipping/import fees for international orders.

- Q: How long does it typically take to manufacture flex PCBs? A: Standard lead times are often 2-3 weeks, but can range from 24 hours (super rush) to 4-6 weeks for complex designs.

Related posts:

- PCB Pricing Guide: Factors Affecting Printed Circuit Board Costs (From Prototypes to Bulk Orders)

- Factors Affecting the Cost of Manufacturing Printed Circuit Boards at RayMing PCB

- What are the Factors Affecting the Cost of Electronic Manufacturing Production?

- What are the Factors Affecting the Cost of HDI PCB Production?