In the world of electronics manufacturing, safety and quality assurance are paramount. One of the most recognized symbols of product safety and reliability is the UL mark. When it comes to Printed Circuit Boards (PCBs), UL marking plays a crucial role in ensuring that these essential components meet specific safety standards. This article will delve into the details of UL marking on PCBs, exploring its significance, requirements, and impact on the electronics industry.

Understanding UL and Its Importance

What is UL?

UL, or Underwriters Laboratories, is a global independent safety science company with more than a century of expertise innovating safety solutions. Founded in 1894, UL has become one of the most respected and recognized safety certification organizations worldwide.

The Role of UL in Electronics

In the electronics industry, UL plays a vital role in:

- Developing safety standards

- Testing products for compliance

- Certifying products that meet these standards

- Conducting follow-up inspections to ensure continued compliance

UL’s involvement in the electronics sector helps manufacturers produce safer products, reduces risks for consumers, and provides a benchmark for quality in the global marketplace.

UL Marking on PCBs

Definition of UL Marking on PCBs

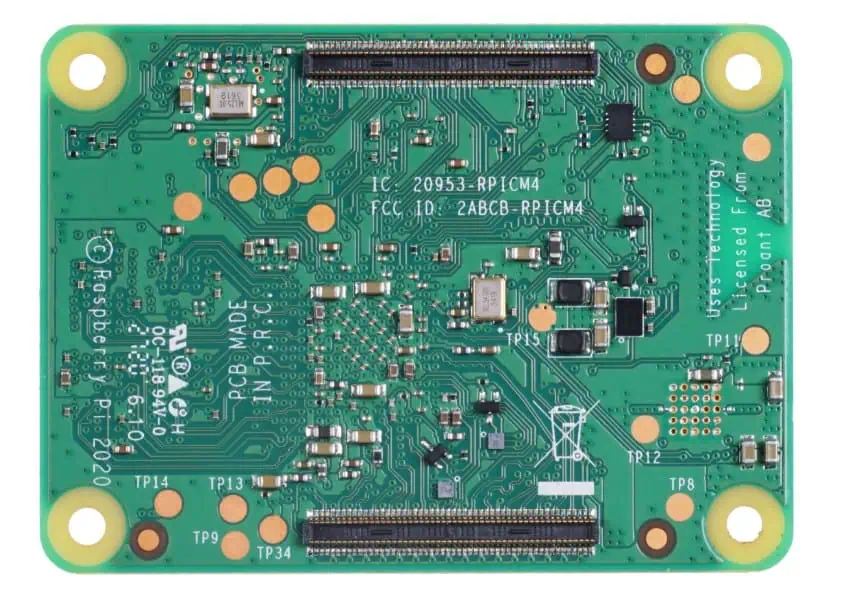

UL marking on a PCB is a visual indicator that the board has been tested and certified to meet specific UL safety standards. This marking typically includes the UL logo, a unique identifier, and sometimes additional information about the certification.

Components of UL Marking

A typical UL mark on a PCB includes:

- The UL logo

- A unique file number (E-number)

- The board’s flame rating

- Additional identifiers for specific standards met

Types of UL Marks for PCBs

There are several types of UL marks that can appear on PCBs:

- UL Recognized Component Mark: This is the most common for PCBs. It indicates that the PCB is a component intended for use in a complete product, which will undergo its own UL evaluation.

- UL Listed Mark: Less common for PCBs alone, this mark is typically found on complete products that have been tested and found to meet UL’s published and nationally recognized standards for safety.

- UL Classification Mark: This mark appears on products that UL has evaluated with respect to specific properties, a limited range of hazards, or suitability for use under limited or special conditions.

The Process of Obtaining UL Certification for PCBs

Step 1: Preparation

Before applying for UL certification, manufacturers must ensure their PCBs meet the necessary requirements. This involves:

- Designing the PCB to meet UL standards

- Selecting materials that comply with UL specifications

- Implementing quality control measures in the manufacturing process

Step 2: Application

The manufacturer submits an application to UL, which includes:

- Detailed product information

- Technical documentation

- Samples for testing

Step 3: Product Investigation

UL conducts a thorough investigation of the PCB, which may include:

- Physical examination

- Performance testing

- Flammability testing

- Electrical safety testing

Step 4: Report and Follow-up Procedures

If the PCB passes all tests, UL issues a report and establishes follow-up procedures to ensure ongoing compliance. This typically involves:

- Regular factory inspections

- Periodic retesting of products

- Documentation of any changes to the product or manufacturing process

Step 5: Authorization to Apply UL Mark

Once all requirements are met, the manufacturer is authorized to apply the UL mark to their PCBs.

UL Standards Relevant to PCBs

Several UL standards are particularly relevant to PCBs:

UL 94: Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances

This standard is crucial for PCBs as it determines the flammability rating of the board. Common ratings include:

- V-0: Highest flame-resistant rating

- V-1: Second highest flame-resistant rating

- V-2: Third highest flame-resistant rating

- HB: Horizontal burning test

UL 796: Standard for Printed-Wiring Boards

This standard specifically addresses the safety requirements for PCBs. It covers aspects such as:

- Electrical properties

- Mechanical strength

- Thermal stability

- Resistance to chemicals and solvents

UL 746E: Standard for Polymeric Materials – Industrial Laminates, Filament Wound Tubing, Vulcanized Fibre, and Materials Used in Printed-Wiring Boards

This standard focuses on the materials used in PCB manufacturing, ensuring they meet safety and performance requirements.

The Importance of UL Marking on PCBs

1. Safety Assurance

UL marking provides assurance that the PCB has been rigorously tested and meets established safety standards. This is crucial in preventing electrical fires, shocks, and other hazards.

2. Regulatory Compliance

Many countries and industries require UL certification for electronic products. Having UL-marked PCBs can help manufacturers meet these regulatory requirements more easily.

3. Market Access

UL certification can open doors to new markets, particularly in regions where UL standards are widely recognized and respected.

4. Quality Indicator

UL marking serves as an indicator of quality, demonstrating that the PCB manufacturer adheres to high standards in their production processes.

5. Liability Protection

Using UL-certified components can provide a degree of liability protection for manufacturers in case of product-related incidents.

6. Customer Confidence

Many customers, especially in industries like aerospace, medical devices, and telecommunications, specifically require UL-certified components, including PCBs.

Impact of UL Marking on PCB Manufacturing

UL marking has a significant impact on PCB manufacturing processes and industry practices:

1. Material Selection

Manufacturers must carefully select materials that meet UL standards, which can influence costs and availability.

2. Design Considerations

PCB designers need to consider UL requirements when creating board layouts and selecting components.

3. Manufacturing Processes

UL certification often requires specific manufacturing processes and quality control measures to be in place.

4. Documentation and Traceability

Manufacturers must maintain detailed records of materials, processes, and testing to comply with UL requirements.

5. Ongoing Compliance

Regular inspections and testing are necessary to maintain UL certification, requiring ongoing investment from manufacturers.

Challenges in Obtaining and Maintaining UL Certification for PCBs

While UL certification offers numerous benefits, it also presents challenges for PCB manufacturers:

1. Cost

The process of obtaining and maintaining UL certification can be expensive, including fees for testing, inspections, and ongoing compliance.

2. Time

Initial certification can be time-consuming, potentially delaying product launches or updates.

3. Technical Requirements

Meeting UL standards often requires advanced technical knowledge and may necessitate changes to existing designs or processes.

4. Material Limitations

UL certification may limit the materials that can be used in PCB manufacturing, potentially affecting performance or cost.

5. Keeping Up with Changes

UL standards are periodically updated, requiring manufacturers to stay informed and adapt their processes accordingly.

Future Trends in UL Certification for PCBs

As technology evolves, so do the standards and processes for UL certification. Some emerging trends include:

1. Increased Focus on Environmental Sustainability

UL is placing greater emphasis on environmental factors, including the use of sustainable materials and manufacturing processes.

2. Adaptation to New Technologies

As new PCB technologies emerge, such as flexible and 3D-printed PCBs, UL standards are evolving to address their unique characteristics.

3. Enhanced Testing for EMC and Signal Integrity

With the increasing complexity of electronic devices, UL is expanding its focus to include more comprehensive testing for electromagnetic compatibility (EMC) and signal integrity.

4. Integration with IoT and Smart Devices

As PCBs become integral components in Internet of Things (IoT) devices, UL is developing new standards to address the unique safety and security challenges these technologies present.

5. Streamlined Certification Processes

UL is working on ways to make the certification process more efficient, potentially reducing time and costs for manufacturers.

Comparison of UL Certification with Other Standards

While UL certification is widely recognized, it’s not the only standard in the electronics industry. Here’s a comparison of UL with other major standards:

| Aspect | UL | CE | CSA | TÜV |

| Geographic Focus | Global (US-based) | European Union | Canada | Global (German-based) |

| Type of Standard | Safety | Safety, Health, Environmental | Safety | Safety, Quality |

| Recognition | High in North America | Required in EU | High in Canada | High in Europe |

| Scope | Product-specific | Broad product categories | Product-specific | Product and process |

| Self-Declaration | No | Yes (for some products) | No | No |

| Third-Party Testing | Required | Often required | Required | Required |

Conclusion

UL marking on PCBs is more than just a symbol – it represents a commitment to safety, quality, and reliability in electronics manufacturing. While obtaining and maintaining UL certification presents challenges, the benefits in terms of market access, customer confidence, and safety assurance make it a valuable investment for many PCB manufacturers.

As the electronics industry continues to evolve, UL certification will likely adapt to address new technologies and challenges. PCB manufacturers who stay informed about these changes and maintain their UL certification will be well-positioned to meet the growing demand for safe, high-quality electronic components in an increasingly connected world.

Frequently Asked Questions (FAQ)

- Q: Is UL certification mandatory for all PCBs? A: UL certification is not legally mandatory for all PCBs, but it is often required by customers, especially in industries with strict safety regulations. Many countries and industries consider UL certification as a de facto requirement for electronic components.

- Q: How long does the UL certification process take for PCBs? A: The duration of the UL certification process can vary significantly depending on factors such as the complexity of the PCB, the readiness of the manufacturer, and the current workload of UL. Typically, it can take anywhere from a few months to a year to complete the initial certification process.

- Q: Can a PCB lose its UL certification? A: Yes, a PCB can lose its UL certification if it fails to meet the ongoing requirements. This can happen if the manufacturer changes the design or materials without approval, fails follow-up inspections, or if new standards are introduced that the PCB no longer meets.

- Q: How often do UL standards for PCBs change? A: UL standards are reviewed and updated periodically to keep pace with technological advancements and new safety concerns. Major revisions typically occur every 3-5 years, but minor updates can happen more frequently. Manufacturers need to stay informed about these changes to maintain their certification.

- Q: Is UL certification recognized worldwide? A: While UL is based in the United States and is most widely recognized in North America, it has global recognition and acceptance in many countries. However, some regions may have their own preferred certification bodies, such as CE marking in the European Union or CCC in China. In many cases, UL certification can help facilitate obtaining these other certifications.