SMA and SMC connectors are two common radio frequency (RF) coaxial connector styles used in telecommunications, test equipment, aerospace, defense, and other microwave applications.

Both connector types provide excellent electrical performance at microwave and millimeter wave frequencies, but they have some distinct differences in their design and usage. Understanding these differences helps engineers select the right option for their specific application and performance requirements.

This comprehensive guide examines the key similarities and differences between SMA and SMC connectors in terms of design, performance, applications, standards and more.

SMA Connectors Overview

SMA (SubMiniature version A) connectors were introduced in the 1960s as a smaller alternative to Type N and C connectors used at the time. The SMA uses a snap-on coupling mechanism and offers broadband performance up to 18 GHz in some configurations.

Key Features

- Compact threaded interface with snap-on coupling nut

- Designed for semi-rigid and flexible cables

- Widely used with test equipment, RF systems, microwave systems

- Provides DC-18 GHz frequency range typically

- Available in 50 ohm impedance

- Robust mechanical design

- Variants like reverse polarity SMA (RP-SMA)

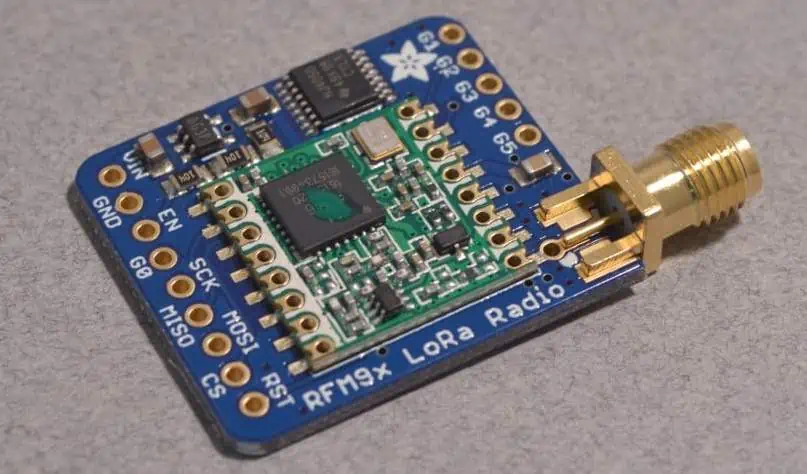

SMA Connector

Where SMA Connectors are Used

SMA connectors are very popular for lower frequency microwave applications including:

- Test and measurement equipment

- Telecommunication equipment

- Aerospace and military systems

- Antennas

- Medical devices

- General purpose RF and microwave component interconnections

They are ideal for applications not requiring the ruggedness or precision of precision connectors. SMA strikes a good balance between performance, cost, and ease of use.

SMC Connectors Overview

SMC (SubMiniature type C) connectors were introduced in the 1980s as a smaller, higher performance alternative to SMA connectors. SMC uses a threaded coupling interface and offers excellent broadband performance to 26 GHz.

Key Features

- Lightweight threaded coupling interface

- Designed for semi-rigid cables

- Stable performance to 26+ GHz

- Broadband impedance of 50 ohms

- Precision machined parts

- Very low reflection coefficients

- Attenuation comparable to 2.92mm connectors

- Used for critical microwave connections

SMC Connector

Where SMC Connectors are Used

SMC connectors are well suited for high performance microwave applications including:

- Aerospace and defense systems

- Satellite communications

- Test instrumentation

- Microwave radio links

- High speed data transmission

- Laboratory equipment

- Microwave component interfacing

Their precision and repeatability make them ideal for measurement, production, and field use in demanding environments.

SMA vs SMC Comparison

Now let’s look closely at how the two connector styles differ across various attributes:

| Parameter | SMA Connector | SMC Connector |

|---|---|---|

| Frequency range | DC – 18 GHz | DC – 26 GHz+ |

| Impedance | 50 ohms | 50 ohms |

| Connector interface | Threaded coupling nut | Threaded coupler |

| Coupling nut material | Nickel plated brass | Stainless steel |

| Dielectric | PTFE | PTFE |

| Body styles | Straight, bulkhead, jack, panel mount | Straight, bulkhead |

| Durability | 500 mating cycles | 500+ mating cycles |

| RF leakage | Good to 12 GHz | Excellent to 18 GHz |

| Intermateability | Connects with most SMA | Primarily mates with SMC |

| Cost | Low cost | Higher cost |

| Return loss | Around -26 dB at 10 GHz | -30 dB at 10 GHz |

| Repeatability | Moderate | Very high |

| Size | Larger diameter | More compact |

| Weight | Heavier | Lighter |

As the table illustrates, SMC offers better electrical performance thanks to its precision design but at a higher cost and lower intermateability than SMA. Key differences are examined in more detail below.

Frequency Range

The SMA connector is intended for operation up to 18 GHz, while SMC provides excellent performance to 26 GHz and beyond. So for microwave applications above 18 GHz, the SMC is a better choice. Both connectors work very well at lower microwave frequencies.

Impedance

SMA and SMC connectors both provide 50 ohm coaxial impedance for matting with cables and components. This matches common RF system impedance.

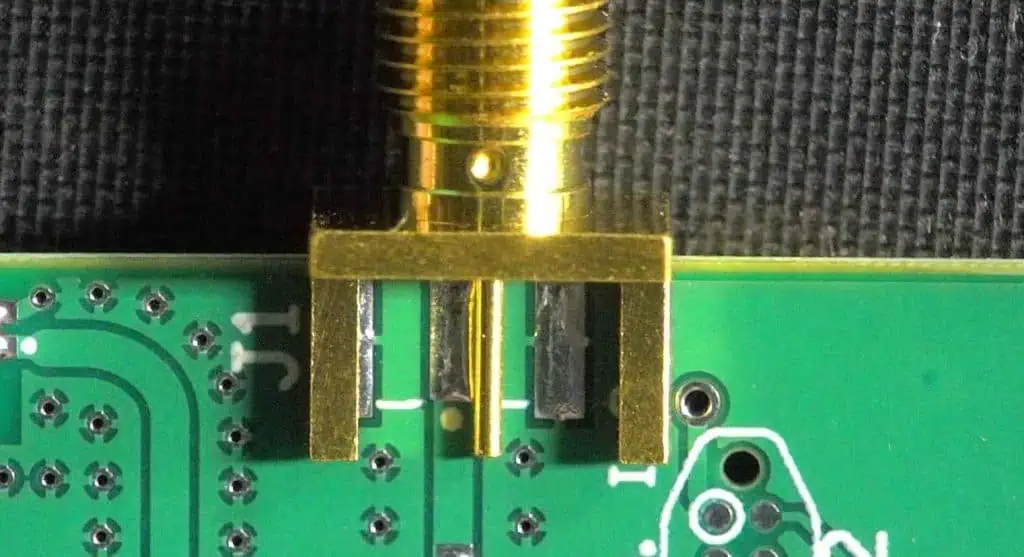

Connector Interface

SMA uses a threaded coupling nut that snaps onto the receptacle so it can rotate independently. SMC utilizes a threaded coupler that engages directly with the receptacle interface.

This difference means SMA connectors tend to be easier to thread together, while SMC achieves better centering and microwave performance.

Coupling Nut Material

On SMA connectors the coupling nut is nickel plated brass. SMC uses passivated stainless steel for the coupler nut, improving corrosion resistance. Stainless steel also has less mass, reducing connector weight.

Dielectric Material

Both connector styles rely on PTFE (polytetrafluoroethylene) for the insulator dielectric material. PTFE provides excellent electrical properties at microwave frequencies along with chemical and temperature resistance.

Body Styles

SMA is available in a wider range of body configuration including straight, bulkhead, jack, panel mount and more. SMC tends to be offered in just straight and bulkhead connector versions.

Durability

The SMA and SMC are rated for approximately 500 mating cycles before performance degradation. This assumes proper mating and unmating procedures are followed. SMC provides a little better cycle life on average.

RF Leakage

SMC provides lower RF leakage than SMA, particularly at higher frequencies. This improves signal integrity and measurement accuracy. At 10 GHz SMC leakage is around -65 dB versus -55 dB for SMA.

Intermateability

Due to their different interfaces, SMA and SMC connectors are primarily intended to mate with same type. However, SMA connectors have some intermateability with Type N and 3.5mm connectors, while SMC connectors only reliably mate with other SMCs.

Cost

SMC connectors cost significantly more than SMA connectors, often 2-3 times as much. This is due to tighter tolerances and precision manufacturing of SMC components.

Return Loss

Return loss describes how much signal power is reflected back due to impedance mismatches in the connector. SMC provides excellent return loss of -30 dB or better at 10 GHz. SMA return loss is around -26 dB typically.

Repeatability

The SMC’s precision threaded interface allows greater mating repeatability than SMA. This ensures consistent performance over many connect/disconnect cycles.

Size

SMC connectors have a smaller diameter and take up less space than SMA connectors. SMC’s compactness provides more connector density in multi-connector assemblies.

Weight

Related to their size differences, SMC connectors are appreciably lighter than SMA models. This provides weight savings which are important in aerospace and portable applications.

SMA and SMC Standards

SMA and SMC connectors are standardized by different organizations:

- SMA – MIL-PRF-39012, IEC 61169-42

- SMC – MIL-PRF-39012, IEC 61169-65

These specifications define the critical dimensions, materials, electrical properties, environmental testing levels and other requirements that connectors must meet to be compliant.

Using connectors that adhere to the standards ensures interchangeability between suppliers and reliability in the field. The standards documents provide all the key technical details needed for manufacturers and users.

Typical Applications of SMA and SMC

SMA Applications

SMA connectors are very commonly used for:

- Antenna connections

- RF signal routing in wireless communications equipment

- Interfacing test equipment like signal generators, spectrum analyzers, power meters and vector network analyzers

- Microwave component evaluation and prototyping

- General purpose coaxial jumpers and adapters

- Lower frequency aerospace and defense electronics

- Biomedical instruments like MRI machines

SMC Applications

SMC connectors are an excellent choice for:

- High performance aerospace and defense communications

- Fast data collection systems

- Microwave instrumentation and metrology

- High frequency antenna feeds

- Satellite payloads

- Microwave radio links

- Calibrated measurement port extensions

- Research labs and test facilities

- Microwave component characterization

So SMCs are often found where accuracy, precision, and repeatability are paramount.

SMA and SMC Cable Assemblies

SMA and SMC connectors are frequently used on coaxial cable assemblies and adapters for interfacing equipment. Common cable types assembled with the connectors include:

| Cable Type | Description | SMA Use | SMC Use |

|---|---|---|---|

| Semi-rigid coax | Solid inner conductor with dielectric/outer conductor tubing | Common | Most common |

| Flexible coax | Center wire, dielectric, braided outer conductor | Common | Moderate use |

| Waveguide | Rectangular or circular metallic tube | Via adapters | Via adapters |

| Multi-cable | Multiple coaxial lines bundled together | Yes | Limited use |

Semi-rigid cables are the preferred medium for both connectors. Flexible coax is more often used with SMA. Custom cable lengths, connector orientation, and configurations can be fabricated for various applications.

Choosing Between SMA and SMC

So when selecting between SMA and SMC connectors, consider the following:

Frequency Range – For applications over 18 GHz, SMC is likely the better choice. Under 18 GHz, either will work well.

Precision – If repeatability and accuracy under mating/unmating is critical, opt for SMC.

Performance – SMC provides lower reflection, leakage, and loss, so for demanding applications it is preferred.

Cost – SMA costs less than SMC, so use SMA if budget is a major factor and performance requirements are moderate.

Size – If a compact, lightweight connector is required, SMC is the smaller choice.

Environment – SMC offers better corrosion resistance for outdoor and humid applications.

Both connector families have proven reliability though, so performance tradeoffs, cost, and other factors specific to the application should all be weighed.

Conclusion

SMA and SMC connectors provide interconnect solutions across DC to 26+ GHz frequencies, with some important differences. SMA offers a balance of modest size, weight, cost and performance. SMC provides top-tier electrical performance for critical microwave connections, with tighter tolerances and somewhat higher cost.

Engineers have the luxury of choosing between two excellent coaxial connector platforms in SMA and SMC. By understanding their capabilities, limitations, and tradeoffs, informed design decisions can be made matching the connector technology to the demands of the application. Both SMA and SMC will continue serving the RF and microwave community well into the future.

Frequently Asked Questions

Here are some common FAQs about SMA and SMC connectors:

Q: Can SMA and SMC connectors be mated together?

A: Direct mating is not recommended. The different interfaces can cause damage. Adapters can allow interconnection in certain cases.

Q: How are SMA and SMC connectors identified when disconnected?

A: SMA has a larger nut with knurled brass surface. SMC uses a stainless steel threaded coupler. Visual markings also differentiate.

Q: What causes wear out in SMA and SMC connectors?

A: Debris entering the precision interface, contamination, exposure to weather extremes, improper mating, excessive mating cycles, etc. Proper care improves longevity.

Q: What torque should be used when tightening SMA and SMC connectors?

A: SMA is typically torqued to 4-5 in-lbs. SMC uses a lighter 0.9 in-lbs torque to avoid deforming precision threads.

Q: Can SMA or SMC connectors be used above 40 GHz?

A: Performance declines dramatically above 26 GHz for SMC and 18 GHz for SMA as coaxial modes are cut off. Other connector styles like 2.92mm are better beyond 40 GHz.