Introduction to Taiyo PSR 4000

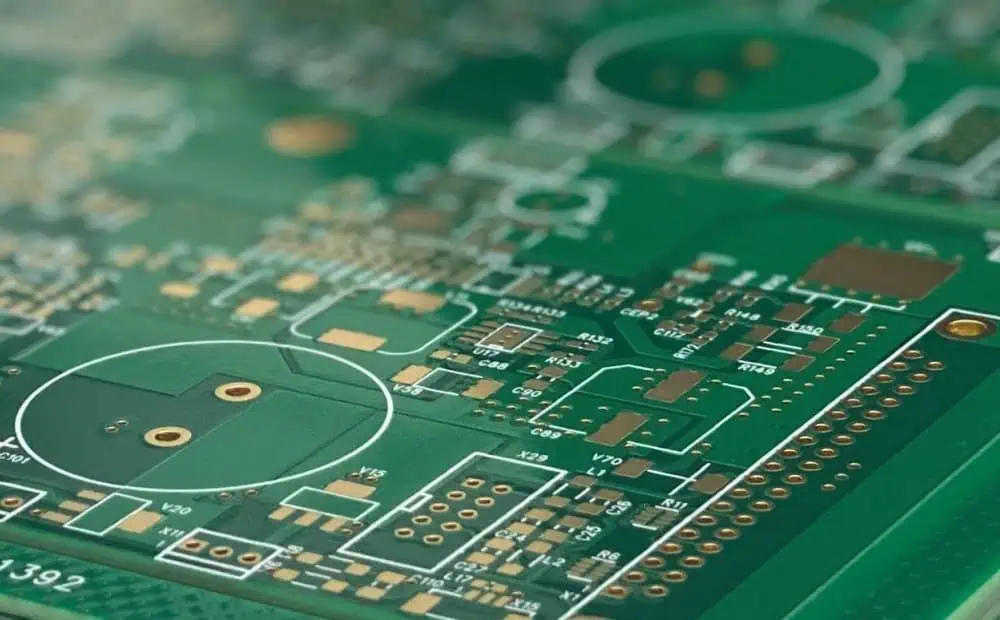

Taiyo PSR 4000 is a high-performance liquid photoimageable solder mask widely used in the printed circuit board (PCB) manufacturing industry. Developed by Taiyo Ink Manufacturing Co., Ltd., a leading company in the field of solder mask technology, the PSR 4000 series has gained significant popularity due to its exceptional properties and versatility in various PCB applications.

In this comprehensive guide, we’ll explore the characteristics, applications, and benefits of Taiyo PSR 4000 solder mask, providing valuable insights for PCB manufacturers, engineers, and electronics enthusiasts.

Understanding Solder Masks

Before diving deep into Taiyo PSR 4000, let’s briefly discuss what a solder mask is and its importance in PCB manufacturing.

What is a Solder Mask?

A solder mask is a thin layer of polymer applied to the copper traces of a printed circuit board. Its primary functions are:

- To protect the copper traces from oxidation

- To prevent solder bridges between closely spaced solder pads

- To improve the board’s appearance and readability

- To protect the board from environmental factors

Types of Solder Masks

There are several types of solder masks available in the market:

- Liquid Photoimageable (LPI) solder masks

- Dry Film solder masks

- Epoxy-based solder masks

Taiyo PSR 4000 falls under the category of Liquid Photoimageable (LPI) solder masks, which are known for their high resolution and excellent performance.

Powered By EmbedPress

Taiyo PSR 4000: Features and Characteristics

Taiyo PSR 4000 stands out among other solder masks due to its unique features and exceptional characteristics. Let’s explore what makes this product a preferred choice for many PCB manufacturers.

Key Features of Taiyo PSR 4000

- High Resolution: Taiyo PSR 4000 offers excellent resolution, allowing for fine line definition and small dam formation.

- Excellent Chemical Resistance: The mask provides superior resistance against various chemicals used in PCB manufacturing processes.

- Thermal Stability: It exhibits good thermal resistance, making it suitable for high-temperature applications.

- Fast Curing: The PSR 4000 series features rapid curing times, enhancing production efficiency.

- Low Odor: Compared to conventional solder masks, Taiyo PSR 4000 has a significantly reduced odor, improving working conditions.

- Environmental Friendliness: The product is formulated to be more environmentally friendly, aligning with global sustainability efforts.

Technical Specifications

To better understand the capabilities of Taiyo PSR 4000, let’s look at some of its technical specifications:

- Color: Available in various colors, including green, black, red, and blue

- Solid Content: Typically around 75% (±2%)

- Viscosity: Approximately 150-250 dPa·s (25°C)

- Exposure Energy: 300-500 mJ/cm²

- Resolution: Can achieve fine lines down to 50 μm

- Hardness: Pencil hardness of 6H or higher after curing

Read more about:

Applications of Taiyo PSR 4000

Taiyo PSR 4000 solder mask finds applications in a wide range of PCB manufacturing scenarios. Its versatility and high performance make it suitable for various industries and product types.

Common Applications

- Consumer Electronics: Smartphones, tablets, laptops, and other portable devices

- Automotive Electronics: Engine control units, infotainment systems, and advanced driver-assistance systems (ADAS)

- Industrial Control Systems: PLCs, HMIs, and other industrial automation equipment

- Aerospace and Defense: Avionics, communication systems, and military-grade electronics

- Medical Devices: Patient monitoring systems, diagnostic equipment, and implantable devices

- Telecommunications: Routers, switches, and cellular base stations

Specialized Applications

- High-Density Interconnect (HDI) Boards: Taiyo PSR 4000’s high resolution makes it ideal for HDI PCBs with fine lines and small vias.

- Flexible and Rigid-Flex PCBs: The mask’s flexibility and adhesion properties make it suitable for flexible circuit applications.

- High-Frequency PCBs: Its low dielectric constant and loss tangent make it appropriate for RF and microwave applications.

- LED Lighting: The mask’s reflective properties can be utilized in LED PCB manufacturing to enhance light output.

Benefits of Using Taiyo PSR 4000

Implementing Taiyo PSR 4000 in PCB manufacturing processes offers numerous advantages. Let’s explore the key benefits that make this solder mask a popular choice among manufacturers.

1. Enhanced PCB Quality

Taiyo PSR 4000’s high resolution and excellent chemical resistance contribute to improved overall PCB quality. The mask’s ability to form fine dams and maintain sharp edges results in better solder mask definition, reducing the risk of solder bridges and other defects.

2. Increased Production Efficiency

The fast curing time of Taiyo PSR 4000 allows for quicker processing, reducing overall production time. This increased efficiency can lead to higher throughput and improved productivity in PCB manufacturing facilities.

3. Improved Thermal Performance

With its excellent thermal stability, Taiyo PSR 4000 helps protect PCBs from heat-related issues during soldering processes and in high-temperature operating environments. This characteristic is particularly valuable in automotive and industrial applications where thermal management is critical.

4. Environmental and Health Considerations

The low-odor formulation of Taiyo PSR 4000 contributes to a more pleasant working environment for PCB manufacturing staff. Additionally, its environmentally friendly composition aligns with global efforts to reduce the use of harmful chemicals in electronics production.

5. Versatility in Applications

The wide range of applications supported by Taiyo PSR 4000 makes it a versatile choice for PCB manufacturers. Its ability to perform well in various scenarios, from consumer electronics to aerospace applications, reduces the need for multiple solder mask types in production facilities.

Best Practices for Using Taiyo PSR 4000

To maximize the benefits of Taiyo PSR 4000 solder mask, it’s essential to follow best practices during the application and curing processes. Here are some tips for optimal results:

1. Proper Surface Preparation

Ensure that the PCB surface is clean and free from contaminants before applying the solder mask. Proper cleaning and microetching can improve adhesion and overall mask performance.

2. Controlled Application

Use appropriate equipment and techniques to apply the solder mask evenly. Screen printing or spray coating methods are commonly used, depending on the PCB design and production requirements.

3. Optimal Exposure and Development

Follow the recommended exposure energy and development parameters provided by Taiyo. Fine-tuning these parameters based on your specific equipment and requirements can help achieve the best results.

4. Adequate Curing

Ensure proper curing of the solder mask by following the recommended temperature and time profiles. Incomplete curing can lead to reduced performance and reliability issues.

5. Regular Maintenance

Maintain and clean the application equipment regularly to ensure consistent quality in solder mask application.

Conclusion

Taiyo PSR 4000 solder mask has established itself as a high-performance solution in the PCB manufacturing industry. Its exceptional features, including high resolution, excellent chemical resistance, and thermal stability, make it an ideal choice for a wide range of applications, from consumer electronics to aerospace and defense.

By implementing Taiyo PSR 4000 in their production processes, PCB manufacturers can benefit from enhanced board quality, increased efficiency, and improved thermal performance. The mask’s versatility and environmentally friendly formulation further contribute to its popularity in the industry.

As the electronics industry continues to evolve, with increasing demands for miniaturization and higher performance, solder mask technologies like Taiyo PSR 4000 will play a crucial role in meeting these challenges. By staying informed about the latest developments in solder mask technology and following best practices in application and curing, PCB manufacturers can ensure they deliver high-quality, reliable products to meet the needs of various industries.