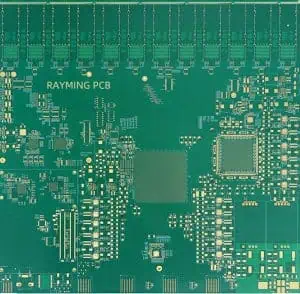

Printed Circuit Boards (PCBs) serve as the backbone of modern industrial equipment, powering everything from factory automation systems to heavy machinery control units. For industrial businesses, understanding PCB manufacturing is crucial for developing reliable, cost-effective electronic solutions that can withstand harsh operating environments and meet stringent performance requirements.

Understanding Industrial PCB Requirements

Industrial PCBs differ significantly from consumer electronics boards in their design specifications and manufacturing requirements. These boards must operate reliably in extreme temperatures, resist chemical exposure, withstand mechanical vibrations, and maintain performance over extended periods—often decades. Industrial applications demand boards that can function in temperatures ranging from -40°C to +125°C, humidity levels up to 95%, and environments with significant electromagnetic interference.

The complexity of industrial PCBs varies considerably based on their application. Simple control boards might require only two layers, while sophisticated industrial computers or motor drives may need twelve or more layers to accommodate dense component placement and complex signal routing. High-power applications often require thick copper layers to handle substantial current loads, while precision measurement equipment demands exceptional signal integrity and minimal noise interference.

Key Manufacturing Considerations for Industrial PCBs

Material selection forms the foundation of successful industrial PCB manufacturing. FR-4 remains the most common substrate material due to its excellent balance of mechanical strength, electrical properties, and cost-effectiveness. However, specialized industrial applications may require alternative materials such as polyimide for flexible circuits, ceramic substrates for high-frequency applications, or metal-core boards for superior thermal management in power electronics.

Copper thickness represents another critical specification for industrial boards. Standard consumer boards typically use 1-ounce copper, but industrial applications often require 2-ounce or even 4-ounce copper to handle high current loads safely. Heavier copper weights improve current-carrying capacity and thermal dissipation but increase manufacturing complexity and cost.

Component placement and routing strategies must account for the harsh industrial environment. Critical components should be positioned away from high-heat areas, and sensitive analog circuits must be isolated from switching power supplies and digital circuits. Proper grounding techniques, including ground planes and strategic via placement, help minimize electromagnetic interference and improve overall system reliability.

The Industrial PCB Manufacturing Process

The manufacturing process for industrial PCBs follows similar steps to consumer boards but with enhanced quality control measures and specialized techniques. The process begins with design verification, where engineers review the board layout for manufacturability, ensuring trace widths can handle required currents, via sizes are appropriate for the layer count, and component footprints match actual parts.

Substrate preparation involves cutting the base material to size and drilling holes for component mounting and layer interconnection. Industrial boards often require precision drilling with tight tolerances to ensure proper component fit and reliable electrical connections. Advanced drilling techniques, such as laser drilling for microvias, may be necessary for high-density designs.

Layer stack-up and lamination require careful attention to impedance control and thermal management. Industrial boards frequently incorporate controlled impedance traces for high-speed signals, requiring precise control of trace geometry and dielectric properties. Multiple pressing cycles may be necessary for thick, multi-layer boards, with careful temperature and pressure control to prevent delamination or warpage.

Surface finishing plays a crucial role in industrial PCB reliability. While HASL (Hot Air Solder Leveling) remains common for cost-sensitive applications, many industrial boards benefit from more advanced finishes like ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative) for improved solderability and corrosion resistance.

Quality Control and Testing Standards

Industrial PCBs must meet rigorous quality standards that exceed typical consumer electronics requirements. IPC-A-600 provides the acceptability criteria for printed boards, while IPC-6012 establishes qualification and performance specifications. Many industrial applications also require compliance with specific industry standards such as IEC 61131 for programmable controllers or ISO 26262 for automotive safety systems.

Electrical testing encompasses continuity checks, insulation resistance measurements, and high-voltage testing to ensure the board can withstand operational stresses. Advanced testing may include impedance verification for high-speed signals, time-domain reflectometry for signal integrity analysis, and thermal cycling to validate solder joint reliability.

Visual inspection using automated optical inspection (AOI) systems helps identify manufacturing defects such as solder bridges, missing components, or improper component placement. X-ray inspection may be necessary for boards with ball grid array (BGA) components or other hidden solder joints that cannot be visually verified.

Cost Optimization Strategies

Managing costs while maintaining quality requires strategic planning and collaboration between design and manufacturing teams. Design for manufacturability (DFM) principles can significantly reduce production costs by minimizing layer count, using standard via sizes, and avoiding unnecessary tight tolerances.

Volume considerations play a major role in cost optimization. Industrial businesses should carefully forecast their requirements to take advantage of volume pricing breaks while avoiding excess inventory costs. Many manufacturers offer flexible scheduling options that allow customers to commit to annual volumes while releasing smaller quantities as needed.

Supplier selection involves balancing cost, quality, and service capabilities. While offshore manufacturing often provides the lowest unit costs, domestic suppliers may offer advantages in communication, shorter lead times, and better quality control for critical applications. Establishing relationships with multiple suppliers provides flexibility and reduces supply chain risks.

Supply Chain Management and Lead Times

Industrial PCB manufacturing requires careful supply chain management to ensure consistent availability of materials and components. Raw material shortages, particularly for specialized substrates or surface finishes, can significantly impact production schedules. Successful industrial businesses often maintain strategic inventory of critical materials or establish long-term supply agreements with key suppliers.

Lead times for industrial PCBs vary significantly based on complexity, quantity, and supplier capacity. Simple boards may be available in one to two weeks, while complex multi-layer boards with specialized materials might require four to eight weeks. Rush services are available but typically carry substantial cost premiums that may not be justified except for emergency situations.

Communication with manufacturing partners throughout the production process helps identify potential issues early and maintain schedule adherence. Regular design reviews, prototype validation, and production status updates ensure that both parties understand requirements and expectations.

Future Trends and Technologies

The industrial PCB manufacturing landscape continues to evolve with advancing technologies and changing market demands. Embedded components, where passive components are built directly into the PCB substrate, offer space savings and improved reliability for high-density applications. Advanced materials like low-loss dielectrics enable higher frequency operation for industrial IoT and wireless communication systems.

Additive manufacturing techniques, including 3D printing of conductive traces and embedded electronics, promise new possibilities for industrial PCB design and manufacturing. While still in early development stages, these technologies may eventually enable rapid prototyping and small-volume production of complex three-dimensional circuits.

Environmental considerations are driving development of lead-free processes, halogen-free materials, and recyclable substrates. Industrial businesses increasingly must consider the complete lifecycle environmental impact of their electronic products, from raw material extraction through end-of-life disposal.

Frequently Asked Questions

What makes industrial PCBs different from consumer electronics boards?

Industrial PCBs are designed to operate in much harsher environments with extreme temperatures, humidity, vibration, and chemical exposure. They typically require heavier copper layers, more robust materials, and enhanced quality control measures to ensure reliable operation over extended periods, often 10-20 years or more.

How do I determine the right copper weight for my industrial application?

Copper weight selection depends on the current requirements of your circuits. Use online current-carrying capacity calculators or consult IPC-2221 standards. Generally, 1-ounce copper handles up to 1-2 amps per trace, 2-ounce copper supports 2-4 amps, and 4-ounce copper can handle 4-8 amps, depending on trace width and temperature rise limits.

What are typical lead times for industrial PCB manufacturing?

Lead times vary from 1-2 weeks for simple, two-layer boards to 6-8 weeks for complex, multi-layer boards with specialized materials. Factors affecting lead time include layer count, board size, material availability, surface finish requirements, and manufacturer capacity. Always plan for potential delays and consider maintaining some safety stock for critical applications.

Should I choose domestic or offshore PCB manufacturing?

The choice depends on your priorities. Offshore manufacturing typically offers lower unit costs but may have longer lead times, communication challenges, and quality consistency issues. Domestic manufacturing provides better communication, shorter lead times, and often superior quality control, but at higher unit costs. Consider the total cost of ownership, including logistics, inventory, and potential quality issues.

What quality standards should industrial PCBs meet?

Most industrial PCBs should comply with IPC-A-600 for acceptability criteria and IPC-6012 for qualification requirements. Depending on your industry, additional standards may apply, such as IEC 61131 for industrial automation, ISO 26262 for automotive applications, or DO-254 for aerospace systems. Discuss specific requirements with your manufacturer to ensure compliance.

How can I reduce PCB manufacturing costs without compromising quality?

Focus on design for manufacturability by using standard materials, minimizing layer count, avoiding tight tolerances unless necessary, and designing for volume production. Consider panelization to improve manufacturing efficiency, standardize board sizes across products, and establish long-term supplier relationships for better pricing. Regular design reviews with your manufacturer can identify cost-saving opportunities.

What surface finish is best for industrial applications?

ENIG (Electroless Nickel Immersion Gold) is often preferred for industrial applications due to its excellent corrosion resistance, flat surface for fine-pitch components, and long shelf life. OSP is cost-effective for simple applications, while HASL remains common for through-hole components. The choice depends on your specific requirements for component types, environmental exposure, and shelf life needs.