Looking for reliable low volume PCB solutions? Whether you’re developing prototypes, testing new designs, or serving niche markets, low volume PCB manufacturing offers the perfect balance of cost-effectiveness and flexibility for your electronic projects.

What is Low Volume PCB Manufacturing?

Low volume PCB manufacturing refers to the production of printed circuit boards in smaller quantities, typically ranging from 10 to 1,000 units. This approach bridges the gap between prototype development and mass production, making it ideal for businesses that need quality PCBs without committing to large-scale orders.

Why Choose Low Volume PCB Production?

Cost-Effective Solution for Small Orders

Low volume PCB production eliminates the need for massive upfront investments. You only pay for what you need, making it perfect for:

- Startups with limited budgets

- Research and development projects

- Custom electronics applications

- Market testing initiatives

Faster Time-to-Market

Unlike high-volume manufacturing that requires extensive setup time, low volume PCB production offers:

- Shorter lead times

- Quick turnaround options

- Rapid prototyping capabilities

- Immediate production flexibility

Quality Without Compromise

Despite smaller quantities, professional low volume PCB manufacturers maintain strict quality standards:

- Rigorous testing procedures

- Advanced quality control measures

- Industry-standard certifications

- Consistent performance across all units

When Should You Consider Low Volume PCB Manufacturing?

Perfect Scenarios for Low Volume PCB Orders

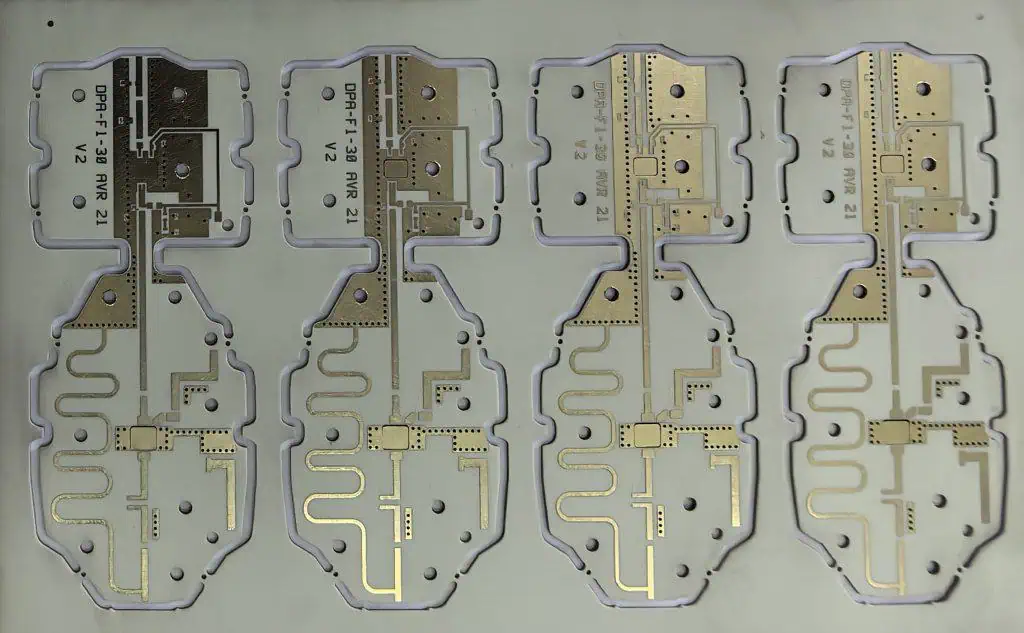

Prototyping and Testing Low volume PCB manufacturing excels when you need to validate designs before full-scale production. This approach allows you to identify potential issues early and make necessary adjustments without significant financial impact.

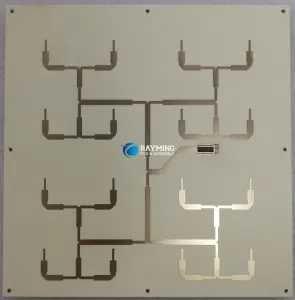

Customized Projects For specialized applications requiring unique specifications, low volume PCB production offers the flexibility to create tailored solutions without the constraints of mass production minimums.

Niche Market Products If your target market has limited demand, low volume PCB manufacturing ensures you don’t overproduce and tie up capital in excess inventory.

Iterative Design Development When your PCB design is still evolving, low volume production enables cost-effective iterations and improvements without the burden of large-scale changes.

Industries That Benefit from Low Volume PCB

- Medical Devices: Specialized equipment with strict regulatory requirements

- Aerospace: High-reliability applications with limited production runs

- Industrial Automation: Custom control systems and specialized machinery

- IoT Devices: Innovative products testing market viability

- Research Institutions: Academic and commercial R&D projects

Key Advantages of Low Volume PCB Manufacturing

Financial Benefits

- Reduced upfront investment compared to high-volume orders

- Lower inventory costs and storage requirements

- Minimized financial risk for new product launches

- Competitive per-unit pricing from experienced manufacturers

Operational Advantages

- Scalable production that grows with your demand

- Faster response times to market changes

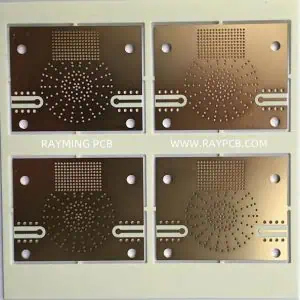

- Enhanced quality control through smaller batch monitoring

- Greater design flexibility for unique requirements

Strategic Benefits

- Risk mitigation for unproven designs

- Market validation opportunities

- Competitive advantage through faster innovation cycles

- Resource optimization for maximum efficiency

Choosing the Right Low Volume PCB Manufacturer

Essential Criteria for Selection

Manufacturing Capabilities Look for manufacturers that offer:

- Advanced production equipment

- Multiple layer capabilities

- Various PCB types (rigid, flexible, rigid-flex)

- Surface finish options

- Component assembly services

Quality Assurance Ensure your low volume PCB manufacturer provides:

- ISO certifications

- IPC standards compliance

- Comprehensive testing procedures

- Quality documentation

- Traceability systems

Service Excellence Priority features include:

- Responsive customer support

- Technical consultation services

- Design for manufacturability (DFM) analysis

- Flexible order quantities

- Reliable delivery schedules

Cost Optimization Strategies

Design Considerations

- Optimize panel utilization

- Standardize hole sizes and spacing

- Minimize layer count when possible

- Choose common materials and finishes

- Consider assembly complexity

Order Planning

- Batch similar designs together

- Plan for reasonable lead times

- Consider volume break points

- Evaluate total cost of ownership

- Factor in shipping and handling

Low Volume PCB vs. High Volume PCB: Making the Right Choice

When Low Volume PCB is Ideal

- Order quantities under 1,000 units

- Prototype development phases

- Custom or specialized applications

- Market testing scenarios

- Limited budget constraints

When to Consider High Volume PCB

- Proven designs with established demand

- Order quantities exceeding 10,000 units

- Cost per unit is the primary concern

- Long-term production contracts

- Stable, standardized designs

Getting Started with Low Volume PCB Manufacturing

Preparation Steps

Design Documentation Ensure you have complete:

Specification Requirements Define your needs:

- PCB dimensions and layer count

- Material specifications

- Surface finish requirements

- Electrical testing needs

- Assembly services required

Working with Your Manufacturer

Communication Best Practices

- Provide detailed specifications

- Ask questions about capabilities

- Discuss timeline expectations

- Clarify quality requirements

- Establish clear communication channels

Quality Assurance Process

- Review DFM feedback carefully

- Approve prototypes before production

- Monitor production milestones

- Conduct incoming inspection

- Maintain quality records

Future Trends in Low Volume PCB Manufacturing

Technology Advancements

- Automated production systems reducing setup times

- Advanced materials enabling new applications

- Improved testing methods ensuring higher reliability

- Digital manufacturing streamlining processes

Market Evolution

- Increased customization demands driving low volume needs

- Shorter product lifecycles requiring flexible production

- IoT proliferation creating diverse PCB requirements

- Sustainability focus optimizing resource utilization

Conclusion: Maximize Your Success with Low Volume PCB

Low volume PCB manufacturing offers an ideal solution for businesses seeking quality, flexibility, and cost-effectiveness in their electronic projects. Whether you’re developing innovative products, serving specialized markets, or testing new concepts, choosing the right low volume PCB manufacturer can significantly impact your success.

The key to maximizing your low volume PCB investment lies in selecting an experienced manufacturer who understands your unique requirements and can deliver consistent quality at competitive prices. With proper planning, clear communication, and strategic partnerships, low volume PCB manufacturing becomes a powerful tool for innovation and growth.

Ready to explore low volume PCB solutions for your project? Contact experienced manufacturers who specialize in small-batch production and can provide the expertise, quality, and service you need to bring your electronic designs to life efficiently and cost-effectively.