High power LED lights have revolutionized the lighting industry, offering unprecedented levels of brightness, energy efficiency, and durability. As technology advances, we’re seeing more powerful LEDs hitting the market, with 100W, 200W, and even higher wattage options becoming increasingly common. This article will explore the world of high power LED lights, their applications, benefits, challenges, and future prospects.

Understanding High Power LED Lights

What Are High Power LED Lights?

High power LED lights are lighting solutions that use light-emitting diodes (LEDs) capable of producing extremely high levels of illumination. These LEDs are designed to handle significantly more electrical power than standard LEDs, resulting in much higher light output.

Key Characteristics of High Power LEDs

- High Lumen Output: Capable of producing thousands of lumens per LED package.

- Improved Efficacy: Higher lumens per watt compared to traditional lighting sources.

- Thermal Management: Requires advanced heat dissipation techniques.

- Longevity: Long lifespan, often rated for 50,000 hours or more.

- Compact Size: High light output from a relatively small form factor.

Applications of High Power LED Lights

Industrial Lighting

- Warehouses: High bay lighting for large storage facilities.

- Manufacturing Plants: Bright, uniform lighting for production lines and work areas.

- Mining: Durable, high-intensity lighting for underground and surface operations.

Outdoor Lighting

- Street Lighting: Energy-efficient illumination for roads and highways.

- Sports Facilities: High-intensity lighting for stadiums and outdoor courts.

- Architectural Lighting: Dramatic illumination of buildings and landscapes.

Commercial Lighting

- Retail Spaces: Bright, attractive lighting for showrooms and display areas.

- Convention Centers: Flexible, high-output lighting for various events.

- Theaters and Studios: Powerful, controllable lighting for stage and film production.

Specialty Applications

- Horticulture: High-intensity grow lights for indoor farming.

- Automotive: High-power headlights and auxiliary lighting.

- Marine: Durable, high-output lighting for ships and offshore structures.

Comparison of 100W, 200W, and Higher Power LED Lights

| Parameter | 100W LED | 200W LED | 300W+ LED |

|---|---|---|---|

| Lumen Output (approx.) | 10,000-15,000 lm | 20,000-30,000 lm | 30,000-45,000+ lm |

| Efficacy (lm/W) | 100-150 | 100-150 | 100-150 |

| Heat Generation | Moderate | High | Very High |

| Typical Applications | Small warehouses, Street lighting | Large warehouses, Sports lighting | Stadiums, Large outdoor areas |

| Initial Cost | Moderate | High | Very High |

| Energy Savings vs. HID | 60-70% | 60-70% | 60-70% |

| Lifespan (hours) | 50,000-100,000 | 50,000-100,000 | 50,000-100,000 |

| Color Rendering Index | 70-95+ | 70-95+ | 70-95+ |

| Beam Angle Options | 60°-120° | 60°-120° | 60°-120° |

Technology Behind High Power LED Lights

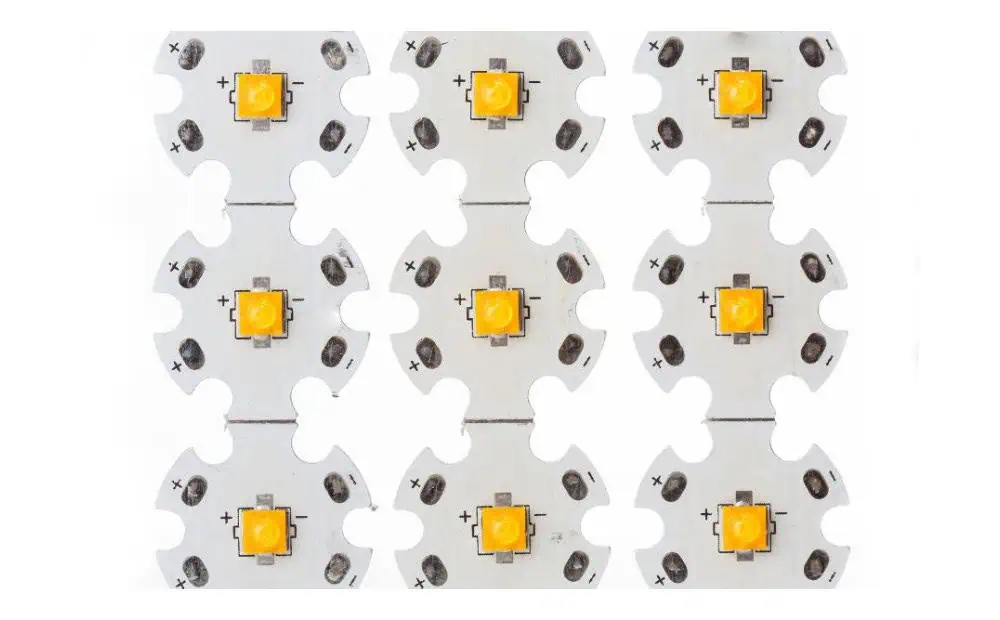

LED Chip Design

- Chip-on-Board (COB) Technology: Multiple LED chips are packaged together to form a single, high-output light source.

- Multi-Die Arrays: Several high-power LED dies are combined in a single package.

- Advanced Semiconductor Materials: Use of materials like Gallium Nitride (GaN) for improved efficiency and heat tolerance.

Thermal Management

- Heat Sinks: Large, often finned aluminum structures to dissipate heat.

- Active Cooling: Fans or liquid cooling systems for extremely high-power applications.

- Thermal Interface Materials: Specialized materials to improve heat transfer from LED to heat sink.

Power Supply and Drivers

- Constant Current Drivers: Ensure stable current supply to maintain consistent light output and protect LEDs.

- High Efficiency Power Supplies: Minimize energy loss in power conversion.

- Intelligent Control Systems: Allow for dimming, color tuning, and integration with smart lighting systems.

Optics and Light Distribution

- Reflectors: Shaped reflective surfaces to control beam angle and light distribution.

- Lenses: Precision-engineered lenses to focus or diffuse light as needed.

- Total Internal Reflection (TIR) Optics: Advanced optical systems for precise light control.

Benefits of High Power LED Lights

Energy Efficiency

High power LED lights offer significant energy savings compared to traditional high-intensity discharge (HID) lamps. They can provide the same or higher light output while consuming up to 70% less energy.

Long Lifespan

With proper thermal management, high power LEDs can last 50,000 to 100,000 hours or more, significantly reducing maintenance and replacement costs.

Improved Light Quality

Modern high power LEDs offer excellent color rendering (CRI 70-95+) and a wide range of color temperatures, providing high-quality light for various applications.

Instant On/Off

Unlike HID lamps, high power LEDs reach full brightness instantly and can be switched on and off rapidly without affecting lifespan.

Directional Light Output

LEDs emit light in a specific direction, reducing the need for reflectors and diffusers, which can trap light.

Environmental Benefits

LED lights contain no mercury and produce less waste due to their long lifespan, making them a more environmentally friendly option.

Challenges and Considerations

Heat Management

As LED power increases, managing heat becomes increasingly critical. Proper thermal design is essential to maintain performance and longevity.

Initial Cost

High power LED lights often have a higher upfront cost compared to traditional lighting solutions, although this is often offset by long-term energy savings and reduced maintenance.

Light Distribution

Achieving uniform light distribution over large areas can be challenging with very high-power LEDs and may require careful optical design.

Power Supply Reliability

The performance and lifespan of high power LED systems are heavily dependent on the quality and reliability of their power supplies and drivers.

Glare and Light Pollution

The intense brightness of high power LEDs can cause glare issues if not properly managed, potentially contributing to light pollution in outdoor applications.

Future Trends in High Power LED Lighting

Increased Efficiency

Ongoing research aims to push LED efficacy even higher, potentially reaching 200 lumens per watt or more in commercial products.

Advanced Materials

Development of new semiconductor materials and phosphors to improve performance and expand the range of available spectra.

Smart Integration

Integration of high power LEDs with advanced control systems, sensors, and IoT technologies for improved energy management and customization.

Miniaturization

Efforts to reduce the size of high power LED packages while maintaining or improving output and thermal performance.

Specialized Spectra

Development of LEDs with spectra tailored for specific applications, such as horticulture, human-centric lighting, and wildlife-friendly outdoor lighting.

Choosing the Right High Power LED Light

Factors to Consider

- Application Requirements: Determine the required light output, distribution pattern, and color characteristics.

- Environmental Conditions: Consider temperature, humidity, and potential exposure to dust or water.

- Energy Efficiency Goals: Calculate potential energy savings and return on investment.

- Maintenance Considerations: Evaluate accessibility and frequency of required maintenance.

- Control Requirements: Assess needs for dimming, color tuning, or integration with building management systems.

- Regulatory Compliance: Ensure the chosen solution meets relevant safety and performance standards.

Comparison of High Power LED Fixtures for Industrial Applications

| Feature | 100W Fixture | 200W Fixture | 300W Fixture |

|---|---|---|---|

| Lumen Output | 13,000 lm | 26,000 lm | 39,000 lm |

| Efficacy | 130 lm/W | 130 lm/W | 130 lm/W |

| Color Temperature Options | 3000K, 4000K, 5000K | 3000K, 4000K, 5000K | 3000K, 4000K, 5000K |

| Beam Angle Options | 60°, 90°, 120° | 60°, 90°, 120° | 60°, 90°, 120° |

| Weight | 3.5 kg | 5.2 kg | 7.8 kg |

| Dimensions (LxWxH) | 300x250x100 mm | 400x300x120 mm | 500x350x140 mm |

| IP Rating | IP65 | IP65 | IP65 |

| Lifespan (L70) | 100,000 hours | 100,000 hours | 100,000 hours |

| Warranty | 5 years | 5 years | 5 years |

| Typical Mounting Height | 4-6 m | 6-9 m | 9-12 m |

| Recommended Coverage Area | 100-150 m² | 200-300 m² | 300-450 m² |

Installation and Maintenance Best Practices

Installation Tips

- Proper Mounting: Ensure fixtures are securely mounted and properly aligned.

- Adequate Ventilation: Allow for sufficient airflow around fixtures to aid heat dissipation.

- Correct Wiring: Use appropriate gauge wires and ensure all connections are secure and properly insulated.

- Surge Protection: Install surge protection devices to guard against voltage spikes.

- Proper Aiming: Adjust fixture angles to minimize glare and optimize light distribution.

Maintenance Recommendations

- Regular Cleaning: Keep fixtures clean to maintain optimal light output and heat dissipation.

- Inspection Schedule: Regularly inspect fixtures for signs of damage or degradation.

- Driver Maintenance: Monitor and replace drivers as needed, as they often have a shorter lifespan than the LEDs themselves.

- Thermal Management Check: Periodically inspect heat sinks and cooling systems for proper operation.

- Light Level Monitoring: Use light meters to track output over time and plan for replacements.

Conclusion

High power LED lights with 100W, 200W, and higher wattages represent the cutting edge of lighting technology. They offer unprecedented levels of brightness, efficiency, and versatility, making them suitable for a wide range of demanding applications. While challenges such as heat management and initial cost remain, ongoing technological advancements continue to improve performance and reduce barriers to adoption. As the technology matures, we can expect to see even more powerful and efficient LED lighting solutions, further transforming how we illuminate our world.

Frequently Asked Questions (FAQ)

1. How do high power LED lights compare to traditional HID lamps in terms of energy efficiency?

High power LED lights are significantly more energy-efficient than traditional HID (High-Intensity Discharge) lamps. On average, LED lights can provide the same or higher light output while consuming 60-70% less energy. This efficiency translates to substantial energy savings over the lifetime of the fixture. For example, a 200W LED light might replace a 400W or 600W HID lamp, depending on the specific application and light requirements.

The higher efficiency of LEDs is due to several factors:

- LEDs convert a higher percentage of electrical energy directly into light, with less energy lost as heat.

- LED light is more directional, reducing the need for reflectors that can trap light.

- LED efficacy (lumens per watt) continues to improve with technological advancements.

It’s important to note that the exact energy savings can vary depending on the specific products being compared and the application requirements.

2. What are the main challenges in thermal management for high power LED lights?

Thermal management is one of the most critical challenges in high power LED lighting. As the power of LEDs increases, so does the amount of heat generated. Effective heat dissipation is crucial for maintaining LED performance and longevity. The main challenges include:

- Heat Concentration: High power LEDs produce a lot of heat in a small area, which can lead to hotspots.

- Temperature Sensitivity: LED performance and lifespan decrease as temperature increases.

- Limited Space: Many applications require compact designs, limiting options for heat sinks and cooling systems.

- Environmental Factors: Ambient temperature and airflow can significantly affect cooling efficiency.

- Material Limitations: Finding materials with high thermal conductivity that are also cost-effective and suitable for manufacturing.

To address these challenges, manufacturers employ various strategies:

- Advanced heat sink designs with increased surface area

- Use of high thermal conductivity materials like aluminum and copper

- Integration of active cooling systems (fans or liquid cooling) for very high-power applications

- Thermal simulation and testing to optimize designs

- Use of thermally conductive interface materials to improve heat transfer from the LED to the heat sink

Proper thermal management is essential to ensure that high power LED lights achieve their rated lifespan and maintain consistent performance over time.

3. How long can I expect a high power LED light to last?

The lifespan of high power LED lights is typically much longer than traditional lighting sources. Most high-quality LED fixtures are rated for 50,000 to 100,000 hours of operation. However, it’s important to understand what this rating means:

- LED lifespan is usually quoted as L70, which is the time it takes for the light output to decrease to 70% of its initial value.

- This doesn’t mean the LED will completely fail at this point, but rather that its output has diminished to a level considered the end of its useful life for most applications.

Factors affecting LED lifespan include:

- Operating Temperature: Higher temperatures can significantly reduce lifespan.

- Drive Current: Running LEDs at higher currents can decrease lifespan.

- Thermal Management: Proper heat dissipation is crucial for longevity.

- Environmental Conditions: Exposure to humidity, vibration, and temperature fluctuations can impact lifespan.

- Quality of Components: The driver and other electronic components can fail before the LED itself.

In real-world applications, a high power LED light operated for 12 hours per day could potentially last over 11 years before reaching its L70 point. However, it’s important to note that other components in the fixture, particularly the driver, may need replacement before the LEDs themselves reach end-of-life.

Regular maintenance and proper installation in accordance with manufacturer specifications can help ensure that high power LED lights achieve or even exceed their rated lifespan.

4. Are high power LED lights suitable for outdoor use in extreme weather conditions?

Yes, high power LED lights can be designed for outdoor use in extreme weather conditions, but it’s crucial to choose fixtures specifically engineered for such environments. When selecting LED lights for challenging outdoor applications, consider the following factors:

- IP Rating: Look for fixtures with appropriate Ingress Protection (IP) ratings. For most outdoor applications, a minimum of IP65 is recommended, which provides protection against dust and water jets. For more extreme conditions, higher ratings like IP66 or IP67 may be necessary.

- Operating Temperature Range: Check the fixture’s specified operating temperature range. High-quality outdoor LED lights can often operate in temperatures from -40°C to +50°C or even wider ranges.

- Corrosion Resistance: For coastal or industrial areas, choose fixtures with corrosion-resistant materials and finishes, such as marine-grade aluminum or stainless steel.

- Wind Load Resistance: In areas prone to high winds, ensure the fixture and mounting system are designed to withstand expected wind loads.

- Thermal Management: Look for designs with effective passive cooling systems that can operate reliably without fans or other moving parts.

- Surge Protection: Outdoor fixtures should have robust surge protection to guard against lightning strikes and other electrical surges.

- UV Resistance: Ensure all external materials, including lenses and gaskets, are UV-resistant to prevent degradation from sun exposure.

- Vibration Resistance: For applications in areas with high vibration (e.g., bridges, industrial facilities), choose fixtures tested for vibration resistance.

Many manufacturers offer high power LED lights specifically designed for extreme environments, such as arctic regions, tropical climates, offshore installations, and high-altitude locations. These specialized fixtures often undergo rigorous testing to ensure reliability in challenging conditions.