What is HDI PCB? Types, Design, Stackup & Manufacturing Guide [2026]

RAYPCB manufactures and assembles high-density interconnect PCBs with blind, buried, and micro-vias, built-up laminations, and the highest signal integrity in the industry.

I’ve been designing HDI PCBs for over a decade now, and I still remember the first time I had to route a 0.4mm pitch BGA on a conventional board. It was a nightmare. The traces were too wide, the vias took up too much space, and I ended up needing 12 layers just to break out from one chip. That’s when I really understood why HDI PCB technology exists—and why every serious PCB engineer needs to master it.

In this guide, I’ll walk you through everything you need to know about HDI PCB technology in 2026. Whether you’re trying to understand the basics or looking to optimize your next high-density design, this article covers the fundamentals, the different types, design guidelines, stackup configurations, and the manufacturing process. Let’s dive in.

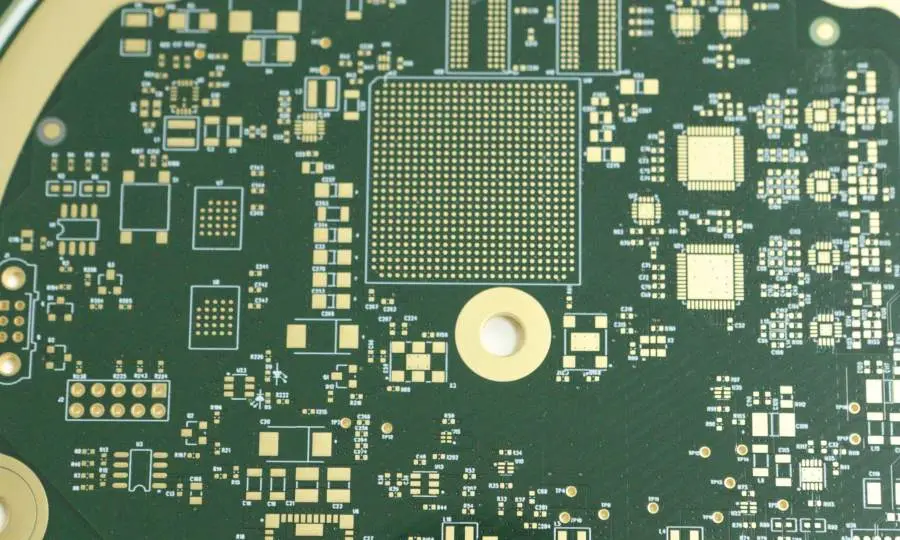

What is HDI PCB?

An HDI PCB (High-Density Interconnect Printed Circuit Board) is a type of circuit board that packs more wiring density per unit area than conventional PCBs. According to IPC-2226, the international standard for HDI design, these boards are characterized by:

- Finer lines and spaces (≤100 µm or 0.10mm)

- Smaller vias with diameters less than 150 µm

- Capture pads smaller than 400 µm (0.40mm)

- Higher connection pad density (more than 20 pads per cm²)

What makes HDI PCB technology special is its use of microvias—laser-drilled holes typically ranging from 50 to 150 microns in diameter. These tiny vias, combined with blind and buried via structures, allow designers to create compact, high-performance boards that would be impossible with traditional through-hole technology.

Why HDI PCB Matters in Modern Electronics

The push toward smaller devices with more functionality has made HDI PCB technology essential. Your smartphone, for instance, contains a motherboard that would have filled an entire desktop computer just 20 years ago. This miniaturization is possible because HDI PCB technology allows:

- Higher component density: More components fit in smaller spaces

- Better signal integrity: Shorter signal paths reduce delays and crosstalk

- Reduced layer count: An 8-layer conventional board can often become a 4-layer HDI board

- Lighter weight: Critical for portable and wearable devices

- Improved reliability: Smaller aspect ratios in microvias mean better plating and fewer failures

The global HDI PCB market was valued at approximately $16.2 billion in 2024 and is projected to reach $24.8 billion by 2029, according to industry research. This growth reflects just how fundamental HDI technology has become across consumer electronics, automotive, medical devices, and telecommunications.

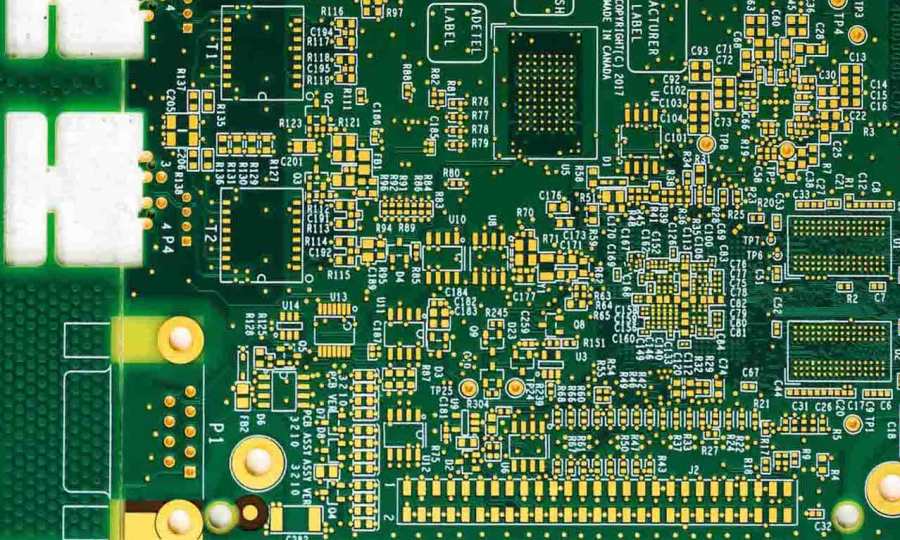

HDI PCB We Served

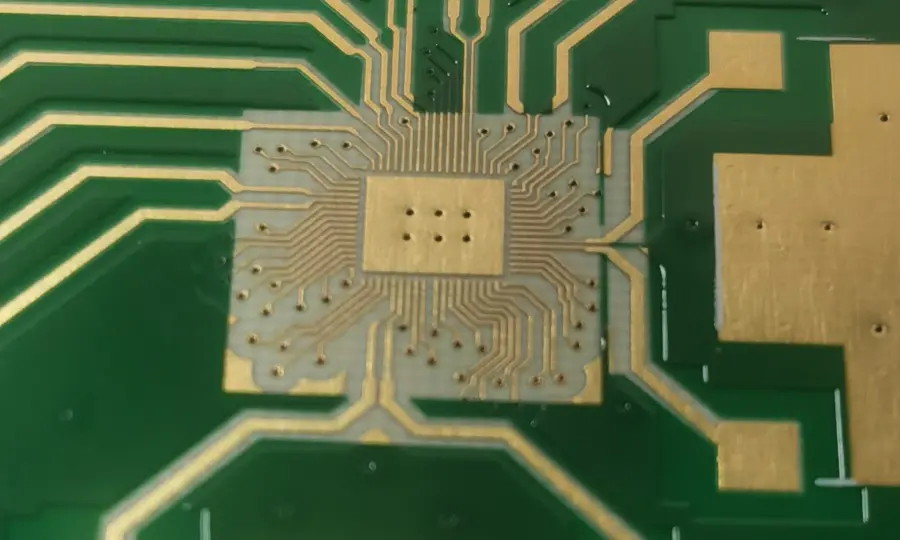

1+N+1 HDI Stack up

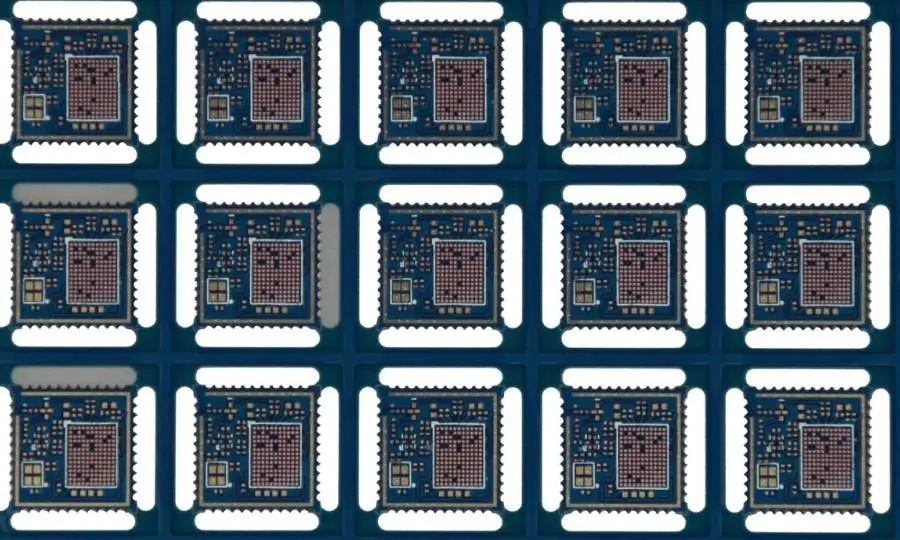

2+N+2 HDI Stack up

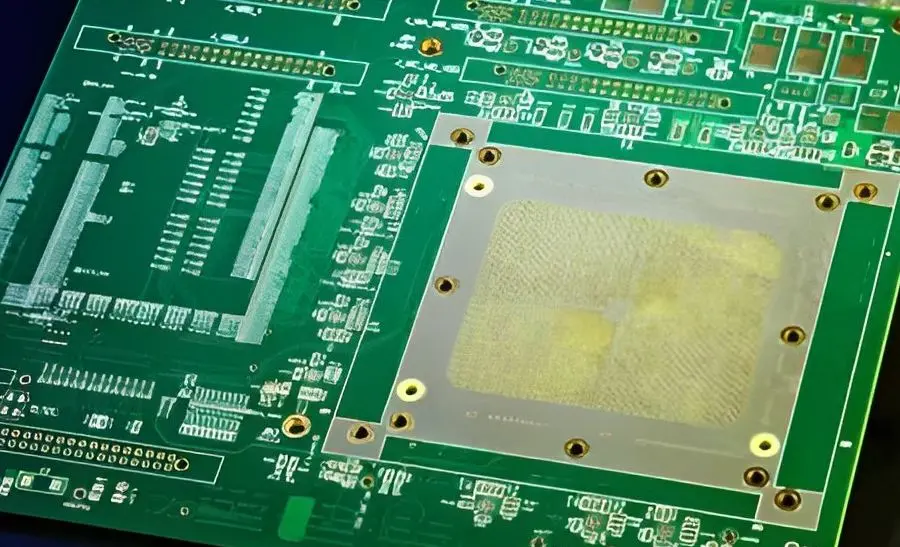

3+N+3 HDI Stack up

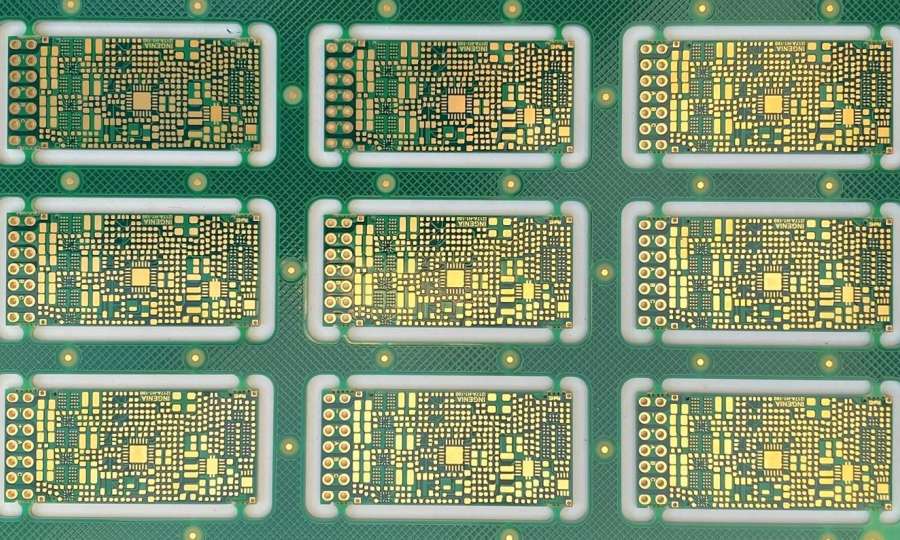

ELIC Anylayer Stackup

HDI PCB vs Standard PCB: Key Differences

Understanding the distinction between HDI PCB and conventional PCB is crucial for making the right design decisions. I’ve worked on projects where clients initially pushed for HDI when conventional boards would have sufficed, and others where they tried to force a design onto standard technology when HDI was clearly needed. Knowing when to use each saves both time and money.

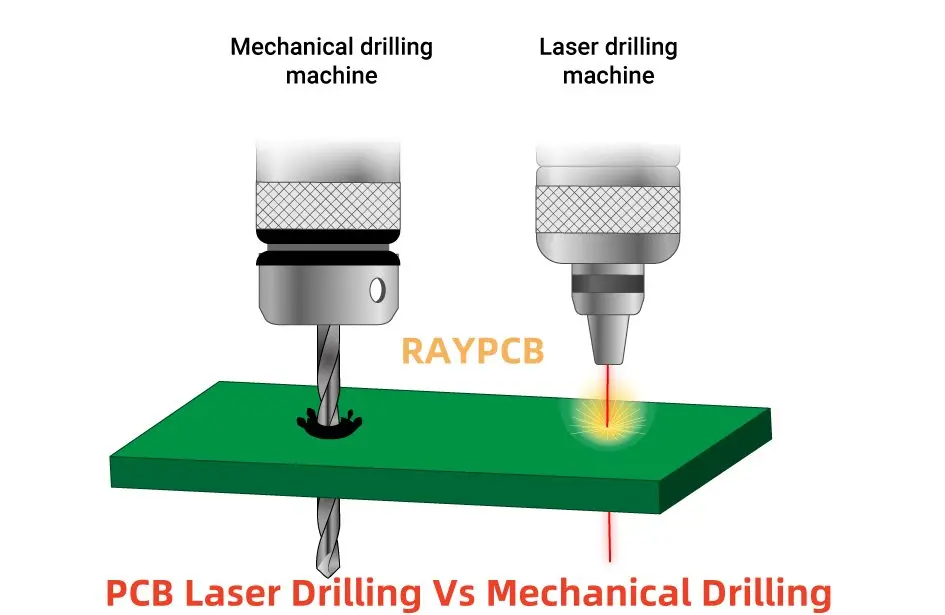

The fundamental difference comes down to interconnect density. A standard PCB relies on mechanically drilled through-holes that span the entire board thickness. These through-holes have practical minimum diameters around 200-250 microns due to drill bit limitations. HDI PCB, in contrast, uses laser-drilled microvias that can be as small as 50 microns and only connect adjacent layers.

Here’s a detailed comparison:

| Feature | Standard PCB | HDI PCB |

|---|---|---|

| Minimum Trace Width | 100-150 µm (4-6 mils) | 50-75 µm (2-3 mils) |

| Minimum Via Diameter | 250-300 µm (10-12 mils) | 50-150 µm (2-6 mils) |

| Via Type | Through-hole vias only | Microvias, blind, buried, stacked |

| Drilling Method | Mechanical drilling | Laser drilling + mechanical |

| Layer Count for Same Function | Higher (8-12 layers) | Lower (4-6 layers) |

| Aspect Ratio | Up to 8:1 | 0.75:1 to 1:1 for microvias |

| BGA Pitch Supported | ≥0.8mm | Down to 0.25mm |

| Manufacturing Cost | Lower | Higher (1.5x to 4x) |

| Lead Time | Shorter | Longer (sequential lamination) |

The key takeaway? HDI PCB isn’t just about making things smaller—it’s about enabling designs that simply cannot exist with conventional technology. When you’re working with modern fine-pitch BGAs, high-speed DDR memory interfaces, or compact IoT devices, HDI becomes a necessity rather than a luxury.

HDI PCB Design Calculator

RAYPCB Engineering Tools

HDI (High Density Interconnect) PCBs use microvias, blind/buried vias, and fine lines to achieve higher routing density. Select the appropriate type based on your design complexity and component requirements.

One buildup layer on each side of the core. Single laser drilling step. Most cost-effective HDI option.

Two buildup layers each side with stacked or staggered microvias. Higher density for complex BGAs.

Three buildup layers with stacked microvias and buried vias in the core. Premium density solution.

Every layer interconnected through stacked copper-filled microvias. Maximum routing flexibility.

| Design Rule | Your Value | Min Required | Max Allowed | Status |

|---|---|---|---|---|

| Line Width | 75 μm | 50 μm | — | ✓ Pass |

| Line Spacing | 75 μm | 50 μm | — | ✓ Pass |

| Microvia Diameter | 100 μm | 75 μm | 150 μm | ✓ Pass |

| Microvia Aspect Ratio | 0.75:1 | — | 1:1 | ✓ Pass |

| Annular Ring | 75 μm | 50 μm | — | ✓ Pass |

| Pad-to-Pad Clearance | 100 μm | 75 μm | — | ✓ Pass |

| Via-to-Via Pitch | 350 μm | 250 μm | — | ✓ Pass |

| Solder Mask Registration | 50 μm | — | 75 μm | ✓ Pass |

Estimates are approximate. Contact your PCB manufacturer for accurate quotes.

- Laser Drill Diameter75-150 μm

- Aspect Ratio (Max)1:1

- Capture Pad≥200 μm

- Target Pad≥150 μm

- Dielectric Thickness60-100 μm

- Copper FillRequired for stacking

- Type I (1+N+1)≥0.4mm pitch

- Type II (2+N+2)≥0.35mm pitch

- Type III (3+N+3)≥0.3mm pitch

- Any Layer HDI<0.25mm pitch

- Via-in-Pad (VIP)Required <0.5mm

- Dog Bone Fanout≥0.65mm pitch

- 4L (1+2+1)0.8-1.6mm

- 6L (1+4+1)1.0-1.6mm

- 8L (2+4+2)1.2-2.0mm

- 10L (2+6+2)1.6-2.4mm

- 12L (3+6+3)1.6-2.4mm

- Buildup Layer60-100 μm typ.

- Standard Line/Space75/75 μm

- Advanced Line/Space50/50 μm

- Ultra Line/Space30/30 μm

- Min Annular Ring50 μm

- Registration Tolerance±25 μm

- Impedance Tolerance±10%

- Type I vs Standard1.3-1.5×

- Type II vs Standard1.8-2.5×

- Type III vs Standard2.5-3.5×

- Any Layer vs Standard4-6×

- Copper-Fill Vias+20-30%

- Advanced Materials+30-100%

This reference guide provides typical industry specifications. Always verify requirements with your specific PCB manufacturer as capabilities may vary.

Types of HDI PCB Structures

HDI PCB structures are classified based on their buildup configuration and via arrangements. The IPC-2226 standard defines six types (Type I through Type VI), but in practice, most designs fall into three main categories plus the advanced Any-Layer HDI option.

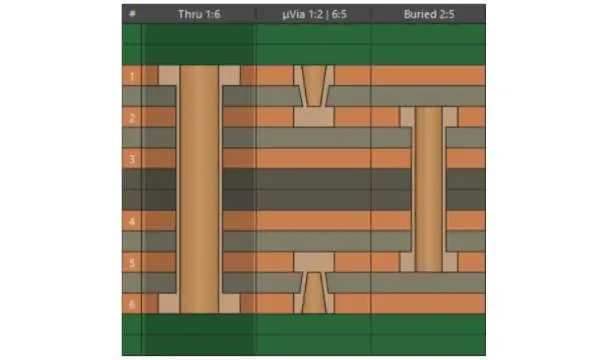

Type I HDI (1+N+1)

Type I HDI represents the simplest and most cost-effective entry into high-density interconnect technology. The notation “1+N+1” means:

- 1 = One HDI buildup layer on the top

- N = Number of conventional core layers

- 1 = One HDI buildup layer on the bottom

In this configuration, you have a single layer of microvias connecting the outer layer to the first inner layer on each side. The core layers use conventional through-hole vias for interconnection.

Specifications for 1+N+1 HDI PCB:

| Parameter | Typical Value |

|---|---|

| Minimum BGA Pitch | 0.4mm |

| Microvia Diameter | 75-100 µm |

| Microvia Depth | 60-80 µm |

| Buildup Layer Thickness | 60-100 µm |

| Cost Multiplier vs Standard | 1.3x – 1.5x |

Best Applications: Basic smartphones, GPS devices, memory cards, tablets, and other consumer electronics that need moderate density improvements.

Type II HDI (2+N+2)

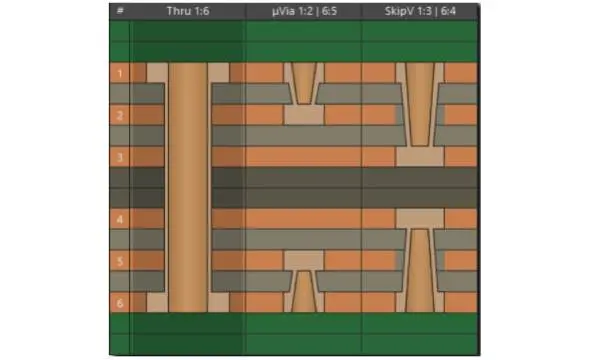

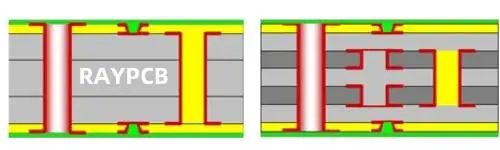

Type II HDI steps up the complexity with two buildup layers on each side of the core. This structure supports either stacked or staggered microvia configurations:

- Stacked microvias: The microvias from layer 1 to 2 align directly on top of microvias from layer 2 to 3. This requires copper-filled vias and precise registration.

- Staggered microvias: The microvias are offset from each other, which is easier to manufacture but uses slightly more routing space.

Key Characteristics of 2+N+2 HDI PCB:

| Parameter | Typical Value |

|---|---|

| Minimum BGA Pitch | 0.35mm |

| Sequential Lamination Cycles | 2 |

| Microvia Configuration | Stacked or staggered |

| Cost Multiplier vs Standard | 1.8x – 2.5x |

The 2+N+2 configuration is probably the most popular HDI stackup for complex designs. It strikes a good balance between routing density, manufacturing complexity, and cost.

Best Applications: High-end smartphones, advanced gaming consoles, automotive ECUs, and network equipment.

Type III HDI (3+N+3 and Beyond)

When 2+N+2 isn’t enough, Type III HDI with 3+N+3 or even 4+N+4 structures come into play. These configurations offer:

- Three or more sequential lamination cycles per side

- Support for BGA pitches down to 0.25mm

- Multiple stacked microvia layers

- Significantly higher routing density

However, with each additional buildup layer, manufacturing complexity and cost increase substantially. Many fabricators recommend staying at 2+N+2 or 3+N+3 unless absolutely necessary.

| HDI Type | Lamination Cycles | Cost Multiplier | Typical Applications |

|---|---|---|---|

| 1+N+1 | 1 | 1.3-1.5x | Consumer electronics |

| 2+N+2 | 2 | 1.8-2.5x | High-end mobile, automotive |

| 3+N+3 | 3 | 2.5-3.5x | 5G infrastructure, AI processors |

| 4+N+4 | 4 | 4x+ | Cutting-edge computing, aerospace |

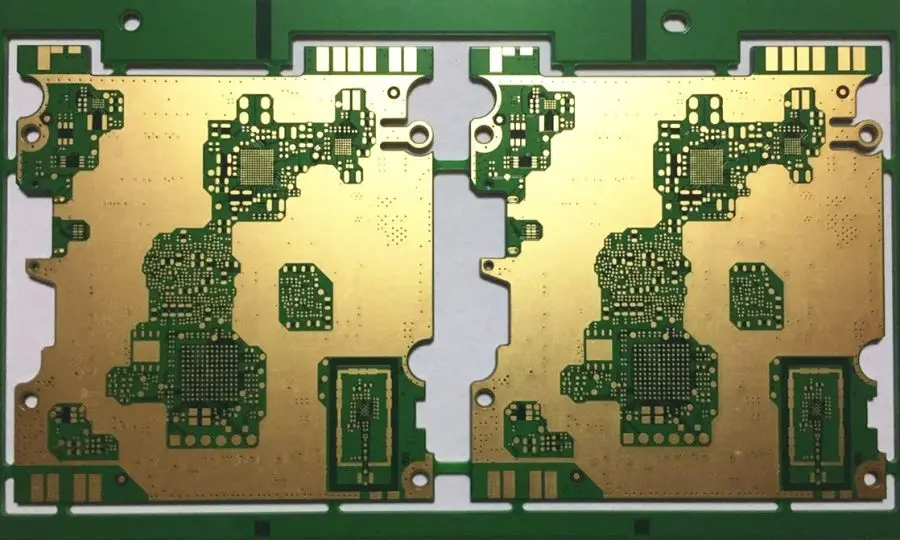

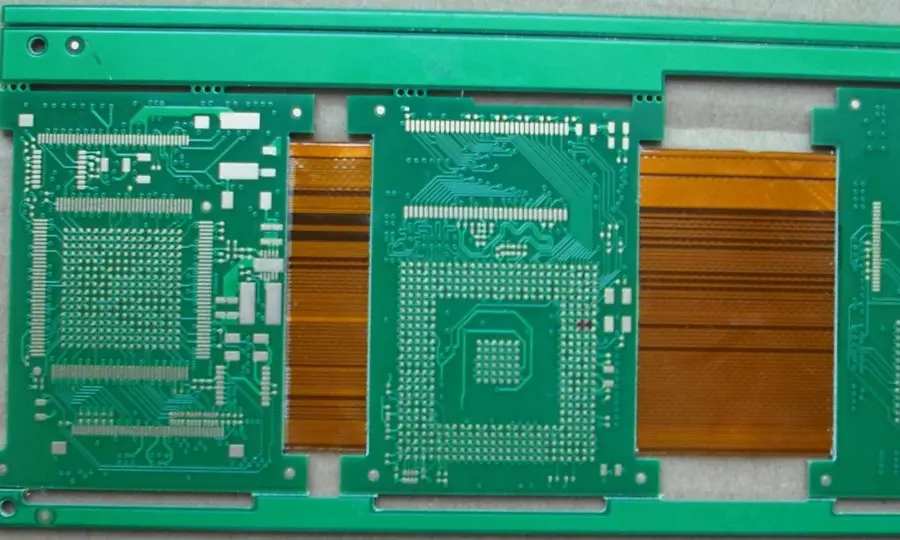

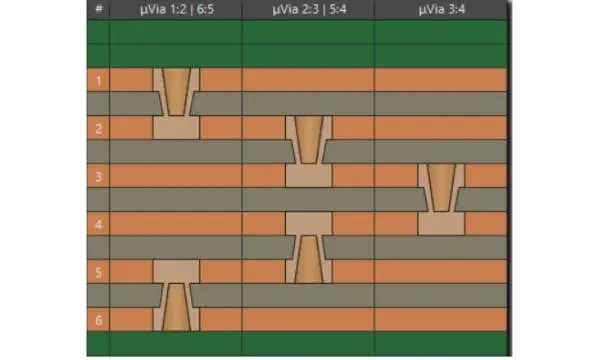

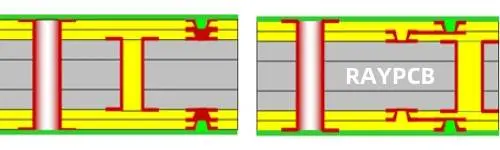

Any-Layer HDI (ELIC)

Every Layer Interconnect (ELIC), also called Any-Layer HDI, represents the pinnacle of HDI technology. In ELIC designs:

- Every layer in the stackup can connect directly to any other layer

- All vias are copper-filled stacked microvias

- There is no conventional core with through-hole vias

- Maximum routing flexibility is achieved

ELIC is commonly used in flagship smartphones (like those from Apple and Samsung), advanced CPUs/GPUs, and cutting-edge AI accelerators. The cost premium is significant (4-6x vs standard PCB), but for applications where space is at an absolute premium, there’s no substitute.

HDI PCB Design Guidelines

Designing an HDI PCB requires careful attention to details that might seem minor but can make or break manufacturability and performance. Here are the critical guidelines I follow in my own designs.

Via Design Rules for HDI PCB

Microvias are the heart of HDI PCB technology, and getting their design right is essential. In my experience, via-related issues account for a significant portion of HDI manufacturing problems. Understanding these rules thoroughly will save you countless revision cycles.

The aspect ratio—the ratio of via depth to diameter—is perhaps the most critical parameter. A microvia with a 100-micron diameter and 100-micron depth has a 1:1 aspect ratio. Why does this matter? When the aspect ratio exceeds 1:1, the copper plating solution cannot adequately reach the bottom of the via during electroplating. This leads to voiding (air pockets in the copper fill) which can cause failures during thermal cycling.

Microvia Specifications:

| Parameter | Recommended Value | Notes |

|---|---|---|

| Diameter | 75-150 µm | Smaller requires UV laser |

| Aspect Ratio | ≤0.75:1 to 1:1 | Critical for reliable plating |

| Capture Pad | 250-350 µm | Larger than via by 100µm+ |

| Target Pad | 200-300 µm | On landing layer |

| Annular Ring | ≥50 µm | Minimum for manufacturing |

Stacking Rules:

- Stacked vias must be copper-filled for structural integrity

- Don’t stack more than 3-4 microvias without consulting your fabricator

- Staggered configurations are more forgiving for manufacturing

Trace Width and Spacing

HDI PCB designs push traces to their limits:

| Design Class | Trace Width | Spacing | Application |

|---|---|---|---|

| Standard HDI | 75/75 µm | 75 µm | Most HDI designs |

| Advanced HDI | 50/50 µm | 50 µm | High-density BGA fanout |

| Ultra HDI | 30/30 µm | 30 µm | Cutting-edge designs |

Important Considerations:

- Always verify your fabricator’s capabilities before committing to fine-pitch designs

- Trace widths below 75 µm require advanced photolithography

- Spacing below 50 µm significantly increases yield risk

BGA Fanout Strategies

One of the main reasons for using HDI PCB technology is BGA fanout. Here’s how different via strategies enable various BGA pitches:

| BGA Pitch | Via Type | Fanout Strategy |

|---|---|---|

| ≥1.0mm | Standard through-hole | Dog bone with PTH |

| 0.8mm | Microvia | Dog bone with microvia |

| 0.65mm | Via-in-pad | Microvia directly in pad |

| 0.5mm | Via-in-pad + HDI | Filled microvia in pad |

| 0.4mm | 1+N+1 or 2+N+2 | Stacked/staggered microvias |

| ≤0.35mm | 2+N+2 or ELIC | Multiple stacked microvias |

Signal Integrity Considerations

HDI boards often carry high-speed signals, making signal integrity a major concern:

- Impedance Control: Target ±10% tolerance on controlled impedance traces

- Reference Planes: Maintain solid ground/power planes beneath signal layers

- Via Stubs: Microvias naturally eliminate stubs, improving high-frequency performance

- Return Path: Keep signal and return current paths close together

- Crosstalk: Use 3W rule (space between traces = 3× trace width) where possible

Thermal Management in HDI PCB

Dense HDI PCB designs concentrate heat in smaller areas:

- Use thermal vias (arrays of small vias) under hot components

- Consider copper-filled vias for better thermal conductivity

- Plan power and ground planes to spread heat laterally

- Follow IPC-2226 guidelines for thermal design

HDI PCB Stackup Design

The stackup is the foundation of any HDI PCB design. Getting it right affects everything from signal integrity to manufacturing yield.

Understanding HDI PCB Stackup Notation

The i+N+i notation describes the HDI buildup structure:

- i = Number of HDI buildup layers on each side

- N = Number of conventional core layers

For example, a 2+4+2 stackup has:

- 2 HDI layers on top (Layers 1 and 2)

- 4 core layers in the middle (Layers 3-6)

- 2 HDI layers on bottom (Layers 7 and 8)

- Total: 8 layers

Common HDI PCB Stackup Configurations

Here are typical stackup configurations I use for different applications:

6-Layer 1+4+1 HDI Stackup:

| Layer | Type | Thickness | Purpose |

|---|---|---|---|

| L1 | Signal | 35µm Cu | Top routing + components |

| Prepreg | Dielectric | 75µm | Microvia dielectric |

| L2 | Ground | 35µm Cu | Reference plane |

| Core | Dielectric | 400µm | Core dielectric |

| L3 | Power | 35µm Cu | Power distribution |

| Prepreg | Dielectric | 100µm | Lamination |

| L4 | Ground | 35µm Cu | Reference plane |

| Core | Dielectric | 400µm | Core dielectric |

| L5 | Signal | 35µm Cu | Inner routing |

| Prepreg | Dielectric | 75µm | Microvia dielectric |

| L6 | Signal | 35µm Cu | Bottom routing + components |

Total Thickness: ~1.2mm

Material Selection for HDI PCB

Material choice significantly impacts HDI PCB performance:

| Material Type | Dk Value | Df Value | Tg | Best For |

|---|---|---|---|---|

| Standard FR-4 | 4.2-4.5 | 0.02 | 130-140°C | General HDI |

| High-Tg FR-4 | 4.2-4.5 | 0.02 | 170-180°C | High reliability |

| Mid-Loss (Megtron 4) | 3.8-4.0 | 0.005-0.008 | 175°C | High-speed digital |

| Low-Loss (Megtron 6) | 3.4-3.6 | 0.002-0.004 | 185°C | RF, mmWave |

| Rogers RO4350B | 3.48 | 0.004 | 280°C | RF applications |

Material Selection Tips:

- Match CTE (Coefficient of Thermal Expansion) across layers to prevent warping

- Use laser-drillable prepregs for HDI layers

- Consider cost—advanced materials can be 2-5x more expensive than FR-4

HDI PCB Manufacturing Process

Understanding the manufacturing process helps you design more manufacturable boards. HDI PCB manufacturing differs significantly from conventional PCB fabrication, and this knowledge has saved me from countless design mistakes over the years.

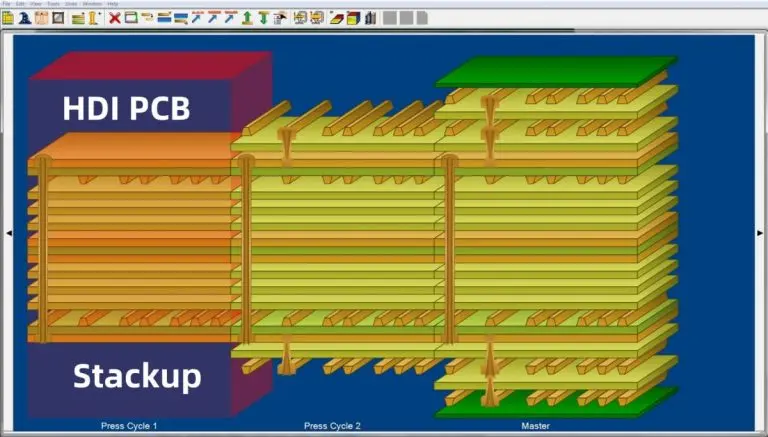

The complexity of HDI manufacturing explains both its higher cost and longer lead times. While a conventional 4-layer board might go through the press once and be done, an HDI board with a 2+N+2 structure goes through the press four times, with drilling, plating, and imaging steps between each lamination cycle.

Sequential Lamination: The Core of HDI Manufacturing

Unlike conventional PCBs that are laminated in a single step, HDI PCBs use sequential lamination:

- Core Fabrication: Inner layers are manufactured and laminated as a conventional multilayer

- First Buildup: Prepreg and copper foil are laminated to the core

- Laser Drilling: Microvias are drilled in the first buildup layer

- Via Metallization: Microvias are plated and possibly filled

- Pattern Transfer: Circuit pattern is imaged and etched

- Repeat: Steps 2-5 repeat for each additional HDI layer

For a 2+N+2 stackup, this means at least 4 lamination cycles (one for the core, plus one for each buildup layer on each side).

Laser Drilling Technology

Laser drilling is what makes microvias possible:

Laser Types for HDI PCB:

| Laser Type | Wavelength | Hole Size | Best For |

|---|---|---|---|

| CO2 | 10.6 µm (IR) | 75-150 µm | RCC, non-glass materials |

| UV (Nd:YAG) | 355 nm | 25-100 µm | Glass-reinforced materials |

| UV Excimer | 248/308 nm | <50 µm | Ultra-fine microvias |

| CO2 + UV Combo | Both | 50-150 µm | Production flexibility |

Key Laser Drilling Parameters:

- Typical microvia depth: 50-100 µm

- Maximum aspect ratio: 1:1 (depth:diameter)

- Hole size tolerance: ±3 mils (much tighter than mechanical drilling)

- Throughput: Much faster than mechanical drilling for dense via arrays

Via Metallization Methods

After laser drilling, microvias need to be metallized:

- Desmear: Remove resin residue from via bottom

- Electroless Copper: Deposit thin conductive seed layer

- Electrolytic Plating: Build up copper thickness

- Via Filling (if required): Fill with conductive or non-conductive material

- Planarization: Flatten surface for subsequent layers

For stacked microvias, copper filling is essential to provide a solid base for the next via.

Quality Control in HDI PCB Manufacturing

HDI PCBs require more rigorous testing than conventional boards:

| Test Type | Purpose | Standard |

|---|---|---|

| Microsection Analysis | Via quality, layer thickness | IPC-A-600 |

| Impedance Testing | Verify controlled impedance | IPC-2141 |

| Flying Probe | Electrical continuity | IPC-9252 |

| X-Ray Inspection | Layer alignment, via fill | Internal |

| Thermal Cycling | Reliability verification | IPC-TM-650 |

HDI PCB Applications by Industry

HDI PCB technology has become essential across multiple industries. Understanding where and why HDI is used helps designers appreciate the requirements and constraints specific to each application.

Consumer Electronics

This sector drives the majority of HDI PCB demand and has been the primary force pushing HDI technology forward:

- Smartphones: Flagship phones use 2+N+2 or ELIC stackups with 8-12 layers to integrate application processors, modems, memory, power management, and RF front-ends in incredibly tight spaces. The latest iPhones and Galaxy devices use any-layer HDI to achieve the thinnest possible form factors.

- Tablets: 1+N+1 to 2+N+2 depending on complexity. While tablets have more space than phones, the push for thinner devices and longer battery life drives HDI adoption.

- Wearables: Ultra-thin HDI with flexible sections. Smartwatches and fitness trackers often use rigid-flex HDI to wrap around batteries and accommodate complex sensor arrays.

- Gaming Consoles: High layer count HDI for powerful processors. The PlayStation and Xbox use HDI to support high-bandwidth memory interfaces and powerful APUs.

- True Wireless Earbuds: Perhaps the most extreme example of miniaturization, where entire audio systems must fit in a tiny enclosure.

Automotive Electronics

Modern vehicles are essentially computers on wheels, and the automotive sector has become one of the fastest-growing markets for HDI PCB:

- ADAS Systems: Camera modules, radar, LiDAR processing units that enable collision avoidance, lane keeping, and autonomous driving features require dense, high-reliability HDI

- Infotainment: High-resolution displays, connectivity modules, and audio processing demand HDI for space efficiency

- EV Battery Management: High-current, high-reliability designs that monitor and balance hundreds of battery cells

- Autonomous Driving: AI processors requiring ELIC-level HDI to support massive computational requirements

- Vehicle-to-Everything (V2X): Communication modules for connected vehicles

Automotive HDI must meet IATF 16949 quality standards and often requires extended temperature range operation (-40°C to +125°C). The reliability requirements are significantly higher than consumer electronics, with expected lifetimes of 15+ years.

Medical Devices

Healthcare relies heavily on compact, reliable electronics, and HDI enables life-saving miniaturization:

- Implantable Devices: Pacemakers, neural stimulators, cochlear implants—devices that must function reliably inside the human body for years

- Diagnostic Equipment: Portable ultrasound, patient monitors, blood analyzers that bring laboratory-quality testing to the bedside

- Surgical Instruments: Minimally invasive tools with cameras and sensors that fit through tiny incisions

- Imaging Systems: CT, MRI, endoscopes with high-resolution image processing

- Wearable Health Monitors: Continuous glucose monitors, ECG patches, and other devices for chronic disease management

Medical HDI PCBs require ISO 13485 certification and extreme reliability. Failure is simply not an option when patient lives are at stake.

Telecommunications and 5G

The 5G rollout has accelerated HDI adoption significantly:

- Base Stations: RF front-ends with mixed HDI/RF materials, massive MIMO antenna arrays

- Network Equipment: High-speed routers and switches processing terabits of data

- mmWave Modules: Ultra-low-loss HDI for 28GHz+ frequencies where every dB of insertion loss matters

- Small Cells: Compact 5G nodes for dense urban deployments

- Fiber Optic Transceivers: High-speed optical modules for data center interconnects

Aerospace and Defense

Mission-critical applications demand the highest reliability and often the most advanced HDI technology:

- Avionics: Flight controls, navigation systems, communication equipment—all subject to extreme vibration, temperature, and reliability requirements

- Satellite Electronics: Space-qualified HDI designs that must survive launch stresses and operate in radiation environments

- Radar Systems: High-frequency, high-reliability HDI for defense applications

- Unmanned Vehicles: Drones and autonomous systems with size and weight constraints

- Military Communications: Secure, ruggedized electronics for battlefield use

HDI PCB Cost Factors and Optimization

HDI PCBs cost more than conventional boards, but smart design choices can control expenses. Understanding where costs come from allows you to make informed trade-offs between performance and budget.

The cost premium for HDI comes from several factors. First, the equipment: laser drilling machines cost millions of dollars and require specialized maintenance. Second, the process: sequential lamination means the board goes through the fabrication cycle multiple times, with each cycle adding time and opportunities for defects. Third, yields: tighter tolerances mean more boards fail inspection.

However, I’ve seen many cases where HDI actually reduced total product cost. How? By enabling smaller boards (less material), fewer layers (less processing), and smaller enclosures (less mechanical cost). The key is to optimize the HDI design itself.

Primary Cost Drivers

| Factor | Impact | How to Optimize |

|---|---|---|

| Layer Count | High | Maximize routing efficiency per layer |

| HDI Structure | High | Use 1+N+1 if 2+N+2 isn’t necessary |

| Via Stacking | Medium | Staggered vias cost less than stacked |

| Trace/Space | Medium | Stay at 75/75 µm if possible |

| Materials | High | Use standard FR-4 unless specs require otherwise |

| Panel Size | Medium | Design for optimal panel utilization |

Cost Comparison by HDI Type

| HDI Type | Relative Cost | Lead Time |

|---|---|---|

| Standard PCB | 1x | 5-7 days |

| 1+N+1 HDI | 1.3-1.5x | 10-14 days |

| 2+N+2 HDI | 1.8-2.5x | 14-21 days |

| 3+N+3 HDI | 2.5-3.5x | 21-28 days |

| Any-Layer ELIC | 4-6x | 28-35 days |

Design-for-Cost Tips

Based on my experience optimizing HDI designs for production, here are the strategies that deliver the best cost savings:

- Right-size your HDI: Don’t use 2+N+2 when 1+N+1 will work. I’ve seen designers default to more complex structures “just in case” when a simpler approach would suffice.

- Standardize via sizes: Stick to your fabricator’s preferred dimensions. Non-standard sizes require tooling changes and slow production.

- Consider staggered vias: They’re easier and cheaper than stacked vias because they don’t require the same precision in registration.

- Optimize layer count: Every 2 layers adds 15-20% to cost. Spend time on routing efficiency to minimize layers.

- Early DFM review: Catch issues before they become expensive changes. A via that’s 10 microns too small might require complete redesign.

- Panel utilization: Design board dimensions to fit efficiently on standard panel sizes. An extra 5mm can sometimes drop panel utilization significantly.

- Standard materials: Use FR-4 where possible. Advanced materials like Megtron or Rogers add 30-100% to material costs.

- Minimize buried vias: Buried vias in the core require additional drilling operations before lamination. Use them only when necessary.

- Consistent copper weights: Mixing heavy copper on some layers with thin copper on others complicates manufacturing.

- Consider volume: HDI becomes more economical at higher volumes due to reduced setup time per unit.

Useful Resources for HDI PCB Design

Here are essential resources every HDI PCB designer should bookmark. I’ve used all of these over the years and can vouch for their value.

IPC Standards (Available at ipc.org)

These are the authoritative documents for HDI PCB design and manufacturing:

- IPC-2226: Sectional Design Standard for HDI PCBs—the primary reference for HDI types and design rules

- IPC-2315: Design Guide for HDI and Microvias—practical guidance beyond the standards

- IPC-4104: HDI and Microvia Materials Specification—essential for material selection

- IPC-6016: Qualification and Performance for HDI PCBs—defines acceptance criteria

- IPC-A-600: Acceptability of Printed Boards—visual inspection criteria with excellent photos

- IPC-2221: Generic Standard on Printed Board Design—foundational PCB design rules

While IPC standards require purchase, they’re essential investments for serious HDI designers. Many fabricators can provide access or summaries.

Design Software Resources

Most major EDA vendors provide HDI-specific documentation:

- Altium Designer HDI Documentation: resources.altium.com—excellent tutorials and application notes on HDI stackup design, via structures, and signal integrity

- Cadence Allegro HDI Guide: cadence.com/resources—comprehensive guides for high-density design in Allegro

- Mentor Xpedition HDI: siemens.com/eda—focused on complex HDI routing and DFM

- KiCad HDI Guides: Community-developed guides for open-source HDI design

Calculators and Tools

These free and commercial tools help with HDI design calculations:

- Saturn PCB Toolkit: Free impedance and via calculator—a must-have for any PCB designer

- Altium PDN Analyzer: Power delivery network analysis for HDI designs

- Polar Instruments SI Speedstack: Professional stackup and impedance design tool

- ANSYS SIwave: Signal integrity simulation for high-speed HDI

- Cadence Sigrity: Advanced electromagnetic simulation for HDI validation

Manufacturer Design Guides

Most reputable HDI PCB manufacturers offer free design guides. Check the documentation sections of companies like:

- NCAB Group: Excellent HDI design guidelines available for download

- Sierra Circuits: Detailed HDI design rules and DFM guides

- TTM Technologies: Technical resources for advanced HDI

- AT&S: European manufacturer with strong HDI documentation

- Unimicron: Major Asian HDI producer with design support

- PCBONLINE: Comprehensive HDI manufacturing guides

- WellPCB: HDI design tips and manufacturing capabilities

Industry Publications and Websites

Stay current with HDI technology developments:

- IPC APEX EXPO: Annual conference with HDI technical sessions

- PCB Design Magazine: Regular HDI-focused articles

- Printed Circuit Design & Fab: Industry news and technical features

- LinkedIn HDI Groups: Professional networking and knowledge sharing

Frequently Asked Questions About HDI PCB

What is the difference between HDI PCB and multilayer PCB?

A multilayer PCB refers to any board with three or more layers, while HDI PCB specifically refers to boards with high wiring density achieved through microvias, blind/buried vias, and fine traces. All HDI PCBs are multilayer, but not all multilayer PCBs are HDI. The key distinction is the via technology: HDI uses laser-drilled microvias (typically <150µm diameter) while conventional multilayer boards rely on mechanically drilled through-holes (typically >200µm). HDI also features finer traces (≤100µm) and higher pad density (>20 pads/cm²) as defined by IPC-2226.

How much does HDI PCB cost compared to standard PCB?

HDI PCB typically costs 1.3x to 6x more than standard PCB, depending on complexity. A basic 1+N+1 structure adds about 30-50% to the cost, while 2+N+2 adds 80-150%. Advanced Any-Layer HDI (ELIC) can cost 4-6 times more than conventional boards. The higher cost comes from sequential lamination (multiple pressing cycles), laser drilling equipment, tighter tolerances, and lower manufacturing yields. However, HDI often reduces total system cost by enabling smaller enclosures, fewer layers for the same functionality, and improved performance that eliminates the need for additional signal conditioning components.

What is the maximum aspect ratio for HDI microvias?

The industry-standard maximum aspect ratio for HDI microvias is 1:1 (depth-to-diameter ratio), though 0.75:1 is preferred for optimal reliability. This means a microvia that is 100µm deep should have a minimum diameter of 100µm. Higher aspect ratios make it difficult to achieve uniform copper plating inside the via, leading to potential voids and reliability issues. For comparison, conventional through-hole vias can have aspect ratios up to 8:1 or even 10:1. The lower aspect ratio requirement for microvias is why they’re limited to connecting adjacent layers (maximum depth around 100µm) and why stacking is required for deeper connections.

When should I use HDI PCB instead of conventional PCB?

You should consider HDI PCB when your design requires: BGA components with pitch below 0.8mm, high component density that can’t be achieved with through-hole technology, thin board profiles (<1mm), high-speed signals requiring short via stubs, or reduced layer count for cost optimization. Specific indicators include: inability to fanout from fine-pitch BGAs using conventional vias, needing more than 8 layers with conventional technology for routing, weight-critical applications like wearables or aerospace, or signal integrity issues caused by via stubs in high-frequency designs. If your design can be achieved with conventional 4-6 layer boards and 0.8mm+ pitch components, standard PCB is usually more cost-effective.

What IPC standards apply to HDI PCB design and manufacturing?

The primary IPC standards for HDI PCB include: IPC-2226 (Sectional Design Standard for HDI) which defines HDI types I-VI and design requirements; IPC-2315 (Design Guide for HDI and Microvias) which provides design recommendations; IPC-4104 (HDI and Microvia Materials Specification) covering material requirements; IPC-6016 (Qualification and Performance Specification for HDI PCBs); and IPC-A-600 (Acceptability of Printed Boards) for visual inspection criteria. Additionally, IPC-2221 provides general PCB design guidelines that apply to HDI, and IPC-6012 covers rigid PCB performance specifications including some HDI requirements. For quality management, manufacturers should be ISO 9001 certified, with automotive applications requiring IATF 16949 and medical requiring ISO 13485.

Conclusion: The Future of HDI PCB Technology

HDI PCB technology continues to evolve as electronic devices demand even greater miniaturization and performance. Looking ahead to 2026 and beyond, we’re seeing several trends:

- Ultra-fine features: Lines and spaces pushing below 30µm

- Embedded components: Resistors and capacitors buried within PCB layers

- Advanced materials: Lower-loss dielectrics for mmWave applications

- 3D integration: HDI combined with IC substrates and interposers

- Sustainable manufacturing: Lead-free, halogen-free HDI processes

For PCB designers, mastering HDI technology is no longer optional—it’s essential for working on modern electronics. The investment in understanding HDI PCB types, design rules, stackup configurations, and manufacturing processes pays dividends in better products and more successful designs.

Whether you’re designing a smartphone, an automotive ADAS system, or a medical implant, HDI PCB technology provides the tools to pack more functionality into less space while maintaining the signal integrity and reliability your products demand.

The key to success? Start with a solid understanding of the fundamentals, work closely with your fabrication partners, and never stop learning as this technology continues to advance.