Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry, allowing for smaller, more complex, and more reliable electronic devices. However, maintaining high-quality standards in SMT assembly processes can be challenging. This comprehensive guide explores various effective measures to improve SMT assembly quality, ensuring that manufacturers can produce consistent, high-performance electronic products.

Understanding SMT Assembly

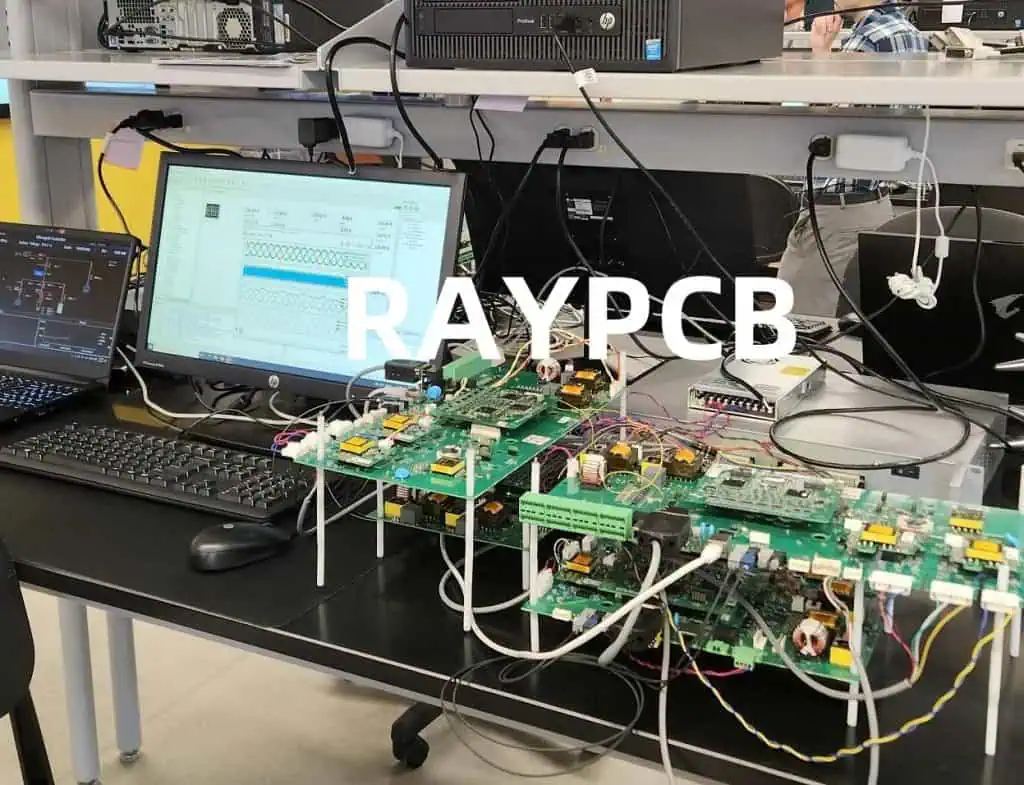

Surface Mount Technology (SMT) assembly is a method of producing electronic circuits where components are mounted directly onto the surface of printed circuit boards (PCBs). This technique has largely replaced through-hole technology in modern electronics manufacturing due to its numerous advantages:

- Increased component density

- Smaller overall product size

- Improved electrical performance

- Higher production speeds

- Lower manufacturing costs

However, the complexity of SMT assembly processes also brings challenges in maintaining consistent quality. Understanding these challenges is crucial for implementing effective quality improvement measures.

Key Factors Affecting SMT Assembly Quality

Several factors can significantly impact the quality of SMT assemblies. Identifying and addressing these factors is essential for improving overall production quality.

Component Quality

The quality of individual components used in SMT assembly plays a crucial role in the final product’s performance and reliability. Key considerations include:

- Component specifications and tolerances

- Storage and handling procedures

- Supplier quality management

PCB Design and Quality

The design and quality of the printed circuit board itself can greatly affect the success of SMT assembly. Important factors include:

- PCB material selection

- Trace width and spacing

- Pad design and solder mask considerations

- Thermal management features

Solder Paste Application

Proper solder paste application is critical for creating reliable solder joints. Factors affecting solder paste application quality include:

- Stencil design and thickness

- Solder paste composition and viscosity

- Printing pressure and speed

- Storage and handling of solder paste

Component Placement

Accurate and consistent component placement is essential for high-quality SMT assemblies. Key considerations include:

- Pick-and-place machine accuracy and calibration

- Component feeder maintenance and setup

- Vision system performance

- Placement force and speed

Reflow Soldering

The reflow soldering process is critical for creating strong and reliable solder joints. Factors affecting reflow quality include:

- Reflow oven profile design

- Temperature uniformity across the PCB

- Atmosphere control (e.g., nitrogen vs. air reflow)

- Cooling rate management

Process Optimization Techniques

Optimizing the SMT assembly process is crucial for improving overall quality. Here are some effective techniques:

Design for Manufacturability (DFM)

Implementing DFM principles early in the product development cycle can significantly improve SMT assembly quality. Key DFM considerations include:

- Component selection and placement optimization

- Standardization of pad layouts

- Thermal relief design for large components

- Adequate spacing for inspection and rework

Statistical Process Control (SPC)

Implementing SPC techniques can help identify and address process variations before they lead to quality issues. Key SPC tools include:

- Control charts for monitoring critical parameters

- Capability analysis to assess process stability

- Root cause analysis for addressing recurring issues

Poka-Yoke (Error-Proofing)

Implementing error-proofing mechanisms can prevent common assembly mistakes. Examples include:

- Barcode scanning for component verification

- Automated optical alignment for stencil printing

- Sensor-based detection of missing or misaligned components

Process Documentation and Standardization

Developing and maintaining comprehensive process documentation helps ensure consistency across production runs. Key elements include:

- Detailed work instructions

- Process flow charts

- Equipment setup parameters

- Quality check procedures

Quality Control Measures

Implementing robust quality control measures is essential for identifying and addressing issues in SMT assembly. Here are some effective quality control techniques:

Automated Optical Inspection (AOI)

AOI systems use high-resolution cameras and advanced image processing algorithms to detect defects in SMT assemblies. Benefits of AOI include:

- High-speed inspection capabilities

- Consistent and objective defect detection

- Early identification of process issues

X-ray Inspection

X-ray inspection is particularly useful for detecting defects in hidden solder joints, such as those found in Ball Grid Array (BGA) components. Advantages include:

- Non-destructive inspection of internal structures

- Detection of voids, bridging, and insufficient solder

- 3D imaging capabilities for complex assemblies

In-Circuit Testing (ICT)

ICT involves electrically testing assembled PCBs to verify proper component placement and functionality. Benefits of ICT include:

- Comprehensive electrical testing of assemblies

- Rapid identification of faulty components or connections

- High throughput for production environments

Functional Testing

Functional testing involves operating the assembled product under simulated real-world conditions to verify performance. Key aspects include:

- Custom test fixtures and programs for each product

- Environmental stress testing (e.g., temperature cycling)

- Long-term reliability testing

Data Collection and Analysis

Implementing a robust data collection and analysis system can help identify trends and opportunities for improvement. Key considerations include:

- Automated data collection from inspection and test equipment

- Real-time monitoring and alerting systems

- Advanced analytics for identifying correlations and root causes

Advanced Technologies for SMT Assembly

Leveraging advanced technologies can significantly improve SMT assembly quality. Here are some cutting-edge solutions:

3D Solder Paste Inspection (SPI)

3D SPI systems use advanced optical techniques to measure solder paste volume and alignment with high precision. Benefits include:

- Early detection of solder paste application issues

- Improved process control through real-time feedback

- Reduced defects related to insufficient or excess solder

Artificial Intelligence and Machine Learning

AI and machine learning algorithms can enhance various aspects of SMT assembly, including:

- Defect classification and prediction

- Optical inspection accuracy improvement

- Process parameter optimization

Industry 4.0 Integration

Implementing Industry 4.0 principles can improve overall SMT assembly quality through:

- Real-time equipment monitoring and predictive maintenance

- Automated material tracking and inventory management

- Digital twin simulations for process optimization

Advanced Placement Technologies

New component placement technologies can improve accuracy and speed, such as:

- Multi-head placement systems for increased throughput

- High-precision linear motors for improved placement accuracy

- Advanced vision systems for component recognition and alignment

Training and Workforce Development

Investing in workforce training and development is crucial for maintaining high-quality SMT assembly operations. Key areas to focus on include:

Technical Skills Training

Provide comprehensive training on SMT assembly techniques, equipment operation, and troubleshooting. Topics should include:

- SMT process fundamentals

- Equipment-specific training

- Defect identification and resolution

- Process control techniques

Quality Awareness Programs

Develop programs to foster a culture of quality throughout the organization. Elements may include:

- Quality management system principles

- Root cause analysis techniques

- Continuous improvement methodologies

- Customer requirements and expectations

Cross-Training and Skill Diversification

Encourage cross-training to improve flexibility and problem-solving capabilities:

- Rotate staff through different SMT assembly stages

- Provide opportunities for learning advanced inspection techniques

- Offer training in related areas (e.g., PCB design, component engineering)

Certification Programs

Support employee participation in industry-recognized certification programs, such as:

- IPC Certification for SMT Processes

- Six Sigma and Lean Manufacturing certifications

- Equipment-specific certifications from manufacturers

Environmental Considerations

Maintaining proper environmental conditions is crucial for SMT assembly quality. Key factors to consider include:

Temperature and Humidity Control

Maintain stable temperature and humidity levels in the production area:

| Parameter | Recommended Range |

| Temperature | 20-26°C (68-79°F) |

| Humidity | 30-60% RH |

Electrostatic Discharge (ESD) Protection

Implement comprehensive ESD protection measures:

- ESD-safe flooring and workstations

- Proper grounding of equipment and personnel

- Use of ionizers in critical areas

Contamination Control

Minimize contamination risks through:

- HEPA filtration systems

- Regular cleaning and maintenance schedules

- Proper storage and handling of materials

Lighting Conditions

Ensure adequate lighting for assembly and inspection tasks:

- Use high-quality, flicker-free LED lighting

- Implement task-specific lighting for inspection areas

- Consider color temperature for optimal visual acuity

Cost-Effective Quality Improvement Strategies

Implementing quality improvement measures doesn’t always require significant capital investment. Here are some cost-effective strategies:

Process Audit and Optimization

Regularly review and optimize existing processes:

- Conduct value stream mapping to identify inefficiencies

- Implement 5S methodology for workplace organization

- Encourage employee suggestions for process improvements

Preventive Maintenance Programs

Develop comprehensive preventive maintenance schedules:

- Regular calibration of critical equipment

- Proactive replacement of wear items

- Cleaning and lubrication of mechanical components

Supplier Quality Management

Work closely with suppliers to improve component quality:

- Develop clear quality specifications and requirements

- Implement vendor rating systems

- Collaborate on continuous improvement initiatives

Lean Manufacturing Principles

Apply lean manufacturing concepts to SMT assembly:

- Reduce work-in-progress inventory

- Implement pull systems for material flow

- Minimize non-value-added activities

Future Trends in SMT Assembly Quality

As technology continues to evolve, several trends are likely to shape the future of SMT assembly quality:

Miniaturization and High-Density Assemblies

- Increasing use of 01005 and 008004 components

- Development of advanced placement and inspection technologies

- New challenges in thermal management and signal integrity

Flexible and Stretchable Electronics

- Integration of flexible substrates in SMT processes

- Development of new solder materials and techniques

- Challenges in maintaining reliability under mechanical stress

Green Manufacturing Initiatives

- Increased adoption of lead-free and halogen-free materials

- Energy-efficient equipment and processes

- Improved recycling and waste reduction strategies

Augmented Reality in Assembly and Inspection

- AR-assisted assembly instructions and training

- Enhanced visual inspection capabilities

- Real-time process monitoring and guidance

Additive Manufacturing Integration

- 3D printed electronic structures and components

- Hybrid manufacturing processes combining SMT and additive techniques

- New design possibilities for complex 3D electronic assemblies

Frequently Asked Questions

- Q: What is the most critical factor in improving SMT assembly quality? A: While many factors contribute to SMT assembly quality, process control is often considered the most critical. This includes optimizing and maintaining consistency in solder paste application, component placement, and reflow soldering processes. Implementing robust statistical process control (SPC) measures can significantly improve overall quality by identifying and addressing variations before they lead to defects.

- Q: How can I reduce solder defects in SMT assembly? A: To reduce solder defects, focus on the following areas:

- Optimize solder paste printing parameters (e.g., stencil design, printing pressure, and speed)

- Implement 3D solder paste inspection for early defect detection

- Carefully control reflow oven profiles and ensure temperature uniformity

- Use high-quality, properly stored solder paste and components

- Maintain a clean, controlled assembly environment

- Q: What are the benefits of implementing automated inspection systems? A: Automated inspection systems, such as AOI and X-ray inspection, offer several benefits:

- Consistent and objective defect detection

- High-speed inspection capabilities for increased throughput

- Early identification of process issues for quick corrective action

- Improved data collection for trend analysis and process improvement

- Reduced reliance on manual inspection, freeing up skilled workers for other tasks

- Q: How important is operator training in maintaining SMT assembly quality? A: Operator training is crucial for maintaining high SMT assembly quality. Well-trained operators can:

- Properly set up and maintain equipment

- Recognize and respond to process variations

- Identify defects and understand their root causes

- Implement and follow standardized procedures

- Contribute to continuous improvement initiatives Investing in comprehensive and ongoing training programs is essential for achieving and maintaining high-quality standards.

- Q: What emerging technologies should I consider for improving SMT assembly quality? A: Several emerging technologies show promise for improving SMT assembly quality:

- Artificial Intelligence and Machine Learning for defect prediction and process optimization

- Industry 4.0 integration for real-time monitoring and control

- Advanced 3D inspection technologies for improved defect detection

- Augmented Reality systems for operator guidance and training

- Additive manufacturing techniques for creating complex electronic structures Consider evaluating these technologies based on your specific production needs and quality improvement goals.