In the world of integrated circuits and digital design, two technologies stand out for their widespread use and distinct characteristics: Field-Programmable Gate Arrays (FPGAs) and Application-Specific Integrated Circuits (ASICs). Both play crucial roles in modern electronics, but they serve different purposes and come with their own sets of advantages and limitations. This article will explore the key differences between FPGAs and ASICs, their applications, and the factors to consider when choosing between them.

Understanding FPGAs

What is an FPGA?

Field-Programmable Gate Arrays (FPGAs) are semiconductor devices that are based around a matrix of configurable logic blocks (CLBs) connected via programmable interconnects. FPGAs can be reprogrammed to desired application or functionality requirements after manufacturing.

Key Features of FPGAs

1. Programmability

The most distinctive feature of FPGAs is their ability to be reprogrammed after manufacturing. This allows for:

- Rapid prototyping

- Field updates and upgrades

- Adaptation to changing standards

2. Flexibility

FPGAs can be configured to implement almost any digital circuit, making them highly versatile for a wide range of applications.

3. Time-to-Market

The reprogrammable nature of FPGAs often results in shorter development cycles and faster time-to-market for products.

4. Cost-Effectiveness for Low-Volume Production

For low to medium volume production, FPGAs can be more cost-effective than developing an ASIC.

FPGA Architecture

FPGAs consist of several key components:

- Configurable Logic Blocks (CLBs)

- Input/Output Blocks (IOBs)

- Programmable Interconnects

- Memory Elements

- Digital Signal Processing (DSP) Blocks

- Clock Management Units

Applications of FPGAs

FPGAs find use in a wide variety of applications, including:

- Aerospace and Defense

- Automotive

- Broadcast and Pro AV

- Data Center

- Industrial

- Medical

- Wired and Wireless Communications

Understanding ASICs

What is an ASIC?

An Application-Specific Integrated Circuit (ASIC) is an integrated circuit chip customized for a particular use, rather than intended for general-purpose use. ASICs are designed and manufactured for a specific application or function.

Key Features of ASICs

1. Customization

ASICs are designed for a specific application, allowing for optimized performance, power efficiency, and size.

2. High Performance

Due to their specialized nature, ASICs typically offer higher performance compared to general-purpose chips.

3. Power Efficiency

Custom design allows for optimization of power consumption, making ASICs more energy-efficient for their specific tasks.

4. Cost-Effectiveness for High-Volume Production

While initial costs are high, ASICs become cost-effective in high-volume production scenarios.

ASIC Design Process

The ASIC design process involves several stages:

- Specification

- Architecture Design

- RTL Design

- Functional Verification

- Logic Synthesis

- Physical Design

- Timing Analysis

- Fabrication

- Testing

Applications of ASICs

ASICs are used in a wide range of applications, including:

- Consumer Electronics

- Automotive

- Telecommunications

- Medical Devices

- Industrial Equipment

- Cryptocurrency Mining

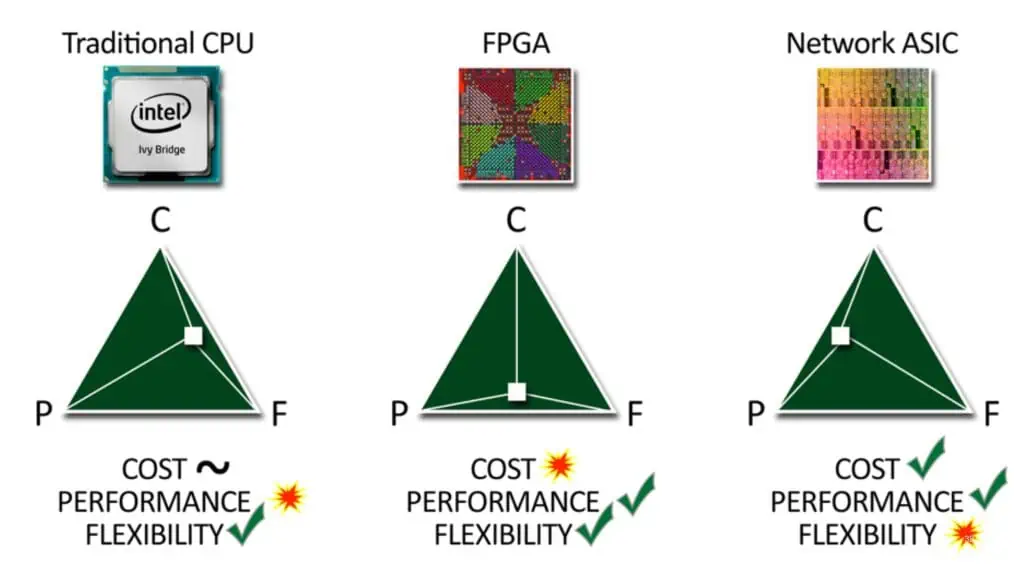

FPGA vs. ASIC: A Comparative Analysis

To better understand the differences between FPGAs and ASICs, let’s compare them across several key parameters:

| Parameter | FPGA | ASIC |

|---|---|---|

| Flexibility | High (Reprogrammable) | Low (Fixed functionality) |

| Performance | Moderate | High |

| Power Efficiency | Moderate | High |

| Time-to-Market | Short | Long |

| Development Cost | Low to Moderate | High |

| Unit Cost (Low Volume) | Lower | Higher |

| Unit Cost (High Volume) | Higher | Lower |

| Design Complexity | Moderate | High |

| Customization | Limited | Extensive |

| Obsolescence Risk | Low | High |

Detailed Comparison

1. Design Flexibility and Time-to-Market

FPGAs offer significant advantages in terms of flexibility and time-to-market:

| Aspect | FPGA | ASIC |

|---|---|---|

| Design Changes | Can be made after deployment | Require new manufacturing run |

| Prototyping | Rapid, can be done in-house | Lengthy, requires foundry involvement |

| Time-to-Market | Weeks to months | Months to years |

| Field Upgrades | Possible through reprogramming | Not possible without hardware replacement |

2. Performance and Power Efficiency

ASICs generally outperform FPGAs in terms of raw performance and power efficiency:

| Aspect | FPGA | ASIC |

|---|---|---|

| Clock Speed | Moderate (100-500 MHz typical) | High (1 GHz+ possible) |

| Power Consumption | Higher | Lower |

| Performance per Watt | Moderate | High |

| Area Efficiency | Lower | Higher |

3. Cost Considerations

The cost dynamics of FPGAs and ASICs vary significantly based on production volume:

| Aspect | FPGA | ASIC |

|---|---|---|

| Non-Recurring Engineering (NRE) Costs | Low | High |

| Unit Cost (Low Volume) | Lower | Higher |

| Unit Cost (High Volume) | Higher | Lower |

| Break-Even Point | Typically 5,000 to 10,000 units | Varies based on complexity |

4. Development and Design Complexity

The development process and design complexity differ substantially between FPGAs and ASICs:

| Aspect | FPGA | ASIC |

|---|---|---|

| Design Tools | Vendor-specific, relatively user-friendly | Complex EDA tools required |

| Design Verification | Simpler, can be done in-house | Complex, often requires specialized teams |

| Manufacturing Process | Standard for all designs | Custom for each design |

| Design Reuse | High (IP cores readily available) | Moderate (requires more adaptation) |

5. Application Suitability

FPGAs and ASICs are suited for different types of applications:

| Application Type | FPGA | ASIC |

|---|---|---|

| Rapid Prototyping | Excellent | Poor |

| Low to Medium Volume Production | Good | Poor |

| High Volume Production | Poor | Excellent |

| Frequently Changing Standards | Excellent | Poor |

| High-Performance Computing | Good | Excellent |

| Power-Critical Applications | Moderate | Excellent |

Choosing Between FPGA and ASIC

The decision to use an FPGA or an ASIC depends on various factors. Here’s a decision matrix to help guide the choice:

| Factor | FPGA Preferred | ASIC Preferred |

|---|---|---|

| Production Volume | Low to Medium | High |

| Time-to-Market | Critical | Less Critical |

| Performance Requirements | Moderate | Very High |

| Power Efficiency | Moderate | Critical |

| Design Flexibility | High | Low |

| Budget for Initial Development | Limited | High |

| Expected Product Lifetime | Short to Medium | Long |

| Need for Field Updates | Yes | No |

Future Trends

As technology continues to evolve, the landscape of FPGAs and ASICs is also changing:

1. Hybrid Solutions

The emergence of hybrid chips that combine FPGA fabric with hard-wired ASIC components is blurring the lines between the two technologies.

2. Advanced Process Nodes

Both FPGAs and ASICs are benefiting from advancements in semiconductor manufacturing, enabling higher performance and lower power consumption.

3. AI and Machine Learning

The rise of AI and machine learning is driving innovation in both FPGA and ASIC design, with specialized architectures emerging for these applications.

4. Open-Source Hardware

The growing open-source hardware movement is making ASIC design more accessible, potentially reducing the cost barrier for custom chip development.

Conclusion

FPGAs and ASICs each have their unique strengths and weaknesses. FPGAs offer unparalleled flexibility and faster time-to-market, making them ideal for rapid prototyping, low to medium volume production, and applications with changing standards. ASICs, on the other hand, provide superior performance, power efficiency, and cost-effectiveness in high-volume production scenarios.

The choice between FPGA and ASIC ultimately depends on the specific requirements of the application, including factors such as production volume, performance needs, power constraints, time-to-market, and budget. As technology continues to advance, we can expect to see further innovations in both FPGA and ASIC technologies, as well as the emergence of hybrid solutions that combine the best of both worlds.

Understanding the differences between FPGAs and ASICs is crucial for engineers, product managers, and decision-makers in the electronics industry. By carefully considering the trade-offs and aligning the choice with project requirements, organizations can optimize their product development processes and deliver innovative solutions to the market.

FAQ

Q1: Can FPGAs be used in high-volume production?

A: While FPGAs are typically more cost-effective for low to medium volume production, they can be used in high-volume production in certain scenarios. This is particularly true when:

- The product lifecycle is expected to be short.

- The ability to update functionality in the field is crucial.

- The performance and power efficiency requirements are not too stringent.

- The unit cost difference compared to an ASIC is outweighed by other factors such as time-to-market or flexibility.

However, for very high volume production (typically over 100,000 units), ASICs usually become more cost-effective due to their lower per-unit cost.

Q2: How long does it typically take to develop an ASIC compared to implementing a design on an FPGA?

A: The development time for ASICs and FPGAs can vary significantly:

- FPGA: Implementing a design on an FPGA typically takes a few weeks to a few months, depending on the complexity of the design. This includes design, verification, and implementation phases.

- ASIC: ASIC development is a much longer process, usually taking 6 to 18 months or even longer for complex designs. This includes stages such as RTL design, verification, logic synthesis, physical design, fabrication, and testing.

The shorter development time for FPGAs is one of their key advantages, allowing for faster time-to-market and easier design iterations.

Q3: Are there any situations where an FPGA might outperform an ASIC?

A: While ASICs generally offer higher performance, there are scenarios where an FPGA might outperform an ASIC:

- Rapidly evolving standards: In fields with frequently changing standards or protocols, an FPGA can be updated to support new standards, while an ASIC would become obsolete.

- Adaptive algorithms: For applications requiring real-time adaptation of algorithms, FPGAs can be reconfigured on-the-fly, potentially outperforming a fixed-function ASIC.

- Parallel processing: Modern FPGAs excel at parallel processing tasks and can sometimes outperform ASICs in specific parallel computing scenarios.

- Latest process nodes: High-end FPGAs are often manufactured using the latest process nodes, which might not be economically viable for lower-volume ASIC production.

Q4: How do the power consumption characteristics of FPGAs and ASICs compare?

A: Generally, ASICs are more power-efficient than FPGAs for the same functionality:

| Aspect | FPGA | ASIC |

|---|---|---|

| Static Power | Higher | Lower |

| Dynamic Power | Higher | Lower |

| Power Efficiency | Moderate | High |

ASICs consume less power because:

- They are optimized for specific functions, eliminating unnecessary circuitry.

- They don’t require the programmable interconnects that contribute to power consumption in FPGAs.

- Custom design allows for advanced power-saving techniques.

However, the power consumption gap has been narrowing with advancements in FPGA technology. For some low-power applications, modern FPGAs can be competitive with ASICs.

Q5: What are the key considerations for choosing between FPGA and ASIC in terms of long-term cost?

A: When considering long-term costs, several factors come into play:

- Production volume: ASICs become more cost-effective at higher volumes, typically beyond 10,000 to 100,000 units, depending on complexity.

- Product lifetime: For products with a long lifetime, ASICs can be more cost-effective even at lower volumes due to lower per-unit costs.

- Upgrade requirements: If field upgrades are necessary, FPGAs can be more cost-effective as they avoid the need for hardware replacement.

- Development costs: ASIC development costs are significantly higher, which must be amortized over the product lifetime.

- Power consumption: In applications where power usage has ongoing costs (e.g., data centers), the higher efficiency of ASICs can lead to long-term savings.

- Maintenance and obsolescence: FPGAs may have lower long-term costs in rapidly evolving fields due to their adaptability.

A simplified cost comparison over time might look like this:

| Time Period | FPGA Cost | ASIC Cost |

|---|---|---|

| Initial Development | $100,000 | $1,000,000 |

| Per-Unit Cost | $50 | $10 |

| 10,000 Units | $600,000 | $1,100,000 |

| 100,000 Units | $5,100,000 | $2,000,000 |

| 1,000,000 Units | $50,100,000 | $11,000,000 |

These numbers are illustrative and can vary widely based on specific circumstances. It’s crucial to perform a detailed cost analysis based on the specific requirements and lifecycle expectations of your project.