When you think of a printed circuit board (PCB), what color comes to mind? For most people, it’s green. The iconic green PCB has become synonymous with electronics and technology. But have you ever wondered why green is the predominant color for these essential components? In this article, we’ll explore the fascinating world of green PCBs, delving into the science behind their color, the history of their development, and the practical reasons for their widespread use in the electronics industry.

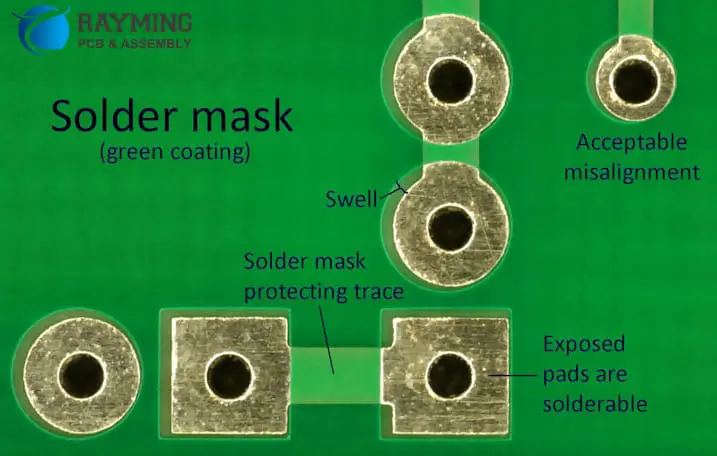

What is a Solder Mask?

Before we dive into the reasons behind the green color, it’s essential to understand what a solder mask is and its role in PCB manufacturing.

Definition and Purpose

A solder mask is a thin layer of polymer applied to the copper traces of a printed circuit board. Its primary functions are:

- To protect the copper traces from oxidation

- To prevent solder bridges between closely spaced solder pads

- To insulate the board from environmental factors

Application Process

The solder mask is typically applied using a screen printing or photoimaging process. After application, it’s cured using UV light or heat, depending on the type of solder mask material used.

The History of Green PCBs

The use of green as the standard color for PCBs has an interesting history that dates back several decades.

Early PCB Manufacturing

In the early days of PCB production, boards were often left uncoated or were coated with a clear or yellowish epoxy resin. These boards were prone to oxidation and other environmental damage.

Introduction of Green Solder Mask

The green solder mask was introduced in the 1960s by the U.S. military. The specific shade, known as “military green” or “olive drab,” was chosen for its ability to meet certain visual and functional requirements.

Widespread Adoption

As the electronics industry grew, the use of green solder mask became increasingly common due to its effectiveness and the standardization of manufacturing processes.

The Science Behind Green Solder Mask

The choice of green for solder masks isn’t just about aesthetics. There are several scientific and practical reasons why green has become the industry standard.

Optimal Light Absorption for Exposure

One of the primary reasons for using green solder mask is its optimal light absorption properties during the manufacturing process.

UV Light Exposure

During PCB manufacturing, the solder mask is exposed to UV light to cure and harden it. The green pigment used in the solder mask has been found to absorb UV light effectively, ensuring proper curing of the mask.

Wavelength Considerations

The specific wavelength of light absorbed by the green pigment aligns well with the UV light used in the curing process, leading to consistent and reliable results.

Better Visibility for Inspection

Green solder mask offers significant advantages when it comes to visual inspection of PCBs.

Contrast with Copper Traces

The green color provides excellent contrast with the copper traces and other components on the board, making it easier for inspectors to identify defects or issues.

Reduced Eye Strain

The green color is also known to be easier on the eyes, reducing fatigue for workers who need to inspect PCBs for extended periods.

Material Composition

The composition of the green solder mask contributes to its effectiveness and durability.

Epoxy Resin Base

Most green solder masks are made from epoxy resin, which offers excellent adhesion to the PCB surface and resistance to environmental factors.

Pigments and Additives

The green color is achieved through the addition of specific pigments and additives to the epoxy resin. These additives not only provide the color but also contribute to the mask’s overall performance.

Read more about:

Are There Other PCB Colors?

While green is the most common color for PCBs, it’s not the only option available.

Common Alternative Colors

Other colors used in PCB manufacturing include:

- Red

- Blue

- Black

- White

- Yellow

Reasons for Different Colors

There are several reasons why manufacturers might choose a different color for their PCBs:

Aesthetic Considerations

Some companies opt for different colors to match their branding or to create a unique visual identity for their products.

Functional Requirements

Certain applications may benefit from specific colors. For example, white solder masks are often used in LED applications to improve light reflection.

Industry-Specific Standards

Some industries have developed their own color standards. For instance, many aerospace applications use blue PCBs.

Why Green Remains the Standard

Despite the availability of other colors, green continues to be the most widely used color for PCBs. There are several reasons for this:

Manufacturing Efficiency

Green solder mask has been optimized for the PCB manufacturing process over many years, leading to consistent and reliable results.

Established Processes

Many manufacturers have fine-tuned their processes specifically for green solder mask, making it the most efficient option.

Quality Control

The widespread use of green PCBs has led to well-established quality control standards and inspection procedures.

Cost-Effectiveness

Green solder mask is typically the most cost-effective option due to its widespread use and economies of scale in production.

Bulk Production

The high demand for green solder mask allows manufacturers to produce it in large quantities, reducing overall costs.

Standardized Equipment

Most PCB manufacturing equipment is optimized for use with green solder mask, making it a more economical choice for many companies.

Industry Familiarity

The long-standing use of green PCBs has created a sense of familiarity and trust within the electronics industry.

Engineering Expectations

Many engineers and designers are accustomed to working with green PCBs, making it easier to spot issues or anomalies.

Consumer Recognition

The green color has become synonymous with PCBs in the public eye, creating a sense of authenticity and reliability.

Environmental Considerations

In recent years, there has been growing interest in the environmental impact of PCB manufacturing, including the choice of solder mask color.

Eco-Friendly Alternatives

Some manufacturers are exploring more environmentally friendly solder mask options, which may impact color choices in the future.

Recycling Challenges

The color of PCBs can affect their recyclability, with some colors being more challenging to process than others.

The Future of PCB Colors

As technology advances and new materials are developed, we may see changes in the predominant colors used for PCBs.

Emerging Technologies

New manufacturing techniques and materials may lead to a broader range of color options or even color-changing PCBs.

Customization Trends

Increasing demand for product customization may drive more variety in PCB colors, especially for consumer electronics.

Conclusion

The prevalence of green PCBs is a result of a complex interplay of historical, scientific, and practical factors. The green solder mask has proven to be an optimal choice for PCB manufacturing due to its light absorption properties, visibility benefits, and overall performance characteristics. While other colors are available and may be chosen for specific reasons, green remains the industry standard due to its efficiency, cost-effectiveness, and familiarity within the electronics industry.

As we look to the future, it’s possible that advancements in technology and changing industry needs may lead to shifts in PCB color preferences. However, the iconic green PCB is likely to remain a familiar sight in the world of electronics for years to come. Whether you’re an electronics enthusiast, a professional engineer, or simply curious about the technology around you, understanding the science behind green PCBs provides valuable insight into the intricate world of electronic manufacturing.