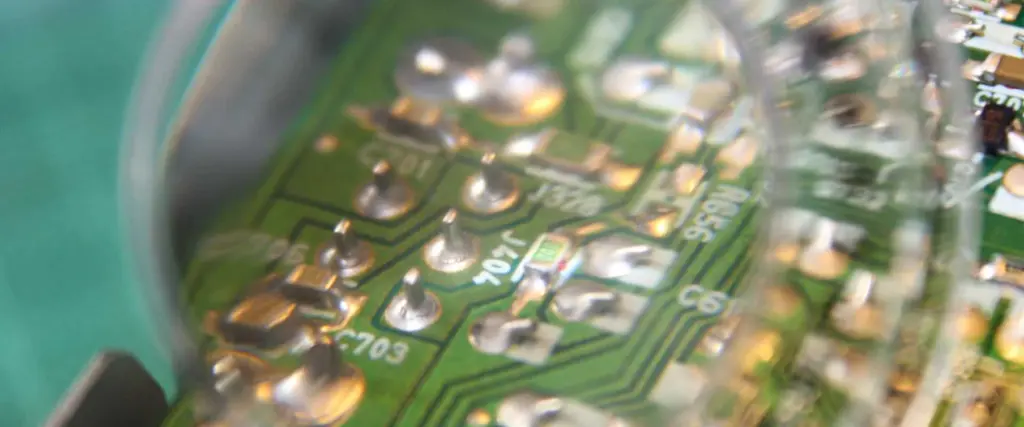

With respect to soldering of the PCB components, the use of hand soldering by manufacturers has been an important skill. If you will be dealing with high-level PCB manufacturing, for example, then it is very possible that you will solder making use of some specialized machines.

Anyone could try to use his or her hand in soldering components onto a PCB. However, with these parts becoming smaller and compact each passing day, there is an increased chance that you will encounter soldering issues. One of these problems is solder skip.

What Does Solder Skip Mean?

From the name, solder skips happen whenever solder gets to skip or spill over some of the surface mount pads. These solder skips are not desirable because they usually leave unconnected areas or pads. The solder skips are like surface mount joints that are unsoldered on the PCB.

Furthermore, the soldering quality has a great effect on the PCB’s overall quality. With soldering, the different PCB components would be connected to the remaining electrical components in order to make the PCB function effectively and fulfill what it is intended for.

When professionals in the industry are checking the electronic components’ quality, one important factor they consider during their assessment is the quality of soldering.

There could be solder skips in factories where robots take responsibility of soldering the components onto the printed circuit boards or someone inexperienced handles the job. This might happen as a result of the human operator not having full concentration. Also, robots that are poorly considered could easily skip joints, or just one of the parts.

When this happens, the circuit will be left open and then some or all of the entire PCB will be rendered non-functional. Ensure that you carefully inspect all solder joints.

How to Prevent Solder Skips

PCB manufacturers need to ensure the solder gets in contact with pads long enough when soldering surface mount components. Also, this process must be long enough for wetting to occur. Solder skip occurs when the solder fails to wet the interface and create a joint. It is not easy to deal with this problem. The best way to solve this problem is to create design strategies and machine modifications.

Soldering issues occur when surface mount components are wave-soldered to polymer PCBs. As chip components had fewer issues, active component formats weren’t easy to solder, especially PLCCs and SOICs.

Molten solder has high surface tension and as such it is difficult for solder waves to get to these corners. The solder surface appears somehow when it is in contact with a component. When wetting occurs, the solder surface becomes better.

When there is no contact this means the smooth waves produce poor SM soldering results. This is because the movement can’t break the solder’s surface tension at the pad interface. A similar condition occurs in cases where there is a close spacing between SMT parts. This makes it hard for solder to have access to the joint.

Manufacturers usually address this problem during circuit board design. They use waves with a high level of turbulence and a proper angle of attack. Solder skip is a common problem that can be easily addressed with some preventive measures.

Important Precautions and Tips when Soldering

The task of soldering isn’t an extremely tough one. Though this could be fun if we really wish to create great soldering. Below are some of the qualities of a high-quality PCB soldering.

First, we will consider some important tips to work with when soldering

Tips

- Solder with a great electrical conductivity

- Ensure that the soldering surface is kept clean

- The joints must have a greater mechanical strength

- Try to make use of a reliable solder for your soldering

- Joints mustn’t have loose connections

Precautions

- Your soldering gun must have a stand

- When using your soldering gun, ensure that your face is kept at a height or distance from it

- Any soldering gun that is heated during soldering could burn your face. Therefore, throughout this period avoid touching the gun

- The place used for soldering has to be safe to prevent any harm from coming to others

- When removing the PC boards’ bridging effect, avoid coming in contact with the solder. Make efforts to take out the solder using a gun as well as other materials that are safe.

Other Soldering Issues that may occur

Asides from solder skip, there are other soldering issues. These issues are a major concern for PCB manufacturers.

Cold joints

Circuit boards with cold joints usually appear dull and lumpy. Sometimes, they even look pock-marked. So, what causes cold joints? A cold joint occurs when solder fails to melt completely which leads to a rough or lumpy surface. A good number of PCB manufacturers experience this problem; hence, it is a major concern for them. Cold joints can cause further issues in a circuit board as they are unreliable.

Excess solder

Another common soldering issue manufacturers face is excess solder. Excess solder results from circuit boards taking too much solder during wave soldering. In this case, the circuit board absorbs excess solder in the wave soldering machine. Too much solder on a circuit will have a negative effect on its functionality.

Solder balling

Solder balling occurs when a circuit board comes in contact with a moisture surface and water vapor begins to flow with heat. There are several reasons behind solder balling. This problem is most likely to occur during wave or reflow soldering.

Conclusion

If you will be dealing with high-level PCB manufacturing, for example, then it is very possible that you will solder making use of some specialized machines. Solder skips happen whenever solder gets to skip or spill over some of the surface mount pads. These solder skips are not desirable because they usually leave unconnected areas. There could be solder skips in factories where robots take responsibility of soldering the components onto the printed circuit boards or someone inexperienced handles the job.