Overview

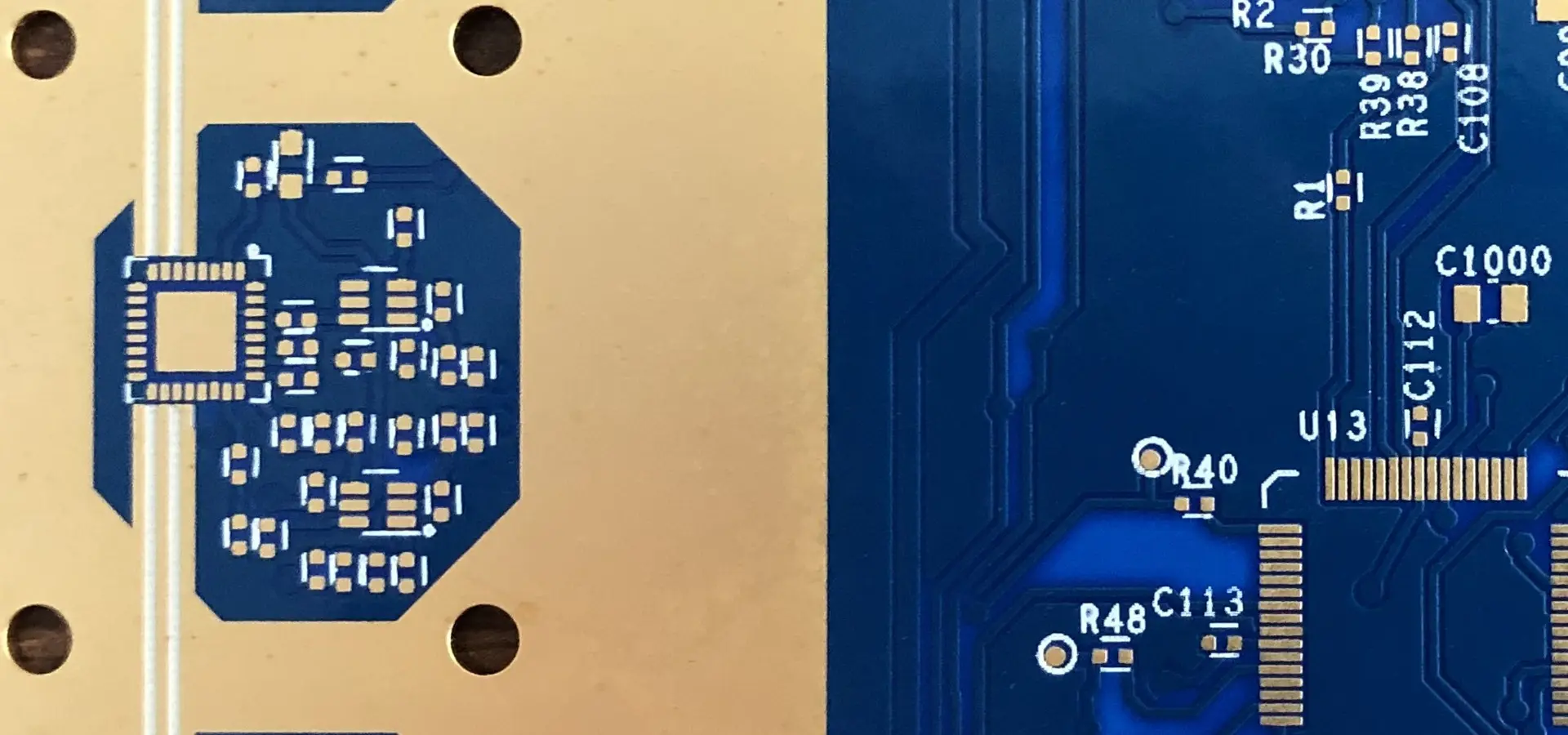

Rogers Ceramic PCBs represent the pinnacle of high-temperature circuit board technology, engineered specifically for demanding applications where conventional PCB materials fail. These advanced ceramic substrates deliver exceptional thermal stability, electrical performance, and mechanical reliability in extreme operating environments up to 1000°C and beyond.

Key Features

Superior Thermal Performance

- Operating temperature range: -55°C to +1000°C

- Ultra-low thermal expansion coefficient (CTE): 6-8 ppm/°C

- Excellent thermal conductivity: 20-170 W/m·K depending on ceramic type

- Outstanding thermal shock resistance

Exceptional Electrical Properties

- Low dielectric constant (Dk): 9.6-10.2

- Minimal dielectric loss tangent: <0.0002

- High dielectric strength: >40 kV/mm

- Excellent high-frequency performance up to millimeter-wave frequencies

- Superior electrical insulation properties

Mechanical Reliability

- High flexural strength: >300 MPa

- Excellent dimensional stability across temperature cycles

- Superior resistance to thermal fatigue

- Chemical inertness and corrosion resistance

- Hermetic sealing capability

Applications

Aerospace & Defense

- Satellite communication systems

- Radar and electronic warfare equipment

- Missile guidance systems

- High-altitude aircraft electronics

- Space-based instruments

Automotive

- Engine control modules

- Exhaust gas sensors

- Brake system electronics

- Electric vehicle power electronics

- Autonomous driving sensors

Industrial

- High-temperature sensors

- Power semiconductor modules

- Furnace control systems

- Oil and gas exploration equipment

- Chemical processing instrumentation

RF/Microwave

- High-power amplifiers

- Antenna feed networks

- Millimeter-wave circuits

- Base station equipment

- Test and measurement instruments

Technical Specifications

Material Composition

- Aluminum oxide (Al₂O₃) or aluminum nitride (AlN) ceramic base

- Thick film or thin film metallization options

- Gold, silver, or platinum conductor systems

- Multiple dielectric layer capability

Physical Properties

- Thickness range: 0.25mm – 6.35mm

- Surface finish: Ra < 0.4 μm

- Flatness: ±25 μm over 100mm

- Edge quality: Laser-cut or diamond-cut options

Manufacturing Standards

- IPC-6012 Class 3 compliance

- ISO 9001:2015 certified manufacturing

- MIL-STD-883 qualified processes

- RoHS compliant materials

Design Advantages

Thermal Management The ceramic substrate’s high thermal conductivity enables efficient heat dissipation, eliminating hot spots and extending component life. The low CTE ensures minimal stress on solder joints and wire bonds during thermal cycling.

Signal Integrity Low dielectric loss and stable electrical properties across temperature and frequency ranges ensure optimal signal transmission with minimal distortion, making these PCBs ideal for high-frequency applications.

Reliability The inherent stability of ceramic materials provides exceptional long-term reliability in harsh environments, reducing maintenance requirements and system downtime.

Custom Solutions

Rogers offers comprehensive design and manufacturing services including:

- Application-specific material selection

- Custom circuit layout optimization

- Prototype and production quantities

- Multi-layer constructions

- Integrated passive components

- Hermetic packaging solutions

Quality Assurance

Every Rogers Ceramic PCB undergoes rigorous testing including:

- Thermal cycling validation

- Electrical parameter verification

- Visual and dimensional inspection

- Reliability stress testing

- Certificate of compliance documentation

Support Services

Design Support

- Material selection guidance

- Thermal modeling and simulation

- RF/microwave design optimization

- Design rule verification

Manufacturing Support

- Rapid prototyping capabilities

- Volume production scaling

- Quality system integration

- Technical documentation support