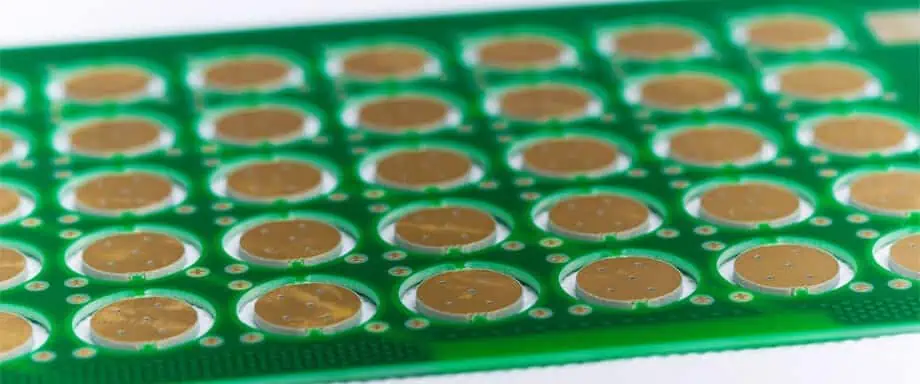

If you dismantle an electronic device, you will find a small green board. This board is what we refer to as a printed circuit board. It functions as the life of that electronic device. An electronic or electrical device can’t function without this board.

The green board you see in your electronic device has markings that look like a maze. A printed circuit board allows connections between components. All PCB boards are printable as they allow you to print a specific design on them.

What is a PCB?

A printed circuit board offers mechanical support and connection to electronic components via pads and conductive pads. Furthermore, a PCB features pre-designed copper tracks. These tracks minimize wiring and as such decreases the errors that arise as a result of loose connections.

PCB lays the foundation for the assembly of components. When manufacturing electronic devices, components are usually placed on the bare circuit board. A PCB is a bare board that features pads and conductive tracks. The placement of electronic components like resistors, capacitors, and more makes a PCB a fully assembled board.

What is a Printable PCB?

The manufacturing of a printed circuit board goes through several steps. Manufacturers ensure they carefully carry out these steps to achieve a functional board. Printing the design is one of the crucial steps involved in PCB manufacturing. A printable board is a board that has a film which reveals its layers and details.

A plotted printer is used in printing the design of the board. A printable PCB has two ink colors on the layer of the board. The white ink reveals the non-conductive areas while the blank ink reveals the circuits and conductive copper traces. Some manufacturers fabricate printable PCB using specialized PCB 3D printers. These printers are much faster than plotted printers.

Steps Involved in Manufacturing a Printed Circuit Board

Design

Before the manufacturing process commences, you need a design. The design is a blueprint in which the manufacturer begins the process. A computer software application is usually integrated for this step.

Print the design

Creating a design doesn’t just end there. In this step, you will be printing the PCB design with the help of a plotted printer. The PCB will have two different colors of ink. A clear ink and a black ink. The black ink reveals the circuits and conductive copper traces.

Creating the substrate

In this step, the manufacturer pre-bonds the copper to both sides of the layer. The substrate holds the components. It is the base of the material.

Inner layer printing

Here, the design is printed to the body of the structure, which is usually called the laminate. The photo-sensitive film will harden when you expose it to ultraviolet light. With this, the blueprints and the specific print of the circuit board will be aligned. Also, to aid the alignment process, the manufacturer drills holes in the PCB.

Unwanted copper removal

The PCB manufacturer will need to get rid of unwanted copper from the circuit board. Here, the board is dipped in a chemical solution that gets rid of the unwanted copper.

Inspection

There is a need to inspect the layers to ensure alignment. The drilled holes help in aligning the outer and inner layers. Inspection is necessary to ensure the boards are not defective.

Solder mask application

The panels of the PCB need to be properly cleaned before applying solder mask. The manufacturer then applies the epoxy with the solder mask. An ultraviolet light helps to remove unwanted solder mask.

Silkscreening

This is an important step in PCB manufacturing. Silkscreen prints crucial details on the board. After applying silkscreen, the PCB goes through a curing process and one more coating.

Surface finish

This step involves the application of coating on the board. Surface finishes are available in different types. Coating the board with a surface finish helps in preventing the copper in the printed circuit board from oxidizing.

Testing

An electrical test is usually performed on the circuit board. This helps in confirming the functions of the circuit board.

Applications of Printed Circuit Boards

Printed circuit boards are applicable across several industries ranging from the medical to military and consumer electronics.

Consumer electronics

Consumer electronics are electronic appliances we use everyday. These include televisions, smartphones, and computers. PCBs play a crucial role in the development of these electronics. Some consumer electronics require the use of advanced PCBs while some require simple PCBs. Circuit boards integrated for consumer electronics should be low-cost.

Automotive components

Automotive parts and components features PCBs. In the past, circuit boards were widely integrated for vehicle parts such as headlight switches and windshield wipers. However, things have changed as PCBs are integrated in advanced features. PCBs are now being used in control systems, sensors, and navigations systems of vehicles. The majority of the systems that regulate the function of a vehicle depend on electronics powered by circuit boards.

There is a growing use of printable PCB in the medical industry. As technology advances, more and more medical devices are being innovated. All these innovations were made possible due to printable PCB. This circuit board is available in medical devices like infusion pumps, medical imaging systems, internal devices, and monitors. PCB manufacturers need to pay attention to the PCBs used in the production of medical devices. These boards must meet some strict standards to ensure safety.

Aerospace components

Aerospace devices are usually exposed to harsh weather conditions. Therefore, high-end PCBs are widely integrated for the manufacturing of these devices. Printable PCBs are a core component in power supplies, communication equipment, and monitoring equipment used in the aerospace industry. These boards are necessary for the development of aerospace components.

Conclusion

PCB lays the foundation for the assembly of components. When manufacturing electronic devices, components are usually placed on the bare circuit board. A PCB is a bare board that features pads and conductive tracks. The placement of electronic components like resistors, capacitors, and more makes a PCB a fully assembled board. Printed circuit boards are applicable across several industries ranging from the medical to military and consumer electronics.