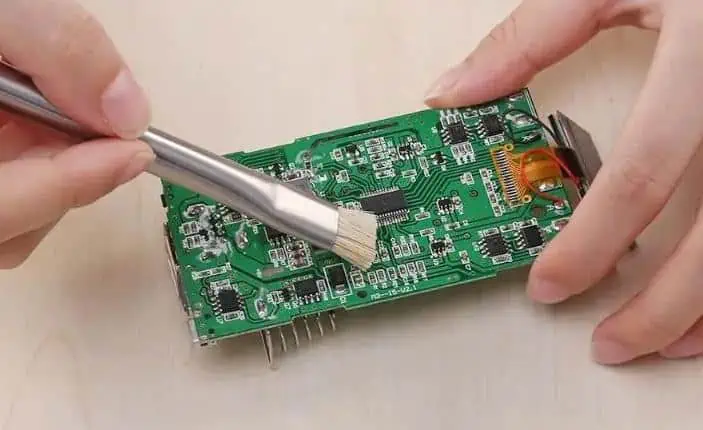

Printed circuit boards (PCBs) form the foundation on which all modern electronics function. However, during PCB handling, assembly, rework/repair and testing, various debris gradually accumulate requiring cleaning for reliable performance. ESD (electrostatic discharge) safe brushes present an efficient solution to remove contaminants without damaging sensitive onboard components.

Need for PCB Cleaning

Numerous particulate contaminants degrade PCBs demanding routine cleansing:

1. Flux Residue

Soldering operations deposit sticky flux remnants around joints hindering electrical contact, preventing inspection and trapping heat. Removing excess flux maintains quality.

2. Solder Paste/Splatter

Printing solder paste for surface mount device placement as well as hot reflow can scatter solder droplets shorting clean pads. Their removal restores insulation.

3. Dust/Fibers

Handheld boards attract various dirt, debris and textile microfibers obstructing clearances reducing airflow/cooling around high power parts. Periodic brushing clears ventilation gaps.

4. Manufacturing Impurities

Traces of chemical process agents, mask particles, plating salts and metallic burrs lingering post-fabrication also require final onboard cleansing before system integration.

Keeping PCB surface free of micro-detritus is thus vital for functionality and longevity. This demands specialist cleaning tools like soft static-dissipating brushes tailored for electronics use.

Hazards of Manual Cleaning

Traditional metal wire brushes with steel or copper bristles often excessively abrade board surfaces, tear delicate traces and damage surface mount components through:

- Deep gouging of fragile substrates

- Ripping off loosely anchored tiny chip parts

- Breaching protective coatings like solder mask

- Fragmenting brittle ceramics parts through impact

- Dislodging embedded glass fiber with torn fabrics

- Deforming soft exposed pins on connectors

Further, rapid brush strokes build up static charges which discharge through sensitive CMOS ICs destroying internal gate oxides through high voltage/current spikes. Such collateral harm radically degrades reliability accelerating field failures.

Hence purpose-built ESD-safe cleaning brushes with customized materials and ergonomics prove vital.

ESD Brush Composition

Conductive carbon suffused anti-static polymer filaments featuring soft rounded tips offer controlled cleaning power without electronics damage through following properties:

1. Flexible Bristles

Gentle filaments easily conform to varied board geometries – reaching narrow spaces between tall components to dust hidden areas while averting harm.

2. Carbon Infusion

Up to 20% conductive carbon particles dissipate static charges safely preventing sparking and IC damage meeting ANSI/ESD standards.

3. Chemical Resistance

Withstand cleaning agents like IPA without losing brush integrity or conductivity.

**4. Soft Touch **

Low bristle hardness prevents abrasions even on bare PCBs lacking masking while elastic rebound avoid part dislodgement.

Advances in ESD brush materials science foster electronics-safe cleansing.

Construction Styles

Integrating antistatic filaments in ergonomic holders allows excellent control and access suited for various board types and regions:

1. Handle Brushes

Cylindrical easy grip holder with dense radial bristles works well for broad surface dusting. Available in multiple sizes.

Handle Brush

2. Needle Nose Brushes

Conical narrow bristle arrangement access constrained spaces between tall components like transformers. Ideal for precision localized cleaning.

Needle Nose Brush

3. Detail Brushes

Flat compact bristle pad permits delicate wiping of residue around fine pitch components and connectors without causing collateral harm.

4. Rotary Brushes

Motorized circular brush with control box for automated forensic dust removal in factories via custom mounting over conveyors.

Diverse brushes suit unique topologies and cleaning challenges across production, rework/repair, prototyping, debugging etc. Use-case specificity allows superior results sans damage.

Cleaning Mechanisms

The cleaning action leverages varied working principles tailored for flux residues, solders and other contaminants:

1. Adhesion

When pressed against surface, micro-debris mechanically adhere to carbon bristle edges allowing lift-off from boards.

2. Absorption

Porous conductive filaments soak up light flux films and solvents clearing boards.

3. Displacement

Wedging action of bristle tips pushes thicker debris clusters out of crammed spaces rescuing confined parts.

4. Exfoliation

Gentle brush buffing helps detach and strip caked layers of aged flux restoring pad surfaces almost to the bare state without affecting copper below.

Integrated together, these interplayed mechanisms allow comprehensive cleaning activity.

Cleaning Best Practices

Adhering to optimal techniques maximizes results while avoiding harm:

1. Visual Inspection

Check board under bright light to identify contamination type and location needing precision versus broad cleaning.

2. Protect Components

Mask off delicate parts like exposed connectors using latex adhesive film to avert brush contact risks.

3. Low Pressure

Use light brush strokes allowing bristles to contour board instead of excessively stressing rigid parts at harsh angles.

4. Uni-directional Scrub

Employ repetitive linear strokes consistently brushing debris towards board edge for removal instead of spreading contaminants randomly through bi-directional chaotic scrubbing.

5. Follow Geometry

Edge-following brush movements leverages natural channels between components, connectors, slots to coax out deeply lodged particles instead of forcing abrasion through vertical attack angles.

6. Solvent-Soak Assist

For stubborn heavy flux buildup, pre-loosen goo through brief solvent soak before brushing away liquefied spill-offs.

With care and planning, ESD brushes boost cleaning efficacy.

Selecting Optimal Brushes

Choosing the right ESD brush depends on various factors:

| Parameter | Considerations |

|---|---|

| Bristle material | Conductive polymer filaments balance static control with softness |

| Filament thickness | Thinner ≤ 0.15mm bristles suit fragile parts while thicker 0.5mm fibers handle robust systems |

| Filament firmness | From supple urethane for wipe cleaning to stiff nylon for aggressive scrubbing |

| Brush width | Tiny 5mm miniature brushes reaching narrowly spaced SOC ICs versus large 50mm edge dusting |

| Bristle length | 10-25mm Goldilocks length prevent buckling versus surface smacking |

| Holder shape | Cylindrical, conical or flat profiles delivering maneuverability |

| Hand comfort | Lightweight holder with contoured grips reduce fatigue |

| ESD standards | ANSI/ESD S20.20 certification validate antistatic efficacy |

With a spectrum protecting delicately wired IoT sensors to high current welding controls,users enjoy optimal choices balancing safety with cleaning needs across applications.

Cleanliness Validation

Post-brushing, various techniques confirm sufficient particle removal and surface purity:

1. Visual Checks

Inspect under intense light for any remaining visible debris. Repeat localized brushing at soiled spots.

2. Microscopic Analysis

Use stereo microscopes or high zoom cameras to probe tiny hidden residues between dense components.

3. Ionic Tests

Ionization testers scan board surfaces detecting trapped salts, chemicals revealing spots needing further focus.

4. UV Inspection

Some flux residues fluoresce brightly under UV lighting indicating regions necessitating additional brush pass.

5. Air Purity Detectors

Particle counter instruments sampling air blown over board can confirm counts lower than class ISO-6 cleanroom standards.

Multimodal verification methodology assures contamination eradication and pristine PCBs ideal for corrosion-free operation even in harsh environments.

Applications

With suitable adaptations, antistatic brushes assist electronics maintenance across sectors:

Defense – Battle-ready military hardware feeding combat system data survive grueling desert/marine climes after field brushing cleans insulation shorting debris.

Aerospace – During preflight maintenance checks, plane communication racks get brush-swept tracing any faults causing radio interference.

Automotive – Sensor-heavy engine control units prone to stalling issues due to tin whiskers enjoy extended uptime after fast localized brushing treatment clears dendrites.

Indeed, the range and criticality of applications relying on the delicate instrument underscores the importance of purposeful brush cleaning activity supporting dependable functioning.

Consumable Materials

Proper care and recommended replaceable accessories further aid optimal brush effectiveness:

1. Cleaning Solutions – Neutral pH non-conducting deionized water or selective pure solvents (IPA, acetone) dissolve stubborn ionic contaminants and heavy fluxes.

2. Adhesive Film – Blue polyethylene tapes block connector cavities and fragile SMDs preventing fluid/brush ingress.

3. Hand Protection – Nitrile gloves worn while brushing using chemical solvents minimize skin contact risks.

4. Wipes – Soft absorbent wipes mop-up dislodged debris suspensions avoiding recontamination.

5. Brush Filters – Some power brushes feature external vacuum filters trapping dust from being blown back.

Ancillary items thus boost safety, production rates and eventual quality.

Consumables Cost Analysis

| Consumable | Typical Price Range | Notes |

|---|---|---|

| ESD Brush | $10 basic handle brush to $250 motorized rotary brushes | Hand brush costs rise with more delicate bristles, slimmer profiles and ergonomic handles. |

| Adhesive Tapes | $10 per roll for standard blue poly tapes | Specialized high temperature/anti-static tapes cost extra |

| Cleaning Agents | $50 per gallon | Reagent purity level affects pricing |

| Hand Protection | $100 per box of 100 nitrile gloves | Look for intact gloves with electrostatic discharge protection |

| Cleaning Wipes | $2 per pack of 30 wipes | Microfiber wipes prevent linting versus paper |

| Vacuum Filters | $500 per standard filter cartridge | Depends on particle filtration rating and installed airflow capacity |

Bulk purchases combined with centralized dispensing systems allow amortizing lifetime costs.

Traditional Cleaning Approaches vs. ESD Brushes

| Method | Risks | Benefits |

|---|---|---|

| Hand Wiping | Lint generation, recontamination through contact | Basic dry dust removal |

| Air Blowers | Creates harmful particulates mists due to spreading | Fast, tool-less blast cleaning |

| Liquid Cleaning | Conductive solutions short circuits, chemical spill corrosion | Removes ionic fluxes, loosens caked debris coatings |

| Ultrasonic Bath | Cavitation damage to brittle components, liquid residue trapping | Vigorous energized cavitation blasts particulate films |

| Abrasive Pads | Deep scratches causing conductor opens & dangerous leakage currents | Rapidly abrades thick debris layers |

| ESD Brushes | None | Controlled cleaning action, antistatic safety, operational simplicity |

Purposeful ESD brush-based approaches hence provide electronics-safe, efficient and comprehensive dust/residue removal vital for product longevity and field dependability.

Historical Perspective

The specialized PCB cleaning brush domain reflects wider industry trends:

Vintage Era – Stiff horsehair brushes in early vacuum tube gear attempted rudimentary dusting but caused electrostatic sparking failures.

Pre-ESD Days – Cheap plastic/nylon brushes with static prone filaments plagued early microelectronics with destructive latch-up faults and crashes.

Manual Assembly – Conductive brush innovation eased device failures albeit requiring labour intensive manual brushing between production steps.

Automated Production – Antistatic rotary brushes integrated into conveyorized SMT lines accelerated cleaning speed in tandem with surface mount densification.

Current Times – Miniturized handheld ESD brushes safely service compact mobile devices with delicate pinned connectors, bare die stacking which are incompatible with wet cleaning.

Indeed today’s spectrum of scope-optimized specialized brushes sanitize electronics across production, testing and operational settings with excellence.

The Future of Automated Smart Brushes

Next generation automated ESD brush designs leverage mechatronic and data analytics advances for cleaning perfection:

Onboard Sensors – Force, temperature and ionization sensors provide real-time feedback allowing delicate yet thorough scrubbing.

EdgeVision Systems – High resolution optical scanning combined with machine learning assists selective debris removal at board perimeters without scraping off components barely overhanging edges.

Adaptive Control Algorithms – Multimodal sensor inputs help dynamically modulate brushing pressure, speed and passage numbers tailoring cleaning needs.

Blockchain Data Logging – Each automated brushing operation updates immutable distributed ledger logging details like date, asset ID, program parameters and before/after metrology analytics for tracing overall equipment effectiveness.

RFID Brush Heads – Smart RFID tagged brush heads detect unique PCB ID by wireless interrogation and accordingly select optimal program from cloud database through edge computing delivering supreme asset-specific cleaning.

- The upgradable smart brush platform hence promises continued innovation leadership balancing efficacy with economy.

Frequently Asked Questions

Q1. How frequently should PCBs get cleaned?

General electronics benefit from periodic preventive brushing every 6 months dislodging gradual debris buildup. Mission-critical systems demand more frequent monthly/quarterly upkeep for reliable performance. Production environment also affects schedules. Harsh industrial atmosphere causes faster particulate fouling versus cleanroom settings allowing less frequent system brushing.

Q2. Will the ESD brush remove conformal coating from PCBs?

Most ESD cleaning brushes lack the harshness to abrade away tough protective acrylic/epoxy/urethane conformal coats shielding PCBs from environment threats. Users should take care to avoid contact between coating and brush. For removing old conformal coating during repairs, avoid ESD brushes in favor of specialized solvent stripping methods.

Q3. Can ultrasonic bath complement ESD brush cleaning?

Used judiciously, ultrasonic bath offers vigorous energized cavitation cleaning action ejecting trapped debris from tiny crevices between high density PCB components where bristles cannot reach. However the violent implosions also risk damaging fragile parts. Hence ultrasonic bath before final soft ESD brush passes provide balanced approach.

Q4. How are ESD brushes cleaned themselves?

Used brushes carrying a particulate load can face bristle matting losing cleaning efficiency. Gently rinsing brushes in compatible solvents followed by gentle blow drying clears debris clinging between and restores fluffiness. Some brushes feature auto-cleaning motions allowing self-purging. Proper brush hygiene maintains performance.

Q5. Can ESD brushes substitute vacuuming?

ESD brushes physically dislodge surface contaminants but cannot suck and filter fine airborne particles like vacuum cleaners. Hence vacuuming first traps loose coarser dust, while subsequent ESD brushing cleans up remaining stuck-on flux/paste residues restoring pad surfaces. The dual protection keeps components cooler and reliable especially in hot regions and cramped enclosures seeing forced airflow cooling.

Performing the delicate balancing act across size scales from bulky industrial motor control cabinets to wafer-thin portables, automated ESD brush technology continues serving PCB cleaning needs across applications!

Indeed keeping electronics debris-free demands diligence and purpose-built tools like antistatic brushes. When used with care and attention, ESD brushesCLEARLY make the difference empowering system longevity through contamination CLEARANCE!!