Why LED PCBs Dominate Modern Lighting: Benefits, Types, and Applications

RayMing Technology is a professional LED PCB manufacturer with 20 years of industry experience. We specialize in providing high-quality PCB solutions for various LED applications, offering comprehensive expertise across different segments of the LED industry.

What is an LED PCB?

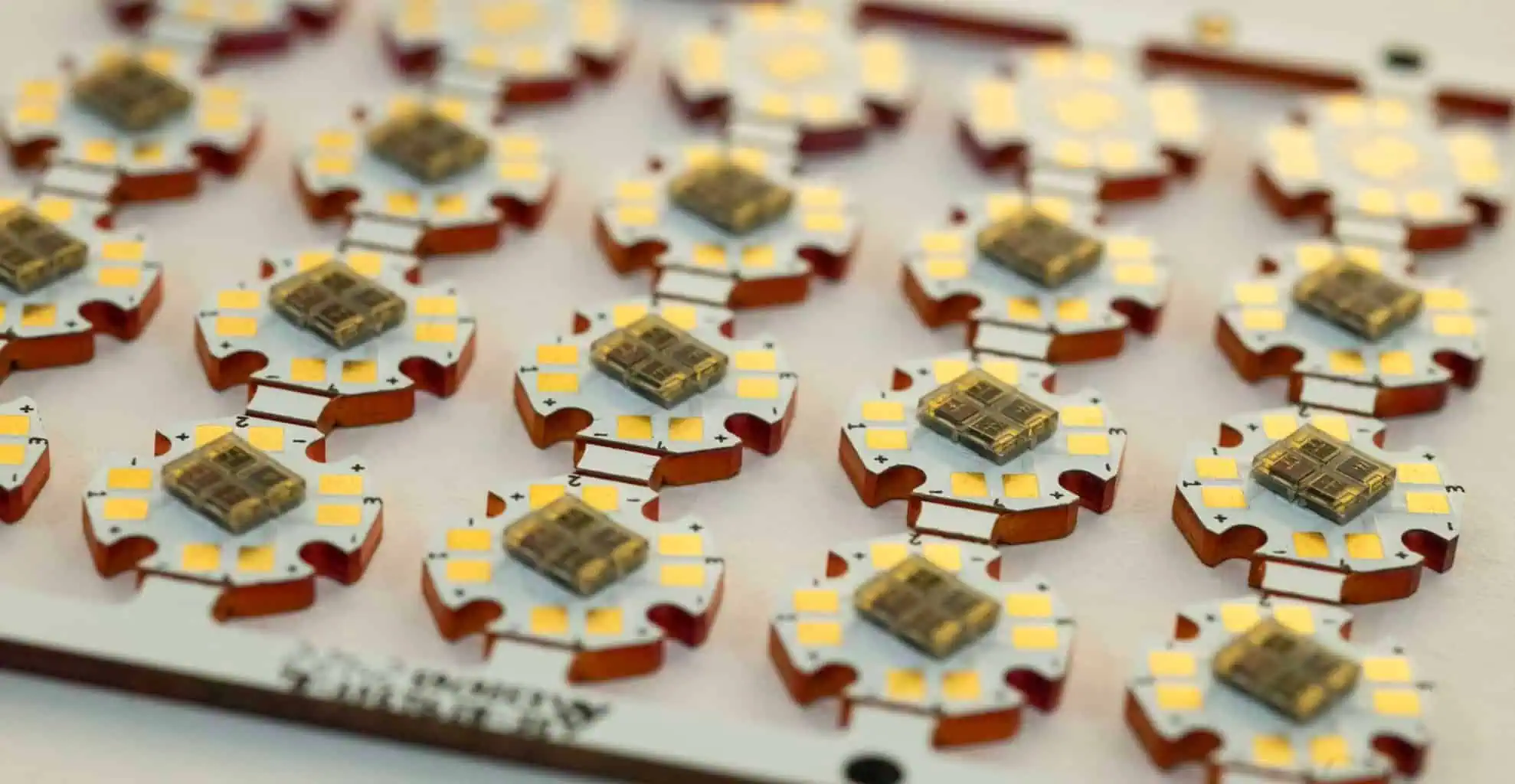

An LED PCB, or Light Emitting Diode Printed Circuit Board, is a specialized circuit board designed to mount and connect LEDs efficiently. These PCBs not only provide a stable platform for the LEDs but also incorporate features that enhance their performance, longevity, and thermal management.

Key components of an LED PCB include:

- Substrate: The base material that provides mechanical support and electrical insulation.

- Copper traces: Conductive pathways that carry electrical current to the LEDs.

- Solder mask: A protective layer that prevents short circuits and oxidation.

- Silkscreen: Printed markings that provide information and component placement guides.

- Thermal management features: Designed to dissipate heat generated by the LEDs.

Advantages of LED PCBs

LED PCBs offer numerous benefits that have contributed to their widespread adoption in the lighting industry. Let’s explore these advantages in detail:

1. Energy Efficiency

One of the most significant advantages of LED PCBs is their exceptional energy efficiency. LEDs consume substantially less power compared to traditional lighting sources, resulting in lower electricity bills and reduced environmental impact. The efficiency of LED PCBs stems from their ability to convert a higher percentage of electrical energy into light, with minimal heat loss.

2. Longevity and Durability

LED PCBs are designed for longevity, with many high-quality LEDs lasting up to 50,000 hours or more. This extended lifespan translates to reduced maintenance costs and fewer replacements over time. Additionally, LED PCBs are more resistant to shock, vibration, and temperature fluctuations, making them ideal for various applications, including outdoor and industrial lighting.

3. Compact Design

The small size of LEDs allows for more compact and flexible lighting designs. LED PCBs can be manufactured in various shapes and sizes, enabling designers to create innovative lighting solutions that were previously impossible with traditional light sources. This compact nature also contributes to reduced material usage and lower shipping costs.

4. Improved Light Quality

LED PCBs offer superior light quality compared to many traditional lighting options. They provide consistent, flicker-free illumination and can be designed to emit light in specific color temperatures or even change colors on demand. This versatility makes LED PCBs suitable for a wide range of applications, from mood lighting to task-specific illumination.

5. Instant On/Off and Dimming Capabilities

Unlike some traditional lighting sources that require warm-up time, LED PCBs provide instant illumination when switched on. They also offer excellent dimming capabilities without color shift, allowing for precise control over light output and energy consumption.

6. Environmental Friendliness

LED PCBs contribute to a greener environment in several ways. Their energy efficiency reduces carbon emissions associated with power generation. Additionally, LEDs don’t contain harmful substances like mercury, making them safer to dispose of at the end of their life cycle.

| LED Type | Size (mm) | Power | Lumens | Application |

|---|---|---|---|---|

| 2835 SMD | 2.8 × 3.5 | 0.2-0.5W | 20-60 lm | LED strips, backlighting |

| 3528 SMD | 3.5 × 2.8 | 0.06-0.08W | 6-8 lm | Indicator, decoration |

| 5050 SMD | 5.0 × 5.0 | 0.2-0.5W | 15-25 lm | RGB strips, signage |

| 5630 SMD | 5.6 × 3.0 | 0.5W | 45-55 lm | High brightness strips |

| 3030 SMD | 3.0 × 3.0 | 1-1.5W | 100-140 lm | Downlights, panels |

| CREE XP-E2 | 3.45 × 3.45 | 1-3W | 100-350 lm | Flashlights, spotlights |

| CREE XP-L | 3.45 × 3.45 | 3-10W | 350-1150 lm | High-power applications |

| COB 10W | 13.5 × 13.5 | 10W | 900-1100 lm | Downlights, track lights |

| COB 30W | 20 × 20 | 30W | 2700-3300 lm | Commercial lighting |

| COB 50W | 28 × 28 | 50W | 4500-5500 lm | Floodlights, industrial |

• COB LEDs: Higher power density, better color consistency. Ideal for spotlights.

• High-Power LEDs: Require proper thermal management. Use with metal core PCBs.

• Maximize copper pour area around LEDs - aim for at least 2x LED footprint

• Consider 2oz copper or thicker for high-power applications

• Place LEDs away from board edges for better heat spreading

• Use thermal interface material (TIM) between PCB and heatsink

• Add bypass capacitors (100nF) near power input

• Design adequate trace widths: I = W × 0.048 × T^0.44 × ΔT^0.725 (IPC-2221)

• Series resistors for current limiting: R = (Vs - Vf) / If

• Consider ESD protection for sensitive LED applications

• Use white solder mask for maximum light reflection (15-20% improvement)

• Place decoupling capacitors within 5mm of LED drivers

• Keep high-current traces short and wide

• Separate analog and digital grounds to reduce noise

• Specify solder paste stencil thickness: 0.1-0.15mm for SMD LEDs

• Add fiducial marks for automated pick-and-place accuracy

• Include test points for production testing

• Design panel layout to optimize material usage

• Consider lens/optics mounting requirements in PCB design

• Account for LED viewing angle in placement decisions

• White soldermask improves overall light output efficiency

• Use reflector cups or secondary optics for beam control

Read more about:

Lighting PCB vs. LED PCB

Traditional lighting PCBs were designed to support various types of light sources, including incandescent bulbs, fluorescent lamps, and halogen lights. These PCBs primarily focused on power distribution and basic control functions. In contrast, LED PCBs are specifically engineered to support and optimize the performance of Light Emitting Diodes (LEDs), offering several advantages over their predecessors.

The LED Lighting Industry: A Growing Market

The LED lighting industry has experienced exponential growth over the past decade, driven by technological advancements, falling prices, and increasing awareness of energy efficiency. According to market research, the global LED lighting market is expected to reach $127 billion by 2027, with a compound annual growth rate (CAGR) of 13.4% from 2020 to 2027.

Several factors contribute to this growth:

- Government initiatives promoting energy-efficient lighting

- Increasing adoption in commercial and industrial sectors

- Growing demand for smart lighting solutions

- Expansion of urban infrastructure in developing countries

- Advancements in LED technology, improving efficiency and reducing costs

As the industry continues to evolve, LED PCBs play a crucial role in driving innovation and meeting the growing demand for efficient, high-quality lighting solutions.

Types of LED Light PCBs

LED PCBs come in various types, each designed to meet specific requirements and applications. Understanding these different types can help in selecting the most appropriate LED PCB for a given lighting project.

1. Aluminum PCB

Aluminum PCBs, also known as Metal Core PCBs (MCPCBs), are one of the most popular choices for LED applications. They feature a thin layer of thermally conductive dielectric material bonded to an aluminum base.

Key features of Aluminum PCBs:

- Excellent heat dissipation

- High thermal conductivity

- Suitable for high-power LED applications

- Cost-effective for large-scale production

Applications: High-power LED lighting, automotive lighting, streetlights

2. FR4 PCB

FR4 (Flame Retardant 4) PCBs are widely used in the electronics industry and have found applications in LED lighting as well. These PCBs are made from a composite material of woven fiberglass cloth with an epoxy resin binder.

Key features of FR4 PCBs:

- Good electrical insulation properties

- Relatively low cost

- Suitable for low to medium-power LED applications

- Easy to manufacture and modify

Applications: Indoor LED lighting, decorative lighting, low-power LED displays

3. Copper-based PCB

Copper-based PCBs utilize a thick copper layer as the base material, offering superior thermal management compared to FR4 boards.

Key features of Copper-based PCBs:

- Excellent thermal conductivity

- High current-carrying capacity

- Suitable for high-power and high-density LED applications

- More expensive than aluminum PCBs

Applications: High-power LED flood lights, industrial lighting, specialized LED applications

4. Ceramic LED PCB

Ceramic PCBs are made from materials like alumina (Al2O3) or aluminum nitride (AlN), offering exceptional thermal performance and electrical insulation.

Key features of Ceramic LED PCBs:

- Superior thermal conductivity

- Excellent electrical insulation

- High temperature resistance

- Suitable for extreme environment applications

- Higher cost compared to other options

Applications: Aerospace lighting, medical equipment, high-reliability LED systems

5. Flexible LED PCBs

Flexible LED PCBs are made from materials like polyimide or polyester, allowing them to bend and conform to various shapes.

Key features of Flexible LED PCBs:

- Ability to bend and flex without breaking

- Suitable for curved or irregularly shaped surfaces

- Lightweight and space-saving

- Can be designed as rigid-flex boards for added versatility

Applications: Wearable LED displays, automotive interior lighting, curved architectural lighting

6. Hybrid LED PCB

Hybrid LED PCBs combine different materials or technologies to achieve specific performance characteristics.

Key features of Hybrid LED PCBs:

- Customized thermal and electrical properties

- Combination of rigid and flexible sections

- Can incorporate both FR4 and metal core elements

- Tailored to meet specific application requirements

Applications: Complex LED lighting systems, multi-functional LED products, specialized industrial lighting

Challenges and Considerations in LED PCB Design

While LED PCBs offer numerous advantages, their design and implementation come with several challenges that need to be addressed to ensure optimal performance and longevity.

1. Temperature Management

One of the most critical challenges in LED PCB design is managing heat dissipation. Despite being more efficient than traditional lighting sources, LEDs still generate heat that can affect their performance and lifespan if not properly managed.

Considerations:

- Proper thermal design to efficiently dissipate heat

- Selection of appropriate PCB materials with good thermal conductivity

- Implementation of thermal vias and heat sinks where necessary

- Optimal component placement to avoid hot spots

2. Lifespan Optimization

While LEDs have a longer lifespan compared to traditional lighting sources, various factors can impact their longevity.

Considerations:

- Proper current and voltage regulation to prevent overdriving

- Protection against voltage spikes and reverse polarity

- Selection of high-quality components and materials

- Design for optimal operating conditions

3. Color Consistency and Quality

Maintaining consistent color output and quality across multiple LEDs and over time can be challenging.

Considerations:

- Careful selection and binning of LEDs for color matching

- Implementation of color mixing techniques for tunable white or RGB systems

- Use of high-quality LED drivers to maintain stable current

- Design for uniform light distribution

4. Cost vs. Quality Trade-offs

Balancing cost considerations with performance and quality requirements is an ongoing challenge in LED PCB design.

Considerations:

- Material selection based on application requirements and budget constraints

- Optimizing component placement for efficient manufacturing

- Considering the total cost of ownership, including energy consumption and maintenance

- Evaluating the return on investment for higher-quality components

5. Number of Layers

Determining the optimal number of layers for an LED PCB involves balancing performance, cost, and design complexity.

Considerations:

- Single-layer designs for simple, low-cost applications

- Multi-layer designs for complex circuits and improved heat dissipation

- Balancing copper thickness with layer count for optimal thermal performance

- Considering EMI shielding requirements in layer stack-up design

Steps Involved in Manufacturing Your LED PCB

Understanding the manufacturing process of LED PCBs can help in designing more efficient and cost-effective lighting solutions. Here’s an overview of the typical steps involved:

Design and Layout:

- Create the schematic diagram

- Design the PCB layout using CAD software

- Perform design rule checks and optimizations

Material Selection:

- Choose appropriate substrate material (e.g., aluminum, FR4, ceramic)

- Select copper thickness and layer count

- Determine solder mask and silkscreen specifications

Prototype Development:

- Manufacture a small batch of PCBs for testing

- Assemble components and perform initial tests

- Make necessary design adjustments

Fabrication:

- Create photoresist masks for each layer

- Etch copper traces and drill holes

- Apply solder mask and silkscreen

Assembly:

- Apply solder paste to the PCB

- Place LED components and other elements using pick-and-place machines

- Reflow soldering to secure components

Testing and Quality Control:

- Perform visual inspections

- Conduct electrical tests for continuity and functionality

- Carry out thermal and stress tests

Final Inspection and Packaging:

- Conduct final quality checks

- Apply conformal coating if required

- Package PCBs for shipping or further integration

Why Choose RAYMING as Your LED PCB Supplier?

When selecting an LED PCB supplier, it’s crucial to partner with a company that offers expertise, quality, and reliability. RAYMING stands out as a leading supplier in the LED PCB industry for several reasons:

Expertise and Experience:

- Years of experience in LED PCB design and manufacturing

- In-depth knowledge of various LED PCB types and applications

- Skilled engineering team capable of handling complex projects

Quality Assurance:

- Strict quality control measures throughout the manufacturing process

- Adherence to international standards and certifications

- Use of high-quality materials and components

Advanced Manufacturing Capabilities:

- State-of-the-art production facilities

- Ability to handle both small and large-scale orders

- Flexibility in accommodating custom designs and specifications

Comprehensive Services:

- Design assistance and optimization

- Prototyping and testing services

- Full-scale production and assembly

- After-sales support and technical guidance

Competitive Pricing:

- Efficient manufacturing processes to reduce costs

- Transparent pricing structure

- Volume discounts for large orders

Commitment to Innovation:

- Continuous investment in research and development

- Adoption of latest technologies and manufacturing techniques

- Proactive approach to addressing industry challenges

Environmental Responsibility:

- Focus on eco-friendly manufacturing processes

- Compliance with environmental regulations

- Promotion of energy-efficient LED lighting solutions

Global Reach:

- Ability to serve customers worldwide

- Understanding of international standards and regulations

- Efficient logistics and shipping capabilities

By choosing RAYMING as your LED PCB supplier, you can ensure that your lighting projects benefit from high-quality components, expert support, and reliable service throughout the product lifecycle.

Conclusion

LED PCBs have undoubtedly revolutionized the lighting industry, offering unprecedented energy efficiency, longevity, and versatility. From consumer electronics to industrial applications, these innovative components continue to shape the way we illuminate our world. As technology advances and new applications emerge, LED PCBs will play an increasingly crucial role in developing sustainable and intelligent lighting solutions.

By understanding the benefits, types, and applications of LED PCBs, businesses and individuals can make informed decisions when selecting lighting solutions for their specific needs.

Composition of LED PCB

An LED PCB (Light Emitting Diode Printed Circuit Board) is the foundation of LED lighting technology. Here’s a breakdown of its key aspects:

Components:

- LED: A semiconductor diode that emits light when electrically connected.

- PCB: The board to which the LED is soldered, providing electrical connections and physical support.

Structure:

- The LED chip is bonded to a ceramic base and a thermal heat sink.

- SMD (Surface Mount Device) packaging is the most common form in LED applications.

Heat Management:

- LEDs generate significant heat, making cooling challenging with traditional methods.

- Metal Core PCBs, especially aluminum-based, are widely used due to their superior heat dissipation.

- These PCBs have a thin layer of thermally conductive dielectric material for efficient heat transfer.

Multiple LED Configuration:

- A single LED often provides limited light output.

- Multiple LEDs are typically used in a single fixture for sufficient illumination.

- The PCB electrically connects these multiple LED components.

Terminology:

- A PCB with soldered LED components is commonly referred to as an “LED PCB.”

This design allows for efficient electrical connectivity and heat management, making LED PCBs crucial in modern lighting applications.